How To Use The Hand Jigsaw Correctly

What material is better to work with

For cutting thin patterns, it is better to use thin, sanded plywood, 3-5 mm thick. Sawing such material is much easier, even for those who do not know how to use a hand jigsaw for wood, and the chance of ruining the product is significantly lower.

Another interesting material suitable for cutting with a hand jigsaw is sheet polystyrene (not to be confused with expanded polystyrene). In fact, it is a durable plastic that can be of all colors and sizes. In order not to complicate manual cutting, it is better to work with sheets up to 5 mm thick. The beauty of polystyrene crafts is accompanied by the high price of the material (from 700 rubles per sq / m) and limited availability. If you are confident in your cutting skills, and are ready to create an original glossy craft, you can start your search from the local construction markets.

Sawing with a hand jigsaw (step by step instructions)

Any creative work, in any industry, requires certain knowledge and skills. If an author wants to create something truly valuable, his technique must be honed to the appropriate level. Such activities can be safely attributed to the work of a hand jigsaw. In skilled hands, this device, seemingly simple at first glance, can create real works of art. Fortunately, it takes quite a bit of time to master curly sawing. All you need is a desire, and we will be happy to provide a detailed guide to action.

How to apply a drawing to a workpiece

Stick the patterned paper onto double-sided tape or glue. In the second case, after cutting, the glued paper will have to be removed with sandpaper. Double-sided tape, you can gently peel off.

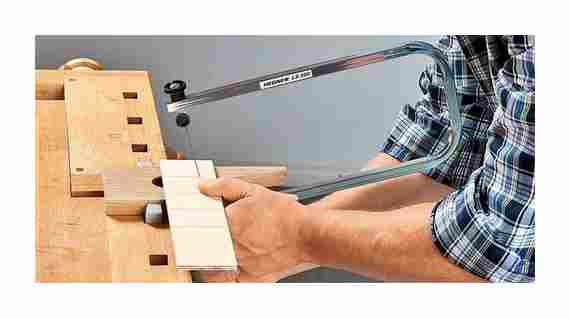

How to assemble a hand jigsaw

When the material is selected, and the cut out contour is applied, you can start assembling the working tool. First of all, we tighten the file in the lower mount (near the handle), after which we thread the free end into the opposite groove and, slightly squeezing the frame, fix it in it. Be sure to remember that the teeth of the saw blade should always look at the tool handle.

When squeezing, do not put strong pressure on the frame trying to bend the metal arc. It is enough for the mounts to come closer to each other by about 1 cm. You can squeeze the metal frame in your hand, or by resting the instrument with the handle on your chest. For devices with tubular arches, there are special devices with grooves. If you can’t tighten the lambs with your bare hand hard enough, use pliers.

If the saw blade is installed correctly, it does not wobble, and during operation, a high-pitched sound of teeth biting into the material is heard. How to properly assemble a jigsaw is best understood from the very beginning, since thin files tend to burst. The easier it is for you to assemble the device, the more pleasant it will work.

How to cut correctly

During shape sawing, you will often come across the same types of shapes. Despite the fact that the technology of sawing with a hand jigsaw is quite simple, it will be useful to know a few nuances:

Metal processing

In this case, the cutting blade should have fine teeth, the distance between which does not exceed 1.2 millimeters. In the process of sawing metal blades, the pendulum stroke is completely disabled. Material is processed at the lowest speed.

Move the jigsaw very slowly, eliminating any pressure on the tool. Before processing, the material is fixed so that the cutting line is as close to the support as possible.

Selection and preparation of the material web

The jigsaw can be used to cut canvases of various densities. Sawing material can be wood products, plastic or tiles. You can also cut metal with an electric tool.

The workpieces for sawing must have a uniform structure. If wood-based panels are used, the presence of knots or metal elements such as staples, nails or screws should be excluded. Wood blanks are used for cutting only in a dried form. It is recommended to select material with a flat surface for cutting a pattern.

The canvas selected for processing is fixed in a horizontal position. On its surface, using a pencil, a mowing line is applied for cutting.

Manual

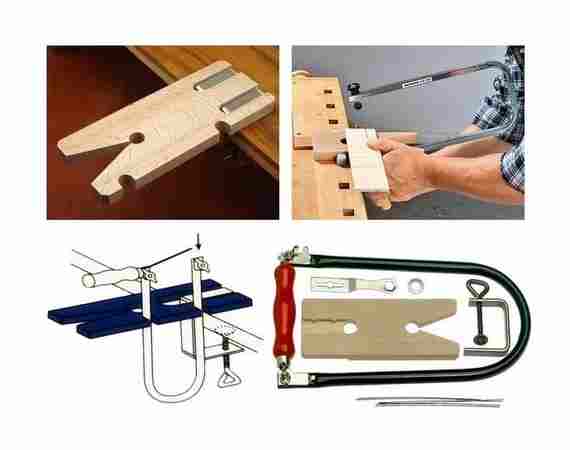

Such a tool is of the simplest type. It consists of a frame, a saw blade with clamps and a handle. A manual jigsaw is used mainly for small jobs requiring a certain accuracy of cutting.

The bottom tool allows you to perform artistic cutting of material. But using it takes patience and skill. The cutting speed of the handheld device is low, therefore it is impractical to use it for large volumes.

How to use a jigsaw correctly: personal experience of craftsmen

The jigsaw is a versatile tool designed for shape cutting of various materials. The device easily copes with wood, plastic, tile and even metal products. You can understand how to use a jigsaw by studying in detail the operational and technical features of the tool.

Depending on the area of application, jigsaws are divided into two main classes. household and professional. Regardless of the type, the design of the tool is equipped with a saw fixed in a special frame.

For home use, a small size cutting device is used. These jigsaws can be manual or electric. Each type of tool has its own technical and design characteristics.

Round and oval elements

The contour of the figure is applied to the prepared canvas. After that, using a drill, a hole is made in the workpiece, into which the jigsaw cutting element is installed.

The sawing process begins and ends at the hole made. If you drill several holes, then the circle or oval can be cut out in parts.

Nuances of straight cutting

A guide bar or rip fence is often used to cut material in a straight line. Such additional devices greatly facilitate the work process and improve the quality of the cut.

Electric jigsaw technology

With the help of a jigsaw, you can cut various materials without much effort. Still, the quality of work requires a special approach to each type of canvas.

Step-by-step instructions for curvilinear cutting

If everything is more or less clear with a straight cut, then you will have to sweat a little for curved cutting.

Curvilinear cutting stages:

- A file is selected. When the degree of rounding is not very large, then the standard version of the canvas will do. In the case of a sharper rounding, it is necessary to use narrower canvases. However, here it is also important to find a middle ground, because an unnecessarily narrow canvas will resist being pulled to the side during the sawing process.

- As mentioned earlier, the cut begins with drilling a hole for the saw.

- If the radius is small, then in the process of work it will be necessary to keep the landmark depending on the position of the canvas, because all sorts of points-marks can knock off the required course.

- Moving along the markings, the jigsaw is guided, turning around the axis of the part. No lateral force is required. Do not push the tool forward. he must walk calmly.

Quick-release fastening

This is how most current models of jigsaws are equipped for home use. If the clamp is frontal, the key is in front, if it is lateral, respectively, on the side To equip the tool with a file, you just need to release the key, insert the file into the slot of the clamp and release the key.

In the new models of jigsaws, changing the saw blade is even easier. For example, for those who are interested in the question of how to insert a file into a “Makita” jigsaw, let’s say that often in the latest models of the household class, the release of the quick-release key is carried out by pressing the protrusion (key) located on the front small casing of the upper protection that fits the front part. In this case, the rim of the casing moves forward from the edge from which the pressing is carried out, the saw shank is inserted into the slot of the holder, the key is released, the casing is in place, and at the same time the saw shank is fixed in the mount.

You can make sure that the fastening is strong and working by pulling the file. If you didn’t jump out, then everything is in order. It will be useful to remind that it is strictly forbidden to grasp the saw blade when the tool is connected to the mains (with the battery, not switched on).

Change of stock

How to use a jigsaw. My tools

Setting up a jigsaw for work. a master class for beginners and professionals

Setting up a jigsaw for work

For the jeweler, as well as for many other needlewomen, the jigsaw is an important tool. When I just started to study, one of the difficult questions was the question. with what force it is necessary to pull the saw blade so that on the one hand it saws well, and on the other, it does not break with careless movement. And asking that question, I got advice: “It comes with experience. “,” We must try the tension of the file with the fingers. ” etc. However, my jewelry fencing teacher helped me to resolve these issues once and for all. I hope his advice (in combination with my research in this area) will help you too.

The first thing to do is to mercilessly ruin the jigsaw. When buying a jewelry jigsaw, it looks something like this:

The red line marks the part designated for amputation.

Why? Correct work with a jigsaw assumes that it is necessary to hold it exactly along the axis of the hand and as close to the crossbar as possible. (My teacher also changes the jigsaw handle for a piece of the mop handle, claiming that it is easier to hold the tool in hand correctly. I don’t know, I don’t know. I haven’t reached such perfection yet.) Therefore, we saw off part of the frame so that when clamping the file it protruded from the clamping screw by about half a centimeter.

Modification of the tensioning screw. It’s very simple. we do it on one of its blades. at risk, or, like mine, we remove part of the metal. This is necessary to count the number of revolutions at which we pull the file.

The jigsaw is ready to go.

The desired file tension depends on the thickness of the file. I proceed as follows:

- I unscrew the upper tension screw of the jigsaw by the required number of revolutions. For example, for a thin file / 0 this would be 2.5 turns of the screw. This is where the risk applied to the propeller blade will help you. you can clearly see how many times you have turned the propeller on your weapon. (For thicker files. the tension should be greater, respectively, I will unscrew the screw by a higher number of turns, for example. for the thickest file (as in the photo). by 3.5 turns. (The numbers above are not the only possible ones. the tension should be more or less depending on the stiffness of your jigsaw and the length of the file. I recommend making a few trials and understanding what tension is comfortable to work at. The main thing that gives the number of revolutions. you know exactly how much you pulled the file. And if it breaks too easily, you can try to loosen it by half a turn. Or tighten it if it cuts poorly. Another benefit is you can use the fragments of the files, respectively, loosening the tension. For example, for / 0 files, with their length 2/3 from the original, I set the preload to 1.5 turns of the screw. That’s enough.)

- I clamp the file with the upper clamp. This is convenient if the file needs to be drawn into the hole of the part.

- I clamp the file with the lower clamping screw. At the same time, I strive to keep the file straight (when the part is put on it).

- I tighten the upper tension screw until it stops. It is important! It is always necessary to do this, because in this case the file will not “walk” from side to side and you have complete control over it.

- Done. You can cut it out! For example, make such a decoration:

I will be glad to answer your questions.

How To Use Hand Saws. Ace Hardware

Master classes on preparing the basis for sawing (finagel) and on jigsaw techniques will be separately.

Classification of files for jigsaws

Sometimes specialists make cuts in different materials with some files. We will be guided by the advice of experienced experts and explain why it is best to use this or that file, based on their recommendations.

- T101D. large teeth, so the cut will be rough, but the fastest. Perfect for regular wood (beams, boards). Cope with both chipboard and plywood.

- Т101В. the teeth are smaller, and therefore the edges of the puncture will be kept clean. Suitable for plywood and plexiglass.

- Т101BR. the letter “R” at the end means reverse. So the teeth are located in the opposite direction, although the file itself is the same. It is best to cut glued wood, laminate with such saws.

- T119VO. due to the thin cross-section of the file, it can be used for very neat curly cutting on materials such as fiberboard or chipboard, keeping their edges as clean as possible.

- T118A. small teeth and high-strength steel of such saws allows them to make cuts in metal blanks and plastic.

- Т224D. excellent for cutting / sawing aluminum blanks.

The difference in files

Looking at the window, you can see that some files have large teeth, while others have smaller ones. This is what suggests that each file has its own material. It can be understood that a file with large teeth is more suitable for soft wood, while cutting metal blanks will only be able to be done with a file with small teeth.

The files differ in the materials from which they are made and in length. A more detailed classification of them will be given below.

How to choose a jigsaw?

- Lack of practical skills often leads to quick breakage of saw blades, because they do not take any bending loads poorly.

- Drive jigsaws are more often purchased by craftsmen who are engaged in the mass production of curly crafts from wood and plywood.

- It is impossible to cut a complex profile with an electric jigsaw.

- The primary skills of sawing with a hand jigsaw on wood have already been fixed at the level of manual labor lessons at school, so mastering the tool will go much faster.

So, a hand jigsaw is a tool that disposes to unhurried, thoughtful and quiet work somewhere in the country, or on the balcony. a good alternative to mechanized options.

The first step is to choose the right hand jigsaw itself. Selection criteria are usually:

- Frame shape: depending on its configuration, it will become clear what the longest cut is. There are jigsaws on sale whose frame length reaches 300 mm, which significantly expands the technological capabilities of the tool, but at the same time leads to an increase in its weight and dimensions. For DIYers who do not have experience in curly sawing, it is worth purchasing hand jigsaws with a frame length of no more than 150 mm.

- Frame material: when pressing on the bow, the frame should spring, which is a good sign of quality. such a frame will not break when noticeable lateral loads are applied to the hand jigsaw on wood.

- Frame height: for strength reasons, this parameter should not be more than three times the length, otherwise the rigidity of the jigsaw will decrease and the quality of the mowing line will be unsatisfactory.

- How to tension the saw blade: Typically, wing nuts with different lengths are used for this, which, in turn, depends on the diameter of the thread. With an increase in the diameter, the length of the tendrils of the nut increases, which increases the convenience when tightening. The presence of holes in the antennae increases the accuracy of fixation. Nuts should not be cast, but stamped.

How to use a hand jigsaw?

Working with a manual jigsaw, even of the smallest size, is a painstaking and tedious task. In the previous section, it is no coincidence that there is no mention of the shape of the handle. all manufacturers have long worked out the most ergonomic shape for the jigsaw handle. However, my hands still get tired. In order for this to happen as late as possible, you must adhere to the following recommendations:

- A hand jigsaw, or rather, its replaceable blades, are not intended for making cuts at an angle. If necessary, figure sawing is paused and continued from the opposite side. Naturally, for this, markings are first made in the place where the length of the cut deviates by more than 5. 10 ° from the horizontal / vertical.

- To save energy, especially for shape cutting, it is recommended to use the maximum saw swing: this not only increases the sawing speed, but also improves the conditions for chip removal. This is especially important for working with thick wood (more than 1.5 mm).

- Use only jigsaw blade designs that are designed for this purpose. For example, spiral blades are good for curly cuts, and spur blades are good for straight.

- It is extremely inconvenient to work with a workpiece that is not securely fixed. Therefore, a clamping device or a reliable clamp is usually purchased for hand-held jigsaws, which will help to quickly and correctly fix the workpiece on the desktop.

- In order for the saw blade to be easily inserted into the gap, there must be a gap between the clamping surface and the top end of the table, at least 3. 5 times the thickness of the workpiece.

- It should be remembered that the hand jigsaw is not a saw, and any strong pressure on the frame can break the saw blade. Therefore, during the execution of the cuts, the effort is applied gradually. The criterion for the correctness of the force is the nature of the formed chips. if they are small and uniform, then the force is optimal. When the pressing force is exceeded, the chips become coarse, and a burr begins to form on the surface of the cut.

- Often, when working with a hand jigsaw on wood, you have to make sharp turns of the saw blade. To exclude the breakage of the file, in the place of the intended turn, pre-drill a hole with a diameter of no more than the thickness of the workpiece material, insert the blade there, and, without tilting the frame, continue the cut.

Manual jigsaw for wood. Selection and work rules

Despite the abundance of electric jigsaws, manual versions of this tool are still trending. A manual jigsaw for wood is both good physical activity for the entire shoulder joint, and an increase in the level of your woodworking skill, and the ability to do what you love in any conditions.

How much is a manual jigsaw for wood?

The price of the tool is determined by the manufacturer, based on the capabilities of the jigsaw. For example, a wooden handle is simpler and safer than a plastic one, but a jigsaw with such a handle will cost more, since durable types of wood (pear, hornbeam, oak) are used for the manufacture of this part.

The price of a hand jigsaw for curly cutting also depends on the design of the fixture. Aluminum wings are lighter, which has a positive effect on the weight of the tool, but negatively on its durability: over time, the aluminum wings on the nuts will begin to deform, and the quality of the saw blade clamping will deteriorate. Manual jigsaws for wood, equipped with brass or steel clamping nuts, are more reliable and durable.

The shape of the frame also contributes to the pricing. rectangular frames reduce the cost of a jigsaw, and square frames increase.

Thus, manual jigsaws, adapted for household, and not for professional needs, will be cheaper. The rest will be determined by the characteristics of the saw blades.

How to assemble?

After you have selected the material and applied the outline of the pattern, you need to assemble the working tool. This is not difficult to do. First, you need to tighten the file near the handle at the bottom, then carefully thread the free end into a special groove on the opposite side and, pressing the handle a little, fix it in it. Keep in mind that the teeth of the saw surface must also point downward, towards the handle of your tool.

Many inexperienced users try to squeeze the frame as much as possible. this should not be done: the only thing you will achieve in this way is to break the metal arc. It is quite enough just to bring the ends closer to each other by 1-1.5 cm. Usually the handle is squeezed by hands or rests against the chest with the tool. If you do not have enough strength to tighten the drums with your hands, you can resort to using pliers.

It is very easy to make sure that the saw blade is secured correctly. in this case, during cutting, you can hear high-pitched sounds made by teeth screwed into wood or plastic.

Keep in mind that thin files often break. if you plan to use the tool regularly, you will have to collect it quite often. That is why it is better to learn how to assemble before starting work, because the faster and easier it is to change the saw blade, the easier the whole work will be.

Description and device

A manual jigsaw, from a technical point of view, is a very simple device. It consists of a metal arc, between the tips of which a sawing tool is attached. A handle is attached to one of the ends of this arc. for it the master holds the device during his work. The most important element of a jigsaw is the saw blade, since its quality and sharpness determines how easy, convenient and effective the tool will be.

Unfortunately, modern files are not at all worthy of quality, therefore experts recommend giving preference to imported ones, for example, products from Swedish manufacturers have proven themselves very well.

Many people wonder if a hand jigsaw can completely replace an electric one. The answer to this is categorical. no. Both tools have nuances of use, therefore, in a home workshop, they should complement, and not mutually exclude each other. A handheld device will not be able to cut through thick wood and dense metal, but its cut comes out thinner and much more accurate than the one that is obtained when working with an electrical modification.

It should be noted that a manual jigsaw is much cheaper than an electric one, so it is recommended to purchase it for children and adolescents who are only hone their skills in sawing.

Hand jigsaws are very diverse: large and small, children’s, school and professional. There are models designed for cutting tiles, as well as jewelry options. They all differ in size, as well as the features of the files. There are quite a few manufacturers of jigsaws these days, because the tools differ greatly in prices, equipment and, of course, quality. Saw blades can be of different sizes and structures.

The most common files are with straight double teeth, as well as spiral.

The first option is optimal for creating a fast and straight cut. In most models, the length of such blades is 13 cm, and the working surface is 8.5 cm. These devices can be used to cut wood, plywood, and plastic. Spiral blades, unlike straightened ones, are characterized by a twisted shape, therefore they are often used to create round elements. due to their peculiar shape, the file will not get stuck in a wooden blank.

When making decorative cuts, special tools are required that allow you to create smooth mowing lines and bends even of microscopic dimensions. For such manipulations, it is best to use a jewelry hand jigsaw. unlike the more common analogue used when working with wood and other sheet materials, this device is lighter and more compact.

Manual jigsaws: features and subtleties of operation

- Description and device

- Views

- How to choose?

- How to assemble?

- Work rules

- Safety engineering

A hand jigsaw is used to cut all kinds of figures from wood, plastic, thin metal and plywood. It is used both by experienced professionals to create art objects and by children who are just taking their first steps in making toys and interior items with their own hands.

How to choose?

In order to choose the right hand-type jigsaw, you need to pay attention to several factors that are important for the features of the operation of the tool.

- The form. It can be rectangular and pointed. each of them is used for certain types of sawing.

- Tool weight. Working with a hand tool is usually quite painstaking and lengthy, so the hand gets tired very quickly. That is why it is worth giving preference to lightweight models with ergonomic handles. It is optimal if the shape of the handle is anatomical. that is, corresponding to the curves of the human palm (it is much more convenient to use them).

Keep in mind that in most cases lightweight models are produced abroad, domestic manufacturers are increasingly offering tools that have a very solid weight.

- Jigsaw frames are available in aluminum, iron, titanium or steel. If you need a durable and sturdy tool, then it makes no sense to opt for jigsaws with an aluminum frame, since the strength of this metal is not high. It is better to give preference to titanium or steel options. They, of course, cost an order of magnitude more, but they are able to cope with heavy loads, last much longer, and the work process itself is much more comfortable.

- Tool clamps can be nuts or drums. The second option is considered more preferable, since it provides the most comfortable work with such a jigsaw. in this case, no additional devices are required, for example, wrenches to replace the blade. All that is required of you is simply to unscrew the drum, and then replace the canvas manually.

- Manufacturing company. Chinese tools are cheap, but not worth buying because they tend to have a very short lifespan. Professionals recommend working with the products of the world famous brands Stanley and Intertool, Mastertool, and Topex. These companies have long and firmly established themselves in the market as manufacturers of the highest quality reliable sets of locksmith tools.

Work rules

The manual jigsaw has a fundamental difference from the usual hacksaw: the saw cuts at the moment when the master pushes it away from him, and the jigsaw, on the contrary, makes the cut when the tool moves towards the worker. This is because the working teeth point towards the handle and not away from it.

So, the procedure for working with a hand jigsaw is as follows.

- First you need to make a blank. If you have already decided on the drawing, then you can safely transfer it to the work surface. usually copy paper is used for this. It is applied to the workpiece, the necessary pattern is placed on top and, with the help of a sharp pencil, transferred to wood or plywood.

- After that, the workpiece must be well fixed. for this purpose, a special stand is attached to the workbench or any other table using a clamp. The workpiece is placed directly on the stand and the main process is started. sawing. Cutting technology has its own characteristics. Professionals advise cutting in a seated position, with the jigsaw handle on the bottom. The worker moves his hands up and down, while trying to keep the saw exactly vertical, otherwise the workpiece can simply be damaged. In those areas where the contour is curved, it is advisable to rotate the workpiece itself, but not the jigsaw, otherwise you can break the canvas. If you need to make an acute angle, then you need to stay in one place until the saw blade unfolds, and then continue working.

Sometimes it becomes necessary to cut out the figure starting from the center of the workpiece. in this case you will have to use a hand drill to drill a small hole inside the drawing and start cutting from it.

However, try to make it not too close to the planned contour, otherwise chipping may form on the plywood. Then the file should be pulled out of the tool, inserted exactly into the hole, then. again fixed on the tool and continue your work.