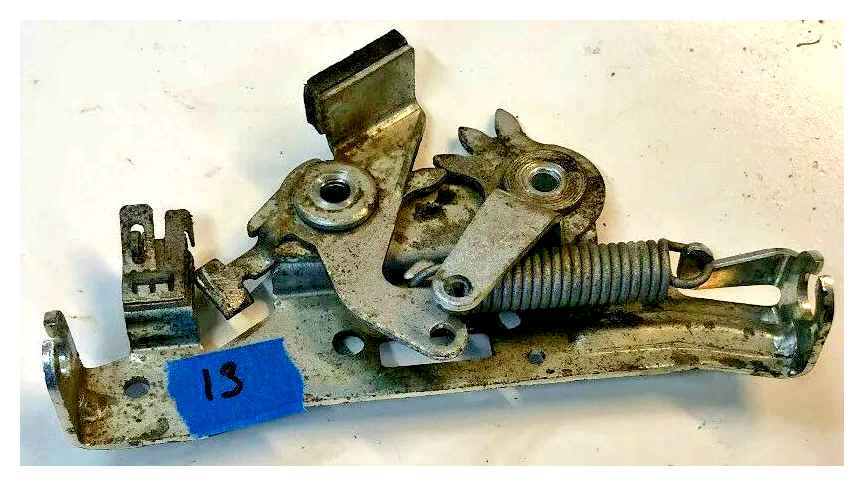

Lawn mower flywheel brake. Flywheel brake lever

flywheel brake lever

Suitable sparepart for Limited Edition EM 2012 Petrol Lawn Mower Einhell Home GH-PM 46 S BS Petrol Lawn Mower Hanseatic RM 46 HW-RA Hanseatic Petrol Lawn Mower Einhell Home GH-PM 46 BS; EX; CL Petrol Lawn Mower Einhell Classic GC-PM 46/1 S HW BS Petrol Lawn Mower Limited Edition LE-PM 2014 Petrol Lawn Mower Gardenline GLBM 46 Petrol Lawn Mower Hanseatic RM 46 HW Hanseatic Petrol Lawn Mower Gardenline GLBM 46; EX; CH; SLO Petrol Lawn Mower Gardenline GLBM 46 Petrol Lawn Mower

Spareparts for flywheel brake lever displayed via list view or via explosion drawing

Suitable products

Item number 3404491

Item number 3400773

Item number 3400774

Item number 3400772

Item number 3400779

Item number 3404710

Item number 3400777

Item number 3400775

Images

Contact us

If you have any questions to our products or services of Einhell, just contact us. we will help you.

Call in to our Service Center in the United Kingdom or checkout our service contact in other countries.

Monday. Thursday from 08:45 am to 05:00 pm

Friday from 08:45 am to 03:15 pm

Alternatively you can reach us via our contact form or maybe you find the answer to your question in our FAQ section.

Monday. Thursday from 08:45 am to 05:00 pm Friday from 08:45 am to 03:15 pm

Item has been added to cart

Co-Browsing (Bildschirm teilen)

Du kannst deine Browser-Ansicht temporär mit einem Einhell-Service Mitarbeiter teilen (Co-Browsing), damit wir dich besser unterstützen können. Der Service Mitarbeiter kann in diesem Fall lediglich die auf deinem Bildschirm angezeigten Browser-Fenster sehen. Andere Browser-Inhalte oder Teile deines Bildschirms sind für ihn dagegen nicht einsehbar. Optional kannst du dem Service-Mitarbeiter auch Schreib- oder Bearbeitungsrechte erteilen aber nur, wenn du dies auch wirklich wünschst. Du kannst den Vorgang jederzeit abbrechen. Diese Funktion kann nur in Verbindung mit einem Einhell-Service Mitarbeiter aktiviert werden. Einzelheiten findest du auch in der Datenschutzerklärung auf unserer Webseite. Jetzt Co-Browsing starten.

How To Turn Off a Lawn Mower – Quick, safe solutions

When a mower is working correctly, releasing the bail lever turns off the mower. If your mower doesn’t have a bail lever, then the throttle lever doubles as the on-off control. However, a mower that just won’t turn off is actually quite common, the solution is usually simple, but first, we’ll need to kill the engine.

So, how to turn off a lawnmower? The fastest way to turn off a mower that won’t stop is to remove the spark plug wire. The wire carries voltage, so you’ll need insulated pliers.

Other options include:

Most mowers come with what’s known as the dead man’s lever, you may know it as the Bail lever and as you know you must hold it to start the mower and release it to shut it down. Check out “How to start / stop a lawn mower”. The dead man’s lever doesn’t give much trouble, but if the wiring has come loose at the engine, the mower may not shut down.

Other mowers may simply employ a cable-operated lever to turn the mower on/off. These types of controls are usually fitted to mowers that also have a blade engage control lever. Anyway, I’ll show you three options to shut off your mower, and then we’ll take a look at what could be causing the problem.

Bail Lever – Releasing the bail lever kills the engine.

Stop/Start Lever – Move the lever to stop position kills the engine.

Shut Down The Engine

You have three options to shut down a mower with a faulty on/off switch. The fastest way by far is to pull the plug wire, but wow, not so fast, you’ll need a pair of insulated pliers.

The other options work for most mowers, but they may flood the engine with gas and so the engine might not restart for 30 minutes or so until it dry’s out, but it won’t hurt the engine any.

Option 1

Choke – Apply full choke, this will cause the engine to get too much gas and it will likely stall.

If your mower has an auto choke or a primer bulb you won’t be able to apply the choke manually so instead remove the air filter cover and air filter.

Using a clean cloth, cover the mouth of the carburetor, this restricts airflow and chokes the engine.

Option 2

Gas Tap – Most lawn mowers will have a gas tap, it lives usually beside the carburetor and when turned to the off position, kills the gas flowing to the engine. Need help finding your gas tap, click here.

Turning the gas off won’t take effect right away, it may take a minute or two before the engine starts to stumble and eventually stalls.

If you don’t have a tap, you can stop fuel flowing to the carburetor by pinching the gas line with pliers or vice grips.

Option 3

Plug Wire – The plug wire carries voltage and will shock if you just grab it, it’s not enough to kill you but if you have a heart complaint it could. It’s quite safe to pull the plug wire while using plastic-handled pliers.

The plug wire is a push-on pull-off fit and is pretty easy to remove, sometimes, however, they can be on pretty tight, so twisting while pulling helps. Be mindful, the mower will move towards you if not secured, you don’t want your toes going under the deck.

Be Smart about this, move the mower so that the front wheels face a wall, then yank on the wire.

Why Won’t The Engine Turn Off?

Faulty wiring is the common reason a mower won’t shut down, the wiring as you expect is simple. Banging into fences and cutting under hedges and shrubs can cause small components to come loose.

Other common causes include:

- Loose wiring

- Cable out of adjustment

- Faulty flywheel brake

- Faulty on / off switch

How’s it Work?

The coil and flywheel create the energy that the plug needs to fire. At its simplest – the positive charge travels from the coil through the plug wire to the spark plug. The positive energy is always looking for the shortest path to negative/ground (engine casing), and since its only option is to jump the spark plug gap, it does so and creates a spark in the process.

But if you offer the coil a more direct path to negative/ground it will bypass the spark plug and send the voltage to the ground instead. This is exactly what happens when you switch off the mower. The most common reason the mower won’t shut down – the small single ground wire has become detached or is making poor contact. The mower will run just fine without this wire, it just won’t shut off.

Look for any obvious signs of loose wiring, you might find this post helpful “Toro won’t shut off”.

Spark – Voltage passes down the plug wire through the plug and jumps the gap causing the spark. If the coil is given a more direct path, it won’t travel down the coil wire to the plug.

Turning the mower off offers the coil a shorter path, it does this by connecting a ground wire to the coil.

Lever On/Off Switch – The Bail lever is a common way to turn off a mower engine. It has 4 components bail lever, cable, brake assembly, and on/off switch.

Other mowers may have a throttle lever and stop-start unit combined. These types of setups will have a cable that will need adjustment from time to time.

Brake Assembly – When the bail lever is released or throttle lever set to stop, depending on which type you have, a brake is pressed against the flywheel and a direct ground path is given to the coil through a switch and or single wire.

This, as you know, stops the flow of volts to the spark plug, if it’s disconnected it won’t divert voltage and so your engine won’t turn off.

The black switch seen here with a single wire push-on the connector is the on/off switch.

Related Questions

How does a small engine kill switch work? The small engine kill switch sends the coil a direct path to the ground. The stored voltage in the coil is then discharged, instead of firing the plug. To start the engine, the kill switch simply takes away the coil path to the ground.

How do I start my lawnmower with a choke? First, check the oil and make sure the gas is fresh.

Hey, I’m John, and I’m a Red Seal Qualified Service Technician with over twenty-five years experience.

I’ve worked on all types of mechanical equipment, from cars to grass machinery, and this site is where I share fluff-free hacks, tips, and insider know-how.

And the best part. it’s free!

Introduction: Mower Kicks BackReplace the Flywheel Key

About: I miss the days when magazines like Popular Mechanics had all sorts of DIY projects for making and repairing just about everything. I am enjoying posting things I have learned and done since I got my first to… About Phil B »

Your mower does not start. Sometimes it fires weakly, but yanks the starter cord from your hand.

Your flywheel key is sheared and it needs to be replaced. The flywheel moved and sheared the key. Now the engine timing is very much incorrect. The spark comes at a time that makes the engine want to run backwards, but it cannot.

As a safety precaution, always remove the spark plug wire before working on a small engine.

Step 1: Why?

The flywheel key shears to protect the crankshaft from twisting, which would cause a very expensive repair. A soft key allows the flywheel to move on the crankshaft when your mower blade hits a tree root, an old stump, a large dried clod of dirt, etc. If the mower blade is loose, that will cause enough shock to shear the flywheel key, too.

Pictured is a repair I made to the blade holder. It had two raised tips to fit the blade slot. Those had become battered and the blade had some looseness, no matter how tight the center bolt was. I drilled out the tips and replaced them with hardened bolts. (Because of space limitations, I had to grind one side of each bolthead away at the top of the blade holder. This blade is actually a thatching blade. Somehow it is causing flywheel keys to shear. I think I will no longer use a thatching blade on this mower.)

Step 2: A New Key

Although sold by Sears, my mower engine is made by Tecumseh. There are several flywheel keys used on Tecumseh engines. Even if your mower is sold by Sears, you can take the Sears model number to your local mower shop and they can find the correct key for you. The key shown is part number 611004. It has a wider, thicker portion at one end. That end faces down on my engine. I was assured the key and flywheel would fit only when the key is in the correct position. (The photo is from Google Images.) A new key is about one dollar (US) in cost.

Step 3: Begin

The first step is to remove the gasoline tank. You will need to remove the oil dipstick first and set it aside someplace clean where it will not attract dirt. Set the tank aside, even though connected by its rubber hose. Set it with the cap upward so gasoline will not leak out. Also remove the red cooling shroud.

Step 4: Prepare to Loosen the Flywheel

Most people will not have a factory issue flywheel puller in their toolbox. You do not need one, if you are careful. Remove the starter rope cup and put the nut back onto the threaded portion of the crankshaft. Turn it until the face of the nut is exactly flush with the top of the crankshaft.

Step 5: Pry and Tap Sharply

Use a long screwdriver to pry from below the flywheel. Do not pry too hard. You do not want to crack the crankcase. At the same time, tap sharply on the nut. The nut protects the threads. Turn the flywheel a quarter turn after 3 or 4 taps. It will come loose more easily than you would expect. When it breaks loose, remove the nut and lift the flywheel off.

Step 6: Remove the Old Key Fragments

The old key will come out in pieces. Use a finish nail to pry what is left out of its keyway.

Step 7: Insert the New Key

Insert the new key with the wider, thicker end downward. You can see the new key properly installed on the shaft.

In the photo the green spring attaches to the automatic engine brake. Before placing the flywheel back onto the crankshaft, tie the dead man’s clutch lever against the mower handle so it is held as when you are mowing.

Step 8: Install Flywheel

Place the flywheel on the crankshaft. It should slide down smoothly over the new key. Oil the threads on the end of the crankshaft. Place the cup, the washer, and the nut onto the crankshaft. Begin to tighten. Never pry against the flywheel cooling fins. They break easily. Turn the flywheel a couple of times to make certain it turns smoothly and nothing is obstructing it. If you did not tie back the dead man’s clutch, you will hear a terrible scraping sound. Torque the flywheel nut. The recommended specifications are usually around 33 foot pounds. On some engines the figure will be 35 or 39 foot pounds. In general, if you are shearing a lot of flywheel keys for no reason, the nut is not yet tight enough.

Step 9: Top Off the Oil

When turning the engine while the oil fill is open you are certain to have some oil belch out of the engine. Top off the engine with new oil. Usually you fill to the level of the opening.

When you place the cooling shroud back onto the engine, you will guide the oil fill tube back into the fill hole on the engine. There is a rubber gasket that goes around the fill tube. It is easy for this to become separated from the fill tube during removal. Be sure this gasket is in place before you finish.

When all of the shrouds are back in place, untie the dead man’s clutch and put the spark plug wire back onto the spark plug. Check the oil just to be safe. Push the primer bulb three times. Grab the dead man’s clutch and pull the rope. The engine should start on the first pull of the rope.

Person Made This Project!

Did you make this project? Share it with us!

Wear It Contest

Metal Contest

Комментарии и мнения владельцев

I installed a new flywheel key sold to me by local Ace Hardware for mower with Briggs Stratton engine. Put mower back together. Pull rope would not pull out. When I took that part off again, I inspected and it is not cracked that I can see and pulls out nicely. The key seems a hair bigger than the one I could get at Amazon that is specificly for this mower engine. Ace said this would work. the key causes it to be just slightly off center. I’ve attached a picture. What do you think?

Hi I had a question since I am not really that mechanical with engines. My JS40 Walk behind mower was running ok and then all of a sudden I went to start it and the pull chord just locks up and will not turn the flywheel. First I thougt it was a spark plug so I replaced it. nothing. Then I seen it could be a flywheel key and I removed it and it looks perfectly fine? Any advise? Because the chord is still working off the engine but so hard to pull and make the flywheel move?

If you take the spark plug out, can you turn the engine by means of the mower’s blade, or is it very difficult to turn? (Do not turn the engine with your hand on the blade underneath unless you have removed the spark plug. You do not want it to start accidentally with your hand under the mower.) If you remove the plastic oil fill tube, is there oil up to the top of the engine casting where the plastic fill tube fits into the hole on the metal crankcase casting, or can you barely see any oil? I am wondering if the engine was run without enough oil and the rings may have seized in the cylinder. You can try putting a spoonful of oil in the spark plug hole and slowly turning the engine slowly in a clockwise direction to see if it loosens up. (I once ran a small 2-cycle engine with a gas oil mixture that was too old. After a few minutes the engine rings seized. I thought I had ruined the engine, but a little oil in the spark plug hole after letting it cool and slowly turning it with a long wrench brought it back.) it will probably be best if you keep the mower level so oil does not flow into parts of the engine where it does not belong,

I hit a rock in my yard and my Briggs and Stratton mower stopped running. It sounded like the most common issue with this would be the fly wheel key. I took mower apart and replaced the fly wheel key and tried to start the mower. The mower started but with low power and only lasted about 30 seconds. I then did this all over again with the same results. This time I heard a bit of rattling before it died. Any suggestions on what this might be?

The flywheel key is supposed to prevent damage to the crankshaft by absorbing the sudden deceleration and shearing. If and when it does not, there is the possibility the crankshaft bent. Remove the spark plug and set the mower up on its side, the side that does not allow the oil to get into everything. Look at the crankshaft closely as you turn the blade. Is there any wobble? There are ways to straighten a crankshaft. It might be time for a different crankshaft from a donor engine, or a different engine.

I have lawn mower Craftsman model # 917.377823. I am having problem to fix it. flywheel key has been sheared. I did replace key on new one. After I was able to start engine for testing, after running engine about 2 minutes I turned off engine, but after I could not start it back. After dissembling I realized it sheared key again. Any advice about this problem will be appreciated.

I ran into the same problem. I found the torque specifications for the crankshaft nut on my engine. I believe it was around 30 or 35 foot pounds. That was just the minimal amount needed to keep the flywheel from shearing the key again. would have helped, but I am cautious about torquing more than specified.

Phil B,I just took apart my lawn mower, replaced the key, put it back together and she runs like new!

2 hours, including improvising a jig for my bearing puller and a trip to the hardware store for a new key. Next time I could do it in 30 minutes.

Bill, Welcome to Instructables. I am glad you found my Instructable and that it solved your problem. I hope you enjoy Instructables. I am eager to see anything you might want to publish here. Once I had a situation that caused our mower to shear the flywheel key often. I eventually made timing marks on the engine shrouds so I could check the timing before the work of tearing into the engine. Here is the AC powered timing light I made.

My BS mower stopped working after running over a small piece of styrofoam. Initially, it would sputter for about 10 seconds before dying. Now it does that the first try, and nothing after that. I’m not much of a repair guy, but I’ve checked the carb, gas line, replaced filter, spark plug, gas oil, cleaned everything out with compressed air. Thought it might be the flywheel key, but couldn’t get the 15/16˝ nut that covers it off, even with PB Blaster and a blowtorch. Starting to think I should bite the bullet and take it to a repair shop, but worried about the cost. Anything I missed?

Please add to the checklist below a look for loose screws or hardened gaskets that do not allow the carburetor body to seal completely against the intake mount on the engine block. This is something that you cannot detect visually, but any screw even a quarter of a turn loose can allow air to leak into the gas/air mixture. That makes the mixture extra lean and lessens the engine’s ability to draw fuel into the combustion chamber. If gaskets are ten or so years old, they are probably too hard to seal well. You can get some gasket material and cut your own gaskets using the old gasket or the flange on the carburetor as a guide.

I’ve checked many of these things already. I need to check compression and the carburetor diaphragm. it could very easily be one of those. Thanks a lot for the thorough check list!

The symptoms you describe seem to be consistent with an engine timing problem caused by a sheared or partially sheared flywheel key. I have always been able to remove the flywheel nut on the crankshaft with a long wrench handle and the blade as levers to work against one another. That must have been some piece of Styrofoam.

I usually go through a process of steps when checking a small engine to discover why it will not run. You may have already covered these. Be sure to look at the final paragraph marked IMPORTANT. It is crucial on certain popular B S engines.

Fuel flows into the carburetor float bowl freely?

No dirt obstructing the idle mixture screw valve?

Clean air filter? (Test by removing the air filter and starting the engine. Air filters can appear clean to the eye, but are not.)

Adequate compression? (If you have a compression tester, you need 60 psi at minimum. Or, if you spin the top of the flywheel clockwise rapidly by hand, it should bounce back in the reverse direction on the compression stroke, not just stop and wheeze a little.)

Clean, new spark plug? (Spark plugs can appear clean, but degrade with age so that they do not fire under the pressure of the compression stroke.)

A good blue spark when the engine is cranked? (Remove the spark plug from the engine, but leave it attached to the plug wire. Wrap some bare copper wire around the threads and fasten the wire to the engine frame for a good ground. Deactivate any dead man clutch that cuts the spark out. Spin the mower engine and look for a blue spark. The fatter the spark, the better.)

Engine timing? (This is the matter addressed in this Instructable. It is necessary to remove the nut and washer holding the flywheel on the crankshaft and seeing if the keyways in both the flywheel and the crankshaft align exactly.

IMPORTANTMany vertical shaft B S engines use a rubber diaphragm in the carburetor. This diaphragm is about 2.5 x 3.5 inches in size (just guessing from memory) and it has a stiff wire fastened to its center. After 5 or 6 years these diaphragms stretch and do not pulse properly any longer so that the choke plate is not controlled properly in the carburetor. Unscrew the top half of the carburetor after removing the air filter and replace the diaphragm if the mower is more than 5 years old. There is no way to tell visually that this diaphragm is defective, but replacing it makes a big change in the way the engine starts.

I think one of these checklist items should help you find the problem.

Why Is My Lawn Mower Turning Over But Not Starting: Easy Fix

“Why is my lawn mower turning over but not starting?” is a question we get a lot from lawn owners. This is a common problem that may arise for a number of reasons.

The good news is that it is very easy to figure out why a mower is not starting despite it turning over. Read our comprehensive list of all these lawn mower faults and their easy solutions in this guide.

- Why Is Your Lawn Mower Turning Over But Not Starting?

- – Problematic Spark Plug

- – Wire Not Connected to Spark Plug

- – The Air Filter Might Be Dirty

- – An Empty or Contaminated Fuel Tank

- – A Faulty Carburetor Filter

- – The Mower Deck Might Need Cleaning

- – The Flywheel Brake Might Not Be Working

- – Fix Your Spark Plug

- – Connect the Spark Plug Wire Properly

- – Clean the Dirty Air Filter

- – Clean Your Fuel Tank

- – Fix the Carburetor Fuel Filter

- – Clean the Mower Deck

- – Repair the Flywheel Brake

- – How Do You Clean a Lawn Mower Carburetor Without Removing It?

- – How Do You Know if Your Lawn Mower Fuel Line Is Clogged?

- – How Do You Get Your Lawn Mower To Start After Sitting All Winter?

Why Is Your Lawn Mower Turning Over But Not Starting?

Your lawn mower turning over but not starting due to several reasons, such as a faulty or disconnected plug, a disconnected spark plug wire, a clogged air filter, or a contaminated fuel tank. A faulty carburetor, a dirty cutting deck, or a dysfunctional flywheel brake can also cause this.

– Problematic Spark Plug

The most probable cause of a mower not starting properly might lie in a problematic spark plug. This plug is responsible for producing the spark that ignites the fuel in the engine.

This plug usually stops working when it becomes loosened or disconnected and cannot generate a spark. Over time, it can become coated with carbon or water residue and stop working properly. It is very easy to fix a faulty plug – you simply have to take it out and visually figure out where the problem lies.

HRR Flywheel Brake Honda Lawn Mowers

– Wire Not Connected to Spark Plug

If the spark wire is not in close contact with the plug, the lawn mower naturally will not start, regardless of how hard you try. If the rubber cover over the plug is not placed properly, then this will also prevent the wire from contacting the plug. You will need to check the plug and the wire without removing either of them to see if this is where the problem lies.

– The Air Filter Might Be Dirty

The purpose of an air filter is to let air inside the engine so that the oxygen in it can help combust the gas and start the engine. Over time the airflow into the engine gets compromised because of a dirty filter.

The filter naturally collects things like dirt, dust, and other impurities. Eventually, it becomes so clogged that it stops all but a little air from entering the engine.

Usually, this filter is located near the top of the filter and is covered by a plastic or metal coating. You will have to unscrew the coating to get access to it.

– An Empty or Contaminated Fuel Tank

An empty gas tank can commonly cause this problem. Also, if the gas in the fuel tank has been left standing for too long without changing, then such a fuel tank will not catch a spark either. Even if the gas is just one month old but is being used without a fuel stabilizer, you will face this problem.

Similarly, a gas that has somehow been contaminated with dirt or moisture is useless and will not work.

– A Faulty Carburetor Filter

Another common reason why push-type or riding lawn mowers do not start despite turning is a carburetor that’s filled with too much residue. That is why it is recommended that carburetors be cleaned up at least once a year as part of regular maintenance.

This is not such a common problem. That is why you must first check that the ignition switch, air filter, etc., are working properly.

Another common sign of a clogged carburetor is that the engine might turn and start stalling. There might be black smoke emitting from the muffler. There will also be increased fuel consumption by the machine or weird noises from the engine.

Weird sounds like something splashing in the engine also means something is wrong with the carburetor. Other signs are the engine backfiring or being unable to accelerate.

– The Mower Deck Might Need Cleaning

The concept of a cutting deck is that it collects grass clippings and prevents them from spraying into the air. However, these clippings eventually clog up the mower and prevent the blade from cutting grass.

This especially happens when you habitually mow wet grass because such grass clumps together. That is why mowing dry grass is better for the lawn and the lawn mower over the long run.

– The Flywheel Brake Might Not Be Working

The purpose of a flywheel brake is to keep the engine running smoothly. They also help cool the engine and maintain the speed of the power strokes.

When the riding mower hits a hard spot, the brakes help absorb some of the damage. If your flywheel has been damaged, the mower won’t start but will, in fact, turn.

How To Fix a Lawn Mower That Is Turning Over But Not Starting?

To fix a lawn mower that is turning over but not starting, you can fix your spark plug. clean the airway filter, clean the fuel tank, fix the carburetor fuel filter, clean the mower deck, and repair the flywheel brake.

– Fix Your Spark Plug

First of all, find where the faulty plug is located. Usually, it is present at the front of the mower. Disconnect the plug wire to reveal the plug present underneath. You will likely need a wrench to unscrew the plug and take it out for observation, especially the insulator and the electrode on the plug.

If it is dirty with residue build-up, then only an easy clean-up is needed. Use a brake cleaner spray on this build-up, let it stay there for a few minutes – so the dirt gets dissolved – and then wipe it off with a clean cloth. Reinstall the plug in the machine and see if the problem has been resolved.

In some cases, you will need to change the plug with a new one. See if the electrode is missing or burnt or if the plug coating has been compromised. You can easily find new spark plugs at a reasonable price at any hardware shop.

– Connect the Spark Plug Wire Properly

If the problem lies in the wire not contacting the plug properly, then all you need is to connect the two. See if the rubber coating on the plug appears loose and pushes down in that case.

Tighten the rubber covering and also make sure that the wire is exposed enough to make adequate contact. If the rubber covering has been burnt, torn, or damaged in any way, then order a new one and replace the old one.

– Clean the Dirty Air Filter

If your machine won’t start because of a clogged air filter, then all you have to do is to clean it. Before unscrewing and removing the covering to the filter. you must disconnect the spark plug first. Then remove the metal or plastic encasing protecting the filter.

Take the filter out and inspect it carefully before cleaning. In the case of a paper filter, tap it gently on a flat surface to remove dust and dirt. Hold the filter up to a light source and see if it is blocking light from it. If so, replacing the filter with a new one is best.

In the case of a foam filter, use water and any dishwashing soap to cut grease and remove dirt. Squeeze it to remove all extra water, and then dry it thoroughly. Apply oil to your hands and use it to lubricate the filter thoroughly. Ensure that the oil is not dripping off the filter but only lightly wetting its surface.

Before reapplying for a clean filter, you should also cover the fitting with which the filter will be attached. Only use dry cloth because using compressed air or solvents might damage it. Replace it carefully and then cover it with its covering that has been cleaned as well.

– Clean Your Fuel Tank

If the problem lies in bad gas within the fuel tank, then you need to take it out. Use an oil siphon pump to drain the old gasoline out. Use the good old gravity method if you do not have a pump. Disconnect the carburetor from the fuel tank and place a container underneath to collect the gas.

Be careful not to spill the gasoline anywhere because this can lead to several problems. After your tank is emptied, it is time to clean any impurities. First, use only boiling water to wash the inside of the tank. and then use water mixed with a good quality fuel detergent.

Use a brush to scrub the inner walls if impurities are stuck. Give a final wash using clean water, dry the tank, and then refill it with fresh gas. This time add a fuel stabilizer to the gas to keep it from going bad.

– Fix the Carburetor Fuel Filter

Before cleaning the dirty carburetor, it is better to clean the outside of the mower beforehand. In most riding mowers, the carburetor lies on top of the air filter. and you will need to disassemble it and take it out in order to gain access to the carburetor. For other mower types, use the instructions manual to find out where and how to gain access to it.

You can use a carburetor cleaner to clean the insides of the carburetor bowl while it is still attached to the mower. To clean it thoroughly, however, you must take the carburetor out. Unscrew the nuts first and then disconnect the cables attached to them.

Before disconnecting the fuel cable, put something underneath to collect the draining fuel. Notice the carburetor’s position so you know where to put it back.

One way is to spray carburetor cleaner all over it and allow it to soak for a while. Give it an hour until all the grime and grease get dissolved, and then rinse off with clean water. You can then allow the carburetor to dry in the air or speed up the process using a blow drier.

Please do not put the carburetor back until all its parts are completely bone dry. Make sure that everything is back exactly how it was beforehand.

– Clean the Mower Deck

If your blades seem unable to rotate and cut properly, it might be time to clean them. In fact, the deck needs to be cleaned at least twice during each regular mowing season. Cleaning the deck is a piece of cake, but you must do it properly.

Either run the mower or the lawn tractor for as long as it takes for the fuel to run out. Otherwise, you can drain the fuel yourself by collecting it into a can. Disconnect the plug that starts the engine because you should not risk the lawn mower starting accidentally while cleaning the blades.

Tip the mower on a flat surface over its side, making its blades easily accessible. The easiest method is to use a hose to blast the blades at full speed. Most of the grass clippings and dirt will be forced off by this alone. Then use water, soap, and a sponge to scrub off all the rest of the dirt stuck on the deck and the blades.

Wash everything off using clean water and allow the deck to dry. A clever hack we employ is to spray some vegetable oil all over the deck lightly. Move the mower back into the standing position and reattach the ignition plug. Start the mower to see if it has started working now.

– Repair the Flywheel Brake

First, check the brake pad to see if it makes adequate contact with the flywheel. Also, check if something is blocking the cutting blade and preventing the flywheel lever from moving freely.

Sometimes the flywheel brake’s covering gets torn when something particularly hard gets tangled in the cutting blades. You will need to change the brake in this case. In order to do that, the entire mower will need to be taken apart.

Frequently Asked Questions

– How Do You Clean a Lawn Mower Carburetor Without Removing It?

You clean a lawn mower carburetor without removing it by getting a commercial mower carburetor cleaning solution. However, in order to gain access to the carburetor, the filter that cleans the air going into the engine must be unscrewed first.

Make sure you have removed the gasoline from the fuel tank beforehand and disconnected the ignition plug. After gaining access to the carburetor, spray the cleaning solution into it. Allow at least an hour, so the cleaning solution dissolves all the grease.

HRX Flywheel Brake Honda Lawn Mowers

Use a sponge or a brush to scrub the insides of the bowl as thoroughly as you can. Then use hot water to clean off the cleaning solution and all the dirt.

– How Do You Know if Your Lawn Mower Fuel Line Is Clogged?

You know if your lawn mower fuel line is clogged if the engine will take a long time to start after significant spluttering. The overall performance of the mower engine will drop drastically, and you will experience a lot of random stopping or braking while using the mower.

Especially while driving at low speeds, your mower will frequently come to a halt by itself. This naturally happens when the fuel line randomly blocks the fuel supply to the engine.

– How Do You Get Your Lawn Mower To Start After Sitting All Winter?

You get your lawn mower to start after sitting all winter by charging your battery. If the battery has rusted over the winter, use hot water to clean it up first and then charge it. You’ll also need to empty the gas tank if you haven’t done it before winter.

So if your gas tank still contains fuel, the new spring season is the time to empty it. The carburetor will need to be unscrewed first. and then you need to disconnect the line connecting it to the fuel tank. Collect the old gasoline dripping down from the carburetor into a container.

Next, you must fill the fuel tank with fresh and clean gas. Smelling carefully is one of the easiest hacks to check if the gas is fresh. Check the oil in the mower and refill it with clean oil. Lastly, we suggest you clean the mower thoroughly before starting it after a long break.

Conclusion

Congratulations, this marks the end of our complete article regarding why your mower might not be starting properly.

Here is a summary of all the reasons and their quick fixes:

- A faulty or disconnected spark plug is the number one reason why lawnmowers might not start. All you have to do is to fix it or have it exchanged in case it is beyond repair.

- If the air or fuel filter is not working properly because it has clogged over, it will also need to be cleaned or changed.

- A mower deck with wet grass clippings and grime should be washed off regularly to keep the mower going.

- If your blades seem unable to rotate and cut properly, it might be time to clean them.

We have discussed all the common reasons that stop a mower from starting despite turning over. If your mower is giving you problems, our guide will help you find out the problem and solve them in no time.