Which orbital sander to choose

What to evaluate when choosing

There are 2 main parameters:

- Speed. Similar to tape models. adjustment limits.

- Depth of processing. Such machines are excellent for working with samples, on the surface of which there are significant differences in height. For example, after drying the material, if it was organized in violation of technology.

Starting.

How to choose a reliable wood sander. all parameters and types

The processing of most types of wood, due to its not too dense structure, is not particularly difficult. But if it is necessary to achieve high quality, to prepare the material for subsequent coating (for example, with varnish), then you will have to spend a lot of time and effort using only traditional methods (plane, file, sandpaper). Unfortunately, not every home has a wood sander.

And first of all, for the reason that not everyone is familiar with its capabilities. This article will not only help you understand that a good owner really needs a wood sander, but also tell you how to choose it correctly.

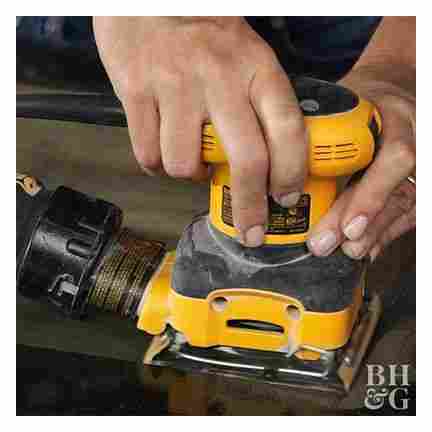

Vibration type CMM

Sanders of this type are used for surface finishing. It is advisable to purchase them when the quality of grinding is a determining factor. For example, when restoring furniture before covering the wood with wood stain and varnish. Such work requires special care, since the smallest defects are clearly visible through the applied transparent layer.

Modification of vibrating CMM. a machine with a deltoid working part. Its application is specific. wood processing in corners, grooves, grooves and the like, so they are rarely used in everyday life. But if the owner deals with wood processing all the time, then you should pay attention.

What to evaluate when choosing

- Grinder power. For the category “household tool” 1 kW is sufficient. is unlikely to be needed.

- Speed regulation range. The larger it is, the wider the scope of application of the grinder. Such CMM work with all types of “skins”, therefore, they are suitable for processing various materials. metals (removing rust, preliminary polishing), wood (stripping, cutting off the remaining knots, etc.).

- Linear parameters of the tape (mm). For household models, the standard width is 76, but along the length there is a certain size range (standard). 457, 533 and 610. The last samples are larger, but with their help it is more convenient to process workpieces such as a board, log, timber or flooring with a large area.

- Centering mechanism. In the process of work, the tape is constantly shifting (“leaves” from the rollers), and it has to be periodically corrected. The presence of a special device greatly simplifies this task, since the adjustment is carried out automatically, and you will not have to spend time on it.

Starting.

Useful Tips

Practice shows that if the rules for choosing a grinding machine are basically clear to everyone, then you cannot say the same about the criteria by which an abrasive cloth is evaluated. It is this question that confuses many.

Examples of

“Makita” (series 9741). power 0.86 kW; brush diameter 13 mm; number of revolutions. up to 3,500; weight 4.2 kg.

“Makita” (AG1014P). low-power equipment (1.4 kW) with a speed of up to 3000. Weight. 3.3 kg. Accordingly, and.

What can be done with similar models?

- Removal of foreign deposits (scale, rust, oxides).

- Removing a layer of old paint.

- Cleaning of wooden surfaces (plank and parquet floors, external walls, etc.).

With certain skills, brush grinders are used to artificially age wood products.

Brush models

They are distinguished into a separate group, although this is just a type of tape CMM. The working tool is a shaft-mounted brush that does the roughest work.

How to choose a grinder: professional advice

We devoted our previous articles to screwdrivers, angle grinders, chain saws, jigsaws, mixers, spray guns, cross-cutters, jackhammers, perforators. Today, all our attention will be focused on the tool, wielding emery.

- Belt Sanders

- Surface grinding (vibration) machines

- Eccentric (orbital) sanders

- A few general tips for choosing

To grind or age a wooden part, remove paint and varnish, remove rust, grind off burrs, rub down putty, process plastic, polish a stone. all this and much more can be done with modern grinding machines. So, we offer the slogan: “Choose a grinder with us, choose like us, choose better than us!”

Grinding: This process is unpleasant for many, even at the mere mention of it. What can you say, grinding is a monotonous, time-consuming, laborious, dusty, sometimes noisy, slightly harmful operation, but, unfortunately, inevitable. Modern requirements for finishing work have reached unprecedented heights, no one doubts the fact that the planes should be perfectly flat and smooth. Finishing high-tech coatings are increasingly striving for a thin layer and only emphasize the shortcomings of the base. Even enlarged, with a ready-made decorative coating, sheet building materials have to be connected, followed by filling / puttying or sealing of the seam, followed by grinding. Domestic builders, finishers and shop workers (manufacturers of furniture, “carpentry”, stone products, bulk polymers, metal) are slowly but surely getting used to new standards, previously unknown.

Fortunately, the materiel has not lagged behind for long: a highly specialized, relatively inexpensive tool. grinding machines, which we cannot do without, helps the workers to cope with the task at hand. The painfully familiar emery, fixed on a wooden block, or squeezed in the hands, remained in the past. The foremost workers of capitalist production have produced a lot, a lot of wonderful professional grinding machines designed for any occasion, not depriving the attention of home craftsmen. those who like to create something with their own hands. It’s really easy to understand the variety of grinders and make the right choice, the main thing is to know what a particular tool is intended for, and also clearly understand what tasks you will set for a grinder.

It is customary to distinguish between three main types of grinding machines: belt, eccentric (orbital), surface grinding (vibration). All of them have their own specialization and form a kind of cascade of possibilities, directed from fast rough processing to delicate finishing sanding. Many of those who are closely related to grinding “on duty” have in their arsenal a complete set of tools of this class. Belt sanders are heavy artillery for removing large layers from large surfaces. FSHM are focused on finishing. And ESHM are able to give an even higher quality result, bordering on polishing, but, in comparison with vibration machines, they have a different principle of operation and a different filling.

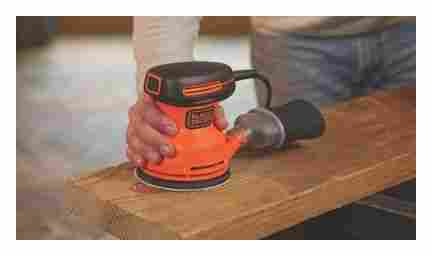

Eccentric (orbital) sanders

This type of grinder is designed for high quality processing. Delicate sanding and even polishing is their element, although the performance of such machines can be no less impressive than that of vibrating machines. They will cope with any material, most often you will find ESHM at wood craftsmen, car painters. In work with profile, volumetric, curved objects, eccentric grinders have no equal, they also have no problems with planes. The only place where such a machine will fail is in the corners and shallow recesses. the “plate” simply cannot reach there.

As well as surface grinding units, “orbitals” have an eccentric and a counterweight, with the help of which a circular grinding plate performs not only movement around its axis, but also in an “orbit” with a small amplitude. Interestingly, the axial movement usually occurs by inertia, and in some models, it is forced (by means of a gear transmission. Kress 900 MPS). Such a complex movement of the working blade, coupled with the highest rotation speed, just allows you to get a surface of excellent quality, without grooves, waves and scratches.

From 200 to 900 watts. this is how much the motors of modern ESHM consume. Those that are more powerful, of course, will be more productive, they can easily pull the sole larger, up to 150 mm in diameter (for example, 400-watt Bosch GEX 125-150 AVE or Interskol EShM-150 / 600E).

Bosch GEX 125–150 AVE

Orbital vehicles also have differences in the speed of their translational motion. If we talk about rotation, then this figure can be from 4 to 14 thousand eccentric revolutions per minute for models with adjustment (Metabo SXE 425), and about 12,000 for models without it. If we talk about the concept of “fluctuation”. then these figures will be half. In fact, everything is simple here, the higher the speed, the rougher the processing will be, but the faster you can get the job done.

Metabo SXE 425

The eccentric of orbital machines may not have the same “span”. from 2 to 7 mm (Festool WTS 150/7 E-Plus). This is called the wobble amplitude. The smaller it is, the less vibration the device generates, the more compact the plate goes, the smaller the area we process, but the cleaner the grinding will be. In some ESM, the operator can set a certain amplitude, affecting the productivity and fineness of grinding.

Compared to their counterparts (LSHM and PSHM), “orbiters” are usually well stuffed with electronics. We have already talked about setting the speed and amplitude, in addition to this, the professional tool is equipped with an automatic frequency control system (Bosch GEX 150 Turbo) so that it does not fall under load. this is a constant electronics. Some models are equipped with an electrodynamic brake (AEG EX150ED K), which, after the start button is turned off, instantly locks the work plate, preventing damage to the workpiece and reducing the possibility of injury. For powerful professional machines, an inrush current limiter (Makita BO6040) can be provided, which smoothly accelerates the tool, avoiding a starting jerk and protecting the network from a short-term, but several times increased load.

Makita BO6040

Very nice options include a detachable power cable, an adjustable or detachable front handle, locking the start button, functional dust extraction.

Be sure to pay attention to the type of sanding pad. Firstly, if you need a particularly delicate treatment, do not chase after a large cymbal, by the way, it has a larger dead zone and an amplitude of about 5–7 mm. The slab made of metal is stable, highly durable and has excellent heat dissipation. The resilient saucer works well with curved surfaces. All of them have Velcro for fixing the emery and dust suction holes. These holes from individual manufacturers may be different in size, number and location, on this basis, you need to select the appropriate equipment.

Random Orbit Sander Buying Advice

A few general tips for choosing

If the financial issue is not the least important, then for a home workshop, you can purchase a model from the category of “hobby”. Quite good copies are offered by Makita, BlackDecker, Skil, Sparky, Bosch. Look in the direction of the domestic manufacturer. “Interskol”, “Fiolent” have noticeably improved in terms of the quality and functionality of their tools.

Pay attention to the weight and dimensions of the product of interest, especially if a lot of work is planned “in place”, by weight, with outstretched arms. Give preference to a not too powerful car, but a faster one, it will be lighter, more compact and cheaper. But for the regular performance of operations on the workbench, the large weight of the device will be more a plus than a minus.

Be sure to thoroughly “feel” the grinder, find the most suitable for you in terms of ergonomics. Decide on the type of main and additional handle, most likely you will have to choose between “mushroom” and “bracket”. See if the switches are conveniently located and how they work, how easy it is to change accessories, if the power cord is getting in the way.

Weigh all the pros and cons, do not rush to make a choice, then all repairs will go smoothly.

Surface grinding (vibration) machines

If we take into account the cleanliness of the processing of parts, then surface grinders occupy an intermediate position between belt and orbital. With their help, they carry out the finishing grinding of flat surfaces made of a wide variety of materials. plastic, wood, stone, metal. Due to the relatively large working plane, the PSHM is suitable for working with serious quadrature. The secret of the popularity of vibrating grinders lies in their moderate cost, accessibility of tooling elements, as well as in the absence of dead zones of processing (a flat outboard sole easily handles corners).

The main working body of a surface grinder is a plate, which, with a small amplitude, makes frequent reciprocating movements. The motor in such machines is located vertically, which makes it possible, using the “eccentric-counterweight” tandem, to translate the rotational movements of the shaft into translational movements of the platform.

Most vibration grinders traditionally boast a motor with a power of 150-300 W, they are quite maneuverable, moderately light and compact. This level of power plant is almost always sufficient. However, such a consensus among manufacturers would be at least strange. there are models with a capacity of up to 600 W (Makita 9046). They are, of course, heavier and larger, but they can work for a long time without overheating at low speeds.

Makita 9046

The most important indicator of the PSHM is the amplitude of the sole stroke. In different models, it can vary, although it is invariably a relatively small value. On average in the class, the platform moves by 1–3 mm, in more mobile models, figures of 5–6 mm may appear (Festool RS 100). A large amplitude helps to sand the surface faster, but this treatment will also be coarser.

Another nuance is the stroke rate of the sole. At high speeds, the machine quickly removes a relatively thicker layer, while at lower speeds it is easier to achieve a precise finish sanding. Some manufacturers make the platform movement frequency variable, exceeding 20,000 strokes per minute (Bosch GSS 280 AE L-BOXX), which allows you to adapt to the processing of various types of materials, to the characteristics of specific surfaces.

Bosch GSS 280 AVE

When choosing a vibratory sander, special attention must be paid to the platform. With its dimensions, everything is quite simple, there are two options: a kind of “standard” and “mini” models. the area of the plate is about 100 mm 2 (Makita BO4557, Sparky MP 250). Toddlers are good for tight, tight spaces. Obviously, the sole must be of high quality, perfectly flat, with clear geometric shapes. Budget cars are equipped with a platform made of steel or high-strength plastic, and more expensive analogs are equipped with cast platforms made of alloys with m aluminum or magnesium (Festool RS 100). A good sole is characterized by accurate balancing, which is easily determined by low vibration when working without load (idle). It is important what the pad is made of, the most suitable option is a porous polymer, it is better than rubber, it “holds” the plane.

Makita BO4557

Vibrating grinders with a deltoid platform are distinguished into a separate class; they are popularly called “iron” (Hitachi SV12SH, Makita BO4565). Due to their miniature size and good “cross-country ability” they are used for processing objects with small details and complex surfaces, such as furniture, woodwork, elements of stairs, car body. Their triangular platforms are rotatable. you can continue to work with an uneven “eaten” emery petal (Festool Deltex DX 93E) or removable (with a quick installation of another type of platform. for concave / convex surfaces, for structuring, polishing, rubbing).

Festool Deltex DX 93E

Emery can be attached to the site in different ways. It is more convenient when the paper is fixed with Velcro, but special equipment is relatively expensive. The version with spring-loaded clamps is somewhat more complicated, but you can use inexpensive sanding paper, cut with your own hands (you just have to make holes in the right places for dust extraction).

Dealing with fine dust, which inevitably forms when using a sander, poses many challenges for developers. They have to work hard to protect all mechanisms. In this case, a special sealing of the motor, protected bearings and switches, an impermeable housing, a system of channels with a forced dust extraction are used. So that dust is removed from the working area and does not saturate the air, it is sent to a collection bag or filter, in most cases a vacuum cleaner can be connected to the nozzle. this is the most effective method of protection.

Belt Sanders

Above, we inadvertently called the belt sander heavy artillery, in fact, it would be more appropriate to say “tank”. The working element of this highly recognizable tool is an abrasive belt, glued together in the form of an endless ring, which moves along two end rollers and clearly resembles a tracked vehicle track. Such units are relatively powerful, they have a relatively simple, reliable design (bevel gear plus V-belt transmission), a low center of gravity, and a solid speed of movement of the abrasive material. With a belt sander, you can easily remove a layer of material a few millimeters, make an edge or rounding on a workpiece, remove old paintwork or rust. She is subject to: wood, metal, polymers, mineral building materials. Clean the floors from paint. yes, correct the planed timber. please, align the plastered wall with the marriage. no problem. However, it should be understood that high performance is not the best friend of quality, there will certainly be scratches and sinks. For finishing sanding it will be necessary to use an orbital or surface sander.

It is no secret that the power consumption of its motor directly affects the performance of an electric tool. the higher it is, the more we can squeeze out of a particular unit. In the case of LSHM, the consumer has the opportunity to choose from models with a motor from 0.5 to 1.2 kW (Skil Masters 7660MA. 1200 W).

Skil Masters 7660MA

Please note that the instrument of Chinese brands is often declared with overestimated engine power ratings, or, if there are indeed sounded watts, then they are not balanced with the rest of the device’s characteristics. Record power is praised by those manufacturers who have nothing more to show, except perhaps the great weight and bulkiness of the “unique” product.

The next characteristic that is important for a belt sander is speed. Obviously, it also needs to be considered to determine the capabilities of the instrument. A fast car will do more, but you won’t be able to pin it down unless the outstanding speed is backed up by extra power. It’s all to blame for the notorious torque, which says that the more speed the tool has, the less power remains for it. A responsible manufacturer carefully balances these characteristics, makes them mutually mutable, which is sometimes the responsibility of smart electronics. The speed of the belt in these grinders can be in the range of 150-550 meters per minute (Fiolent MShL1-100. 550 m / min.).

The question may arise, why even produce nimble, but relatively weak-powered LSM? It’s just that a super-productive (fast and at the same time strong) car is more difficult to control, it is heavier, larger, more expensive. With excessive pressure, it is easy to spoil the workpiece with it. In turn, maneuverable high-speed light weights are convenient in a short time, often “on site”, to process a large surface area. If you do not yet know what loads await the grinder, choose a slower model that you can apply a little pressure on, so it will be more versatile. Even more versatile are LSMs with the ability to preset the speed mode (Sparky MBS 976, DeWalt DW433). Among them there are options with smooth or step adjustments.

DeWalt DW433

It’s time to say about the electronic systems that help in the work of belt sanders. These machines are not rich in electronic stuffing, compared to other types of electrical tools. This is usually limited to adjusting the belt speed. The switch responsible for this function is performed in the form of a slider or a wheel with divisions. There are models with overheating protection (Metabo BAE 75). With some stretch, this includes the function of fixing the start button in the on position.

Much more interesting is the case with mechanical “bells and whistles”. The kit may include a stand or special clamps designed for stationary fastening of the tool (very convenient for processing small parts). The sanding frame serves as a kind of stop that helps to avoid damage to the workpiece. A rip fence or miter fence is useful for a precise bevel or flat, parallel surface. The thin front roller in some LShM (BlackDecker KA88) has a small diameter, which minimizes the dead zone in the inner corners. Automatic centering of the belt (the tricky barrel shape of one of the rollers) does not allow the latter to treacherously slide at the most inopportune moment. An additional handle with a variable inclination or removable will significantly increase the functionality of the machine in “clamped” places. sometimes noticeably.

BlackDecker KA88

Special attention should be paid to the dimensions of the working plane. the sole, respectively, the length and width of the tape. Wide soles (100 mm) are characteristic of powerful professional shoes, making them more stable and productive. The hobby class is usually limited to 75 millimeters. The long and wide sole of expensive LSHM has a complex structure, consisting of a substrate and an elastic plate, which allows you to have constant uniform contact of emery with the part, such a tool “holds the plane well”. It is necessary to mention the “ribbons” with narrow accessories. these are the so-called “electric files”, which do not differ in great power and versatility, but experts appreciate them for their unprecedented compactness (for example, Makita 9032 with a tape only 9 mm wide).

Makita 9032

The dust removal system is available in all draw frames, but not all of them work equally effectively. The fight against dust is carried out either with the help of a vacuum cleaner connected through the branch pipe, or by collecting it in a bag, built-in filter. Of course, a vacuum cleaner is preferable, especially when sanding mineral substrates. In super-cheap models, the impeller, which is responsible for air intake, cannot cope with its function, the channels quickly become clogged, a lot of harmful “flour” remains in the air.

Makita Trading. large selection of Makita

Professional equipment

Let’s take a simple example. Answering the question: “What sander to choose for the car?”, You need to know who is asking it. If this is a car mechanic working on a stream in a service station, then he needs a professional tool that can withstand serious loads.

The quality of materials for advanced technology, as well as the reliability of assemblies and electronics is noticeably higher than that of household counterparts. In addition, if you need to choose a professional-grade grinder, then be prepared to look closely at bulky, as well as powerful models, because a modest-sized tool simply cannot accommodate a high-performance engine on board.

BOSCH GSS 230 AE

This is a vibration machine from a well-known brand, and this series comes exclusively in a proprietary Swiss assembly. On the market you can find rare options from China, but the price, and at the same time, the effectiveness of the tool will be almost two times lower.

If you want to choose a sander for wood, then you should take a closer look at this professional model. The lower part of the body is equipped with a universal platform (92 x 182 mm), which allows you to attach the sheets both with clips and Velcro.

As for ergonomics and protection, everything is fine here too. Despite the practically bare handle, it does not vibrate during operation, and dust and dirt do not get on the operator. The grip is equally comfortable for right-handers and left-handers. The only thing that some users complain about is a very modest configuration, where, unlike other similar equipment, there is no interchangeable platform for bottlenecks and spare sanding sheets.

- good power (300 W) and performance;

- vibration during operation is practically absent;

- comfortable main handle and the presence of an additional one in front;

- reliable protection against dust;

- low noise level.

- ascetic equipment.

Eccentric (orbital) machine

As the main working tool, a special disk is used here, securely fixed to the body. He simultaneously performs both reciprocating and circular movements. Unlike an angle grinder, polishing and grinding becomes more efficient, high-quality and, importantly, convenient.

Consumable sheets can be attached to the sole in two ways. with a special clip or Velcro. The first ones are much cheaper, and more consumables are produced for them. But it is much more comfortable to work with Velcro, or rather, to change sheets. The whole process takes place in a matter of seconds, not minutes as with a clamp. The sheets themselves can be felt or foam sponges. Also with this tool many people use fur discs.

The answer to the question of which orbital sander to choose depends on the type of surface that needs to be processed. If you are working with wood or plastic, then you can choose simpler models. With it, you can also carry out the finishing treatment of already finished surfaces (paints, varnishes, putty, etc.).

If the question is, which eccentric sander to choose for metal and stone, then you will find the answer to it on the shelves with powerful, large, as well as expensive equipment. Using a cheap wood and plaster tool in this case will simply burn it.

Household equipment

Such a tool involves working on a case-by-case basis. If you want to choose a grinder for your home, then pay attention to the small-sized equipment. Such a tool is less powerful, lower performance, a modest set of additional functions, but much more attractive in terms of cost.

Household grinders are rated for an average of 10 hours of work per week. In addition, after 10-15 minutes of work, they need to rest for about the same time. You can choose a household-type sander if you have your own summer cottage, a garage with a car, or you are doing some kind of woodwork, of course, without looking at the flow.

Next, consider the classification of the instrument.

Features of using the tool

To answer the question of how to choose a grinder, first let’s figure out some of the features of using the tool. Here we will focus on household and professional appliances. The difference between the first and the second is very significant both in price and in capabilities.

DeWALT D26410

It is a professional yet highly efficient eccentric model. Due to the decent weight, the machine sits well on the surface and does not strive to slip out of your hands. Powerful 400 watt motor for reliable handling of coarse sandpaper.

The functionality of the machine allows you to switch from a coarse 6 mm vibration amplitude to 3 mm for finishing surfaces. The variety of settings involves applying the tool to a wide variety of objects. You can grind even concrete, even plastic, and without any risk of overheating the latter.

The machine behaves equally well both at 4000 rpm and at 10,000. The same can be said about the amplitude. from 8000 to 20,000 vibrations / minute. The well-thought-out design has received reliable protection of the operator from dust, where the latter neatly goes into a special filter bag.

- excellent performance;

- a wide range of vibration and speed settings;

- good ergonomic performance;

- reliable protection of the user from dust;

- full modes for rough and finishing surfaces.

No shortcomings identified.

Vibration machine

Here we have a tool with a soft base, where the body with the motor and controls is located. The unit makes the eccentric mechanism move in a reciprocating manner and acts on the next part of the structure. the sole. The latter spins at high speed and vibrates at the same time.

The sanding sheets are attached to the body with Velcro or clamps. The advantages with the disadvantages of the first and second we covered above, and in this case they remain the same. Sheets can have different grit levels to handle the respective materials.

Many “garage” masters ask themselves the question: “What sander to choose for furniture?” Professionals in this field unanimously declare that there is no better vibration equipment to be found. It is the ideal tool for the final surface treatment of plastics, soft metals, natural stone, and finicky furniture. If you need to choose a sander for wood, then this is just your option.

In addition, such equipment is very often used in auto repair shops for delicate bodywork, where gentle polishing is required.

Next, we will consider several specific options for the tool. This will help you navigate a little in the variety on the market and choose the right sander for walls, metal, wood and other surfaces.

Which sander to choose. professional or household?

A feature of this type of professional equipment is the high quality of components and assemblies.

Thanks to this, as well as the robust design of the case, the professional grinders are designed for tough operating conditions. In addition, this class of tools differs from household equipment in a higher degree of wear resistance, large dimensions, weight and price.

Household models of grinders will appeal to those who wish to purchase a quality tool at an affordable price. However, it is not possible to use such equipment in an intensive mode.

When using grinders of this category, you should take a short break every 15 minutes of operation.

This is necessary in order for the electric motor of the device to cool down.

In addition to the price, the advantages of such a tool include low weight and convenient body design.

Now that you know about some of the features of grinders, let’s look at their types, as well as the technological and design features of each of them.

Angle grinders

Angle grinders, popularly “angle grinders”, can be distinguished into a separate class, since with the help of them you can not only grind various surfaces, but also cut materials such as: metal, stone and concrete.

Despite this feature, the angle grinder is not suitable for wood processing due to its low density.

Also, the advantages of such equipment over other grinders are the ability to install various attachments, a relatively low weight (up to five kilograms) and a high reliability.

Overview of furniture sanders and more

Grinding machines are a category of power tools designed for grinding and polishing, different in their structure of materials, such as: wood, metal, stone, glass and plastic.

With the help of such equipment, you can remove old paint from the surface, cut slate sheets, process wood and chipboard elements, as well as marble and concrete.

Vibration grinders

Such equipment has a flat work surface that reciprocates in a horizontal plane. In this case, the amplitude of such movements is minimal, but the speed is maximum.

The process of sanding the surface to be treated is carried out using a sandpaper fixed to the sole with Velcro or fasteners.

Such devices are equipped with an engine with a power of up to 600 watts, due to which they have a low weight and fairly good maneuverability.

High quality of processing is achieved due to the fact that the presence of a fine-pored polymer lining of the sole ensures the most tight fit of the sanding cloth to the treated surface.

The lower two types are not used in the production of furniture, but we could not miss them in this review.

Grinder device

- Outlet and inlet pipes

- Housing

- Shaft

- Sieve cylinder

- Working chamber housing

- Abrasive wheel

- Outlet and inlet pipes

- Bearing arrangements

- Electric motor

- Stanina

- V-belt transmission

- Bearing arrangements

Brush

Brush grinders are equipped with only one roller, on which a mesh made of metal or nylon is put on.

Typically, this equipment is used to remove a layer of paint or iron oxide from a metal or wood surface.

Also, such a sander is used to structure wood.

Types of grinders

Depending on the design, the nature of the surface to be treated, the principle of operation and the final result of the work, the following types of grinders are distinguished:

- corner;

- straight;

- tape;

- brush;

- vibration grinders.

Let’s look at each of these types in more detail.