How to make a reverse hammer with their own hands

How to turn an old shock absorber into a reverse hammer by yourself?

First of all, the dismantled part must be properly disassembled. If the shock absorber is removed from the VAZ car, the further work will not be too difficult. Of course, you will also need the standard tools, which are usually equipped with a garage of a car enthusiast who prefers self-service and repair: vice, angle grinder, manual welder, gas burner or crucible (for melting lead).

Varieties

Despite the fact that the design of the reverse hammer is quite simple, over time, even it has had several modifications. One or another variant is used in different cases. it all depends on the skill, as well as the type of deformation. But in general, the design is always the same, the same and the principle of operation. The only difference is in the method of attaching such a tool to the body.

- This is a metal bar with a hook on one end and a weight and stop on the other end;

- A hook is hooked to the washer, and the washer is welded to the point of deformation by welding;

- Subject to the application of shock forces on the load, the deformation is stretched to the right moment.

But the second variant (also quite simple) will be somewhat different from the first. At the end instead of a hook there is a simple thread. To level the surface with such a device, a hole is made in the center of the deformation, into which the end with a thread is inserted, and a nut and washer are attached to it on the reverse side.

The vacuum hammer is the most complicated version of its design. It is attached to the surface of the deformed area by means of rarefied air. The suction cup begins to work both by the usual method and with the help of a compressor.

With a vacuum attachment, you can repair minor body damage and keep the paintwork intact.

What is a reverse hammer and what does it do??

This tool is a device that allows you to apply a certain amount of force to an area of metal with limited access. The device is used to level small areas of the deformed car, which suffered from minor accidents.

Some areas of the car body can be leveled with an ordinary rubber hammer, using backhoe blows. However, most surfaces do not have this access. In such cases, this is where a reverse hammer is needed. Its tip is fixed in the place of deformation, and a pulling jerk force is transmitted to the surface with the help of the weight on the other end of the device.

Before making a reverse hammer, it is necessary to describe the varieties of this tool. You will need this to make a drawing of the device you need, and then make it.

How to make a reverse hammer with their own hands from a small number of parts

Every driver knows what dents on the vehicle. The reverse hammer was invented to solve these problems. This tool is very popular among motorists. It helps in repairing hard-to-reach areas. The tool perfectly smoothes out any irregularities or various deformations of both the machine and different kinds of metal. This device works on the basis of the pulling force applied to a certain piece of iron. Before making this “tool”, it is worth familiarizing yourself with its types. This will help to make a drawing of the reverse hammer that you need.

This tool, although simple, has several types, for this or that damage and its complexity. But the design of mechanisms is similar to each other, as well as their functionality Thus, it will not be difficult to make a reverse hammer from improvised means, which will not be inferior to the purchased mechanism. The difference of such equipment is in the method of attachment.

The first type of hammer consists of an iron pin, on one side of which is a nut and on the opposite side, a weight with a stop. Huck is clamped to the washer attached by welding in the place of bending. Having made an impact force on the weight, goes the correction.

The second kind is similar to the first, but differs in that instead of a wisp there is an ordinary spiral. This type of tool in its characteristics resembles a homemade reverse hammer. To straighten a dent with this mechanism, you need to drill a hole in the place of the bend. On the reverse side we lean the washer and screw.

The third kind has a cryogenic unit at the end. In the action, everything is done both with a special pump and by hand. This variant is good, because it doesn’t leave any marks or scratch car paintwork.

The self-made one

To make a reverse hammer at home with their own hands is simple enough. It does not take much time, and does not require special materials and tools. For a better understanding you can watch a video on the Internet. A primitive drawing will also not be superfluous.

To make this tool with their own hands will need the following:

- metal pin about 50 cm and 20 mm in diameter;

- A load that has an inner hole;

- A threading tool (optional);

- welding machine;

- angle grinder.

If it is decided to make a reverse hammer with a hook type of attachment, a hook is made at the end of the pin. It can be made with a vice or pliers. Or weld with a welder an already finished hook from another device.

If the tool is made with a threaded grip, the end of the pin is threaded with the appropriate tool. A lot of threads should not be cut, since the metal of the body is quite thin.

After making the tip, a weight is put on the pin, which is restricted on the back side of the tool. This can be done by welding, or using a threaded stop. The second method is more advantageous because it allows the use of different weights depending on the required force at the end of the reverse hammer.

Tools

Body repair shops always have a special set of tools and special equipment for dent repair without straightening and painting the metal. And although the damage is serious, and even located in a large area without the use of powerful stands slipways can not be corrected, pull in small areas of the dent with difficult access is quite realistic. For this purpose it is only necessary to use a special small-sized car tool called a reverse hammer.

Using a reverse hammer

The reverse hammer can be called one of the best tools for auto body repair. It is also often used to repair arches, sills or uprights when access from the inside of the part is not possible. The device is very simple, and operation does not require much skill.

The following types of hammers are available. Pneumatic reversing tools and reversing hammers. There are also hammers with two and three weights, thanks to which the impact force can be adjusted. In addition to the standard version, there is vacuum equipment that also removes dents. The advantage of this reverse hammer is the suction cup. It acts as a gripper for the equipment and does not disturb the paint finish of the body.

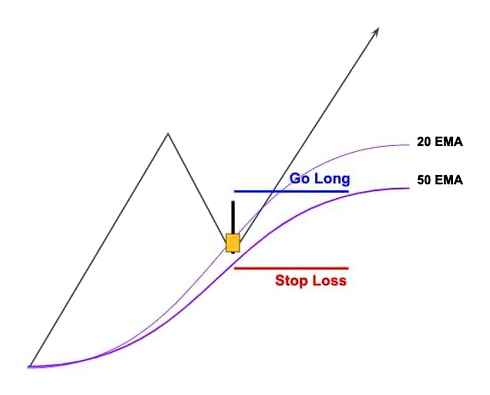

Inverted Hammer Candlestick Pattern (Hindi/Urdu) | Inverted Hammer Trading Strategy

Performing straightening involves a number of tools in addition to the basic tools. It is a straightening hammer, file, machine tool, saw, bench and spacers, electric reverse hammer, reverse hammer. Reverse hammer is often used in conjunction with other contact welding tools. The reverse hammer is usually part of a straightening kit, which is usually included with welding machines.

A reverse hammer is often included in bearing removal sets. These are designed for use in vehicle workshops for removing various parts by gripping their inner workings with the slide hammer. The specially designed grips fit snugly on the bearings, allow the bearings to be removed without damage, and the handle can also be turned clockwise. Thus, the purpose of the hammer may differ, but the price of the reverse hammer remains the same.

Backhammer design

The design of this tool is very simple. It has a steel rod with a diameter of 20 millimeters and a length of 500 millimeters (base) and weights freely placed on it, as well as a hook and washer. On the base, the kettlebell or several kettlebells, which may differ in weight, are attached. On one side of the rod is placed a hook, and on the other side is a washer that does not let the weight fly out, and transmits the force of the blow of the reverse hammer to the rod.

The modern tool is equipped with several types of grips that allow you to use it to level out damaged areas, particularly dents, on different areas of the body. With a good combination of weight and length you can knock out quite a lot. From the crumpled sills to the crumpled double metal that is in the rear fender. Reverse hammers are often used in conjunction with a spotter during repairs.

Working with a reverse hammer

Before you start working with this tool, you should familiarize yourself with the damaged area of the car body (or other object). The places to be pulled should be well cleaned to metal, degreased and primed and then painted. Next, you need to drill a small hole and weld special repair washers. Often such reverse hammers, no matter how you subsequently do not want to paint, act as the only solution to repair the body. After these actions a hammer is attached to the damaged area.

Grasp the washer with the hook of the tool and gently tap the dent out. This action should be repeated until the dent is completely leveled and removed. After a number of these steps, the part of the bodywork is to be painted. To remove long dents and edges, some washers must be welded and a metal rod slipped through the holes.

It is very important to remember that the standard slide hammer cannot be used to repair too large areas such as the center of the roof, hood or trunk lid. In these places, you can overextend the metal by welding washers, so the part will just have to be thrown away.

The use of a reverse hammer requires the creation of a paint coating on the surface. But there are hammers, which are equipped with pneumatic suction cups, for the application of which there is no need to make holes in the metal and thus save the machine from unnecessary painting work. This option is recommended for repairing large areas. To create a pneumatic fixation to the surface it is necessary to conduct a supply of compressed air, so the vacuum hammer is connected to a special compressor during operation.

Making a reverse hammer with their own hands

The technology of making a reverse hammer at home is quite simple. Before you start your work, you need to prepare well. You should carefully plan and think about your work in advance. It is necessary to prepare a steel or stainless steel rod with a diameter of 20 millimeters and a length of 500 millimeters. You will also need a steel weight and a hook. A standard reverse hammer is made very quickly. You will spend for its creation only thirty minutes.

Let’s look at the reverse hammer drawing, where you can use improvised tools. Suppose you have a very thick pipe, like a ski pole, and a weight with a hole in the middle to attach it to the pipe. On one end of the pipe, you need to make a limiting pad for the load, which will bang against it, and to the other side attach a hook or other version of the hook.

Instead of a hook, you can use a stud that has a long thread. In this case, the stud should be threaded into the hole in the body, and a securing temporary nut should be screwed on the back side through the washer.

Many people have a question about how to attach interchangeable hooks? The answer is very simple. The pipe should only end with a threaded stud. Similarly, the nozzle should have the same stud at the end. To connect them, you can screw about 10 nuts on one stud and weld them together.

When the hook hooks on the metal of the body, you should use the weight of the load on the tube, that is, you have to accelerate the load to your side. It will hit the restraining pad, which can be a large washer welded to the pipe. There will be a strong impact that will be transmitted to the metal being pulled. Builders recommend using a load of at least three kilograms.

You can make the hook from sheet metal, which is about four millimeters thick. If you want to make a vacuum backhammer with your own hands, instead of a hook should be adapted suction cup from a plunger. The beauty of vacuum back hammers is that they do not disturb the exterior paintwork of the car.

When building a reverse hammer, experts advise machining each part with a file. All nicks and burrs must also be removed. Remember that the backhammer is a hand tool, so try to make it as comfortable and pleasant for your hands as possible.

Body sheeting at home

A car with smooth and level forms involuntarily attracts the eyes of passersby. Nobody wants to drive around with dents in the bodywork and asymmetry. Car owners know that damaging the body is easy. This is caused by branches, fences, small traffic accidents, accidentally falling objects, etc.д. In order to restore your car to its former beauty, you need to perform straightening, which will return your car to its original attractive appearance.

Performing straightening consists in restoring the deformed shape and individual body parts. This problem can be eliminated at home by yourself, so that you do not have to pay too much for the services of specialists. A homemade slide hammer is the best way to do this.

So you need to pull out or straighten concave areas. If the detail of the car is badly damaged, it is better to just replace it with a new one and not waste extra time on repairs, which may not give the desired result. Before you start the work, the paint is removed and the putty and grouting is done. Some experts heat the metal to a reddish hue before tapping, but it is important not to overheat or melt it.

Then you start the straightening process. You should get a blowtorch or a torch for tightening the metal. When the bulge is warmed up, the edges should be covered with a wet rag. The metal will shrink due to the change in temperature. Examine all dents carefully, and be sure to estimate the difficulty and size. A large dent is straightened out around the edges and a small one in the middle.

At the same time with dents on the car can appear and cracks, so it is necessary to have a welding machine. To do a quality job, you will probably need a spotter, a reverse hammer with a sharp beater, and a notching block. Perhaps you should get some more tools, which are needed only for your case.

Many people prefer vacuum straightening at home, which can remove dents without painting, and in a matter of seconds. It works by means of special vacuum suction pads and can even be used on large dents. The problem with vacuum straightening is that it can’t get rid of the defect completely. Also, if there are cracks in the damaged surface, vacuum straightening can further damage it.

Therefore, it is necessary to pay attention to the method of straightening and the choice of tools. After using the reverse hammer it is necessary to fill the holes or weld them. Then the repaired part should be grouted and painted. Deep and small dents, which have a strong stretching, in addition to the standard work on pulling and tapping, require pulling of excess metal.

In some cases it is necessary to cut the stretched areas and patching with a spotter (welder). Knocking out is done with a reverse hammer. Usually the deformed body element is removed, but if this is not possible, the dent can be squeezed out with a special spoon. This method is often used if it is possible to get through the trim to the concave. But if this option falls away, you have to drill holes on the damaged part and pick up through them, resorting to the help of special tools.

The reverse hammer is one of the most important tools for making body repairs. If there is no access from the inside. it’s indispensable. Any craftsman knows how to make a reverse hammer at home in about an hour. If you pay attention to the selection of parts and clearly follow all the stages of assembly, you can make a reliable tool that will complement your home collection.

Self-Made

Making a reverse hammer at home with your own hands is simple enough. It does not take much time, and does not require special materials and tools. For a better understanding you can watch a video on the internet. A primitive drawing will also not be superfluous.

To make this tool with your own hands you will need the following:

- a metal pin about 50 cm and 20 mm in diameter;

- The weight, which has an inner hole;

- threading tool (optional);

- welding machine;

- angle grinder.

If it is decided to make a reverse hammer with a hook type of attachment, a hook is made at the end of the pin. You can make it with a vise or pliers. Or use a welder to weld on a prefabricated hook from another device.

If the tool is made with a threaded grip, the end of the pin is threaded with the appropriate tool. Do not thread too much because the body metal is quite thin.

After the tip is made, a weight is placed on the pin, which is restrained on the back side of the tool. This can be done by welding, or using a threaded stop. The second way is more advantageous, since it will allow you to use different weights depending on the desired force on the end of the reverse hammer.

Advantages and disadvantages

If we talk about the obvious advantages of using the tool, it is worth noting the ease of operation, the possibility of fairly rapid alignment of the impressive area of the damaged body.

Additionally, it is necessary to mention a special kind of tool. vacuum reverse hammer. A distinctive feature of the auto body straightening tool is the ability to repair extensive areas without the need to remove the primer layer and paint.

As for the disadvantages, vacuum hammers are not very effective when it is necessary to restore the central parts of the roof, hood, trunk of a car. The result of welding brackets under the gripping hook in this case is a significant deformation of the metal, its excessive pulling. Therefore, after using the device is often necessary to make a complete replacement of these body elements.

Reverse hammer from an anchor bolt for removing bearings and more

Reverse hammer, which I made from an anchor bolt with my own hands, will be useful not only for knocking out small bearings, this craft can be found a lot of applications, I think that such a hammer should be in every garage.

So, what we need for this, and the first thing we need of course anchor bolt, its size depends on your needs, at the end you’ll see why.

Also, we need an iron bar or rod, which will run the side, its thickness I have 13 mm, and a length of 60 cm.

The first thing I did was to weld the anchor bolt to the rod.

Then, in the garage I had lying here is such a weighty hedge)),

I don’t know what to call it, but it was just right for me, I just had to drill a little bit inside the hole for the size of the rod on which it will run.

On the other end of the rod welded a nut, that’s, perhaps, our handicraft is ready. Nothing complicated, practically three parts, but how much will be useful from it.

Well now we need to try, take the cover from the old engine and try to remove the inner bearing from it.

For this, we put the anchor bolt in the bearing and twist it until it clamps there, and then just a few strokes with a reverse hammer and the bearing popped out.

So everything works great, my garage was enriched with a new and necessary craftsmanship).