How To Spin A Keyless Drill

What to do if the key is lost?

If the key is missing, it will be difficult to remove the drill. The easiest option is to deal with the problem with brute force. The parts of the clamping device are held with the right and left hand and rotated in opposite directions. However, if the chuck is tightened too tightly or the drill has been used for a long time, it is unlikely that it will be possible to unscrew the thread.

During use, parts of the power tool become hot and the metal expands. This leads to jamming. To release the chuck easier, wait until the tool has completely cooled down.

To enhance the applied impact, use various tools or homemade devices. Here are some ways:

- Experienced craftsmen loosen the fastening of the cartridge with several tangential blows with the edge of the right palm. In this case, the drill is held with the left hand in the position of the drill from itself. The disadvantage of this method is that the palm can be injured from habit. Yes, and a tightly tightened (and even more so a behavioral or jammed) mechanism cannot be handled in this way.

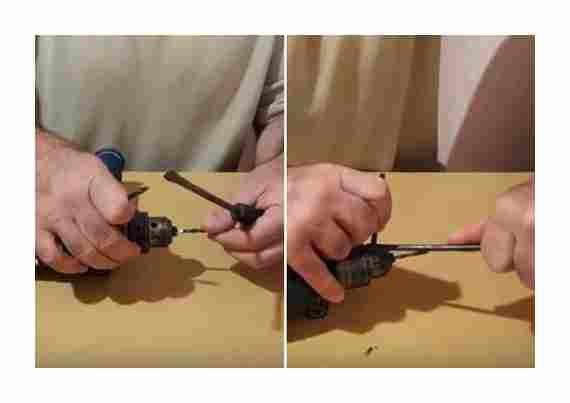

- A metal shaft is selected, the diameter of which allows it to be inserted into the hole on the chuck. In this capacity, you can use a nail, an old drill, a hairpin. The main thing is that the metal is strong enough and does not bend from the applied effort. The screwdriver is inserted into the slot of the chuck and acts as a lever (while the support goes to the shaft). It is enough to slightly loosen the thread, and you can pull out the drill by untwisting the mechanism with your hands.

- The cartridge is clamped in a vice or held tightly with a gas wrench. The shaft is inserted into the hole, and then, applying muscular effort, the mechanism is unwound or twisted.

The second method can help if the chuck is clogged with chips. Then his body is clamped in a vice, and the lever is lightly tapped with a hammer. Vibration causes parts to move and the mechanism wedges.

How to spin a drill without a key

How not to lose the key?

In order not to face empty-handed unfinished work, it is important to properly organize the workspace. Such an organization will allow you not to lose sight of the key every time after changing the tool.

It is better to provide the key with a large bright keychain. This way he won’t get lost in the mess on the workbench and won’t be forgotten in the of work clothes.

The easiest way to protect yourself from loss is in your own workshop. Here you need to create a permanent place to store the turntable and always put it there. At the same time, the storage place should be convenient enough and at hand:

- Many manufacturers provide their instrument with an eyelet for attaching a turntable. It is placed either under the handle or near the fork. By inserting the key into this hole, you can rest assured that it will not get lost. The only drawback is that over time, the mount wears out and breaks.

- The keyhole is made of insulating tape. It is attached to the power cord. The attachment point is usually located 50-60 cm from the handle. So the turntable will not interfere with your work and will always remain at hand.

- By attaching a ring to the key, you can hang it on a hook next to the workbench.

If possible, you should stock up on one more key. It is stored in a box in a workshop, away from the place of work. If the master key is lost, the backup turntable is close at hand and saves the day.

If in the process of work it turned out that the spinner from the clamping mechanism was lost, the main thing is not to panic. With the help of folk methods, it is quite possible to release the chuck, get or change the drill, finish the job.

Each instrument has its own peculiarity. It is characteristic of a drill that the drill should be held as tightly as possible. This is done by a mechanism that, when rotating, clamps the drill with its “fingers”. To make this operation possible, the manufacturers of the drill came up with special keys that are inserted into the groove and, by turning, fix the grooves. This article will discuss several methods for opening the cartridge.

The essence of opening with a key

If everything works as it should, then getting the drill is easier than ever. There are 2 types of cartridges, key and keyless. With the second, everything is easier: you just need to turn on the reverse on the drill, fix the cartridge in your hand and gently press the trigger. Thus, everything will unwind and you can insert the drill.

Key drill access. Source: instrument-tehnika.ru

Key access. a special small tool is inserted into the grooves of the drill, and then rotated counterclockwise. Spinning works on the principle of gears. the teeth unscrew the chuck. Usually the keys are supplied with the drill, some inside the box, some are attached directly to the wire. But what if the key is lost??

How to open the drill chuck?

The purpose of the chuck on the drill is to securely attach the drill or other attachments (construction mixer, grinding wheel, etc.). Fixation is carried out by three mechanical “fingers”, which are brought together and spread using a threaded mechanism.

There are two main types of cartridge:

- Keyless variety. To open such a structure, it is enough to grab the body with your fingers and, turning on the reverse rotation, briefly press the trigger of the tool. The drill will turn the shaft by itself, spreading the “fingers” securing the drill. Such a chuck is easier to work with, but the reliability of fixing the tool will be slightly lower.

- Variety equipped with a key. The key is a T-shaped device, at one of the ends of which there is a bevel gear. The other two ends serve as a handle for rotation. To unscrew or tighten the cartridge, the key is inserted into the hole on the body and rotated, holding the body with the other hand.

The wrench is usually supplied with the power tool. It either lies in the box or is attached to the power cord with a special fastener.

How to remove a drill with a working chuck

If everything is in order, then in theory there should be no problems with getting it. Therefore, this section is rather devoted to users who are completely ignorant of anything about the power tool, since the operation itself is elementary. But still there are a lot of people, so perhaps someone will need this information as well.

Dewalt Drill Chuck Wobble issue! Vs. Hitachi and

In this situation, you will need a special key to unlock the key cartridge, or straight arms to relax its quick-release analogue.

In the first case, you need to insert the key into one of the grooves on the chuck, and start rotating it counterclockwise. The promotion occurs due to the existing teeth on both objects.

In the second, the drill should be turned on in reverse (reverse rotation) mode. With one hand we hold the outer shell of the cartridge, and with the other we press the start button. If your machine is not equipped with a reverse, then this is not very good. this actually should not be, since only key cartridges are placed on such devices. But still, if this happens, then it is necessary to fix the axis of the drill in some way (for example, with an open-end wrench) and rotate the outer body of the chuck counterclockwise. In general, here it would be better to remove such a cartridge and put a key.

If the chips are clogged

An option is possible in which the chips could clog into the chuck and interfere with its scrolling. There is a way out of this. It is necessary to fix the chuck in a vise and apply light blows with a hammer on a tangent. This will cause the shavings to be distributed through the chuck due to vibration and will allow the mechanism to spin quietly. Sometimes you need to pull the chuck out of the drill and insert its pin into the vice, and try to unscrew the outer edge with a wrench. Thus, it will definitely be possible to achieve the result.

The cartridge is in a vice. Source: mekkain.ru

In this article, the options for opening the cartridges were considered, what to do if the key is lost, and what actions to take when chips get into the thread of the cartridge.

Greetings to everyone in the next article! While operating this or that device, the user sometimes encounters unpleasant moments. Today I will touch on one of them. In this text, I decided to give some tips on how to remove the drill from the drill if you can’t do it. The reasons why this seemingly simple thing cannot be done can be very different. Here I described the main aspects on this topic and identified three main areas that I consider necessary to disclose:

- replacement of a drill in a normally working chuck;

- pulling out the drill without a key;

- removing a drill that is stuck due to one or another existing damage.

Let’s consider each of these circumstances separately.

How to unscrew a nut without a key and pliers

If there was no key at hand, when it was urgently and suddenly necessary to unscrew a nut or bolt for which a key or a head is needed, then if available, you can replace the adjustable wrench with another bolt and two nuts for its size.

Just screw one nut a little on this bolt, and then the second (see the picture below); Your goal is to keep the distance between the nuts equal to the size of the bolt or nut you are loosening. Throw a bolt with nuts on the target bolt, press one nut tightly to one of the bolt faces, and tighten the second nut so that it also fits snugly against the opposite face of the bolt to be unscrewed. And then try to unscrew the bolt (or nut).

It is important that the bolt that will replace the key for us is as long as possible, but this life hack is also suitable in the case when the standard key is too long to crawl it to the bolt / nut being unscrewed, in which case our homemade an adjustable wrench, but using a shorter bolt (the main thing is that you have enough strength to unscrew the target bolt / nut with it).

In particular, I am interested in the nut fastening the mixer to the sink in the kitchen.

First, about the problem in general.

Well, for a particular case.

I can advise the following.

The best all-round tool for such interesting places is the plumbing wrench with a self-locking movable jaw. He climbs well to places like this.

You can bend the jaws at a thin wrench (there are some in the spare parts kits of motorcycles, bicycles and chainsaws), following an example as shown in the photo below.

For a specific size of a nut located in a hard-to-reach place, you can make such a “grip” from a metal plate 4-5 mm thick. on the handle and with a crank.

Mainly on the clamping nuts of the mixers, the edges are 32.36 or 38 mm. Car enthusiasts may have a hub wrench of this size and will work well for this purpose too. It looks like the picture below. In the same figure, I highlighted the area of the key, which can be taken as the idea of a home-made key. weld two pins on a tube of a suitable size, which will abut against the corners of the nut faces, and make a knob from below.

And of course, do not forget about the usual adjustable wrench. Often, by placing it while standing, you can get to the clamping nut of the mixer, and loosen or tighten it with the ends of the jaws.

Perhaps my answer will be somewhat off topic, but with the kind consent of the author of the question, I want to give three tips on how to unscrew / tighten large nuts without having a key of a suitable size. Of course, the described devices are unlikely to be suitable for fixing the mixer to the sink, but the mixer still has other large nuts, for example, for the “gander” or for taps, which also have to be unscrewed / tightened quite often. And just in everyday life, such devices can come in handy when a suitable tool is not at hand.

All the devices presented are so simple that they do not need a detailed description. just look at the images.

The first device. unscrew / tighten the nut using two files.

To assemble this device, you need two files and a metal ring (the ring can be replaced with wire or cord). Slide the ends of the files farthest from the handles into the ring, spread the files to the sides and grab the nut. Squeezing lightly, start unscrewing slowly.

To avoid damaging the chrome parts, place leather or rubber pads in the contact points. Remember that files, although hard, are fragile and can break with great effort. However, in the mixer mountings, as a rule, much effort is not required.

The versatility of this device can be noted. it can work not only with faceted nuts, but also with completely round products.

Files can be replaced with strips of hard metal or even wood planks.

We assemble the second device from a long bolt and two nuts. (Or from a stud and two nuts)

Screw the nut onto the bolt, initially by hand, and then tighten the fastener with a wrench so that it tightly contacts the unscrewed nut and cannot come off the edges during operation. In principle, it turned out to be a simplified adjustable wrench.

Third device. A clamp is used here (can be replaced with small vise).

I think everything is clear here without comment. The only thing. do not forget to protect the chrome parts with an insert of rubber gaskets.

This method is called “Old White Sea-Baltic”. For this purpose, you need to take a chisel and a hammer. Instead of a chisel, any sturdy piece of iron with a pointed end or a large screwdriver with a sturdy handle will do. But a chisel is better. Its sharp end is abutted in the area of any convenient angle on the face of the bolt tangentially and begin to knock towards its unscrewing. Most often counterclockwise. (We usually have all right-hand thread bolts). They knock until the bolt starts to rotate. Or a piece of the head won’t break off. It happens so but rarely. Then they rest against another corner and again knock on a tangent. If the thread is not rusted and not clogged with dirt, then after a turn, the bolt begins to rotate from the effort of the hand.

If nothing came of this event due to severe corrosion and dirt, then the bolt, if it is with a nut, is simply cut off with a hacksaw, an angle grinder or a drill with an emery stone, and after repair, a new bolt with a nut is screwed on.

How to unscrew the hex bolt?

This problem most often arises before motorists who decide to repair the car on their own. The car hex is located in the drain plug located in the gearbox, and sometimes in the sump plug of the engine crankcase.

Drawing of a bolt with an internal hexagon.

In everyday life, people are faced with hexagons when repairing water mixers or a ball valve, since ordinary fasteners in these places cannot be placed due to their size.

The size of the hex in these cases is quite impressive, so the hex head of a bolt inserted into the hex slot, unscrewed with a gas wrench, will help. Well-wedged 3-4 nuts are screwed onto its thread, which are then unscrewed with a spanner wrench.

A special device has been created for working with a hexagon. With the help of it, when unscrewing, a nut close to the head rotates. But tightening is carried out using the far nut. If the hexagon has a non-standard size, then the head of the bolt is sharpened with a file.

Methods for unscrewing a bolt with an internal hexagon.

If an attempt to unscrew the hexagon screw by various improvised means led to the breakdown of the edges, then you can find a way out.

A TORX sprocket is driven into a small hexagon, with which the screw is unscrewed. If the head is available, the screw can be easily unscrewed with pliers, a gas wrench or a hand vice.

Sometimes a hammer and a mild chisel help, on which blows are applied tangentially towards the upcoming unscrewing.

For steel hexagons, a nut or a piece of some reinforcement is welded to their head, for which the bolt can be turned out.

Tools and materials for loosening a hexagon

You can unscrew the hexagon without a key. Sometimes you have to twist with the means that are currently available.

A hexagon with torn off edges can be unscrewed with an adjustable gas wrench with a compression of the part.

- The hexagon, which turned out to be torn off the edges, can be unscrewed with an adjustable gas wrench with crimping the part.

- Often its head is sheared off by an angle grinder or removed with a chisel. Next, the central part is drilled with a small diameter, and the resulting thread is driven using a tap.

- A small hexagon is struck with a hammer or chisel in the direction of the forthcoming unscrewing.

- With a small diameter of the bolt being machined, a cut is applied to its head of the angle grinder, with which a screwdriver can be used to unscrew.

But the above methods are not the only help in unscrewing the hexagon.

There are many other methods of unscrewing with the help of an improvised and special tool.

The help will be provided by drills with a left rotation and a small diameter, a drill with a low rotation speed.

The purchase of a special tool for loosening depends on the frequency of its use.

- The stud driver allows you to unscrew the bolt pin when the head is completely torn off. But its use is considered advisable only in the case of several revolutions carried out before the break of the head.

- The electric wrench unscrews shock, but is applied before the break of this spare part.

Countersunk hex bolts are common. This is where the Torx sprocket helps. It is hammered into the saddle of the licked head and the unscrewing operation is successful.

How to unscrew the hexagon yourself without a key?

At the present time, the details of fasteners are quite diverse. These can be bolts, nuts with six faces, various screws, Torx sprockets. Hexagonal elements of various parts are considered separately, which are difficult to turn away without a suitable tool. Many do not know how to unscrew the hexagon without a key.

The internal hex is a fastening tool.

For the first time a patent for an internal hexagon was obtained back in 1936 abroad.

Currently, a hex wrench for unscrewing any part is common and can be selected in any car market.

But for the sake of one use, you shouldn’t buy it.

Step-by-step instructions for unscrewing the hexagon

There are several options for step-by-step instructions for unscrewing the hexagon.

Hex head screw diagram.

A hex bolt or screw can be damaged at any time. Various tools at hand can help in its repair, but it may require the use of special tools, without which unscrewing the hex head of the damaged element is impossible.

Therefore, it is important to know all the currently valid methods for repairing this element. The hexagon is found in various types of indoor water mixers, in car spare parts. At the moment, these bolts are considered quite convenient fasteners, so they are widespread and found in many mechanisms.

Their use is advisable where a reliable power connection is required. This type of fastener is perfectly adapted to high loads and significant physical pressure. These bolts are especially often used in industries such as construction and mechanical engineering.

If we turn to the process of creating a hexagon, it becomes clear that the process of their manufacture is long and rather laborious. Such bolts are made from steel wire rod, which then softens after a long stay in a red-hot oven. Then the wire rod is placed in a sulfuric acid solution for some time to completely remove rust particles. After washing with water and processing with phosphates, the steel becomes resistant to rust, and then sent to the formation of the hexagonal element.

In the process of creating these products, many people are involved, providing the Russian market with modern high-quality fasteners.

How to force a door open with brute force?

This method is suitable if you urgently need to open the door, other options have not worked or are not feasible. These can be situations when an unclosed door was accidentally locked by a small child. It often happens that the interior door has slammed.

Can be squeezed out of the jamb using a chisel. The tool is inserted into the slot next to the latching tab, then forced into position.

You can cut the hinges. This method will keep the door itself intact.

A canvas that is not too strong can be knocked out. It is easier to do this if the door is unlocked inward. Metal doors that open outward cannot be opened using this method.

How to open a door without a key?

The easiest way is to call the brigade. You will have to pay for such assistance, but specialists will arrive quickly. You can also use the services of a locksmith from the housing office: they are free. The downside will be the waste of a lot of time: you will need to fill out a special form, wait for a specialist. If an autopsy is required urgently (for example, a small child remains inside), you can try to use brute force yourself, use a master key, or disassemble a broken door lock.

Opening a padlock

If the door lock has broken, you can insert 2 open-end keys so that their side ribs touch. Then the handles need to be moved (like scissors). In this case, the device will break, it will not be difficult to remove it.

You can also use a small plate made of tin (it is convenient to cut a suitable one from a can of canned food). The resulting master key is placed in the slot that opens the bow. The latch should open at the same time.

Methods for opening a lever lock

Opening a jammed door with such a lock is possible with the help of master keys. Instead, you can use hairpins, hairpins, paper clips. You will need 2 things at the same time: the first one needs to be inserted all the way inside, the second one alternately select those positions of the lever, at which the pin moves. Such a process will take a lot of time, it often ends in failure if the person has no experience.

There is another technique: the opening is performed using a drill equipped with a drill for metal. Drill should be done at the anchor point. When the hole is created, you need to insert the bent hook there and turn. Suvalds will change the position at the same time. But in the presence of protection against hacking, the technique will not be effective.

How to open a door without a key

Sometimes situations arise when it is necessary to open the door, but there is no key. It is better in this case to call special service workers who will help open the lock. When there is no time to wait for the brigade, you can try to perform an autopsy yourself.

Preventive measures

You should not leave the apartment without a key, even if you need to leave for only 1-2 minutes, it is better to take it with you. This is especially important in situations where you can close the door without a key.

Locking mechanisms must be lubricated in a timely manner. In cases where problems have arisen in their work, it is better to replace the device with a new one: the risk of breakage in such a situation is too great.

It is better to take locks that are equipped with an emergency opening device. A spare set of keys is required for each locking device. If there is no need, complex structures do not need to be installed. It is recommended to place simple locks between rooms, avoid metal structures that are difficult to knock out if necessary.

Cylinder lock opening options

At first, you can use a similar key: it is often possible to use it to open doors. This happens infrequently, only in those cases when the well is badly worn out.

If the attempt is unsuccessful, you can use a screwdriver, hammer and pliers (take tools from neighbors). First you need to remove the decorative strip, then grab the cylinder with pliers and swing it until it breaks. Knock out the rest, insert a screwdriver inside. To open the door, you will have to pick up the mechanism with the tip.

Drill use is also effective. Take a 5mm device and drill a hole below the keyhole. Then insert a screwdriver there and use it to complete the procedure.

There are also special picks for this type of door lock. Their cost varies between 2000-7000 rubles.

How to open an interior door?

It may not work to open the door to the room if the handle is broken, the key has been lost. Most often, complex locks are not installed: only if the housing is communal, intended for living or renting by several different people.

What to do if the key is lost?

If the key is missing, it will be difficult to remove the drill. The easiest option is to deal with the problem with brute force. The parts of the clamping device are held with the right and left hand and rotated in opposite directions. However, if the chuck is tightened too tightly or the drill has been used for a long time, it is unlikely that it will be possible to unscrew the thread.

During use, parts of the power tool become hot and the metal expands. This leads to jamming. To release the chuck easier, wait until the tool has completely cooled down.

To enhance the applied impact, use various tools or homemade devices. Here are some ways:

- Experienced craftsmen loosen the fastening of the cartridge with several tangential blows with the edge of the right palm. In this case, the drill is held with the left hand in the position of the drill from itself. The disadvantage of this method is that the palm can be injured from habit. Yes, and a tightly tightened (and even more so a behavioral or jammed) mechanism cannot be handled in this way.

- A metal shaft is selected, the diameter of which allows it to be inserted into the hole on the chuck. In this capacity, you can use a nail, an old drill, a hairpin. The main thing is that the metal is strong enough and does not bend from the applied effort. The screwdriver is inserted into the slot of the chuck and acts as a lever (while the support goes to the shaft). It is enough to slightly loosen the thread, and you can pull out the drill by untwisting the mechanism with your hands.

- The cartridge is clamped in a vice or held tightly with a gas wrench. The shaft is inserted into the hole, and then, applying muscular effort, the mechanism is unwound or twisted.

The second method can help if the chuck is clogged with chips. Then his body is clamped in a vice, and the lever is lightly tapped with a hammer. Vibration causes parts to move and the mechanism wedges.

How to spin a drill and change a drill without a key?

How to open the drill chuck?

The purpose of the chuck on the drill is to securely attach the drill or other attachments (construction mixer, grinding wheel, etc.). Fixation is carried out by three mechanical “fingers”, which are brought together and spread using a threaded mechanism.

There are two main types of cartridge:

- Keyless variety. To open such a structure, it is enough to grab the body with your fingers and, turning on the reverse rotation, briefly press the trigger of the tool. The drill will turn the shaft by itself, spreading the “fingers” securing the drill. Such a chuck is easier to work with, but the reliability of fixing the tool will be slightly lower.

- Variety equipped with a key. The key is a T-shaped device, at one of the ends of which there is a bevel gear. The other two ends serve as a handle for rotation. To unscrew or tighten the cartridge, the key is inserted into the hole on the body and rotated, holding the body with the other hand.

The wrench is usually supplied with the power tool. It either lies in the box or is attached to the power cord with a special fastener.

How not to lose the key?

In order not to face empty-handed unfinished work, it is important to properly organize the workspace. Such an organization will allow you not to lose sight of the key every time after changing the tool.

It is better to provide the key with a large bright keychain. This way he won’t get lost in the mess on the workbench and won’t be forgotten in the of work clothes.

The easiest way to protect yourself from loss is in your own workshop. Here you need to create a permanent place to store the turntable and always put it there. At the same time, the storage place should be convenient enough and at hand:

- Many manufacturers provide their instrument with an eyelet for attaching a turntable. It is placed either under the handle or near the fork. By inserting the key into this hole, you can rest assured that it will not get lost. The only drawback is that over time, the mount wears out and breaks.

- The keyhole is made of insulating tape. It is attached to the power cord. The attachment point is usually located 50-60 cm from the handle. So the turntable will not interfere with your work and will always remain at hand.

- By attaching a ring to the key, you can hang it on a hook next to the workbench.

If possible, you should stock up on one more key. It is stored in a box in a workshop, away from the place of work. If the master key is lost, the backup turntable is close at hand and saves the day.

If in the process of work it turned out that the spinner from the clamping mechanism was lost, the main thing is not to panic. With the help of folk methods, it is quite possible to release the chuck, get or change the drill, finish the job.

Chinese 5/8 keyless chuck JT3 disassembly

How to tighten a large nut without a suitable wrench?

The type of water distribution device of the mixer also determines the connection method when installing it.

Existing types of mixer installations, which have a fundamentally different connection method, are divided into only two main groups.

Unscrew the nut without a key

Additional Tips

Please note that some mixers require special installation methods, so when buying, you need to carefully study what kind of installation is required. In addition to being mounted on a sink, some mixers are installed in a countertop or wall. over, in the case of a countertop, many difficulties should not arise, but when installing a mixer into a wall, there can be difficulties.

In addition, during the installation of the mixer, you should not overdo it with tightening the nuts, especially when it comes to plastic pipes, so that later there are no problems with the threads. It is important not to forget about water shut-off and the use of gaskets during installation. The use of old, previously used in the old mixer, gaskets is not recommended, as they are already worn out.

It is important not to overdo it when tightening the mixer nuts, otherwise leaks cannot be avoided.

To give tightness to threaded connections, in addition to fum tape, a linen sealant is used. tow, which is wound along the direction of the thread, performing more than 14 turns. Some craftsmen process all joints with paint or sealant, but this method will create many problems when dismantling the product.

Whichever installation method you choose, the main thing is that the final result is efficient and does not disturb the overall interior of the room. Therefore, when buying, pay attention not only to the mixer itself, but also to its installation method and accessories.

Of course, if you have a wrench, it is much more convenient for them to unscrew the nuts and bolts. But it happens that the wrench is not available, or rather there are a lot of keys, but the necessary, as for evil, is not.

Or you get a custom-sized bolt or a rusted bolt.

But you can still assemble the simplest device and unscrew the bolt.

Mixer to pipe connection: rigid connection

This type of installation is considered the most durable, and in this case, a rigid connection for the mixer is required. Instead of flexible hoses, special needles are used, one of which is angled and is screwed into the mixer first, before the mixer is installed in place. It is advisable to set the needle direction to the most free area for installation. As with flexible connection, cold and hot water must be shut off before installation.

Faucet fixing elements.

After that, a gasket is put on the mixer, which will serve as a seal between the sink and the tap, after which the mixer is inserted into the corresponding hole in the sink. For additional protection, another gasket is inserted from below, and after that another, straight needle is screwed into the mixer until it stops. Next, we measure the required pipe size, cut off the excess, and fix them using clamping sleeves and keys.

After all the work is completed, you need to check the correct connection of the mixer by opening the water for some time.

Page links

- Direct link: http://1slovar.ru/phrase_dictionary/4800/;

- Link HTML-code: What does WINNUT mean in the Russian Phraseological Dictionary;

- Link BB-code: [url = http: //1slovar.ru/phrase_dictionary/4800/] Definition of WIND NUT in the Russian Phraseological Dictionary [/ url].

Types of mixer installations: flexible connection

This connection method requires a flexible mixer hose.

In order to keep the mixer coating intact, it is better to wrap it with electrical tape.

Before you start connecting the mixer to the pipe, you first need to shut off the supply of both hot and cold water. Further, by unscrewing the clamping nut and the fastening screw, you need to remove the old mixer and clean the installation site. If the mixer cannot be removed, then the junction of the device and the sink must be covered with a special chemical agent, which after a while will allow you to remove the mixer.

Mixer with flexible attachment.

To install the mixer, an eyeliner in the form of two hoses is screwed into it, as well as a threaded pin, on which the mixer itself will be attached to the sink. Before putting the faucet in place, you must put a rubber gasket on the hoses. This whole structure is inserted into the corresponding hole in the sink. Further work is more convenient to do with an assistant who will support the mixer from above until it is fully secured. For fixing and additional sealing of the system, a sealed ring, or a special gasket, and a pressure washer are inserted on the pin from below. The washer must be tightened firmly, and only then will the mixer hold on by itself.

After the faucet is installed on the sink, the sink connection is connected to the water supply using cap nuts and adapters. It is important to orient yourself correctly and to avoid kinking and kinking the hoses. The nuts are screwed, first by hand, then using keys, and for the reliability of the connections, fum tape is wound. At the end of the work, it is imperative to check the correctness of the connection of hot and cold water, as well as the tightness of all connections. If a leak occurs, it must be repaired. When turning on the water for the first time, you need to let it flow for about 5 minutes to make sure that the structure does not malfunction.

Installation of the flexible mixer.