How to make a single-axle tractor with their own hands from a chainsaw

How to make a single axle tractor from a chainsaw or scooter with your own hands

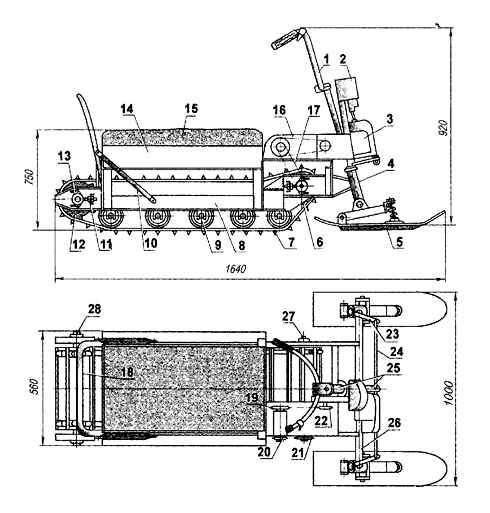

5 years ago made a single axle tractor based on the engine Izh Planeta.3, with a gearbox from Murowja. Long thought after the snowmobile, no money. And I had to work in the field, so I had an idea, I made it in 2 months, because almost everything was at hand. On fishing, errands and in the field, it has become my indispensable assistant. Transport speed reached 70 km per hour, I had to learn how to drive.

Radosneg wrote: based on the engine Izh Planeta.3,

Forced cooling through the ignition, all in detail I will lay out, the constructive device will be clear on the production. If anyone likes it of course. This spring there were cold winds, I almost did not use the air blower on the cultivation. As in the transport version, you don’t need one, either.

This single axle tractor I made to order, here the cooling is better viewed, simple impeller from the stove, side turbulence with conical air supply, cam drive from the pulley to the pulley.

Radosneg wrote: Cooling is forced through the ignition

I just already saw with the engine from the wheelchair There Izhevsky. It works fine. And in the first photo just can’t see. By the way, how much power does it have??

The scheme is suitable for engines Minsk, Voskhod, Muravey, there are design changes when installing the engine, but everything can be solved, Izh has proven to be the best. On a simple slow single axle tractor, I can not put me, in front of the traffic police try to go quieter, and so up to 50 km per hour is quite manageable speed. The original speed is up to 5 or 6 kilometers per hour. Carrying capacity up to 500 kg. Made from 2 old torsion type wheelchairs. I was afraid that the baffles will not hold, in vain, in 5 years, all intact. Gentle going, minimal shaking.

Caterpillars on a power tiller

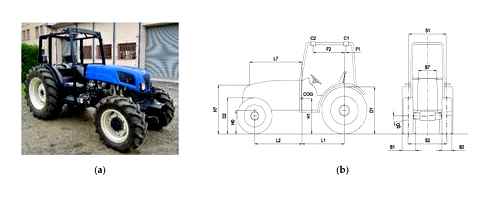

Peasants, dacha owners work in the fields, in the vegetable garden almost till the first snowfall without any frost. To ride on such soil or to leave on the asphalt or gravel it is not easy for a power tiller with a trailer. For clarity, take a picture of a power tiller with your own hands.

Improve traction power setting a kind of tracks from the conveyor belt or old tires. But here you need some experience or a handyman’s tip.

It is easier to put chains for cars on tires in such weather. If you drive out of the mud or snow on the asphalt. remove the chains and you’re home safe.

Druzhba” chainsaws

The legendary Druzhba chain saws from the USSR. Nowadays, they are no longer in production, but you can find them in the garages of our fathers and grandfathers and, surprisingly, still in working order. The year of manufacture of the first Druzhba gasoline-powered saw was 1955. Development started two years before. On the territory of the USSR, these chainsaws were produced by two machine-building factories: Perm and Biysk. Developers were constantly improving something and introducing new technologies.

These changes can be seen in chronological order:

- 1953. beginning of development of the first Druzhba chainsaw.

- 1955. first chain saw Druzhba-2 (handles are attached directly to the blower) and Druzhba-4 (handles are attached to the clamp connecting motor and saw reducer) came off the assembly line, mass production of chain saws was established.

- 1958. victory at the international exhibition in Brussels, after which the chain saws began to be supplied to foreign countries.

- 60- 80-ies. production of modernized Druzhba 4-A chainsaw, chain lubrication system, magneto and carburetor KMP-100 appeared.

- 1990. modernization of the Druzhba 4A chainsaw, production of the improved Druzhba-4A-Electron model. This model was the first to feature electronic ignition and a new KMP-100U carburetor.

Features of the power tiller

Structurally, a single-axle self-made tractor is a two-wheeled unit on a frame, producing up to 4 l. with an average speed of 2.5-2.7 km / h. Features, as well as operational challenges, are largely determined by the choice of propulsion system. If we are talking about remaking from “Druzhba”, it will be distinguished from the purchased power tiller by the following parameters:

- small size, lightness;

- Economy of fuel and lubricants;

- the ability to assemble a unit sharpened to perform specific works (the right size of the frame, a unit for the attachment).

A single-axle homemade tractor can plow, dip crops, harrow, mow or remove the leafy crop, and apply fertilizer. Due to small size it can be used in hard-to-reach places (for stony, bad soil the power of self-made machine may not be enough). It will be especially useful for those on whose site the power and capacity of a large purchased power tiller would be superfluous.

Simple homemade motocultivator from a chainsaw

To make a homemade motocultivator out of a chainsaw, you need a saw engine, a few pieces of pipe and s.

Simple frame design and layout of main components

Open the picture Simple homemade chainsaw tiller in larger size.

Picture “Design of a frame for a power tiller with a chainsaw engine”

Block: 2/8 | Number of characters: 400

Which saw is the right one for you to use?

The most optimal for modification of gasoline saws are “Druzhba”, “Ural”, “STIHL” and similar models with a large power reserve. This is exactly the parameter you need to pay attention to when converting your bike into a moped. Some German chainsaws with high power lend themselves very well to remaking. Machine should be chosen with at least 2 liters of power.с. and engine capacity not more than 50 cm3. Cyclomotors from such units are the most enduring.

In order to make a motocultivator it is not necessary to have a special technical education, but to understand the schemes and drawings, as well as have the skills to repair garden equipment is desirable. Skills in working with a welding machine are not superfluous.

Making a single-axle tractor from a chainsaw with their own hands

According to the evaluation of owners of land plots, who have already experienced all the features of homemade motor equipment from gasoline saws, assembled by their own hands, “Druzhba” demonstrates the most excellent result after the modernization. With a competent choice of power plant for the homemade machine, it works no worse than its industrial prototypes.

The absolute advantages of this device are considered:

- high power, reaching up to 4 horsepower in some samples;

- lightness. the insignificant weight will not weigh the unit and will add to its mobility;

- small size. a small engine does not require strengthening the frame, which reduces the financial cost of its manufacture;

- economical consumption of fuel and lubricants;

- Working capacity, which is conditioned by readiness for prolonged strain;

- the possibility of using all kinds of fuel and lubricants;

- functioning in a completely self-contained mode;

- suitability for different kinds of work.

Assembly procedure depends on the drawing used and may vary, but the main points of the assembly include the following activities. The frame is assembled according to the drawing.

The work process is organized as follows:

- we take a metal tube with a cross-section of at least 20 mm and bend it so that the overall appearance is similar to 2 spars, the end of which is directed upwards

- in the rear area of the spar the handlebar from a motorcycle is welded;

- Strengthen the base with crossbars;

- to the rear bends of the spars electrically welded support platform under the battery.

Then the work proceeds as follows.

- Now we mount a specialized flange, with the help of which the shaft will be fixed to the main structure of the gasoline-powered saw unit.

- You can buy sprockets from a UAZ car on the second-hand market. They will be used to form a clearance (ground clearance) between the ground plane and the connecting wheel beam.

- Take the bearings with 30 mm diameter. Fixing them to the main axle.

- Gearbox with gearbox assembled from motorcycle engine.

- The wheels and cutters of a homemade motocultivator are installed on a metal pipe of the desired diameter.

- Because the power tiller is slow the system needs to be cooled forcibly. The simplest solution is to install a fan. And to keep the air flow on the cylinder, a protective coating is used. It can be an old motorcycle gas tank.

Read also: Adjusting and regulating inspection and measuring tools

After completing the assembly work, be sure to test the equipment, doing it with the utmost care.

Do not forget to install the weight in the front of the machine, firmly fixing it to the body. This will allow the homemade farm equipment to hold the center of inertia. If the element is fixed unstably, while working the single-axle tractor will walk on the move, leading to failure of the engine.

Self-made single-axle tractor: chooses the power plant

The central issue that everyone who has decided to make such a homemade machine will have to resolve will concern its propulsion part. It will depend on it, whether the future single axle tractor “pulls” the loads assigned to it or not.

In this case, there may be several options:

- An old engine from a motorcycle, moped, scooter or even a car, which is not always at hand in good condition, and the purchase of a new one can pull a huge capital investment;

- Motor from professional trimmers;

- Engine component from performance chainsaws.

Each of these can be a good basis for a power tiller, but the most famous way is considered the one based on the use of a chainsaw.

The unconditional advantages of this method are considered:

- high power, reaching up to 10 liters in some models.с.;

- Lightness. a small weight will not weigh the single-axle tractor and add to its maneuverability;

- compact dimensions. a small motor does not need a reinforced frame, which reduces the material costs of its production;

- economical consumption of fuel and lubricants

- endurance, which is determined by readiness for many hours of exertion.

With the right choice of power unit for a homemade power tiller, it functions no worse than its factory counterparts.

Features of making homemade chainsaws from the Druzhba chainsaw

The good old chain saw “Druzhba”

It is, although quite old, but a proven “friend” of all skillful people. This saw, how many decades it would not dust in the garage, will always help out in a difficult minute and will be an assistant in solving a large number of important tasks. The engine is not known for its horsepower, but it is worth enough for modification of devices useful in everyday life and in the country.

Block: 4/5 | Number of characters: 430

A single-axle tractor from a chainsaw

As mentioned above, it is possible to make a variety of home and cottage crafts from a chainsaw. Some of these homemade, are the mower and single axle tractor. The deal with the mower from a chainsaw is not as difficult as with the power tiller, for the production of which it will be necessary to weld a metal frame, and then to adapt to it two wheels on the side.

The principle of making a power block from a chainsaw is to use several sprockets, which could transmit the rotating force to the blades. For this purpose, the sprockets are placed on the sides of the metal shaft, on which several blades are welded.

Self-made single-axle tractor from a chain saw Ural or Druzhba, will be a real helper for those who have a fairly large area of the vegetable garden. This single axle tractor may not be very powerful, but it is enough to do the basic task of tilling the land.

Block: 5/5 | Number of characters: 43

After conquering land and water, inventors turned their eyes to the sky. The media is full of reports of yet another inventor getting off the ground in a homemade gyroplane or a homemade backpack helicopter powered by a chainsaw. There’s even an award in Australia for the pilot who manages to fly one mile. However, aerodynamic calculations showed that the engine power is clearly not enough to lift a 100 kg load off the ground and fly with confidence. Four motors with 5 horsepower each working in sync could theoretically cope with such a task. It’s a matter of timing and tuning the control system.

With the development of quadcopters there was a chance to adapt their control system to the helicopter. self-made.

Block: 5/12 | Number of characters: 746

Cultivator from a chainsaw with their own hands. advantages and manufacturing procedure

Modern motokultivator is equipped with a variety of useful features, which greatly complicate its factory-made device and increases the market price. However, not all gardeners require a high level of comfort when using the agricultural machine. Among them, there are those who need a simple reliable and inexpensive cultivator, which, if broken, can be repaired with their own hands. In these cases, you can try to make a homemade agricultural aggregate, using for his assembly engine from an ordinary chainsaw.

Since a lot of effort is required to cultivate even a small area of land, gardeners think about making a mototapku. These toilers come to the idea of making a homemade single-axle tractor with their own hands due to the fact that factory-made motocultivators are expensive.

Homemade motor blocks are used to carry out the following procedures:

Also motoplug own hands will help with snow removal and weeding, and if you add a trailer, you can use it to transport goods weighing up to 200 kg. The lightweight tiller usually comes with only a tiller and a weeder. On a product of medium weight you can find a cutter, plow, mower and hoe. Heavy products are reliable, have high passability and fixed wheels. With such a device motoblok possible use of the following equipment:

Homemade cultivators. the advantages of assembly

Many enthusiasts embark on their own construction of motocultivators not only because of the significant savings of money. Among other important advantages of making your own agricultural machines stands out:

- The possibility of equipping a power tiller with the set of functions that will be really important in its use on the plot;

- No need to perform frequent maintenance and regular repairs. if you use reliable parts during the assembly of the motocultivator, homemade machinery will turn out many times more durable and long-lasting, especially if you compare it with some Chinese models;

- the ability to adjust the working nodes of the agricultural aggregate as needed to work in specific operating conditions.

At the same time, it is important to remember that a cultivator from a chainsaw will turn out to be truly reliable and effective only when the operator carefully prepares for the assembly and acts strictly according to the algorithm. Otherwise, the maker will end up with a farm implement that will break down frequently and not perform as well as it should on the vegetable garden.

How to make a single-axle tractor from a chainsaw with your own hands: several design options

single-axle tractor on the basis of a chainsaw can be recreated by different techniques:

- universal, designed for any type of powerful chainsaw;

- specific, applicable to a particular modification, for example, “Druzhba” or “Ural” of the Soviet or modern model.

A single-axle tractor from a chainsaw: the simplest and most versatile way

For it we will need:

- motor base from any productive professional chainsaw;

- Steering (motorcycle steering will do);

- Transmission, which can be removed from an old car or moped;

- electric welding;

- stainless pipes;

- metal sheet for the design of grousers or old wheels from used machinery;

- connecting parts, which will be needed to join the frame and the engine.

The home production process can be divided into several steps:

Read also: How to remove torque super glue from your hands

- frame fabrication;

- powertrain modification;

- Designing and assembling additional units. clutch, gearbox, steering, headlights for nighttime operation, running gear.

Making a frame for a power tiller from a chainsaw

The work process is as follows:

- take a metal tube with a cross section of at least 20 mm and bend so that the overall appearance resembles two spars, the edge of which is directed upward;

- In the back of the spar we weld the rudder;

- We reinforce the base with crossbars;

- to the rear bends of the spars we weld the support stand for the battery.

Assembly of the propulsion unit

For a homemade power tiller from a chainsaw, it would be ideal if the engine output would be in the range of 10-13 liters.с.

The creation of the power plant, if there is a functioning engine ready, is done as follows:

- Take a pipe 7 cm in diameter, from which you cut 250 mm with an angle grinder. it will become the future muffler. It is stuffed with woody debris and vented so that the exhausts are directed away from the operator. Ensure that the output circumference is no greater than 1.6 cm in diameter.;

- approximately 4 cm thick stainless steel pipe is used to make a skid-shaped frame. To ensure the bolt ties, to its periphery and the middle part of the metal brackets are welded;

- connect the engine and the frame structure.

Then we move on to the running gear.

The most popular ways to recreate it are:

- use of old tires from Zhigul (all 4 pcs.), which in pairs are connected by half-axles, reinforced by a cotter pin;

- Assembly of the star wheels on the basis of rubberless tires (see drawing below). For better traction with the soil, they are retrofitted with a metal angle.

After installing the transmission, steering wheel, gas tank on the self-made machine, the unit can be tested in the field.

Procedure

Once a suitable blueprint is selected (the layout of the components), the necessary tools are found and the “Druzhba” saw is dismantled, you can begin assembling. You should start with the frame, because all the elements of the engine block will be attached to it. Completing the process. is the assembly of the undercarriage, as well as additional units: if desired. headlights, gearbox and clutch, if the drawing is more complicated and involves them. For the first time it is best to choose an easier drawing.

frame assembly

The first stage involves the following steps:

- The tube is bent so that it took the form of 2 spars with upward directed edges;

- A steering wheel is welded at the back (it is easiest to weld two handles, but if available, you can use a ready-made steering wheel from a motorcycle);

- it is recommended to reinforce the construction with crossbars from the same pipe;

- From a metal sheet cut “shelf” under the battery, which is welded to the rear bends spars.

We get a remote semblance of a sledge. For heavier designs with more powerful power units, the frame can be made in the form of a cube or in the likeness of a tractor frame for four-wheeled self-made.

Assembly of the engine block

The most difficult stage. mounting of accessories. Before you get down to it, you need to mark the places on the frame, where the parts will be attached. The principle is as follows:

- The motor with a gearbox is mounted on top of the crossbars;

- under the motor is installed fuel tank (under it should be welded a separate support), on a special platform mounts the battery;

- so that the exhaust gases do not get into the machine operator, it is possible to make an exhaust pipe from a metal tube 7 cm. up to 25 cm in diameter.

This is the base variant without a gearbox, which is installed at will. The drawings will help to understand the assembly in more detail. By and large, the parts of “Druzhba” simply rearrange in places. The undercarriage is connected to the output shaft of the chainsaw.

Assembling the running gear

There are at least two options: you can use a ready-made half-axle from a car or make a single-axle self-made tractor moving by physical force (the “running gear” of an old cart or wheelbarrow will be useful, which will significantly reduce the weight and dimensions, because the car half-axle will require the use of auto tires). In the first case, you will have to organize the drive from the motor to the half-axle, which is not simple enough, so to weld to the frame “undercarriage” of the wheelbarrow. a more clear option.

It is recommended to strengthen the wheels with grousers (for example, from a chain).

To understand how to make a single axle tractor from a chainsaw is not difficult, if you understand the general principle of operation of both units. saws “Ural” and “TAIGA” are also suitable for a power tiller except “Druzhba. Deciding to experiment, you should understand that the homemade will have limited functionality and little power to handle a maximum of 20 acres.

Pros and cons of homemade design

Having analyzed the results of this self-made machine, based on the owners’ reviews, operation video, we can conclude that the design is effective. With the right approach, the single-axle tractor with the engine from “Druzhba” is not much inferior to its factory counterparts by its characteristics.

The main advantage of this self-made machine, of course, is saving money. Necessary parts and materials can be found by simply rummaging around in your garage or shed, or you can buy for a small amount of money.

Also among the advantages of a homemade unit can be distinguished:

- sufficient power of the obtained device. up to 4 liters.с.;

- compactness, small dimensions of the power tiller;

- low weight, maneuverability, mobility;

- economical consumption of fuel and lubricants;

- The engine “Druzhba” is not fastidious in terms of choice of fuel and lubricants;

- single-axis tractor can perform various operations.

The engine used in chainsaws, especially in Soviet “Druzhba” is hardy and able to withstand long loads.

The main disadvantage of a homemade power tiller from the “Druzhba” chain saw is that with any design you can not get a real single-axle tractor. The power of a power tiller is enough to work areas with good soil. There are also limitations in the performance of operations. Using the entire arsenal of attachments of the factory motoblock, most likely, will not work.

Procedure

Once a suitable drawing is selected (the layout of components), the necessary tools are found and the saw “Druzhba” is dismantled, you can proceed to the assembly. You should start with the frame, since all the elements of the engine block will be attached to it. Assembly of an undercarriage completes the process, as well as additional units: if you wish. headlights, gearbox and clutch, if the drawing is more complicated and suggests them. For the first time it is better to choose an easier drawing.

frame assembly

The first stage involves the following steps:

- Bend the tube so it took the form of 2 longitudinal members with upward facing edges;

- The steering wheel is welded to the back (it is easiest to weld two handles, but if available, you can use a ready-made steering wheel from a motorcycle);

- It is recommended to strengthen the structure with crossbars of the same pipe;

- from a metal sheet cut “shelf” under the battery, which is welded to the rear bends of the spars.

A remote semblance of a sledge turns out. For heavier designs with more powerful power units, the frame can be made in the form of a cube or in the likeness of a tractor frame for 4-wheeled self-made.

Assembly of the engine block

The most difficult stage. assembling components. Before proceeding to it, you need to mark out the places on the frame, to which the parts will be attached. The principle is as follows:

- the motor with a gearbox is mounted on top of the crossbars;

- The fuel tank is installed under the motor (under it a separate support should be welded), the battery is attached to a special platform;

- to prevent the exhaust gases from getting to the machine’s operator, you can make an exhaust pipe from a 7 cm metal tube. up to 25 cm in diameter.

This is a basic version without the gearbox, which is installed as desired. The drawings help to understand the assembly in more detail. By and large, the parts of the “Friendship” are simply rearranged. The attachment is connected to the chainsaw’s output shaft.

Assembling the running gear

There are at least two options: you can use a ready-made half-axle from the car or make a single-axle tractor-homemade moved by physical force (fit “running gear” of an old cart or wheelbarrow, which significantly reduces weight and size, because the car axle will require the use of avtoshin). In the first case, you will have to organize the drive from the motor to the half-axle, which is not easy enough, so to weld to the frame “running gear” wheelbarrow. a more clear option.

To understand how to make a single-axle tractor out of a chainsaw is not difficult, if you understand the general principle of operation of both units. In addition to “Druzhba” for the motor-block are also suitable saws “Ural” and “TAIGA”. When deciding to make an experiment, you should understand that this self-made tractor will have limited functionality and small power, allowing you to work a maximum of 20 acres.

If you found a mistake, please highlight text and press CtrlEnter.

A single-axle tractor is an effective helper in the processes of cultivating the land, as well as further care of the garden and orchard. The easiest way to obtain this device is, of course, to buy it. However, there is an option of making it, using the engine from a chainsaw, in particular from the Soviet “Druzhba”. Thanks to its powerful motor, uncomplicated design and general unpretentiousness, it is well suited for this role.