How to cut polypropylene pipes without scissors

How to cut plastic sheet metal pipes

Metal plastic pipes are usually sold in measured lengths. Therefore, when installing requires cutting them to a predetermined size. And if it is necessary to join, turn or branch, special fittings for metal-plastic pipes are used.

Cutting methods

Metal plastic pipes can be cut in several ways:

It is easy and effortless to cut plastic sheet metal pipes with a hacksaw, but the process will be slower and you do not always get an even edge. If you do not have a hand saw for metal, you can also use a self-sharpening knife, but the aluminum layer makes it difficult to work. Also after using these methods small particles of plastic remain on the edges, which can cause clogging of filters during operation of the pipeline.

If during the assembly of polypropylene pipes uneven edges will melt or melted plastic will overlap them, then there are high requirements for the precision of cutting metal-plastic pipes. It is pressed tightly into the collar during assembling and uneven edges are not permitted. they can cause leaks. Therefore, it is best to cut with scissors designed for this purpose.

Technology of cutting metal plastic pipes with scissors

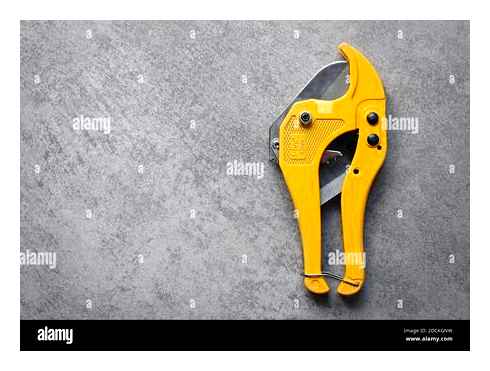

Such scissors are designed for cutting pipes of small diameter. up to 40 mm. The technique does not require professional knowledge and experience, is carried out with one hand without much effort. This is facilitated by a special toothed rail on their blade.

When choosing such a tool, you should not give preference to the cheapest models, because their resource will allow to carry out only a few cutting cycles, after which the return mechanism or a more significant part will fail.

It is highly recommended to cut plastic pipes with the pipe cutter for the cross-section over 40 mm. They come in the following types:

- telescopic. the cutting is carried out by a round roller made of tool steel;

- with a ratchet mechanism. on the principle of action and appearance resemble scissors (trimming is performed by closing the handles of the device).

When using a tool with a ratchet mechanism on the pipe, it is necessary to remove the chamfers and restore its cross-section with a calibrator.

[content-egg module=GdeSlon template=compare]

What to cut metal-plastic pipes

Over time, old pipes wear out, begin to leak, and the inevitable need to replace the pipeline. There are a lot of people who still consider iron pipes almost ideal. But today there is a more modern solution. pipes based on polypropylene and polymer compositions with a metal frame. But what is it, and how does their installation take place?

In order to understand the intricacies of cutting and installing metal plastic pipes, it is worth a little clarification as to why metal piping is not in demand right now. Here it’s obvious and simple. the metal is bulky, hard to get, and prone to corrosion. In addition, the metal pipe is not easy to install. Copper, on the other hand, oxidizes and turns green in a humid environment. In addition, it is significantly more expensive in price than steel pipes.

Below we will talk about the structure of the pipe on the basis of metal-plastic and what to cut metal-plastic pipes.

Preparation of the pipe and the necessary tools

The first thing to do is to choose a suitable tool. At our disposal:

The basis of metal plastic pipes includes a layer of polypropylene plastic, a thin aluminum liner made using ultra-precise laser welding and a final thin layer of plastic. The aluminum tube inside acts as a “skeleton” for the pipe.

The inner surface of the pipeline is perfectly smooth, so unlike iron, such a pipe does not collect rust and other slag on its surface. If you need to strip the outer part of the reinforced coating, you should use a simple socket with blades. The end part of the material is encircled by the collar itself. After inserting the sleeve, you get a perfectly straight cut. The entire process will not take more than five minutes.

Note! Cleaning of the reinforced surface is done in order to get rid of a layer of polymer and protective coating, which is necessary for subsequent welding work. Take into account that the material is cut to the thickness required for fitting attachment.

What is used for cutting plastic sheet metal pipes?

And now let’s talk about how to cut plastic pipes. If there is a need in the cutting of metal plastic pipe, the master comes to the aid of plumber scissors for metal plastic.

Cutting pipes is effortless and well controlled visually. In the process of work it is necessary to bend the pipes at the joint. Requires a simple device. a pipe bender. Without this uncomplicated device ownhand bend tube quality is unlikely to work. If you try to bend the pipe by hand, there is a high probability of damaging the aluminum layer, which will lead to a rapid failure of the entire pipeline.

Please note! When using a tool that is not designed for machining plastic pipes there is a great risk of damaging the reinforcing layer of the pipe, getting an uneven cut at the outlet, which will eventually lead to leaky pipe joints. water will leak in the joints.

Technical scissors for cutting polymer pipes are supplied with welding machines for metal-plastic pipes. This tool has a sharp blade for cutting soft structures and a convenient handle. The simplest models allow you to cut a pipe with a radius of no more than 20 mm, so if necessary, you should get the more advanced scissors, which can handle pipes with larger diameters.

- After selecting the appropriate size and marking, cut off the required length with the scissors.

- Cutting with special scissors is completely waste-free, no crumbs are left after cutting and you can immediately begin assembly work.

- Working with these scissors does not require any skills, and you can cut without any additional skills.

Metal plastic pipes can be cut with the old-fashioned devices, and probably many people are wondering how to cut a pipe with an angle grinder.

First of all a mark is made on the pipe. An angle grinder of any size will do. In this case, you need to have a disk for cutting metal structures. An important digression. do not apply much force when working. Cutting is fast, but there is considerable noise at work, as well as some shavings cannot be avoided.

Get tips on cutting plastic sheet metal pipe. Make the right choice of tool for cutting plastic pipe. Learn how to cut laminate properly.

[content-egg module=GdeSlon template=compare]

General properties of polypropylene pipes

It is worth saying that polypropylene is a synthetic material, which has bright positive properties. It is small weight, high elasticity, heat resistance and zero susceptibility to corrosion, which is very important for the water supply. This material, it is a kind of plastic, but with low density, which is why it is so light.

Soldering polypropylene pipes is easy, having a minimum of tools, which we will talk about next, as well as fittings (special small parts of different shapes, made of polypropylene), which act as connectors.

If we talk about the main advantages of polypropylene materials in more detail, the following points stand out clearly:

- Durability. the service life of such a cavity, if cold water is served through it, is 50-60 years, in the case of hot water. 30-40 years. These figures are much higher than all sorts of analogues.

- Elasticity. polypropylene cavities have pronounced elastic properties. This means that such material responds well to compression and expansion due to changes in water temperature inside the plumbing, and during installation, the risk of ruining the pipe is reduced, t.к. It bends well.

- Lightness. this material weighs little, especially this is noticeable in comparison with metal pipes and the more so. steel.

- Ease of installation. as mentioned above, soldering polypropylene pipes, it is so easy that even a person who has no previous experience with plumbing and similar materials can cope with it.

Temperature resistance

In addition to the general characteristics of water materials made of polypropylene is worth knowing another factor. heat resistance. The fact that polypropylene is a kind of plastic and there is a temperature limit inside the system, at which the site is damaged or melts.

The maximum working temperature of PP pipes. 140 degrees Celsius. This means that if the water is too hot, there is a risk of compromising the integrity of the material and even the solder of polypropylene pipes (the junction) may not hold.

But when creating the discussed pipes, they are assigned their own marking, which indicates the specific properties, such as: heat resistance, wall thickness, allowable pressure in the system and areas of application. Thus, two common markers stand out:

- PN 20. the most popular type of pipe, withstands the pressure of 20 atmospheres and a temperature of 95 degrees Celsius. These indicators allow the use in laying the water pipes with the use of hot and cold water, but not in heating systems.

- PN 25. this type of PP pipes is excellent for laying heating, as it easily copes with a temperature of 95 degrees and a pressure of 25 atmospheres. Such indicators of heat resistance and strength are achieved thanks to partial reinforcement, due to which the material does not deform because of temperature differences.

Thermal elongation

Another property of polypropylene pipes. the ability to elongate when the temperature inside the water pipe increases. It looks like sagging of long sections of the water pipe, or wavy deformation. For this reason it is necessary to solder polypropylene pipes properly and it is highly recommended not to make long straight sections in the water pipeline, but to use compensators (insertion of the pipe in the shape of the letter “P”). Then during thermal elongation the expansion joint “legs” will get closer and the pipe will not deform.

Soldering polypropylene pipes in hot systems also involves the use of reinforced materials, this will reduce the risk of thermal elongation and deformation.

Reinforcing

And last in the properties of polypropylene cavities, which is worth mentioning. reinforced materials, because they have already been mentioned in the text. Reinforcing pipes is important, because it implies the inclusion of aluminum foil or kapron fibers, which increases the strength, stiffness, thermal resistance and terms of operation of water pipes made of this material.

Reinforced polypropylene pipes is simple as conventional, installation is carried out using the same tool, only the melting temperature for bonding sections of water pipes fittings are different.

Required tools

So, with the properties of polypropylene pipes, we dealt with the classification of this material, its advantages over others. Now let’s talk about the tool that is needed to solder polypropylene pipes and install plumbing.

The first and easiest tool for assembling plumbing. scissors. But we are not talking about conventional scissors, but about special scissors that are used for cutting the material in question. This tool is also called a pipe cutter. With it, you can cut the pipe smoothly, without roughness, burrs, spending a minimum of effort and time.

The second tool is a soldering iron, or as it is also called. “iron”. This tool is found in two configurations:

There are no big differences between them, however, soldering irons with a sword-shaped tip are more reasonable to take, t.к. They heat up faster and distribute the temperature more evenly. By the way, it is better to choose an “iron” with the ability to regulate the heating, because a clear soldering temperature of polypropylene is very important.

The price of this tool can be different, depending on the materials from which the welding machine is made. If the nozzles in the “iron” are covered with Teflon, it costs more. But it is easier to solder polypropylene with this brazing unit and you will avoid problems caused by inexperience.

At the same time you should pay attention to the soldering iron set, because in the set there are tips of different diameter with which you will solder polypropylene. Pay attention to the diameter of plumbing materials and be sure to check that the kit has the necessary nozzles or attachments.

If you can not get special equipment, you can solder polypropylene pipes without a soldering iron, but it requires some practice and the process of installing plumbing is somewhat complicated.

How can I cut material using special scissors?

Please advise how to cut MF “SuperPipe” Metserplast, without the use of special scissors. We have to cut two pipes of 1 meter each for DHW and HTW, and buy scissors for this purpose for

Is it really as serious as it says here: “To cut pipes, you must use specially adapted scissors, and in no case other stabbing and cutting objects.”

You can cut with anything, but the cut is going to be sloppy, imho. And scissors. They’ll come in handy.

Metal scissors ! ! ! Only then you need to calibrate (make it round) and grind the inner edges so as not to cut the EPDM rings on the fittings. For this use. A grit remover. It is also unlikely to be available? Then use ordinary scissors, but be careful.

You can cut it with a sharp knife. With it you can also trim, straighten the edge, remove burr, etc.д. Of course Kaliber is better, but if you need to make two fittings, you can cut it off with an improvised tool. But insert it with caution so as not to tear the o-rings.

J.Walker wrote: An ordinary knife, sharp, also cuts like hell.

We sawed with a hacksaw for metal and then with the flare (and it chamfered the inside)

vfx wrote: I need to cut two 1 meter pipes for hot water and hot water,

Well, cut it off where you buy it. They will also be able to press.

BV wrote: Well, cut it where you buy it. They can do presses there, too.

Already got it home. There were a lot of people there. there was no time to deal with me.

Oh, man. Just happened to be passing by the store, went in and bought a cutter for MF (100 rubles), it says Italy

, but not like on the market they sell Chinese for 250, and a calibrator (65 rubles) blue in three sizes with scissors for chamfering. Store, I understand, branded from a well-known manufacturer.

That’s how I got into the store! Thank you all. I’m going to use a piece of pipe to practice with the cutter.

How to cut plastic pipes

Over time, old pipes wear out, begin to leak, and it is inevitable to replace the pipeline. There are many people who still consider iron pipes almost ideal. But today there is a more modern solution. pipes based on polypropylene and polymer compositions with a metal frame. But what is it, and how is their installation?

In order to understand the intricacies of cutting metal-plastic pipes and their installation, it is worth a little clarification as to why the pipeline made of metal is not in demand now. Here everything is obvious and simple. the metal is bulky, hard to deliver and prone to corrosion. In addition, metal piping is not easy to install. Copper, on the other hand, oxidizes and turns green in a humid environment. In addition, it is significantly more expensive in price than steel pipes.

Below we will talk about the structure of the pipe on the basis of plastic and how to cut metal plastic pipes.

Preparation of the pipe and the necessary tools

The first thing is to choose the right tool. At our disposal:

The basis of metal plastic pipes includes a layer of polypropylene plastic, a thin aluminum lining, made using an ultra-precise laser welding and the final thin layer of plastic. The aluminum tube inside acts as a “skeleton” for the pipe.

The inner surface of the pipe is perfectly smooth, so unlike iron, such pipe does not collect rust and other slag on its surface. If the external part of the reinforcement needs to be cleaned, a simple socket with blades should be used. The end part of the material is shrouded by a coupling itself. After the socket is fitted, a perfectly smooth cut is obtained. The whole process does not take more than five minutes.

Note! Cleaning of the reinforced surface is done to get rid of a layer of polymer and protective coating, which is necessary for the following welding works. It is taken into account that the material is cut of that thickness which is necessary for fitting.

What do you cut a plastic pipe?

And now let’s talk about how to cut plastic pipes. If there is a need to cut a metal-plastic pipe, the master comes to the aid of plumber scissors for metal-plastic.

Cutting pipes does not require much effort and is well controlled visually. In the process of work, the pipes at the joint must be bent. A simple device. a pipe bender. is needed. Without this simple device own hand bend tube quality is unlikely to work. If you try to bend a pipe by hand, there is a high probability of damaging the aluminum layer, which leads to early failure of the entire pipeline.

Pay attention! When using tools not designed for machining plastic pipes, there is a great risk of damaging the reinforced layer of the pipe, get an uneven cut at the outlet, which will eventually lead to leaky joints of pipes. in the joints water will leak.

Technical scissors for cutting plastic pipes come complete with welding machines for metal plastic pipes. This tool has a sharp blade for cutting soft structures and a comfortable handle. the simplest models allow cutting pipes with a radius of 20 mm or less, so if necessary you should buy more advanced scissors, which can cut through pipes of larger diameters.

- After selecting the appropriate size and marking, the desired length is cut off with the scissors.

- Cutting with special scissors is completely waste-free, after cutting no crumbs are left and you can immediately start assembling.

- Working with such scissors does not require any skills, and you can perform the cutting without any additional skills.

Plastic pipes can be cut with the old-fashioned devices, and probably many people are interested in how to cut the pipe with an angle grinder.

The first thing to do is to make a mark on the pipe. An angle grinder of any size is suitable. In this case, you need to have a disc for cutting metal structures. An important digression. do not apply much force when working. Cutting is fast, but there is considerable noise at work, as well as some shavings can not be avoided.

[content-egg module=GdeSlon template=compare]

Conclusion and helpful video

In order for the assembly of the pipeline to be successful, the tool for cutting polypropylene pipes must be chosen correctly. Not every pipe cutter is suitable for this kind of work.

You still need to learn how to use it, pre-test it on an unnecessary piece of pipe. The following video reviews will help you choose the right tool.

An overview of the different shears for cutting polypropylene pipes:

Comparison of different ways to cut plastic pipes:

How to use a ratchet pipe cutter:

Without the pipe cutter in hand to perform polypropylene pipeline installation is difficult, cutting pipes will take a long time. One or another variant of the cutting equipment should be purchased. However, you should choose it wisely in the store. And before using it does not hurt and carefully review the attached to the tool rules of operation, after all, this is a specialized professional tool.

Looking for a pipe cutter for home use? Or already have experience with this kind of equipment? Please leave your Комментарии и мнения владельцев, share your experiences, ask questions about the article in the box below.

How to cut polypropylene pipes? Principles of choosing a good tool

First of all, choosing a quality tool for cutting propylene pipes, you should count on the planned intensity of its future use. When single or double cutting is required, precision or roller shears will be made.

If you have to cut pipes often, the best option would be a battery model. Of course, the guillotine pipe cutter will effectively cope with the work, especially when cutting large-diameter pipes.

A characteristic feature! All versions of pipe cutters have an important disadvantage. The blade may deflect slightly to the side when cutting. This is not critical for small diameters, but large polypropylene pipes should be removed from such defects. Therefore, large pipes should be cut with a guillotine pipe cutter!

How to cut plastic pipes

Hello readers! In this article I want to talk about how to properly cut plastic pipes. What tool is better and more convenient to do it.

Metal-plastic pipes capture a larger and larger segment of the plumbing market, so that the question of their maintenance becomes more urgent. There is an opinion that if it is necessary to replace such pipes, it is necessary to change the entire pipeline. But this opinion is wrong.

The products are easy to cut and change piece by piece without harming the overall plumbing or heating system. Below we consider how to properly cut plastic pipes.

Cutting methods

There are several basic ways of cutting, depending on the tool used. First of all, you can cut the products:

- Knife for effective cutting of metal-plastic pipes. A self-sharpening knife should be used in this case.

- Metal hacksaw. The simplest method, which, however, requires a lot of effort and time from the performer. Also, the edges can be jagged.

- With scissors.

- Pipe cutter.

Some tools produce a fairly jagged cut edge, and material particles can cause clogging later on. The best method is considered to be the use of special scissors, which cut evenly, leaving no jagged edges. With these scissors you can cut objects with a diameter of up to 40 mm.

Important! No special efforts in this case will not have to be applied, because the tool is specially designed for such work and has special blades. These blades effortlessly cut through plastic pipes in all areas.

For products with a larger diameter, it is better to choose a pipe cutter. Pipe cutters can be telescopic or ratchet. The first type is based on the work of a special roller that rolls along the entire length of the circle. The second type is more like scissors, because it uses a lever system with two handles.

Metal plastic pipes have many advantages over their competitors. They are much lighter than metal pipes and much more resistant to oxidation than copper ones. They are easy to replace and easy to shape.

Any shape of pipe can be created. And the main advantage is the cost. It is much lower than with copper pipes. And the quality is about the same.

In the process of operation it may be necessary to cut the pipe. For this purpose, a special tool is used, which is designed to work with this kind of material.

Proper pipe and tool preparation prior to operation is recommended to maximize efficiency. Let’s consider the main features of metal-plastic pipes and what to cut them with.

Varieties of pipe cutters are classified according to the objects of cutting and features of the cutting element. Accordingly, the following types of tools are distinguished:

The chain tool differs in that it can cut pipes from dense materials (cast iron, concrete, ceramics), because it has a mechanism for tight fixation of the object to be cut, made on the basis of an ordinary chain and rotary levers.

The ratchet pipe cutter is portable and can cut pipes of small thicknesses. Its design is the simplest among devices of a similar class. 2 handles and a cutting blade.

Electric is equipped with an electric motor

thanks to which the efforts of the worker to cut the pipe are minimal. it is only important to correctly adjust the tool, and the rest of the work he will practically do himself

It is an all-purpose tool that cuts through pipes of all diameters and materials. Application limited only by motor power. However, this pipe cutter has a significant disadvantage. it will not be convenient to use in hard-to-reach areas of work (eg. sewer pipes).

It can be used not only for mechanical cutting of pipes, but also for facing, chamfering with blunt, as well as the outer surface of the pipe.

Pneumatic tube cutters are driven by vacuum air pressure. This device is used in production for cutting very large diameters (up to 1500 mm). At the same time it copes well with cutting dense material (cast iron) and lightweight plastic.

Orbital pipe cutters are designed not only for mechanical cutting of pipes but also for beveling of thin-walled pipes. They are equipped with special chamfered cutters for this purpose.

Cutting the pipe at an angle of 45 and 90 degrees

If you need to cut the pipe at an angle of 45 degrees, which is often required when laying water pipes, heating pipes. Often steel, cast iron pipes are used, which have a cylindrical shape. Rectangular or profiled pipes are used in installation work. However, you should properly cut the pipe with an angle grinder so that you can then easily connect. Therefore, it is necessary to carefully mark the pipe.

Some masters try to mark the place of the cut with a tape measure, but be warned that the result will most likely turn out negative. And for a positive result, consider the following recommendation of professionals.

Take a sheet of paper or cardboard, preferably A4, fold it diagonally and wrap it around the pipe where you plan to make an even cut. The edges of the paper should absolutely coincide with each other. And the side of the paper that is closer to the end of the pipe was perpendicular to the axis. After that, in a circle mark out a fishing line to trim the cut.

If you need to cut exactly at an angle of 90 degrees, then solve the problem quickly, again using paper or masking tape. Wrap it around the pipe so that the ends coincide. Make an even mark and saw off.

Masters are advised to use an angle piece when cutting a profile pipe. To do this, take turns putting the angle piece to the sides, and with smooth motions turn and apply the marks. After the actions, fix the pipe and cut. Prepare yourself a template, which will come in handy in the future and save time. It is better to make the action with an angle grinder, so the cut will be smoother.

When working with cast iron pipe, keep in mind that it is a fragile material. So let’s find a way by which you can cut such metal without damage.

Before you begin, make marks for the cut, just as you would with steel pipes. Put a wooden block for support. Pass an angle grinder around the circumference of the pipe, making small cuts. Then take a chisel, insert it into the groove and hit it hard with a hammer. Keep in mind that bakelite-based cutting discs are used to cut cast iron pipe.

If you do not have at hand an angle grinder to cut cast iron pipe sewer or other purposes, use a hacksaw for metal, chisels or special pipe cutters.

Cutting a gas pipe is a dangerous action, so it’s best to trust professionals. But if you are confident in your strength, then take an angle grinder, weld, hacksaw, gas welder to cut the metal.

- Before you start working, turn off the gas supply. After that, let the rest of the gas out of the pipe. To do this, light the gas in the burners and wait until it goes out.

- After the actions performed, cut. Using the method of welding, the metal base burns when exposed to high temperatures. The result is fast and efficient. But remember that cutting or rooting gas pipes again requires experience.

Methods of cutting large diameter pipes

For cutting large-diameter pipes, such as sewers, there are a number of reliable tools. Below we will consider some of them in detail:

Angle grinder inexpensive and affordable option, but is not considered the safest way to work with such materials. If you decide to use such a method, then be careful and use protective equipment. The roller machine (pipe cutter) is such a tool adapted for such manipulations. The device is attached and begins to remove the material. The pressing force can be adjusted by a mechanical device

It is important to note that machine models vary in shape, so consider the size relationship with the pipe before using. Gas cutting is the most popular option for cutting large diameter pipes, sheet metal. The cut is caused by the high intensity of the flame, the metal melts and exits the cut zone with the gas flow

Quick way to cut the pipe lengthwise with an angle grinder:

The most important thing is to pay attention to the marking. Use for such a case a painting thread, which is widespread in the marking of walls

Before you start, clamp the pipe and use small, controlled movements to carefully saw the pipe. Do not rush, but rather process parts of the pipe delicately and slowly, so the cutting wheel does not jump off the marking lines. Be aware of safety rules.

Thin-walled pipes are made of nonferrous metals: aluminum, copper. Such work should be performed delicately, since there is a high probability of deformation of the material. Use fillers, such as sand, for cutting. The action can be carried out with an angle grinder, a special machine.

How to Choose a Cutting Tool

Plastic pipe scissors are chosen based on what cylinder diameter is expected to be handled in the future. It turns out that the choice has to be made on the basis of the material of the cutting edge. It is divided into categories according to thickness:

- Ten. This cutting material is suitable for the installation of water utilities, floor heating and heating, taking into account that the peak temperature does not rise above 45 degrees, at a pressure of 1 MPa;

- Sixteen. Cutting polypropylene pipes with such a tool is suitable for the construction of the water supply of the house, heating in the apartment when taking into account the pressure of 1.5 MPa;

- Twenty. This standard is universal, it is used to install cold and hot water in the house, with a temperature of 80 degrees and the pressure inside not more than 2 MPa;

- Twenty five. Polypropylene pipes of this type are reinforced with foil or other metal mesh in the process of release. Such kits can withstand the temperature of boiling water and high pressure, they are suitable for the installation of central heating.

Pipe cutter for polypropylene pipes is used not only for pipes, but also for connections that are made by manufacturers. Connections are equipped with brass inserts, so that the fasteners are reliable and will last inside for a long time. Brass rings are pressed inside, so use Kraftul pipe scissors carefully so as not to blunt the scissors on the rings. In addition, such connections are used, which make the transition from steel pipes to plastic, if you need to slightly adjust such an adapter, then use scissors for polypropylene pipes kraftool with care.

When choosing materials take into account the expected water pressure and peak temperature, which is achieved in heating or hot water supply. Therefore, note that the shaped cut pipes from a quality manufacturer should be performed with no less confident hand locksmith. Also for the installation will also need a welder, if you plan to connect the metal-plastic pipes to cast iron, there is not only a machine for cutting foam with his hands, but also some additional equipment.

Basic types of tools offered

The equipment that is sold in the markets for cutting foam plastic is divided into some groups according to classification. Scissors for cutting plastic pipes of the precision type are designed for cutting the product with a diameter of not more than 45 millimeters. It turns out that the tool for cutting pipes of this type is equipped with a sharpened blade and a serrated band, which is necessary to ensure the smoothness of cutting and obtain a quality cut, without burrs and chips.

For home use hand scissors will do well, for larger volumes is better to use hydraulic

The positive thing about this type of plastic scissors is that they can be used with one hand. That is, when you have to cut a lot of hand will not get tired of such mechanical work. If you use a cutter for polypropylene pipes of the classical type, the muscles will get tired quickly and you can not work long. The customer can also choose a roller version of the pipe cutter, which is more convenient to work with. It takes a bit longer to work with it, but the cut of the pipe comes out perfectly smooth and even. When using scissors for cutting polypropylene pipes, the product in relation to the structure is located at an angle of 90 degrees. Keep in mind that cutting a pipe with a deviation from a right angle will result in an incorrect edge that is beveled in the cut line.

There is also a ratchet pipe cutter, which also looks similar to the classic scissors for polypropylene. But externally the difference can be seen at a glance. on one side there is an arched recess in the body of the scissors, in which the cylinder is placed. And on the other side is a blade that presses down on the pipe and cuts. In addition to these variants, there are also such pipe cutters:

- Cordless model, which runs on electricity and allows you to work quickly, spending no more than 10 seconds per cut;

- Guillotine type foam cutting machine is used to process material with a radius of 50 to 400 millimeters.

If you set to work, but the pipe cutter necessary design is not available, then replace the scissors with a classic wood or metal saw, but it is desirable that the saw blade pitch is small.

Keep in mind that during this work, the cut is processed from burrs and chips file, beveled.

Assembling PP products

How to bend a pipe

After the preparation of products polypropylene pipes are assembled. Often when laying a pipeline, it is necessary to slightly bend the products, although manufacturers do not recommend doing this operation. There are several ways to bend a polypropylene pipe:

- Using a hair dryer or electric furnace, the pipe is heated to 150? And bends to the desired angle.

- Carry out a cold bend in the radius, which is equal to no more than 8 diameters of the product.

The first method is the most preferable.

Welding of the pipeline

Connection of pipes with a diameter of up to 63.0 mm, carried out by two methods:

For threaded connections, fittings with socket joints are used.

Products larger than 63.0 mm in diameter are often joined using butt welding technology.

To connect products with a small diameter, a special handheld welder is used. For larger diameters, a stationary welding machine with pre-positioning is used.

Directly the process of installing PP products is discussed in the article “How to weld polypropylene pipes”.

During the installation of the pipeline is laid polypropylene pipes with bypass tubes and fasteners. Usually, when laying a closed water pipe, the pipes are laid in grooves.

Having studied all the ways of working with PP products, if you have an inexpensive special tool, you can in a short time qualitatively lay a pipeline of the necessary configuration.

Top models on the tool market

In the toolbox in the garage of the home handyman most often found pipe cutters for metal-plastic pipes.

In order not to break your head, trying to understand all the variety of tools in the construction departments, it is better to read the rating of popular quality models in different price categories and make a choice based on the experience of other buyers.

Budget tools for home use

Among inexpensive equipment for cutting pipes the most in demand are Sturm and WMT brand pipe cutters.

Practical equipment by Sturm brand

Sturm is an inexpensive and practical option for home use. The tool has a hardened steel blade. Metal parts are coated with a protective agent against corrosion.

Cheap does not mean poor quality. Yes, budget models of pipe cutters do not have all the advantages of professional equipment, but they perform their main function

Handle is made of comfortable plastic with a non-slip surface. The cost of the pipe cutter from the company Sturm ranges from 400 to 450 p.

A brief video review of the pipe cutter of this brand in the following video:

Inexpensive solution from WMT

Another budget pipe cutter comes from WMT. This tool will not cost you more than 300 p.

For such money you can not count on additional functionality and other nice little things, but the device copes with its work within reasonable limits. It can cut plastic and metal pipes up to 42 mm.

Overview of the budget model for minimal money:

Professional pipe cutting equipment

RIDGIT, Milwaukee and KALDE brands stand out with good reviews among professional tools.

Popular among users RIDGIT pipe cutters

RIDGIT is one of the market leaders in pipe cutting tools. This manufacturer offers professional equipment that can work in all conditions. RIDGIT PC 1375 ML. one of the most popular models of this brand.

The lightweight (only 320 g) steel body and robust cutter cuts the pipe in just a few seconds. Wide range of working diameters (up to 42 mm) allows to work with the most popular sizes of pipes. The RIDGIT PC 1375 ML costs from 3600 p.

Any experienced builder could distinguish a professional tool from an “amateur” one just by holding it in his hands. And you don’t need to know the brands for that. If the product is of high quality, it speaks for itself

Another popular model from RIDGIT is the TC-40. It is an automatic pipe cutter. Equipped with a 0.75 kW motor and 12V lithium battery. Can easily cut pipe from 3mm to 42mm just by pushing a button.

It has such a nice addition as backlighting for work in poorly lit places. Since metal plastic pipe is multi-layered, the manufacturer has taken care of a special adapter for this type of material. Price of automatic tool from 18 000 rubles.

Milwaukee reliable models

Milwaukee professional tools from USA. guarantee of quality and reliable work during many years of service.

Milwaukee ProPEX Tubing Cutter for small diameters up to 25 mm. It is made of durable steel, does not corrode. Comfortable handle features high level of ergonomics. But the price for a high quality pipe cutter is also appropriate. from 2300 p.

Wide choice of KALDE tube cutters

The Turkish brand KALDE offers a wide range of scissors for plastic sheet metal pipes. For example, KALDE (40-63) is a model for cutting large diameter pipes from 40 to 63 mm. The blades are sharpened very well, the tool does not bend plastic sheet metal pipes, does not bite on the edges and does not leave behind chips.

All products by KALDE are manufactured according to European quality standards. The price for a particular model in stores is about 4300 p.

Block: 6/8 | Number of characters: 3749

Conclusion and useful video

With such a wide range of construction tools, both manual and electric, it is quite a real task to choose a pipe cutter that will cope with its function, but will not cost more than the heating system itself.

Knowing what kinds of devices, as well as getting acquainted with the most popular models, you can easily choose and buy equipment to work with plastic pipes.

Want to add to our material useful Комментарии и мнения владельцев or share your own experience in cutting metal-plastic pipes? Or do you want to tell about the pros and cons of your pipe cutter?? Write your opinion and recommendations under this article, add unique photos of your pipe scissors model or the cutting process itself.

Block: 8/8 | Number of characters: 886

Number of blocks: 14 | Total number of characters: 22611Number of donors used: 5Information on each donor: