There is no spark on the Huter lawn mower. Piston piston piston (piston, rings, pin, clamps)

Why there is no spark on the chainsaw and what to do

If there is no spark on the chainsaw, then do not be upset, the malfunction is diagnosed and eliminated on its own very simple. The serviceability of the ignition system and the fuel system is equally important for the non.resistant operation of the chainsaw engine.

Symptoms of non.betrayal, both ignition and carburetor are often very similar at first glance at first glance. In order to correctly find and eliminate the cause precisely in the ignition system, in particular the lack of spark, you need to know the principle of its operation, device and diagnostics.

Reasons for the lack of a spark

On the engine of each chainsaw stands, in fact, a miniature power station. The primary impulse for the spark on the candle she receives from the jerk of the starter cord, from muscle energy.

Further, energy is produced due to the rotation of the magnetic rotor with the engine operating due to combustion of fuel.

For reference! In the theory of problems with the formation of a spark, there can be along the entire line of the system, from energy generation to its transmission by wires and transformation in a spark on the lighting of the fuel of the chainsaw. In practice, weaknesses are less.

Is there a fuel in the tank and what is its quality

Checking the presence of fuel in the tank is the first where to start diagnostics. Even if there is still a visually in the tank, make sure that the fuel line is lowered in it. If the fuel in the tank on the bottom, then this is the main reason that it is impossible to start the engine. After adding fuel to the tank, it is necessary to pump the system, and only after that to trial launch of the motor.

If there is enough fuel in the tank, then make sure that the supply hose inside the tank did not disconnect. On some models of chainsaws, such a malfunction is a “disease”. If the tank is full, then this does not mean that the breakdown is not related to the fuel system. Check the quality of fuel (oil and gasoline). Gasoline for chainsaws is used mainly by AI-92 brands. As an oil, only a special two.stroke should be used, but not a motor or at all.

The prepared fuel mixture cannot be stored for more than 2 weeks, since the mixture begins to lose its properties, which affects negatively not only at the operation of the engine, but also on its launch. How does a poor.quality mixture affect the launch of the motor, you ask? Everything is very simple, with prolonged storage of the mixture, the oil is precipitated, which leads to the occurrence of clogging of the channels and nozzles of the carburetor.

The instructions for each brand of the chainsaws indicate the recommendations on what ratio should be diluted with oil with oil. It is such a recommendation that should be followed when preparing a mixture for a two.stroke chainsaw engine, otherwise this will significantly reduce the life of your tool.

Checking the spark on the spark plug and the gap between the coil and the magneto

The sparkling candle is the most important detail that is responsible for ignition of the fuel mixture fed into the cylinder chamber. If the candle has served its own, then it will give out a weak spark or not to give it out at all. This can be checked in the following way:

If the spark arises constantly, then this indicates the serviceability of the candle. over, not only the candle is working, but also the ignition system. the coil and the high.voltage wire. If a spark on a candle occurs, but with interruptions (intermittently), then such a detail must be replaced. You must first check the gap between the contacts. The size of the gap should be from 0.5 to 1 mm.

For each chainsaw model, manufacturers indicate the recommended gap, so you need to use the directory. You can measure the gap with a special probe or a sheet of paper folded several times.

The absence of a spark on the candle indicates a malfunction of the ignition system, so before replacing the part, you should make sure that the ignition coil and a high.voltage wire should be serviceable. Not to start a chainsaw may be due to clogging of the electrodes of the candle. The presence of a black carrier on a candle or wet electrodes. all this can indicate the following faults:

- Black Nagar. the carburetor of the chainsaw is adjusted incorrectly. The incoming mixture in the cylinder has a lot of fuel and little air. You can eliminate the malfunction by cleaning the soil on the electrodes of the candle with the subsequent adjustment of the carburetor

- If the candle is wet (poured), then this may indicate the following. either the ignition system (including the candle itself) is faulty, or an excessive amount of fuel enters the cylinder, thereby the candle is poured. First you need to make sure that the candle gives a good spark, and only after that adjust the carburetor. It is not recommended to dry the wet candle by calcining, so it should be wiped dry dry, and then let it dry in the sun

- If the candle has a red or pink carrier on electrodes, then this suggests that the gasoline used contains a large number of additives. Typically, this effect gives gasoline of the AI-95 brand and above, an increase in the octane number in which is achieved by adding additives

When the candle has a brown color (brick), this indicates not only a properly adjusted carburetor of the chainsaw, but also about the serviceability of the ignition system. If a new spark plug is used, which gives a weak spark when checking (or there is no spark at all), then this is a sign of a malfunction of the ignition coil. The coil must be replaced with a high.voltage wire.

It is interesting! Check the size of the gap between the ignition coil and the magnet. Different manufacturers of chainsaws indicate the recommended gap (usually the value is 0.25 mm), if this value is higher than the norm, then it should be adjusted using the probe.

Wet candle of chainsaws: why and what to do

You can use to clean the carburetor and special washing.

- If the gaskets of the carburetor are worn out, you need to change them. And in case of violation of the tightness of this device, you will have to determine the faulty part of the carburetor and replace it.

- A trimmer for grass may not be launched due to wear of the piston group. However, it is better to change such parts of the lawn mower in the service center.

Immediately after buying a trimmer for grass for grass, we are faced with a lot of questions. how to use it correctly, how to refuel it (if we are talking about a gasoline tool) and, of course, which fishing line for a trimmer is best chosen. Look for the answer to the last question in the article.

How to quickly remove the stump without uprooting?

Many gardeners will sooner or later face the need to cut down trees growing on the site. After that, stumps remain, and if the trees were significant, it is very problematic to uproot them. The article tells about alternative ways to get rid of stumps.

Currant processing in the fall from pests and diseases

Almost every summer resident grows currants, which is loved because of its taste and beneficial properties. It requires proper care, which consists in the processing of plants from pests and diseases. The features of these autumn events are described in the article.

How to choose a gasoline trimmer for grass for grass?

Beautiful well.groomed lawn. decoration of any site. And regular haircut helps to preserve its attractiveness. This case cannot do without a lawn mower or a trimmer for grass. In the article let’s talk about the intricacies of choosing a gasoline trimmer for grass.

We find the reasons why the lawn mower refuses to start

If the lawn mower stubbornly does not want to start, and for some reason you do not want or cannot contact the service workshop, then try to follow the simple algorithm for searching for a malfunction. As always, use an effective search method, moving from simple reasons to more complex.

Check the pressure level in the engine (compression). To do this, you will have to get a special device in advance. a compressometer for measuring the parameters of the lawn mower. Normal engine compression indicators should lie in the range from five to eight atmospheres (all the envy of the individual characteristics of your engine). The compression parameters of your unit should be indicated in the accompanying technical documentation. If the level of compression is much less than the indicated. then your piston system has failed, requires a deeper study, repair or replacement of your elements.

The engine of the lawn mower jammed. Although this type of malfunction is much less common in a cart type, but it cannot be completely excluded. Basically, the engine jamming is due to gross violations of the operation of the lawn mowers. But if this still happened, then the repair of the lawn mower in the service center will cost you not cheap. Therefore, always carefully read and observe the rules of operation, storage and maintenance of the device recommended by the manufacturer.

Falf of the starter of the lawn mower. Checking the functioning of the starter is quite simple: you just need to try to pull out the launch cord from the lawn mower. If it does not stretch, try unscrewing the top cover of the lawn mower with the trigger and try to pull the cord again. If this time the cord does not lend itself, we diagnose the breakdown of the starter.

If the cord after separating the cover from the engine began to stretch out, put the mitch on the side and try to turn the working knife with our hands several times. If the knife does not rotate, then the engine still jammed and you have to send it to the service center, conduct deep diagnosis and, depending on the result, repair or change.

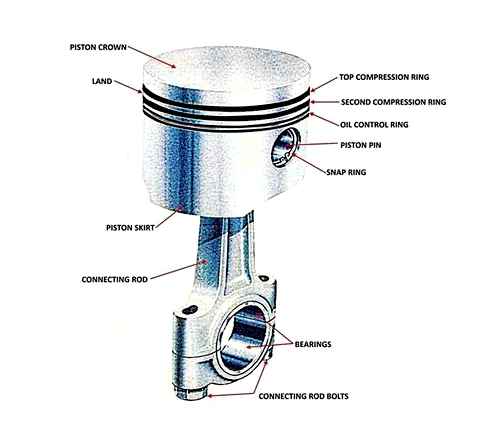

How to Install a Piston and Rings

Carburetor failed. This is the most common cause (more than half) of the breakdowns of the gas mowers of the cart type. The carburetor will have to be removed from the lawn mower, disassemble and carefully consider. Also pay attention to the serviceability of gaskets and the air damper, responsible for mixing air with fuel.

And again the carburetor.

Well, even if after such bullying your trimmer does not start for the grass, you can’t do without disassembling the carburetor for you. It may well be that everything is guilty in the needle in it. In any case, the disassembly and washing of this capricious mechanism certainly will not hurt. Adjustment of the lawn mower carburetor can be adjusted with your own hands, like the entire benzo tool for the garden, is not difficult to maintain equipment. Repair, configure without the help of others you can and necessary. For example, adjusting the carburetor of the lawn mower with your own hands. it is 5 minutes. The carburetor from the lawn mower is a node in the power supply system. Idle…

Many trimmers owners are faced with a problem when the device simply does not start.

One of the reasons for this may be the lack of a spark. This usually happens when the fuel floods the light of the ignition. In addition, you need to check the candles for serviceability, as this can also lead to a lack of spark.

The first sign of a faulty candle is the presence of a short circuit between its contacts, and in short. there is no spark on the trimmer.

In addition, the candle is considered faulty if it is covered with a black wet layer.

Such a layer appears from the oil combustion chamber. In such a situation, you have two exits: either clean the candle as it should, or buy a new.

Sometimes it happens that the candles are clean, but at the same time, the problem can be in its isolation, which is often covered with a black dry soot.

The reason for this may be a weak spark, excessively low spark plug, low fuel quality, dirty air filter or prolonged work at idle.

Here the output is the same. clean the candle or replace it with a new. over, the candle should be replaced if the contacts are strongly worn out.

In the case when there is no spark on the trimmer, how to solve the problem you will be told by professionals for a hundred.

Sometimes, the problem can be with magneto. Magneto may become unusable due to the fact that you could pull the starter cord at the moment when the ignition was turned off, and the candle was not grounded for the mass.

Such actions can easily disable magneto. In such a situation, the only way out is to buy a new magneto.

In addition, the problem may be the ignition node. This option can be considered if the candle and wire do not have any malfunctions.

In such a situation, it is necessary to engage in the replacement of the ignition unit. It can be found attached using two screws to the engine cylinder.

To obtain free access to the node, it is necessary to remove the enclosing casing.

To correct the current situation, you will have to replace the entire node, because, as practice has shown, replacing individual parts gives insufficient result.

If there is no spark on the trimmer, it can only be fixed in one way. replace it.

over, sometimes the problem should be sought in the ignition coil. The absence of a spark can lead to the failure of the coil or a malfunction in the chain.

To check the flow of current into the primary winding of the coil, you can use the light bulb, which must be turned on instead of the coil.

Then you need to carefully examine the contacts of the interrupter. If a strong spark occurs at the time of opening between the contacts, you can be sure that the capacitor is broken.

In this case, you have only one option of further actions. replacing the capacitor.

These are the main reasons why there may be no spark on the trimmer.

And you can also watch a video about the launch of a lawn mower

How not to get confused if the lawn mower does not start

The tool, despite its small dimensions, represents a complex technical device. If you study the operating annotation, it turns out, the reasons

, why the lawn mower is not started, known and eliminated. It is necessary to alternately exclude the reasons that make it difficult to start the tool. They usually start with more affordable nodes with a slight checking check.

Why do you need a good spark.

The quality of the spark determines its ability to ignite the properly formed air-fuel mixture in working conditions. A weak spark in high pressure and temperature in the combustion chamber cannot do this. The ignition occurs later or does not occur at all. There is uneven engine in the engine, the engine does not gain momentum, there is vibration, detonation, the starter can have the effect of the “rear impact”.

The insidiousness of such a breakdown is that the diagnosis below does not give one hundred percent confidence in the effectiveness of the ignition coil. Such an implicit breakdown when there is a spark, but this is not entirely correct, often misleads and makes you write off problems with the ignition coil with a malfunction of the carburetor.

Typical actions in such cases. this is. It turns out that the spark can ignite such a spark, but it does not have the right. But the use of an enriched mixture leads to the rapid wear of the cylinder.piston group and muffler. Therefore, in such controversial situations, check both the carburetor and the ignition reel.

The quality of the spark is determined by its ability to set fire to a correctly formed air-fuel mixture in working criteria. The initial settings of the consistency are carried out in the spark or as it is still called a breakdown of a breakdown from an electronic current pulse developed by the ignition coil. Here the place is actually instant heating of the molecules of gasoline and oxygen, from which factors they come into a chemical reaction reaction.

It is clear that any differences in the characteristics of the spark leads to incorrect work. There are many circumstances of such deviations. Common:

- Inolble in temperature, the operation of the ignition module: it works fine for a cool coil, heating stops working. Manifests itself in the usual work of the motor for cool, and refusal to warm. This is justified by the fact that the snuffs of the coils are diodes, transistors and capacitor. A malfunction at least any of these parts manifests itself only when warming up.

- faulty candle. We will not repeat here here. You will find the material in the web.

- bad contact, rust at the junction and a faulty switch to clarify here we will not

- duffed (transmitted, melted, etc.D.) high.voltage wire. Here, too, what remains to make our client understand

Elimination of malfunctions in professionals

One hundred has not only a car, but also a garden-technique. Typically, the service center is converted with a malfunction of the piston and carburetor of the device. Why and why the gasoline lawn mower does not start in these cases determine the master:

- Damage to the integrity of the device or individual parts. a tonometer, by pressure, find the affected area, seal it.

- Clogging of channels, nozzles. elements are blown by air, cleaning fluids are used.

- Worn pistons, laying. replace the assembly parts.

Fault prevention

The rules of operation of garden equipment are not difficult if you adhere to these points the device lasts longer than the estimated deadline:

- Always use high.quality fuel mixture.

- Do not work in the rain.

- Pump up fuel into a carburetor primer.

- Pour the right amount of gasoline into the tank, eliminate fuel enters the engine.

- Mow with interruptions. The device should be given for some time to cool and rest. The gasoline lawn mower is often not started on a hot.

- Clean the setting of the structure, only after the engine has cooled. Clean: knives, channels, filters, container. It is advisable to do this with the use of special cleaning solutions. this is how it will be possible to avoid corrosion of metal elements.

- Store the device in dry, warm room, eliminate moisture.

- During the work, do not put pressure on the device, make smooth movements forward, advance along the site. Chaotic movements back and forth-wear out the unit faster.

- If the device is unused for a long time, you need to replace the fuel with a new. Gasoline stagnates in the system, does not allow the unit to function normally.

It should be noted that with the onset of cold weather, the car is removed as unnecessary, it is recommended to drain all gasoline for this period (it is explosive with stagnation). How to properly prepare the lawn mower for work after winter: inspect the entire case for defects, drain and replace gasoline, check the presence of oil, start the car with a ajar or closed air damper.

The muffler of his clogging and the inability to start a benzotrimer

What else can be the reason that it is impossible to start a benzotrimer engine? Even before resorting to more cardinal actions, you should check the serviceability of the muffler or exhaust channel. This does not apply to new trimmers that have practically no special development. If the trimmer has been to the trimmer, and the tool has not been subjected to diagnostic measures, then the muffler is checked.

If the lawn muffler is clogged, then the exhaust gases have nowhere to go out, and therefore it is impossible to get the engine. In an instant, the exhaust channel cannot be clogged, therefore, the day before such signs should have been manifested:

- An increase in the sound of the motor, which is associated with overcoming high resistance with exhaust gases to release them

- Black smoke from a muffler is a dozen that settles on the walls of the exhaust system

- Unstable engine operation

- The motor stalls on its own when working at idle

Exclude or confirm this factor by inspecting the exhaust system. If the anti.icing mesh has significant clogging, then the reason for the impossibility of starting the engine is undoubtedly in the exhaust channel. The mesh must be cleaned, only this must be done carefully, since the black carcass is a very dangerous carcinogen that can provoke serious diseases of the human respiratory system. To clean the anti.icing mesh and muffler walls of the trimmer for grass, special tools should be used, and work using protective equipment.

A trimmer does not start for the grass for cold reasons

To begin with, we will analyze the situation when it is impossible to start the engine of the lawn mower to a cold. What does this mean? Surely Kosari came across a situation where a trimmer for grass starts on hot just perfectly, but you just have to make a short break, as the problem arises. This problem with the start of the engine after it cools. What could be the reason? Of course, no one excluded all the above factors, but if the situation is constantly found, then there is no need to check them. If a hot lawn mower starts well, and problems arise on the cold, then you should look for the reasons inside the CPH (cylinder-piston group).

To identify a malfunction, you will need to use a compressometer. We screw the compressometer into the hole instead of a candle, and after that we drive the starter handle. Measure the pressure inside the cylinder. compression. The amount of compression should be at the level of about 8-12 atmospheres. After the tool has warmed up (it is enough to work for 15-20 minutes), you should repeat the verification procedure. If the compression on the hot engine is below 8 atmospheres, then the CPH fault is appropriate. This means that the rings, the piston and the walls of the cylinder are worn out.

You can fix the situation by replacing CPG. When replacing it, it is important to take into account such a recommendation as abundant smearing of parts with motor oil inside the cylinder. This is necessary so that in the first minutes of starting a new cylinder with the piston, no formation of.

With a decrease in engine compression, fuel consumption increases, and the productivity of the tool falls. You can work with such a tool, however, with each subsequent hour of work, wear increases. One day, the lawn mower will not be completely launched even with warming up.

It is interesting! You can warm up the engine of the lawn mower with low compression by pulling the starter handle. When warming up, the metal is expanded, thereby the compression increases.

All the whole, clean, works?

We try to adjust. We take a long screwdriver, we find a bolt of idle speed adjustments (it is on the throttle), twist it a couple of revolutions so that the damper is opened. We start. It works smoothly? Then we go further. Does not start or stall? Open the damper until it starts stably.

Next, adjust the quality of the mixture with a screw l. You need to achieve maximum storage speeds. Here the principle is the opposite. the more the bolt is unscrewed, the richer the mixture. After that, the quality of the mixture at maximum revolutions by the screw h.

If the adjustment of the carburetor has not given its fruits, then it needs to be disassembled. Watch the membrane, clean nozzles and inner moves. For this, it is necessary not only to have a reptile, but also preferably a reserve carburetor.

How to prevent sudden breakdowns during the operation of a trimmer for grass?

So that the unit is always in a functional state, it is worth observing several simple rules:

- Carry out timely, regular technical inspection of the main mechanical nodes of the device.

- Refill a trimmer for grass with exceptionally fresh fuel, the quality and origin of which is not in doubt.

- Check after each use of the tool, whether oxides and soot on the surface of the ignition system were formed.

- Avoid the strong load of the trimmer for grass during work.

In order for the unit to remain in a working state, it is necessary to properly prepare it for storage in the winter period. First of all, you should completely disassemble the tool, and then perform washing and cleaning the constituent elements. It is also important to examine the functional blocks for damage, with the need to eliminate the deformation of the parts, all kinds of distortions, gusts of materials.

REDMAX EBZ8050 PROFESSIONAL COMMERCIAL BACKPACK LEAF BLOWER NO START LOW COMPRESSION PISTON RINGS

How to adjust the carburetor of a trimmer for grass

On trimmers, not counting electronic engines, gasoline internal combustion engines are installed. This mechanism asks for special attention to himself, since he will either refuse to work with incorrect tuning, or will work with interruptions and power loss. In the main thing, the setting of the engine is to adjust the supply of fuel, and this is done using a carburetor of a trimmer for grass.

Clogging of the mesh filter

A mesh filter can be contaminated when dirty fuel is received through a fuel hose or an absorbing head having disadvantages. In the photo below, you can see how the unsuccessful filter and dirty look like (parts are broken by the line).

To eliminate the malfunction, you will need painstaking cleaning and flushing of the mesh filter. It is also recommended to blow out all the holes in the carburetor body with compressed air Trimmer for grass

Determination of the causes of the malfunction

If the trimmer engine for grass does not start or stalls immediately after starting, when overheating or during the functioning of the device, extraneous noises are heard and vibration is clearly felt, it is important to perform a visual inspection and identify a non.working node

To optimize preparatory measures before repairing, a simple diagnosis should be carried out and checked in stages:

- the presence of fuel in the tank and lubrication in the main nodes;

- serviceability of the spark plug and its performance;

- the purity of the fuel and air filter motorcycles;

- Cutting of the exhaust channel and the device’s saepun;

- The quality of the used fuel and lubricants.

To determine the functional performance of the ignition of the lawn mower, you should determine whether the candle works by testing the appearance of a spark in contact with the body of the functional device.

The spark plug itself can be changed to a new one, after driving the candle canal, if necessary, the old element is also dried, cleaned with special devices and returned to place.

Low voltage diagnosis

For this method, you need to find a 2-3 watt control lamp with a voltage of 12V. We connect one contact of the lamp to the contact of the low voltage of the trambler, and the second to the mass.

The next step is to close the Trumbler’s contacts and turn on the ignition. If there is no problem in the low voltage circuit, the lamp will go out with closed contacts and burn with open. If the opening of the contacts does not lead to the glow of the lamp, the cause of the breakdown is the primary winding of the coil or low voltage wires.

If the lamp shines continuously, regardless of the position of contacts, this indicates such possible breakdowns:

- oxidation of the contacts of the Trumbler;

- damage to the wire connecting the Trumbler body and its mobile disk;

- Damage to the wire between the lever and the Trumbler terminal.

Backing

Each fisherman must know how to wind a fishing line for a trimmer for a trimmer for grass and what is backing. Backing is a winding on the roller’s ropes. To do this, often use a thread with a diameter of 0.1 to 0.3 mm. If you use a thicker fluorocarbon as a winding, this can lead to uneven and uneven laying of the main fishing line. It is extremely undesirable for backing to use wet materials, this include nylon and cotton threads. They are unable to dry for a long time, which leads to a debate, and replacing the fishing line on the trimmer. These are additional financial costs.

The amount of thread required for backing can only be determined experimentally. This will require two spools. The required amount of the working fishing line is first wound on one, and then the backing is wound so that two millimeters remain to the edges of the side. After this procedure, a spool with wound fluorocarbon is removed and worn empty, on which the thread is wound, only in the reverse order. first backing, then a nylon worker.