How to Properly Sharpen a Circular Saw Video

How to do something yourself, with your own hands. Home master site

Excellent TOOL FOR MASTERS AND HANDICRAFTS AND EVERYTHING FOR GARDEN, HOUSE AND COTTAGE LITERALLY A GIFT HAS REVIEWS.

There are several types of saws. Depending on the direction of cutting wood, they are divided into transverse, longitudinal and mixed.

Before sharpening the teeth of the saw must be bred. The wiring of the teeth is either a special “wiring” with a limiter, or a metal plate with slots. Carpenters often use an ordinary ax or a chisel for this.

The tooth bite should be no more than one and a half to two thicknesses of the saw. For dry wood, the width of the divorce can be a quarter of the thickness of the saw, for raw. than two.

If you made a mistake when spreading the teeth of the saw and some teeth deviate to the side more than necessary, then this can be corrected by driving two nails into the board at a distance of the width of the wiring and several times passing the saw between them.

Everything NECESSARY FOR THIS ARTICLE IS HERE

They sharpen the saw, holding it in wooden clamps. If there are no clamps, you can simply put it on the table with your teeth and press it with one hand to the countertop.The teeth of the cross-cut saw are first sharpened on one side of the wiring, then the saw is turned over and the opposite side is sharpened. Each tooth is sharpened from two sides, from the top to the base, at an angle of 45 degrees, so that the edges of the sharpened tooth are facing the outside of the saw blade.

The teeth of a longitudinal saw are sharpened sequentially, one after another. The file is held at right angles to the saw blade. Only one short side of the tooth is sharpened.For sharpening mixed saws. The file is sent at an angle of 50-60 degrees and both sides of the tooth are sharpened.

If the saw has broken several teeth, then it can be repaired. To do this, cut down the damaged teeth with a chisel. A notch of new teeth can also be made with a chisel, and if you are lucky and you get a matrix and a punch, then all your problems will be resolved even faster.Spend on the saw blade at risk, having determined the height of the teeth, insert the blade between the punch and the die and hit with a hammer.

When all the teeth have been incised, wire and sharpen the saw.

Device for sharpening a hacksaw (hand saw)

Sharpening hand saws and hacksaws has always been a problem for me. Most of the recommendations that are published in the press are related to the use of a bench vise, in which a dull tool is clamped.

But I do not have a vise and probably will not. So I had to lay the saw on the board and sharpen it on my knees. It is clear that the quality of such sharpening was poor, and most importantly, the tooth profile was violated. And the work on the site. Do not redo it, without a saw as without hands. And finally, my patience ran out, and I decided to make the necessary device from improvised materials myself.

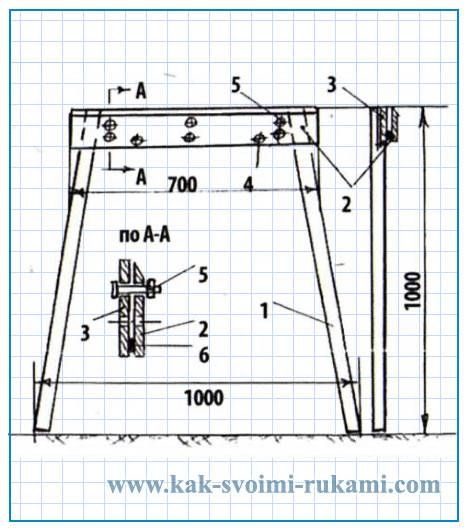

It consists of two legs (det. 1) and two clamping plates 700x130x25 mm in size (front and back), made of boards (details 2 and 3). I also found 4 MB bolts with lambs. The lower bolts (detail 4) are in a continuously tightened state.

Adjustable bolts (det. 5) change their ’position depending on the height of the hacksaw to be sharpened. For example, for narrow garden. The upper position (you can even put a narrow plate), and for two-handed saws. Lower.

To sharpen the teeth on the other hand, the hacksaw needs to be rearranged from the other end. The front plate is beveled at an angle of 30 °. I personally really like this device. It can be placed on a table, a tall drawer or some kind of cross-beam and, sitting on a chair, sharpened. And the back does not get tired.

- Leg (bar 50 × 50)

- Front clamping plate

- Back plate

- Lower wing bolt

- Stop it, the bolt

- Gasket S = 2mm

The case will keep the hacksaw teeth sharp

Having spent a considerable amount on the purchase of a high-quality carpentry hacksaw and the same amount of time for its correct sharpening during subsequent use, I want to save its teeth intact. As an inexpensive means of protecting them, I bought a piece of a profile in a construction supermarket that is used to decorate walls with plastic panels, shortened it exactly along the length of my hacksaw blade and cut off the perforated edge with a sharp knife. The result: a tight-fitting, comfortable and inexpensive case.