How to sharpen a chainsaw chain with a round file correctly

Saw chain depth gauge point

If you have no experience with chain sharpening, we recommend that you use the special depth gauge adjustment templates for setting the correct cutting angle that are included with the chain sharpening kits. Depth gauge templates are also called gauges.

The depth of the stop must be checked every third sharpening of the saw chain.

To correctly measure the chain stop, set the gauge so that only one of the chain stops goes into its groove.

If the chain stop extends beyond the template, it must be filed off with a flat file. Be careful not to allow the limiter to be too low relative to the template.

When working with a flat file, do not grind other chain elements, work only with a template.

The depth stops of the saw chain cannot wear out during the operation of the chainsaw, if you notice wear, replace the chain.

How to sharpen a chainsaw chain with a file

How to sharpen a chainsaw chain with a file

Sharpening the chain cutting teeth with a file

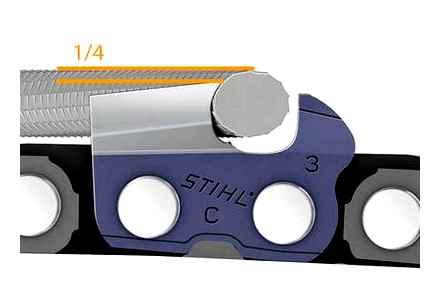

- When sharpening the chainsaw, 1/5 of the file should extend beyond the edge of the saw tooth. To maintain the correct angle of sharpening the chain with a file, use the guide clip (sharpening template for the chain file), which is included in the manual chain sharpening kits.

- When sharpening the chain, observe the sharpening angle indicated on the file holder.

- When sharpening cutting links, the file must move in one direction. from the inside to the outside of the cutting link.

- First sharpen the cutting links on one side, then turn the chainsaw around and continue sharpening the cutting teeth on the other side.

Depth gauge adjustment

Many novice users of chainsaws, after sharpening the cutting tooth, forget to adjust the cutting depth limiter, it must be lowered in proportion to the wear of the cutting link. The required amount of sewing can be determined using the template included in the chain sharpening kits.

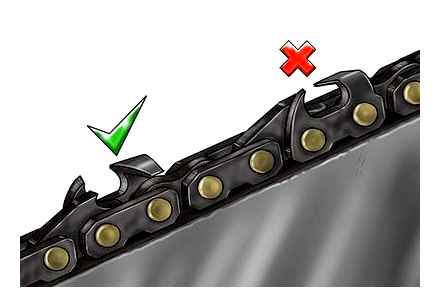

The depth gauge determines the thickness of the wood to be cut in one pass of the saw chain. If the depth gauge is too low, there will be an additional load on the cutting head due to an excessively deep cut of the tree, strong kickback, chain breakage and increased vibration of the chainsaw are possible.

An oversized depth gauge will not provide the necessary cutting of wood, it moves the cutting tooth away from the tree, which will greatly reduce the efficiency of the chainsaw cutting process.

Chain sharpening errors

When manually sharpening the saw chain without a template, the sharpening angle may be violated.

It is necessary to regrind the cutting tooth, to correct the angle, use a guide holder (sharpening template), on which the sharpening angle will be indicated. Depending on the type of chainsaw, the sharpening angle can be from 25 ° to 35 ° (for cross cut), the required sharpening angle is indicated on the chain packaging.

RAZOR SHARP CHAIN! How I use a round file to sharpen a chainsaw to get the saw treeson sharp!

Sharpening the saw chain with an oversized file.

If you use a file of an unsuitable size or if the cutting link is sharpened too much, the formation of a small angle of the cutting tooth or the collapse of the side edge may occur.

In this case, it is necessary to re-sharpen the cutting links with a file of the required size, the required file size (from 4 mm to 6.4 mm) is indicated on the chain packaging.

A file for sharpening chainsaws: types and tips for choosing

The diameter of the round file is selected according to the pitch of the saw chain. The pitch values of 1.3 and 1.6 mm correspond to files with a diameter of 4 and 5.2 mm. A flat tool will be required to reduce the height of the stops of the cutting links.

Do-it-yourself chainsaw sharpening with an angle grinder

Experts strongly recommend not to use this method for inexperienced craftsmen. He’s pretty dangerous.

But if there is no other way out, then you must follow the safety rules. The angle grinder must be installed in a vice and clamped securely. After switching on the tool, bring the edge to be sharpened to the rotating surface of the disc. Since it is impossible to maintain a constant sharpening angle using an angle grinder, a tooth sharpened in this way will differ significantly from a filed one. In addition, there is a risk of the angle grinder’s disc notching the tooth attachment ear.

Sharpening the chain with an angle grinder

How to properly sharpen a chainsaw chain with a file

Templates and patterns must be fixed on the area to be treated. They will give the right direction to the file, making the process easier. When all the preparatory work has been done, you can proceed directly to sharpening the chain.

According to the rules, it is necessary to sharpen the teeth in one direction, then in the other. Work begins with light clicks with a file in the direction away from you, the pressure gradually increases. Reverse file movement. without pressing. The circular tool must be continuously rotated along its axis. The chain is sharpened by movements from the inside of the tooth to the outside. In this case, the file must be located parallel to a special mark on the chain, which is applied by the manufacturer to indicate the standard sharpening angle.

The sharpened tooth should be located approximately in the middle of the tire, this is necessary for ease of work. In the process of processing, you need to move the chain along the tire, not forgetting to set the brake to the working position every time.

Technical Tips- How To Sharpen Chainsaw Chain

The angle of inclination of the tool should be right, and the angle of sharpening of the chain of the chainsaw horizontally. sharp, while its changes are allowed in the range from 10º to 30º. The smallest tooth in the row should be taken as a basis. Turn the tire over and do the same job for the teeth that go in the opposite direction. The disadvantage of this sharpening method is the high time consumption.

Sharpening the chain with a file

You can insert a round file with a broken handle into the chuck of an electric drill or screwdriver. You will get a very convenient mechanized sharpening device.

Sharpening the chain with a drill and file

Hand-operated machines

There are devices designed for sharpening, but without an electric drive. These are manual saw chain straighteners. A regular file is used as a sharpening tool. The machine is attached directly to the rail. Special stop that holds the sharpened tooth. The sharpening angle can be adjusted.

The photo shows a stationary machine in which the grinding disc rotates with a handle through a gearbox. The saw chain itself is clamped in a machine vice. The machine has a base that can be screwed to the table.

Manual Chain Saw Sharpening Machine

A machine for sharpening chainsaw chains: selection criteria, design features, technical and operational characteristics of equipment, the principle of operation of manual and automatic devices, an overview of popular models of sharpening installations.

Chainsaw chain sharpening templates and accessories

It is much easier to work with greater confidence to get the right result, if the master has provided himself with a set of accessories, which includes a template. It maintains the correct values for all sharpening angles of the tooth. The angle of the leading edge is recorded in the instructions, usually its value is 65º. 80º. The value of the clearance angle of the upper blade can only be estimated from the template. Its value should be in the range from 50º to 60º.

The clearance angle of the saw decreases with increasing wood hardness. The optimal value for longitudinal cutting is considered to be the value of the angle 10º… 12º, and 25º… 30º. for cross cutting.

Saw tooth configuration template

How to sharpen a chainsaw chain at home with a file

A tool with an exceptionally round section will help to properly sharpen the chainsaw chain with a file. File parameters are determined by the dimensions of the saw itself. It is important to know the pitch of the teeth. One round sharpener is not enough. For sharpening and dressing chains, two types of tools are used. The first is a file with a circular cross-section with a diameter corresponding to the diameter of the rounding of the working edge of the saw tooth. A flat file is required to cut the depth gauge on the guide tooth.

Sharpening can be done manually using a round file with a working diameter of 4 5.5 mm. It is extremely important to position the tool correctly in relation to the tooth being sharpened. The upper edge of the working part of the file is approximately one fifth higher than the upper edge of the workpiece. The tool is held perpendicular to the chain axis at an angle of 25º… 30º to the upper edge of the tooth.

For sharpening saw chains of household tools, round files with a diameter of 4 and 4.8 mm are used, since they have a small tooth. For professional models, use more powerful chains with a larger tooth. Therefore, files with a diameter of 5.2 and 5.5 mm are needed.

You will need a flat file to sharpen the limiter, and a hook that removes the resulting sawdust to clean the work area. There are also special holders on the market, on which the mowing line is graduated with the direction of movement of the file relative to the axis of the chain. The holder can be mounted on top of the tooth, resting on its upper edge. Since its height is adapted to a certain chain pitch, this device should be selected in relation to chainsaws of specific models and brands. The minimum required set in order to obtain the correct angle of sharpening the chain by hand is shown in the photo.

A set of sharpening tools and accessories

Manual sharpening saves material resources, allows you to work in the field. First, place the instrument on a level surface. If the work is done in the forest, trimming a large diameter log is a good choice. Next, you need to inspect the saw chain for any defects, it can be cracks, completely broken off teeth. After inspection, you need to set the brake in working condition, thereby blocking the movement along the chain bar, which must be tightened during sharpening with a file.

How to sharpen a chainsaw chain on a machine

Sharpening a chain on a lathe is much faster and more accurate than with your hands. There are many different electric sharpeners on the market. Household units are compact, operate on a 220 V network. Abrasive wheels are easily replaced on them, they can be easily rebuilt to different chain parameters: tooth pitch, upper edge thickness, sharpening angle. All machined cutting edges are the same. The process is going fast.

Chainsaw chain sharpening frequency

The decision to sharpen saw chains is not made according to the calendar, but according to the assessment of its performance. First of all, you should inspect the sawdust. If they look like fine dust, then the chain needs sharpening. Otherwise, the engine may overheat, which will lead to the formation of scoring on the cylinder. A dull saw has increased vibration and a difficult entry of the headset into each new cut, which significantly reduces the productivity of sawing work.

File holder

The round file is installed in the holder and fixed with special clamps. There are several markings on the plane of the holder that indicate a specific sharpening angle. When straightening the chain with a file with a holder, the markings on the device are placed parallel to the chainsaw tire, which allows you to accurately maintain the required angle.

The use of the holder is always quite inconvenient. You can use this tool from time to time to check the correct angle of the tooth.

How to Sharpen a Chainsaw by hand with a file

How to properly sharpen a chainsaw chain with a file

During operation, the chainsaw chain periodically requires sharpening. A special machine can be used for dressing, but it is better to learn how to sharpen with files. As a rule, two types are used for sharpening.

Files and fixtures

The main one with which the working saw tooth is sharpened is round. Flat is used to adjust the height of the tooth. cutting depth limiter.

Flat file

Flat should have a width of no more than 1 cm.It is convenient to sharpen the stop tooth with the help of a special bar (filing gauge), which is installed on the chain and shows to what maximum depth the tooth must be sharpened in order to achieve optimal performance of the chainsaw.

Filing gauges

These devices are used to control the angle of sharpening of the teeth, as well as the distance to the depth gauge in conjunction with a flat file.

Application of a roller fixture

The sharpening device, with which you can quickly and efficiently correct the teeth, consists of a small guide template, on which two rollers are installed.

By installing the device on the tire, you can sharpen the teeth of the chainsaw, even without experience in such operations.

Clamp

This device allows you to hold the bar of the chainsaw while sharpening. For its correct use, the process must take place directly at the cutting site. The clamp is hammered into a tree or board, then the tire is clamped into it and securely fixed against displacement. The device can be used for all types of tires, regardless of size.

In some cases, for example, in garage conditions, instead of a clamp, you can use a conventional vise, the tire is clamped in them so that the jaws of the vise do not interfere with the free movement of the chain. Further, sharpening is performed according to the usual scenario.