Trimmer does not develop full power cause

The gas generator does not provide full power for reasons

Is your generator not delivering full power? Lost in conjecture, what are the reasons for this? And is it possible to fix it all on your own?

The reasons for this can be from the most banal things, ending with where it is impossible to cope without the hands of a specialist. If you have exactly the situation where you cannot do without an experienced master, please contact us at “Rem Tech Service”.

We will promptly identify the cause and eliminate the malfunction. Call by phones: 063 202-90-70, 097 023-42-42.

What are the reasons that the gas generator does not give out full power, and how can you try to eliminate them yourself

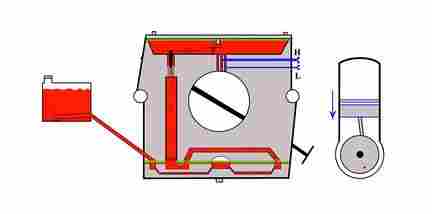

- One of the most common reasons that may be is obsolete fuel. You can try to drain the fuel from the tank and refill it. Also, you should make sure that the fuel comes normally from the tank (for this you need to remove the hose from the gas tap, open the tap and make sure that the fuel is running normally) Try to start the generator.

- If this was not done, and the generator still does not produce the declared power, it is possible that there is not enough fuel, because the carburetor is clogged. It is necessary to clean the air filter and clean the carburetor. First, you need to blow out the air filter (if it is heavily soiled, then wash it in a detergent). Next, we remove the carburetor, clean it, assemble it and try to start the engine again.

- In the event that the generator again does not deliver the declared power, then the problem may be in the incorrect adjustment of the valves.

- If everything is in order with the adjustment of the valves, and the gas generator still does not give out full power, then it is worth checking the condition of the spark plug. The color of the carbon deposits on your spark plug after the generator is running should be brick brown. If it is black and does not burn well or is too white, this means that the mixture is too lean and there is not enough fuel.

Also, important is the fact that you should pay attention to the sticker on the generator, it may not correspond to the actual power of the generator.

If the above attempts to eliminate the malfunction did not work out, there is a possibility that the cylinder-piston group is affected, then it is not possible to do without professionals.

Our masters are always ready to help, call by phone or leave a request for repair on the website.

Dirty air and fuel filters

If the first of them is clogged and does not allow air to pass through well, the mixture will be too rich, that is, there will be a lot of fuel in it, which will stop burning completely. As a result, the engine thrust will drop. If the fuel filter is dirty, the result in terms of the operation of the power unit will be the same, with the only difference that the mixture will become very lean, since there will be little gasoline in it. Premature contamination of the air filter can be caused by the operation of the machine in dusty conditions, and the fuel filter can be caused by poor fuel quality.

Exhaust system resistance

Many consider the only task of the exhaust system to muffle loud sounds and remove exhaust gases. However, in modern cars, a catalyst is installed to reduce the level of emissions of harmful substances. With severe contamination of this element or its destruction, the passage of gases is impeded. As a result, the motor works “like a strangled”.

In Russia, the problem is solved by the elementary removal of the catalyst. However, it must be remembered that in some car models such an operation will require changes in the electronics (programming).

Malfunctioning spark plugs

The planned replacement of these elements of the ignition system is carried out after 20-30 thousand km of run. If the candles are platinum, the resource increases to 100 thousand km. However, the situation when candles (most often one of them) fail ahead of schedule is not uncommon.

You can see and hear this for a number of signs:

- the engine starts with difficulty, especially in winter;

- idling is unstable, the tachometer needle jumps, the motor may stop periodically;

- when the power unit is operating, increased vibration is observed, for example, the gearshift lever is shaking;

- weak acceleration dynamics. the car does not develop its full power, “dulls”;

- when you press the accelerator, “dips” are noticeable;

- fuel consumption increased.

When one spark plug does not work, experienced drivers say that the engine is “troit”, that is, out of 4 cylinders, only 3 work.

To find a faulty part, you need:

- wear dielectric rubber gloves;

- with the engine running, disconnect the high-voltage wire from each candle one by one;

- at the same time, the nature of the engine should change, the speed should fall, but if this did not happen, then the cylinder does not work. the candle does not form a spark.

It is worth finding out the reason for the poor performance of the part, it is quite possible that it is defective. If later other candles begin to fail, you will have to look for the reason elsewhere. the CPG or the fuel system.

Reduced compression

Often, the reasons for the loss of engine power can be associated with the banal wear of the power unit. Do not forget that a car at the age of about 100 thousand kilometers begins to lose its power by 10-15%. If you think that the loss is excessive, you need to check the compression. Its nominal value is indicated in the documentation for the machine. For testing, you will need an inexpensive device. a compression gauge, which is a pressure gauge attached to a hollow tube or connected to a rubber hose equipped with a tip. It is screwed into the cylinder block instead of a spark plug. Next, disconnect the high-voltage wire from the ignition coil. Crank the crankshaft with the starter and read the highest compression gauge reading. The operation should be repeated for each cylinder.

Compression check

A pressure lower than that specified in the instructions by more than 15% indicates worn out rings, pistons, cylinder block walls, valves. To solve the problem, you can bore the BC to the overhaul size, replace the piston rings, grind (or replace) the valves.

Violation of valve timing

The main parts of the gas distribution mechanism (timing) are intake and exhaust valves. They are “obliged” to open and close only at the right time, so that the fuel mixture enters the cylinders on time, and the exhaust gases are removed. This process is called phase distribution. If you break it, you will see that the engine power has disappeared, which will start to “triple”, and sometimes it will not start well.

The reasons for the violation of the valve timing:

- wear, as well as improper installation, displacement of the chain or timing belt (most often this is a jump by one tooth (link));

- play or deformation of the pulley on the crankshaft;

- wear of hydraulic lifters, camshaft and (or) its bed;

- burnout or rupture of the BC head gasket;

- malfunction of the camshaft position sensor (DPRV).

To restore normal operation of the timing, it is necessary to set the position of the timing shafts and the crankshaft according to the marks. If the chain is worn out, replace it. The same applies to the camshaft with bed, hydraulic lifters, gasket and DPRV.

Adjusting the UOZ on an injection engine

Everything here is controlled by electronics. First you need to make sure that it is working properly and that the throttle sensor is working. At idle, it should be slightly open by about 1% (if this is not the case, adjust the mechanical drive), the normal voltage at its contacts is 0.45-0.55 V (the auto’s bot network should give out 13-14.3 V). With a sharp press on the gas pedal, the damper should open to 90 “, and the voltage on the sensor should rise to 4.5 V. If this is not the case, you need to adjust the damper drive and check the sensor’s serviceability (DPDZ).

Trimmer power loss at full throttle

To do this:

- take the tester and put it in the voltage measurement position;

- disconnect the connector from the sensor. you will see three contacts. one goes to ground, the other to the computer (which one is connected to, determine according to the diagram);

- start the engine and check the supply voltage. it should be about 5 V;

- turn off the engine and switch the tester to resistance measurement mode;

- with the damper closed, between the ground and the contact going to the computer, the device should show 0.8-1.2 kΩ;

- with open damper, resistance. 2.3-2.7 kOhm.

If the obtained data does not correspond to the above parameters, the sensor must be replaced. If this does not work, you should check the ECU.

Low-quality fuel

In about 50% of cases, the “culprit” of the loss of thrust is fuel. Due to its poor quality or unsuitable octane number (RON), the engine does not develop power.

It is possible to determine that the fuel in the car tank is unsuitable by a number of signs:

- The engine starts to start worse.

- Detonation appeared. This symptom is most pronounced if the fuel with the required octane number has been diluted with gasoline with a lower RON.

- When inspecting spark plugs turned out of the cylinder block (BC), you can see carbon black or reddish (brick) uncharacteristic for serviceable parts, which indicates the presence of unnecessary impurities. The first option indicates that gasoline does not burn completely, the second confirms the presence of additives containing metal.

- Inefficiently working candles. This can be determined with a sharp increase in speed, when the engine has no room for further acceleration. Candles can be clogged due to low-quality fuel or simply worn out.

It is not difficult to solve the problem: low-quality fuel should be drained and the tank filled with a suitable fuel with the required RON. Clean the candles of carbon deposits, and if their service life has come to an end, replace them with new ones, all at once, in a set from one manufacturer. If carbon deposits appear, you will again have to deal with diagnostics of the cylinder-piston group (CPG) and (or) the fuel system.

Candle

In case of problems with the candle, sometimes it is enough to dry it or clean it with sandpaper and put it back in place, setting the gap correctly. it should be 1 mm. If the candle is heavily soaked, it is better to replace it with a new one. With optimal trimmer operation, the candles do not fail so often.

Little tricks

- If you are unable to tighten / loosen the adjusting screws properly, it may be that the spring is too thick and stiff. Then you can choose instead of her a more suitable.

- If your unit does not need pure gasoline, but its mixture with engine oil, strictly observe the proportions specified in the operating instructions. There is one little thing: the recommended ratio is 1: 25 (for all brands of oil) or 1: 50 (for “native” oils). Try the first ratio first. If, with such a recipe, oil drips appear on the motor, and a strong carbon deposit forms on the candle, reduce the proportion of oil by half. This usually helps to fade traces and reduce the amount of carbon deposits.

- To clean the spark plug electrodes from combustion products, you can use fine-grained “sandpaper”. Wipe them down with a dry cloth first and then gently sand them with sandpaper. If the space between the body of the device and the insulator is also clogged, a regular unbent paper clip can help clean it. To do this, briefly soak the candle in diesel fuel, and then scrape off the dirt. If the blockage is small, one procedure is sufficient. In case of heavy dirt, it is sometimes necessary to repeat it several times. After complete cleaning, the candle must be wiped dry from the remaining diesel fuel, and then it can be used as directed.

- Please note that foreign-made lawn mowers (gasoline, electric or battery) require a little more maintenance than domestic ones. In particular, many strongly recommend entrusting the adjustment of the carburetor of a two-stroke engine to professionals, especially if your purchase has not expired the warranty period.

- And finally, one more tip: follow all the manufacturer’s recommendations for the operation and maintenance of the device. This will prolong its smooth operation.

You will learn more about what to do if the petrol trimmer is not picking up speed.

The modern market offers a wide range of electric and fuel-powered trimmers from various manufacturers. The equipment may malfunction. For example, insufficient speed. Do not panic about this, since the problem of insufficient speed in lawn mowers, trimmers is quite common. There are several reasons for this.

Features of the trimmer

All trimmers are classified by type of power: gasoline or electricity (mains or battery). It should be noted that gasoline mowers are superior in many respects to their electric and battery counterparts. While they all perform similar functions, the differences in performance, agility and efficiency are very noticeable. However, the general principle of operation of all types of hand-held mowers is almost the same. the devices are equipped with motors (two- or four-stroke internal combustion engines or electric motors) that drive the cutting unit (a spool with a fishing line or a metal disc). All elements are fixed to a straight or curved bar, including a trimmer handle, on which the main buttons are located.

Since the problem of low revs is more common with petrol trim options, they will receive more attention. So, the lawn mower is very comfortable to work and unpretentious in maintenance. over, most of its malfunctions are caused by the user’s ignorance of elementary things, which are written about in the instructions. Therefore, before starting to operate the unit, you must carefully study the manufacturer’s manual. In particular, to start the engine, the following steps must be taken:

- turn on the ignition button;

- press the silicone button several times to pump gasoline;

- close the air damper;

- set the throttle lever to the high speed position;

- first make light jerks with the starter handle to feel the resistance of the engine, then jerk sharply.

If the lawn mower starts but stalled, you need to set the choke to the middle position and try again. When the engine starts up, you need to slow down the gas and open the air damper, since the trimmer functions only on suction.

Important! Trimmer operation depends on various environmental influences. In hot weather, the unit should be given more time to cool down. When operating in dense thickets or high vegetation, the engine also overheats. It is necessary to take five-minute breaks every 15-20 minutes.

Filters

A clogged air filter is another reason for the unreliable operation of the device. To check the involvement of this element in the malfunction, you need to start the lawn mower without it. A dirty filter can be washed in gasoline, dried or replaced with a new one.

A clogged fuel filter does not allow fuel to enter the cylinder, and the engine stalls at full throttle due to an elementary shortage of gasoline. This element is located inside the tank on the intake hose. To fix the problem, instead of the old filter, put a new one on the hose or thoroughly rinse the one that was removed.

Advice! If you try to remove the plug in the tank, the hose and filter may fall into the tank. You can get them with tweezers.

How to start a Stihl lawn mower

The main steps for starting a Stihl lawn mower are:

- Before using the petrol trimmer, you should read the instructions and check the Stihl trimmer for the presence of each spare part. Then you can collect it.

- An important step is fuel preparation and refueling. You need to prepare the mixture in a measuring container. Gasoline and oil are poured into it in the specified ratio. Using a funnel, the mixture is poured into the fuel tank.

- When starting for the first time, turn on the ignition without opening the choke. Place the device on a flat and smooth surface for stability. Now. you need to sharply pull the cord 3 to 5 times. The air damper can be opened in any case: the engine has started or not.

The first start may require up to 15 jerks. After starting the engine, it is worth turning on idle to warm up. After a while, it is stopped with the Stop button.

Note! This instruction is universal, as in order to start the Stihl lawnmower, you need to follow the same steps.

In the case of starting an electric trimmer, everything is much simpler: you need to read the instructions and act in accordance with it. Instead of fuel, there is electricity. The appliance is powered by mains, so it is important to provide sufficient power to allow the trimmer to rev up.

Both the petrol and electric trimmer require a thorough inspection after each use.

By following the instructions, you can quickly fix any minor damage yourself. But sometimes it is not possible to start the unit with your own hands. In this case, it is better to seek professional help, especially if it relates to a problem with the engine and the development of rpm at the trimmer or lawn mower.

Any person who owns a summer cottage or land plot is well aware of the problems of dealing with excess vegetation. Now a trimmer has come to the rescue, which has successfully replaced the usual braid in this field. This unit is very convenient in operation, but it, like any mechanism, tends to fail due to difficult working conditions or incorrect operation. Situations when the trimmer does not pick up speed are quite common. To understand this problem, it is necessary to understand some aspects related to the operation of the apparatus.

Causes of Slow Trimmer RPM

If users complain about the trimmer that does not pick up speed, it means that it works fine at idle, and when you press the gas, it does not develop the necessary power. This can occur as a result of a long idle device without activity. These problems are typical for gasoline vehicles, including Husqvarna 128r, Stihl FS 38 and Hitachi of various modifications.

When working with the trimmer, you need to monitor its behavior all the time. a drop in speed and unusual noises signal a malfunction in the unit. Sometimes you give the gas, and the trimmer floats. In such cases, the work should be immediately suspended, the mechanism should be allowed to cool down and the search for possible problems should be started. They can be of a different nature, both a technological plan and external factors associated with the conditions and features of the operation of the apparatus.

Engine problems

Engine problems are more serious. Several variants of the problem are possible:

- damaged carburetor;

- drive problems.

In the case of a carburetor problem, you should first pay attention to the condition of the cable. It may be weakened and this is the cause of the problem. This requires a simple cable adjustment.

If this does not help, then you need to check the usage parameters. The stated operating standards can be found in the technical data sheet of the device. Sometimes it is enough to disassemble the device: wash, clean and assemble.

Note! The solution to the problem with the carburetor can be the purchase of a new element or contacting the service for professional services.

The trimmer drive is fully checked only if manipulations with the carburetor did not give the desired result.

Troubleshooting methods

The first three reasons are fairly easy to eliminate. If the matter is in the mixture, you need to pour out the old fuel from the tank, prepare a new emulsion from high-quality gasoline and engine oil (if your engine requires a mixture) and pour it into the fuel tank. If the trimmer is running on clean gasoline, it’s even easier.

In the second case, it is necessary to carefully free the trimmer parts from the wound grass.

If the filter is clogged, you can try rinsing it. If this procedure does not bring any effect, replace it with a new one.

The last reason a lawn mower doesn’t work properly will require a little more knowledge and skill from you.

To properly adjust the carburettor for lawn mowers, a specific procedure must be followed. First, clean the air filter thoroughly. The easiest way is to rinse it (it is advisable to douse the filter with water regularly after 9-10 hours of operation).

After that, in the diagram of your trimmer, which is in the instruction manual of the device, find the adjustment screws. There are usually three of them: the first is responsible for fuel supply, the second is for idling, and the third is designed to limit the number of maximum engine speed.

Next, turn on the unit and wait for the engine to warm up.

Tighten the first (fuel mixture) adjusting screw slowly. Catch the moment when the motor starts to stall and turn the propeller back 45 degrees. If you did not have time and the motor stalled, the screw should be turned 90 degrees. Open the throttle and watch the revs increase. Next, slowly unscrew the screw (each turn is the same 45 degrees) until the moment when, at full throttle, the engine begins to firmly give out maximum revolutions.

The second screw, as mentioned above, controls the engine idle speed. By loosening it, you decrease the number of revolutions, while twisting it, you increase it. The screw needs to be adjusted so that the motor runs reliably at low revs. For better starting, speed up the engine slightly. At the same time, make sure that the motor rotates several tens of times before starting the movement of the knives / line reel. If the engine starts poorly, tighten the screw a little.

After you have adjusted the first two screws, test the operation of the unit at maximum engine speed. If necessary, you can limit it (maximum). this will protect the motor from “boiling”. To do this, you need to tackle the third screw. Unscrew the locking nut until the adjusting screw can be safely turned. To increase the maximum number of revolutions, the screw must be loosened, to decrease. on the contrary, tighten. Fix the position of the screw with a nut. Test the motor again.

Check the position of the screws regularly. the high vibration levels of lawn mowers can cause them to move unintentionally.

Remember that carburetor adjustment is not a final procedure. During the operation of lawn mowers, you will most likely have to tinker with it more than once, because an unbalanced carburetor means both increased fuel consumption and a quick failure of the candles, not to mention a decrease in the power and performance of the device.

Main causes and remedies

If the motor does not develop full power and there is a drop in this indicator from 20%, you need to immediately take action.

The main symptoms can be:

- sharp dips during overclocking;

- when you press the gas, the car does not react immediately;

- oil and fuel consumption increases;

- the engine is picking up speed, but no acceleration occurs;

- the car moves at reduced speeds and does not pull uphill.

The main reason is poor quality fuel. The solution is simple: change the fuel and never go to this gas station again.

Failure of sensors can force the car into a gentle, emergency mode.

Errors are usually indicated by an orange or yellow motor-shaped pictogram.

In any case, it is worth stopping, opening the hood and checking the condition of all units. Whether there are any leaks of liquids, conduct a visual inspection, check the temperature of the mechanisms.

Stop moving and call for help.

If compression falls, this is a sure sign of piston wear. The gases will enter the crankcase and cause high oil consumption, which is very expensive. In this case, you can replace parts or toil with the engine ad infinitum. The engine device is a complex mechanism, without knowledge, experience and unlimited patience, it is better not to try to fix it yourself.

In this case, everything must be done as quickly as possible, until the pistons are made of ellipses from the rings. Then the repair will be much cheaper. After minor intervention of the auto technician, the engine power will increase, the oil consumption will decrease and there will be a feeling of a new car.

Clogged air filter can also be the cause. Oil filters were installed in old domestic cars, dry filters are used in modern cars. Replacing the cartridge takes literally a few minutes, you can easily do it yourself or contact a car service.

When the clutch is worn, the engine revs up, but no power is transmitted to the wheels. Riding uphills becomes more difficult, unpleasant odors may occur in the cabin.

I-Service

The engine is the heart of the machine, its power and sound. In case of minor problems, you can handle it yourself. But if a serious problem has arisen or you do not want to do all this, you cannot do without the help of specialists. In our service, we will provide any help to your “iron friend”. We employ top-level specialists, we provide only reliable parts from trusted suppliers: original and analogs.

All are presented on the website and do not change. We carry out the work quickly, efficiently and inexpensively. A guarantee is provided for all types of services. They come to us again and bring friends.

Engine does not develop full power

Motorists sometimes face this problem when the engine is not delivering power. This feeling is very unpleasant. The car becomes sluggish, as if something is holding it. In high altitudes, power loss is normal. Under normal conditions, the reasons can be different.

Engine wear can be a natural cause, this happens to all cars, and it cannot be avoided. In normal mode, the process is smooth and almost imperceptible. In abnormal situations, power loss is a bad signal that something is out of order.

Each car has its own mileage before engine overhaul, for maintenance, regulated maintenance, replacement of fluids and additives to extend service life. It is necessary to regularly undergo maintenance, the recommended period is: every six months.

If the problem has arisen abruptly, then the problem is different. Loss of power can happen at the most inopportune moment, for example, when overtaking. And this can be a threat to life not only for you, but also for other road users.

The first thing drivers do is check to see if the parking brake is pressed. Next, you need to pay attention to the dashboard, check for engine errors.

Natural causes of reduced power

If the engine starts to behave inadequately under certain conditions: extreme heat, increased air humidity (for example, in the mountains), this is not a cause for concern.

When the air is rarefied, the engine requires more oxygen, but it is not available in the required amount, so a drop in power occurs.

Due to low-quality fuel, various additives for it, when the temperature rises, fuel vaporization occurs in the gas pump, the fuel stops flowing, the carburetor overheats, and incorrect mixture formation occurs.

The main causes of power loss in carburetor engines

The reason for the decrease in power may be:

- improper mixture formation: the mixture may be lean, or it may be over-enriched: clogged nozzles, jammed dampers, incorrect fuel level in the float chamber, disruption of fuel supply;

- poor sparking: the ignition settings are out of order, problems with high-voltage wires, wear and tear on the spark plugs, breakdown of the ignition distribution cover and wear of its elements;

- malfunctions in the electronic ignition system: failure of the switch, Hall sensor, fuse;

- air leaks: it happens when gaps in the fuel and air systems are formed, cracks occur;

- lack of vacuum in the carburetor and intake manifold. If in manifold, remedy: replace gaskets between engine and manifold.

For diagnostics, you can exclude the reasons one by one or go through those. inspection in a specialized service.

Trimmer does not develop full power cause

Lermontov 12, 400078, Volgograd

avtovolgograd@gmail.com

7 937 091 7077

Or write to us

Car service, which provides a full range of automotive services, including legal.

- In contact with

- Google Reviews

- Yandex Reviews

Service station I-Service

than ten years in the automotive services market with the possibility of cashless payments, the possibility of concluding contracts and a guarantee for services.