How To Set The Spool Clearance For Lawn Mowers

How to check the ignition coil of a chainsaw?

There are several effective ways to check a factory ignition coil. The first one is visual. To do this, the operator must carefully remove the magneto from the saw structure, having previously disconnected all contacts connected to it. After that, you need to inspect the item.

Most often, its malfunctions consist in:

- Damage to standard insulation, initially caused by gradual or sharp overheating, increased vibration, as well as voltage surges in the created electrical network. All this leads to a short circuit in the factory windings of the coil;

- Violation of the integrity of standard high-voltage wires. this results in overload and breakage of electrical wires.

In any of these cases, you will need to immediately replace the electronic ignition of the gasoline chain saw.

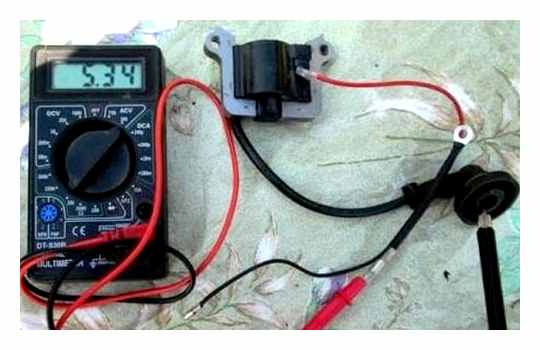

The second way to check the coil is to test it with a multimeter.

This requires:

- Connect the device to the positive and parallel negative factory contacts, having previously configured it in the mode of constant measurement of the generated resistance;

- After ringing the built-in coil, you need to look at the device. In household chainsaws from different manufacturers, the resistance values may differ from each other. Typically, the average is around 0.4–2 ohms. If zero resistance is displayed on the multimeter in use, then an accidental short circuit has occurred in its standard winding. In few cases, the device can show infinity. then the operator will need to find an open circuit.

In each of these cases, the repair of the factory ignition coil is carried out only through a complete replacement of the part.

Each of the methods allows you to obtain information about the health and stability of the factory ignition system of a gasoline saw. In some models of garden power tools, manufacturers provide for the possibility of replacing only the defective coil. In other cases, the owners of chainsaws are required to replace the entire ignition system.

Design features of the factory ignition system

The ignition system for a domestic or professional chainsaw initially consists of:

- Magneto, or factory ignition coil;

- Candles with pre-installed cap;

- Electrical high-voltage wiring, pre-connecting the spark plug to the coil;

- Keys that instantly turn off the running power unit of the chainsaw.

In the device of a household gasoline-powered tool, magneto is a kind of generator responsible for the continuous generation of alternating current with the subsequent transfer of energy to the built-in candle. The design of the magneto initially consists directly of a standard stationary winding of an inductive coil, as well as a permanently operating magnet pre-installed on the built-in flywheel.

Magneto, provided in the standard built-in ignition device for household and professional gasoline saws, are divided by equipment manufacturers into:

- Contact. in the design of these nodes, the first terminal of the built-in factory high-voltage winding is connected to the spark plugs. In the basic design of the contact magneto, a capacitor is initially provided, which prevents overheating and gradual oxidation of the contacts of a standard breaker;

- Non-contact. the principle of operation of units of this type is based on the operation of the built-in control coil of the factory, which, at the same time, plays the role of an element that regulates the supply of voltage. During the regular opening of the thyristor, the standard capacitor begins to actively discharge. As a result, a sufficiently high current is continuously generated in the turns of the high-voltage factory primary winding, which is inducted into the high-voltage voltage. It leads to instantaneous breakdown at the built-in spark plug located in the cylinder of the power unit. The electrical network of the non-contact magneto operates stably in the mode of continuously generated short-term pulses generated in time with each forward movement of the factory cylinder and the corresponding rotation of the engine crankshaft.

Manufacturers of chain garden equipment use different types of factory magneto in the configuration of chainsaws. The main difference between them lies only in the principle of action. At the same time, contact and non-contact magneto have approximately the same working efficiency.

How to determine the advance angle of the built-in ignition?

The design features of the built-in ignition coil ensure coincidence between the factory optimal moving piston position and spark plug discharge. During the operation of 4-stroke power units, the spark must skip even before the piston returns to the uppermost position. This is due to the fact that such engines take longer to burn fuel. In their factory device, the speed of operation of the internal combustion engine parts is equal to the speed of the planned ignition of the refueled fuel. In this regard, the piston manages to pass a certain path from the moment of instantaneous breakthrough of the created spark to the place where the candle is located. Until the period for which the burning gases are guaranteed to have time to create extremely high pressure indicators.

During the mass assembly of engines under normal factory conditions, manufacturers do not perform ignition adjustments. Instead, markings are left on the rotating elements that must be aligned during installation.

Chainsaw ignition

In order for a gasoline saw to start running stably at idle, the fuel located in the factory cylinder of its power unit must ignite. For this, a standard ignition system is provided in the basic configuration of any branded chain tool. The ability of the internal combustion engine to make the first cold start and steadily gain momentum when the operator presses the gas trigger largely depends on its serviceability. The ignition of a commercial saw is distinguished by a simple device and a constant operating principle. Having studied their features, it will be easier for the operator to perform maintenance and self-repair of the unit.

How to set the ignition on a chainsaw?

As in the case of the constant need for self-adjustment of the carburetor, a chainsaw used in a private economy or on a forest shaft must be amenable to timely adjustment of the built-in standard ignition. The essence of this procedure is to install the gap originally provided between the flywheel of the power unit and the standard ignition coil. The size of this gap may initially be different. it all depends on the purpose, as well as the design features of the saw. The average distance is considered to be not less than 0.2 and not more than 0.4 mm. In the event of a violation of the correct gap, the base ignition system will not be able to generate the spark required for timely instant ignition of the filled fuel mixture in time.

In order to initially correctly adjust the appropriate clearance between the flywheel and the ignition coil on the chainsaw, its owner will need a special plate template. However, buying it for a one-time use is not always profitable. In some cases, the template can be replaced with a homemade one. To make it, the operator will need a plastic smooth bottle, from the side of which a thin strip must be cut. At the same time, there should be no embossing on a homemade template.

The operator can adjust the ignition on the chainsaw directly in the following order:

- First you need to slightly loosen the plastic bolts designed to fix the standard ignition element;

- Further, the magnets provided on the flywheel will need to be brought to the factory coil;

- Then, a homemade or previously purchased template must be installed between the base high-voltage coil and the built-in engine flywheel. After that, the coil fixing bolts will need to be tightened in the opposite direction;

- Next, the operator must carefully remove the template.

- At the end, you will need to scroll the built-in flywheel. At the same time, you need to ensure that when rotating, the element does not touch the coil and other parts of the chainsaw.

If, for some reason, adjusting the ignition of the chainsaw led to constant contact with the flywheel, then it is necessary to inspect the antennae that fix it in its original place. If they are deformed, then the fasteners will need to be replaced.

About the chainsaw and its inoperability

Chainsaw. The installation itself is not that difficult. But having the least initial knowledge is extremely important in order to find and eliminate any defect.

Modern electronics has progressed so much that it has revolutionized the world of instruments. Saws of our days are light and at the same time powerful, equipped with electronic ignition systems ESZ.

Not so long ago, saw ignition systems were cam-type. This carried a lot of disadvantages: heaviness, complexity, high cost and much more. And the main drawback of the archaic ignition system is the difficulty of the plant. Some saw model systems could not generate enough spark at all to flash at crankshaft speed.

Modern systems are nearly fail-safe. Saw models are lightweight and durable, the reel is made more professionally and will serve its life almost flawlessly. However, there are also problems, but in most cases they can be corrected on their own.

Consider the main types of chainsaw malfunction associated with the flywheel and the ignition system.

As a rule, the most common ailment of modern chainsaws is the absence of a supply spark. This also directly depends on the shift in the clearance (gap) between the bobbin and the flywheel.

Common installation failures are always associated with internal combustion engines. Problems arise in the fuel ignition system, the fuel intake module, in the internal elements of the engine itself.

As for other units of the chainsaw, malfunctions arise there, as a rule, due to failures of the brake mechanism, poor lubrication performance, etc.

If startup difficulties are associated with the engine, then the following symptoms are most often observed:

- The motor does not develop the necessary power;

- Doesn’t start at all;

- It starts up, but quickly stalls;

- Functioning unstable.

As always, experts recommend identifying fault factors in a way of elimination. In other words, you need to go through the chain, diagnosing each node, each link.

The gap between the ignition coil and the flywheel of the chainsaw

Internal combustion engines are installed not only on cars or motorcycles. They are widely used in various tools, such as a chainsaw or a trimmer. In the event of their malfunction, poor start-up, it is often enough to establish the correct clearance between the flywheel and the ignition coil.

Ignition module

Inoperability of the SZ chainsaw is the most common reason why the engine of the tool does not start. It is recommended in most cases to start troubleshooting from here.

Here’s what to do:

- First of all, carefully check the spark plug by carefully throwing off the armored wire from the head and unscrewing the plug from the socket using a special key;

- The second is to check the spark supply with the help of jerking the starter when the armored wire cap is put on the candle;

- Checking the gap is the main topic of our article (more details below).

So, a spark plug malfunction will clearly indicate its phlegm. A wet spark device for igniting the fuel-air mixture indicates that there is an excess of fuel in the system, the carburetor is incorrectly tuned, or there are problems in the SZ.

The candle is checked only after drying. That is, it must be thoroughly cleaned with a napkin, the insides of the internal combustion engine should be dried, the feed should be blocked, and then the starter should be started a couple of times so that excess combustible mixture comes out.

Then the spark device is put in place and everything is checked again.

In general, a spark device can tell a lot about the entire ignition system. If black carbon is observed on the candle, then this indicates violations in the communications of the gasoline mixture supply. Here either the ratio of gasoline and oil has been violated, or the carburetor needs to be readjusted. In some cases, this also happens due to low-quality oil.

A dirty candle is cleaned of black carbon with a needle or some other sharp object. Then the electrode is cleaned with sandpaper (zero) until a metallic sheen appears. The spark device is returned to its place, everything is checked again.

The next step: checking the spark supply. The spark device skirt is brought up to the cylinder and the starter is started. If a bluish spark jumps at a distance of 2-3 mm, everything is fine. A spark distance of 0.5-1 mm is already considered a malfunction. There may be no spark at all, and this is also a big problem. Perhaps this is a wire break.

And now we come to the topic of our article. The chainsaw may not start due to a violation of the gap between the ignition and the flywheel magneto. This very gap should be within 0.2 mm. It is very simple to check: a special gasket is placed between the flywheel and the bobbin. If it comes in normally, not too loose and tight, then the gap is normal.

The saw flywheel itself is round, and checking the clearance with a conventional feeler gauge is impossible. It would be more qualified to set the gap according to a special template, but it is not always possible to acquire it. And not everyone can afford to buy a template that is not cheap for a single use.

However, instead of a foreign template, you can use a cut-out strip from a plastic container for 1-2 liters from under the juice.

A homemade template is put like this:

- Ignition fixing bolts are loosened;

- A plate is inserted between the flywheel and the bobbin;

- Bolts are tightened.

How to check the magneto of a chainsaw

Magneto, babin, module is an ignition coil. It may have nothing to do with tool failures at all, and the reason is lurking only in the gap or in another. But in some cases, it is she who becomes a factor in violation.

To check the babin itself, you should also, as in the above case, use by excluding the components from the chain. Or in other words:

- Visually assess the condition of the bobbin case for cracks and other visible defects;

- Check the cleanliness of current communications of various nodes and elements;

- Diagnose the insulation and serviceability of the armored wiring, the reliability of fixing the fasteners, the absence of rust, etc.

- Visually assess the condition of the spark device cap;

- Checking the condition of the candle;

- Diagnostics of the circuit breaker, which is especially important for Chinese-made chainsaws.

Again, as in the case described above, certain points are excluded from this chain, thereby, the cause of the problem is found.

Babina herself is investigated like this.

- The magneto resistance is measured. However, this option is not always applicable, since you first need to know the resistance parameters. In addition, for the formation of the required HE pulse, it is necessary to separate the indicators of the various semiconductor elements. A sign of a malfunction, as a rule, is the ringing of the circuit through the BB wire and minus. Should show either “open circuit” or high resistance.

- The check can be carried out as follows. use a device that checks for the presence of a spark. It is installed in the open circuit between the BB wire of the bobbin and the candles. The disadvantage of this method is that the device is so very expensive, it is used mostly in serious repair services.

- “Dedovsky” method of verification, which will save on an expensive device. It is used at your own peril and risk when there are no other options. The method of checking is that the cap is thrown off the candle, a carnation is inserted into it. The candle is re-inserted. The stud should be 6-7 mm from the cylinder. The chainsaw starts up. A spark is examined: it should be bright blue, if not, then this is a sign of a malfunction.

The “grandfather’s” method of checking a bobby has many disadvantages. First of all, this applies to electrical assemblies in the system, which can easily deteriorate. The distance between the cylinder and the stud may differ depending on the different models of the tool.

As for tuning the magneto, it boils down to examining the groove on the flywheel. UOZ for most of the current saw models does not need to be adjusted. But it is possible to determine its exposure only by the angle between the mark after the groove on the flywheel and the magnets installed, again, on the flywheel.

Competently and accurately set the gap between the magneto and the flywheel. that’s what is more important.

You should know that the bobbin on chainsaw systems is installed in the fan fuselage near the flywheel. The coil, in contact with the flywheel magnet, produces energy for a spark.

Replacing the coil itself will be much more difficult, since the installation location is too inconvenient. The installation of a new bobbin should be carried out so that the base of the coil is at a distance of 1-1.5 mm above the flywheel magnets.

In some cases, it is recommended to also check the crankshaft bearing for play.

Forget about fines from cameras! An absolutely legal novelty. Jammer for traffic police cameras, hides your numbers from cameras that are in all cities. details on the link.

- Completely legal (Article 12.2);

- Hides from photo fixation;

- Suitable for all vehicles;

- Works through the cigarette lighter socket;

- Does not cause interference to radios and cell phones.

The first way

You can check the performance of the magneto using a tester. To do this, you must perform the following sequence of actions.

- Correctly configure the tester: use the resistance measurement function and set 200 Ohms to take measurements of the primary winding.

- Direct the first electrode of the measuring device to the “ground” of the magneto, and the second to the output contact. If the primary winding is good, the readings should be from 0.4 to 2 ohms.

- Set the tester switch to 20KΩ to diagnose the secondary winding. Then direct the first dipstick to the candle cap, and the second to ground. If everything is in order, the figures will vary from 4 to 6 Kom, depending on the trimmer model, whether it is a Patriot 547, a Husquarna 128 r or another brand of equipment. If the circuit is open, the tester will display an infinity value. And if there was a short circuit, the display will show zero.

Operating principle

When the flywheel rotates, an electric current is generated in the magneto, creating a spark on the spark plug as the magnets pass under the coil.

How to set the ignition on the trimmer

Often, owners of gasoline braids are faced with the fact that the ignition does not work on their equipment. In most cases, the problem is really with this node. To fix it, you need to adjust the ignition on the trimmer. But at the same time, it is not uncommon for the ignition coil to be in good working order, and the breakdown must be looked for elsewhere. The ignition system is arranged in the same way on four-stroke and two-stroke internal combustion engines, therefore, troubleshooting of this unit is performed in a similar way. In addition, the technique of different brands has almost the same design of this most important component of the tool, which means that the adjustment process will be identical both for the Soyuz or Prorab trimmers, and for Huter or samples of other brands.

Trimmer ignition. principle of operation and possible malfunctions

If the owner of the lawn mower wants to adjust the ignition system on his own, he should understand the principle of operation of this unit. In an internal combustion engine, it consists of a flywheel and a magneto (coil). In turn, the flywheel includes an impeller that performs the function of cooling the motor and a number of permanent magnets.

Typical malfunctions

Before you start adjusting the ignition of the trimmer, you need to cut off other probable causes of damage and make sure that the problem is really in this unit. To do this, it is necessary to carry out a number of actions in the following sequence:

- Inspect the ignition coil housing for damage and defects;

- Make sure that there is no contamination on all nodes and elements that conduct current;

- Check the integrity and insulation of the wiring, contacts, fastening strength, the presence of rust at the joints;

- Inspect the candle cap, as it regularly comes off the high-voltage wire, and they try to restore it manually, and any unreliable connection reduces the power of the electric arc of the candle;

- Check the plug, since the quality of modern gasoline very quickly disables this part, but there is another possible problem. the plug is wet;

- Verify circuit breaker works.

Having excluded all possible malfunctions, you can proceed to adjusting the ignition of the coil.

Features of adjustment on different models of trimmers

The ignition system works in a similar way on different brands of equipment, so the adjustment process will look the same. Differences, if any, are insignificant. They are mainly related to the disassembly of equipment. For example, removing the cover from the engine on different trimmers is done with some differences. So, on Patriot devices, you first need to unscrew the bolts and disconnect the air filter housing with a slotted screwdriver. After that, the plastic cover will be very easy to remove. A detailed diagram and device of a trimmer of a particular model are usually shown in the instruction manual of the tool.

So, you can do the ignition adjustment for a gasoline trimmer with your own hands. This process is not difficult if you know the correct procedure. But first, you need to exclude possible malfunctions of other components and parts, for example, spark plugs or magneto, which may cause the lawn mowers to not start the engine. However, disassembling equipment of different brands, you need to take into account the likely differences in design, which are described in detail in the user manual.

When adjustment is needed

It is necessary to adjust the ignition system so that the fuel ignites in the combustion chamber at the right time.

If the flywheel is offset on the shaft from its original position, the fuel ignites faster than the piston crosses top dead center. As a result, the piston moves backward and the crankshaft rotates in the opposite direction. An early ignition of the fuel can be determined by a broken starter cord, a broken starter assembly or other breakdowns.

Sometimes ignition is late. The piston compresses the unignited fuel, and then goes down, and only then a spark is formed. As a result, the engine either does not work, or its power decreases, and the speed is gained much more slowly.

Typically, the flywheel with magnets is set in an ideal position, precisely coordinated with the piston, and carefully locked to avoid displacement. This allows us to assert that incorrect installation of the part is impossible. But if the flywheel offset is a confirmed fact, then it is a malfunction or an accident. Thus, setting the ignition timing is not required, since problems with early or late fuel ignition are very rare.

Ignition adjustment procedure

Setting up the ignition system is simple and identical on different trimmer models, be it a Stihl FS55, AL-KO BC 4125 or another lawn mower. First you need to remove the casing from the engine, after unscrewing the fasteners that fix it. This disassembly step may differ on different mower models (described below). Next, you need to partially unscrew the fasteners that fix the magneto with a screwdriver, and turn the flywheel so that the magnets are in the upper part.

To make the optimum gap between the coil and the magneto, a special template must be used. It is impractical to buy it for one-time use, therefore, as an alternative, you can use a business card or a small calendar, as well as an A4 paper sheet folded in four. A strip cut from a plastic bottle or other materials at hand that has the required thickness is also suitable. The optimal distance is usually indicated in the user manual. The selected item must be placed between the magnets and the coil.

The coil will then be attracted to the flywheel by the magnetic field. While holding the magneto in this position, tighten the fasteners that fix it, and then pull out the business card. After that, you need to turn the flywheel several times to make sure that it does not touch the coil at all. The process is over. the lawn mower ignition is on. You can learn more about the process of adjusting the trimmer ignition system on the Internet, where many are available. Devoted to this topic.

Second way

If you cannot use a tester, there is another way to test. In this case, it is important not to touch the cylinder with the electrode, otherwise the coil will be damaged.

- Remove the spark plug cap. Do not unscrew the plug, as this will maintain compression.

- Then you need to pick up the nail with the removed cap and insert it tightly into the cap.

- Next, the cap with the nail should be securely tied to the cylinder with a dielectric. In this case, the electrode should be at a distance of 5.5-7 mm from the cylinder body, but not touch the mass.

- Then, using the starter, you need to simulate starting the engine with the ignition button turned on. In this case, you need to carefully monitor whether a spark appears, and try to determine its color.

There is one important point to consider when diagnosing: unheated magneto in any state can form a powerful spark. However, if it is faulty, then, after warming up, it stops creating current, and the trimmer will not start. Later, after cooling down, the coil returns to the operating level, the tiller turns on and runs for some time at idle or under load, until the temperature of the magneto rises again. In this case, the part must be replaced with a new one.

Check the ignition coil on the chainsaw

If the preliminary actions did not help in identifying the cause of the chainsaw malfunctions, then it is necessary to check the saw ignition coil. Diagnostics is performed in several stages:

- Measure the resistance of the coil using a multimeter. To do this, you should know the optimal parameters, which are indicated in the operating instructions. However, due to the use of semiconductor elements in the system, an attempt to “ring” the coil will result in an open circuit reading. This is normal. A positive test result is a sign of a malfunction. T.E.If it was possible to determine the resistance of the coil using a special tool, then it is definitely faulty.

- Check for spark with a special device. This device should be installed in the open circuit located between the spark plug and the high voltage terminal of the saw ignition coil. The readings will be visible on the display. This verification method is more often used in service centers, since the device required for this is expensive and the costs will not be comparable to the benefits rendered.

- Testing the coil with a spark plug, i.e., perform a homemade ignition. To do this, it must be turned out, and then the body must be attached to the cylinder. Now you need to pull the starter and watch the spark. But this method gives only an approximate result, since the flywheel turns faster due to the unnatural position of the candle.

If none of these methods work, or if you need to perform a check in the field, you can proceed as follows:

- Remove the cap from the candle, insert a nail without a cap into the core at a distance of 6-7 mm from the cylinder. This must be done as carefully as possible so as not to damage the part.

- Carry out the steps to be taken when the tool is manufactured. Now you need to look at the presence of a spark and its color. If there is no malfunction, then the spark will be strong and the color will be bright blue.

This method can be used as a last resort and only if there are no electronic components, while it is important to follow the rules:

- It is impossible to completely unscrew the plug, as this can lead to faster rotation of the flywheel, which is not the correct mode of engine operation;

- It should be located at a distance that corresponds to the compression model and the dielectric properties of the fuel mixture, so this parameter can be viewed in the instructions (the value of 6-7 mm is average).

Basic malfunctions and their elimination

If you cannot start the saw the first time, there may be several reasons. The most common problem is with the spark plug:

- Worn electrode or damaged ceramic insulator;

- Loose fitting of the removable cap (if any);

- Spark walk along the ceramic winding, as evidenced by a brown residue on the outer shell;

- Cracks in the candle cap (a saw with this problem will continue to work, but it may hurt the user when touched).

If no problems were found with the spark plug, it is recommended to inspect the wires coming from the coil. They can be cut off or have other mechanical damage. There may be wire breaks inside the insulation, so sometimes these violations cannot be detected by visual inspection.

The cause of the breakdown may lie in the shutdown switches. It is not difficult to check them. To do this, you must disconnect the wires from the module, and then check the ignition. If a spark appears after shutdown, the switch must be replaced.

How the ignition of a chainsaw works and how it works, their main malfunctions and elimination

Gasoline saws are necessarily equipped with an ignition system. It is necessary for the timely ignition of the fuel mixture in the engine cylinder. Therefore, it is so necessary to install the ignition on a chainsaw and its periodic adjustment, since the tool simply will not start without a spark.

How does the ignition of a chainsaw work and how does it work?

The structure of the carburetor engine does not depend on the tool model. Therefore, we can talk about a standard chainsaw ignition system. It consists of the following elements:

- Magneto. It is an alternating current generator. Required to supply the spark plug with electrical current. Outwardly, this part looks like a stationary winding of an inductor and a permanent magnet, which is fixed on the flywheel. The latter rotates simultaneously with the engine crankshaft.

- Spark plug.

- An electrical cable that connects the 2 previous elements.

- Disconnect buttons.

The chainsaw ignition scheme is simple. After starting the tool, a rotating magnetic field is generated by the movement of the flywheel and crankshaft. It creates a moving force in the existing winding, which is transformed into voltage. This potential is enough to create a spark.

Differences in different models of chainsaws can only be whether a contact or non-contact magneto is used. In the first case, one terminal of the winding goes to the candle, and the second goes first to the shutdown button, and then through it to the ground. In the second case, the device has a capacitor, which, when discharged, forms a current.

How to set the ignition on a chainsaw

The ignition of the chainsaw should be adjusted periodically. This action involves setting the correct spark plug gap between the coil and flywheel. The parameter depends on the model of the chainsaw. It is indicated in the instruction manual. The average value is 0.2-0.4 mm. Having the correct gap is important to ensure that the spark appears at the right time, i.e. not earlier and not much later than the fuel supply.

Special templates will help to adjust the ignition on the chainsaw, but it is not always advisable to purchase them for one-time use. Therefore, they can be replaced with a homemade one. To make it, you need to cut a strip from a plastic bottle. The part of the container where there is no embossing is suitable. After that, you can install the ignition, proceeding in the following sequence:

- Unscrew the ignition bolts slightly to loosen.

- Flywheel magnets to ignition coil.

- Clamp the plastic plate between the flywheel and the spool, then screw the bolts back.

- Remove the strip.

- Rotate the flywheel full circle several times in a row, while you need to make sure that it does not cling anywhere.

If during the diagnostics any coil malfunctions were identified and it was not possible to adjust it, then the part must be replaced, since the repair is impractical.

The procedure for checking and adjusting the correct operation of the engine

The most vulnerable element of a carburetor engine is the spark plug. It also allows you to judge the probable causes of malfunction of individual units of a gasoline engine. The following procedure is recommended.

-

Dismantle the spark plug and inspect it. A dry candle with a slight brown tint of the electrodes can be considered serviceable.

Spark plug carbon

Chainsaw ignition coil

When installing a new electrical module on the engine, the magneto gap must be adjusted. The optimum distance between the flywheel and the ignition coil is 0.2-0.4 mm for most chainsaws.

Clearance between magneto and flywheel

To be sure, it is recommended to carefully study the documentation for the purchased model and follow the manufacturer’s requirements.

With such a small gap, it will not be possible to use an available measuring tool for direct measurement. In practice, a Husqvarna saw uses a template in the form of a spacer cut from thin, flexible sheet material of the required thickness. It is clamped in the space between the flywheel and the coil when it is installed, and then pulled out.

In order not to have to resort to adjusting the ignition, operate the tool carefully, avoiding impacts. In particular, this applies to chainsaws with electronic chips in the ignition system, since they are very sensitive to mechanical damage.

Chainsaw ignition device:

- Magneto: a device that converts mechanical energy into electrical energy, provides a current pulse to the spark plug of the chainsaw;

- Spark plug: designed to ignite the fuel-air mixture through a discharge that occurs between the electrodes;

- Electric cable;

- Engine shutdown button.

Candles are spark plugs, arc plugs, incandescent plugs and catalytic plugs. Chainsaw devices use spark plugs for 2-stroke engines. A schematic diagram of the ignition of a chainsaw is shown in the image.

Overview

Overview of how to set coil gap

Chainsaw gap setting overview

Overview of how to replace the reel on a chainsaw

Starter device

Often, manufacturers of chainsaws equip their units with starters that work on almost the same principle, namely: in the groove of the saw body there is a handle through which the cord is passed. When the handle is suddenly lifted, the cord is pulled out, which engages the drum of the ratchet mechanism. Thus, the spitz drum is driven, which is located on the shaft. At this time, the crankshaft makes several revolutions, leading to compression of the fuel mixture, which at this moment is located between the cylinder head and the piston. When the handle is lowered, on the contrary, the ratchet and the spitz loses their contact, which leads to the shaft stop.

With an increase in the power of the chainsaw, the amount of the fuel mixture increases, which should ignite when the chainsaw is started. In such a case, increase the number of jerks of the starter cord to start the engine. To speed up the return of the drum mechanism, manufacturers use a special steel starter return spring, which has excellent elasticity.

In the event of a spring break, it is necessary to: remove the mechanism holder, pull out the spring, fixing its upper part with a finger and slightly pulling the starter handle to the side. Then, wind a new part, while avoiding bends and twisting of the new spring element, then carefully fix the clip.

How to check the ignition coil of a chainsaw?

There are several effective ways to check a factory ignition coil. The first one is visual. To do this, the operator must carefully remove the magneto from the saw structure, having previously disconnected all contacts connected to it. After that, you need to inspect the item.

Most often, its malfunctions consist in:

- Damage to standard insulation, initially caused by gradual or sharp overheating, increased vibration, as well as voltage surges in the created electrical network. All this leads to a short circuit in the factory windings of the coil;

- Violation of the integrity of standard high-voltage wires. this results in overload and breakage of electrical wires.

In any of these cases, you will need to immediately replace the electronic ignition of the gasoline chain saw.

The second way to check the coil is to test it with a multimeter.

This requires:

- Connect the device to the positive and parallel negative factory contacts, having previously configured it in the mode of constant measurement of the generated resistance;

- After ringing the built-in coil, you need to look at the device. In household chainsaws from different manufacturers, the resistance values may differ from each other. Typically, the average is around 0.4–2 ohms. If zero resistance is displayed on the multimeter in use, then an accidental short circuit has occurred in its standard winding. In few cases, the device can show infinity. then the operator will need to find an open circuit.

In each of these cases, the repair of the factory ignition coil is carried out only through a complete replacement of the part.

Each of the methods allows you to obtain information about the health and stability of the factory ignition system of a gasoline saw. In some models of garden power tools, manufacturers provide for the possibility of replacing only the defective coil. In other cases, the owners of chainsaws are required to replace the entire ignition system.

Diagnosis of malfunction with a multimeter

Determine the malfunction of the ignition coil using the so-called hardware method. However, for this you must have a multimeter with which diagnostics are carried out.

Chainsaw ignition adjustment

Semyon Starodubtsev, 54 years old, Krasnodar

“I was cleaning the garden in the spring, the chainsaw began to sneeze, and then it completely stalled. I looked at the candle. it was completely wet, it was obviously flooding. I cleaned the carburetor, changed the spark plug. it won’t start. I looked. there is no spark. I disassembled the ignition and found the reason. the high-voltage cable was completely melted. Why this happened. I still don’t understand. I changed the cable with the module. now everything works fine. “

Why do I need ignition adjustment

In some cases, when the engine does not start, ignition adjustment will be required. Of course, first you need to check the condition of the candle and the high-voltage cable with a cap.

It is necessary to adjust the ignition on a two-stroke engine in order to ensure timely ignition of the fuel in the engine combustion chamber. Below is a diagram from which you can understand the principle of operation of the internal combustion engine.

The spark in the plug should appear at the moment the fuel is compressed by the piston, when it does not even reach the top dead center (TDC). When the piston passes TDC, the fuel mixture ignites, as a result of which the piston goes down under the action of the explosion energy.

Therefore, if for some reason (mainly due to the displacement of the flywheel on the shaft relative to its original position), the fuel ignites before the piston passes TDC, then it goes back, and the crankshaft rotates in the opposite direction. This movement can damage the starter assembly, cut the starter cord, etc. In this case, early ignition of the fuel occurs.

There may also be a late ignition on the trim: the piston, after compression of the fuel that has not ignited, goes down, and at this moment a spark appears. In this case, the engine will either not start, or will significantly lose power and it will be bad to gain speed.

But such problems with early or late ignition on two-stroke internal combustion engines are quite rare, since the flywheel with magnets is already installed in the correct position, which is perfectly synchronized with the movement of the piston. In addition, the flywheel is secured to the shaft with a key and nut. Therefore, incorrect installation of the part is excluded.

How to check the health of a magneto

Magneto is the main part of the engine ignition system and is a coil with primary and secondary windings located around the core. Often, due to a malfunction of the magneto, the spark on the spark plug disappears and the fuel does not ignite. To check the coil, you need to use a tester, and follow these steps.

- On the tester, after switching to the resistance measurement mode, you need to set 200 ohms. This method will check the primary winding.

- Connect one electrode of the tester to coil ground and the other to the lead coming out of the magneto. Normally, the resistance should be between 0.4 and 2 ohms.

- To check the secondary winding, you need to set the device switch to 20 kΩ. Further, one probe of the device is inserted into the candle cap, and the second is connected to the “mass”. Normally, resistance indicators should be in the range from 4-6 kΩ and above (depending on the model).

If you do not have a tester, then you can use the following method, being very careful so that the electrode does not touch the cylinder, otherwise the coil will burn out.

- Remove the cap from the candle. You do not need to unscrew the candle to maintain compression.

- You must insert a nail into the cap without a cap. The nail should be of such a diameter that it adheres well to the cap.

- Tie the cap with the nail to the cylinder using a dielectric so that the gap between the electrode and the cylinder body is between 5.5 and 7 mm (but in no case touches the “mass”).

- Using the starter, simulate the engine start several times. The ignition button must be on.

- Observe if a spark appears and what color it has.

Normally, the spark should be strong, white or bluish in color. If the spark is weak, and its color is orange or yellow, this indicates a faulty magneto.

You should also consider the fact that sometimes cold magneto can give a good spark. But after heating, due to internal faults, it ceases to produce current. As soon as the coil has cooled down, the trimmer starts up again and runs for a while until the magneto warms up again. This coil needs to be replaced.

How the trimmer ignition system works

The ignition system of a two-stroke internal combustion engine consists of 2 elements: a flywheel and a coil (magneto). The picture below shows how they look.

The flywheel has an impeller that acts as a fan to cool the engine. Also on one side of the flywheel are permanent magnets, shown in the figure by an arrow.

When the flywheel rotates, an electric current is generated in the coil, which serves to produce a spark on the spark plug. A spark appears when the magnets are directly below the magneto.

Trimmer ignition setting

Gasoline trimmers use both two-stroke internal combustion engines (ICE) and four-stroke. But the ignition system in them is no different from each other, therefore, the repair and adjustment of this fuel ignition system will be the same for different types of internal combustion engines.

Ignition adjustment algorithm

The trimmer ignition is fairly easy to adjust.

-

Remove the engine cover from the engine by unscrewing all the bolts holding it. For example, on a Patriot (Patriot) PT 2540 lawn mower, to remove the cover, you will need to unscrew the air filter housing, and use a flat screwdriver to remove it from the latches. After that, the plastic case can be easily removed.