Circular Saw Blades: How to Change Them and Which Blade to Use. Scroll saw blade direction

Circular Saw Blades: How to Change Them and Which Blade to Use

When I first started using circular saws, what I knew about the circular saw blades was this: how many teeth the blade has and the size of the blade. Changing the blade was easy…or so I thought….until the day when I couldn’t figure out which way to put the blade in and felt like a fool.

(Sometimes, you don’t know what you don’t know….and then you feel like the biggest idiot. Ammi right??)

In my level of experience, I knew that the number of teeth a blade had made a huge difference in the quality of the cut. Need a rough cut?? Use a 24-teeth framing circular saw blade to cut quickly. Want a smooth cut for your wood? Try a 40-teeth finish blade for fine cuts with less tear-out.

Those two wood circular saw blades were sufficient for my woodworking, DIY, and home improvement needs. I never looked into the huge assortment of blades because I simply didn’t need them. As a carpentry student and now a new Crew Leader with Habitat for Humanity, however, I’m venturing into needing more circular saw blades for different projects and materials.

Back in the spring, I had the opportunity to peer over the shoulder of a demo guy at a Diablo circular saw blades booth at a Home Depot event and was mind-blown at how he was slicing through thick metal like the circular saw blade was a hot knife through butter.

That’s when it became obvious that I had a lot more to learn about circular saw blades!

Here are some questions and answers down below that you might have about circular saw blades, too!

What Circular Saw Blade is the Best?

It’s easy to ask the “what is best?” question when researching anything: What’s the best paint for furniture? What’s the best vinyl flooring? What’s the best power drill? However, the question isn’t about what the best is, but rather, what is best based on my needs?

The same is true for circular saw blades. The question isn’t, “What’s the best circular saw blade?” but rather, “What is the best circular saw blade based on what I need to cut?”

For example, did you know that there are blades specially formulated for cutting composite decking material….cement backer board….and laminate flooring? I’ll be honest with you–I didn’t know that.

Diablo, of course, is one of the most widely used and trusted brands in the industry, offering circular saw blades, miter saw blades, etc., and for a variety of materials and finishes: wood only, wood and metal combined, metal only, aluminum, plastic, composite decking, fiber cement, and laminate flooring. So get out of the habit of asking which circular saw blade is best and rephrase the question, “What is the best type of blade for this type of material?”

What’s the Best Size Circular Saw to Own?

Did you know that circular saws are sized based on the size of the blade? That’s right. They are as small as 5-3/8″ sizes (that use 5-3/8″ blades) all the way up to 7-1/4″ circular saws. The standard size is 7-1/4″. (FYI…Diablo does make smaller blades but I’m not sure they’re used on the circular saws or another tool).

A standard 7-1/4″ circular saw is on the left; a smaller 6-1/2″ circular saw is on the right. If you’re in the market for a new circular saw, I’d definitely recommend you buy the standard 7-1/4″ circular saw. If you’re cutting wood; thin, medium, or thick metal; medium or thick aluminum; or a variety of wood applications, the 7-1/4″ circular saw has blades that can fit to cut all of these types of materials. However, if you buy a smaller circular saw, you may not be able to buy smaller blades that can handle cutting those materials. You have more cutting options with the 7-1/4″ sized circular saw.

Here are a few types of blades that you’ll want to consider adding to your DIY toolbox. You can check them all out on Diablo.com.

Wood Metal

These 7-1/4″ circular saw blades have 36 teeth per inch and can slice through wood and wood that has nails in it! Think about cutting up pallets. If you’re doing any DIY pallet projects, and you need to quickly cut through the wood without worrying about hitting a nail, this blade provides impact resistance for cutting wood with nails, as well as the durability for creating clean, burr-free cuts in metal.

Framing Blade

Every toolbox should have a general circular saw blade for cutting 2 x 4 wood, which is commonly used for framing in rough carpentry (but many DIY furniture builds use 2 x 4 wood, too). Since this has 24 teeth, it’s not for smooth cuts; it’s best for quick cuts where appearance won’t necessarily matter.

Diablo Steel Demon

Now, this circular saw blade cuts through metal as you’ve never seen before!! I had the chance to see a demo of this metal cutting circular saw blade in action and what is different about using it is that is has:

- Cermet teeth (ceramic and metallic blend) provide high heat tolerances.

- Increased hardiness so it will last up to 40X longer than a standard carbide-tipped metal cutting saw blade.

- Triple chip tooth design provides burr-free finishes that require no-rework and longer cutting life

- Advanced laser-cut stabilizer vents trap noise and vibration for maximum stability, keeping the blade cool for straight, accurate cuts in metal cutting applications

The last thing you’d want when cutting metal are sharp burrs that could slice your finger or hot metal that will burn. The Steel Demon blades will cut cleanly without burrs, keeps the metal much cooler than a traditional metal cutting blade, and does the job faster without as much effort (even in a battery-powered circular saw). If you’re cutting any of the following metals, definitely consider the Steel Demon metal cutting circular saw blade:

- Studs/channels – 1/16″ – 1/4″

- Pipes/tubes – 1/16″ – 1/4″

- Angle iron – 1/16″ – 1/4″

- EMT Conduit – 1/16″ – 1/4″

- Plates/bars – 1/8″ – 1/2″

- Threaded Rod – 1/4″ – 1-1/2″

What Circular Saw Blade to Use?

Now that you understand you’re looking for the best type of circular saw blade, check out the infographic below to see which metal cutting blade or wood cutting blade is best, based on your project. Using the right blade for the right project saves you time, cost (since you’re not wasting materials), and saves you frustration!

And don’t forget that there are specialty blades for materials such as composite decking, cement backer board, and laminate flooring. Diablo makes these blades, as well.

Which Way to Change a Circular Saw Blade?

Now that you know which blade is best to use for which material and project you’re working on, let’s talk about how you actually change those blades! If it would be perfect if there was one blade that cut everything…or if you had multiple circular saws with separate blades for each of the types of materials it cuts, but that’s not the case for the everyday DIYer (maybe for professionals!)

Before jumping into which way to insert a circular saw blade when changing the blade, let’s first talk about which direction the blade of the saw actually cuts.

Circular saws cut on the upward stroke, which means that they rotate in a clockwise fashion, cutting from the bottom up. This is why when you’re using a circular saw, the side of the wood that will be your “good” side should be facing down. It’s going to be the cleanest edge (although if you put painter’s tape on the right-side-up side of the wood where it’s being cut, you can help prevent tear-out and you’ll get a great cut).

But before we get into the “how” on changing a blade, just know that each circular saw blade has some info that you can find on its face, including:

- Type of blade it is and the material is best cuts (Wood Metal, Framing, for Metals Stainless Steel).

- The thickness of the material it cuts (min and max)

- Number of teeth the blade has (e.g 24 teeth….48 teeth…)

- The direction the blade should rotate

- Speed of the rotation

- Size of the blade (e.g. 7-1/4″ is standard)

- A warning about reading the warnings included with the blade.

My recommendation is to take a picture of your circular saw blades and file it away because, after repeated cuts, this helpful information wears away as if it’s written in crayons. You’ll be left wondering what the blade is used for cutting.

Anyhow, when you’re ready to change the blade, what you need to pay close attention to is which way the circular saw blade is supposed to be installed.

5 Steps to Change a Circular Saw Blade

Here is how to change the blades pretty easily and quickly!

STEP 1: Unplug or Remove the Battery from the Circular Saw

It’s not a good idea to make adjustments to your tools when there is a battery or when it’s plugged in! Remove that battery and unplug that cord, my friend.

STEP 2: Push and Hold the Blade Lock.

That blade lock is everything when trying to change a circular saw blade. Without pushing it, the blade will keep spinning…and spinning. So make sure you press it down to lock the blade from moving.

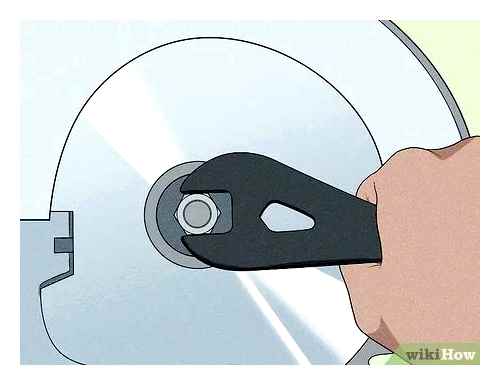

STEP 3: Loosen the Arbor with the Allen wrench

Most circular saws come with an on-board Allen wrench (also called a hex key) that will allow you to loosen the arbor that is holding the blade in place. Remember that you’ll have to keep pushing in that blade lock in order to keep the blade from not spinning and spinning.

STEP 4: Figure out which way the blade should be installed.

This is the step that’s soooo easy to mess up! But after reading this, it will be hard to get it wrong. You see, there are two ways that you’re able to tell which way to insert a circular saw blade.

-

The arrow on the blade. When changing circular saw blades, sometimes the writing will face towards you, and sometimes it will face inside, so all you can see if the blank side of the bade. The arrow on the blade must match the clock-wise direction of the circular saw. In this example with Diablo’s Steel Demon blade, which cuts a variety of metals up to 1/2″, this blade is inserted “backwards” in my circular saw so that the arrow will be rotating in a clock-wise direction.

STEP 5: Tighten the arbor.

Once the blade is installed correctly, replace the arbor, and while pushing and holding the blade lock again, use the Allen wrench to tighten the arbor. Store it back on the circular saw. Now you’re ready to cut!

Why Do Circular Saw Blades Stop or Spin?

Since we’re on the topic of circular saw blades, I wanted to point out that occasionally you might notice a problem with your blades–it may stop while cutting or it doesn’t rotate when you turn the saw on.

When I was changing one of my blades, I didn’t tighten it the arbor enough. This means I needed to remove the battery (or unplug if it’s cordless) and tighten the arbor with the Allen wrench (also called a hex key). Be sure that blade lock is depressed so that the blade doesn’t spin when trying to tighten it.

If your circular saw blade stops while cutting, either your battery died (if you’re using a battery-powered saw, of course), or it means that you’re pinching the blades while cutting. If a blade is pinched, it will simply stop during operation, but watch out. You should NEVER cut a board in the middle that is supported only by the two ends, as shown below. This can result in dangerous kick-back.

To prevent circular saw blades from stopping and being pinched, which puts the saw at risk of kicking back, only cut the free-hanging side of your board, allowing the excess waste to fall away freely. Also, another option for cutting and making sure the blade makes smooth cuts are to properly support the entire piece of wood with insulation foam and then making your cut. This will support your entire piece of wood, making sure that there is no pinching or stress on the blade. Watch my tutorial on How to Use a Circular Saw for more info about using a circular saw and properly and accurately cutting it.

How Do You Clean Circular Saw Blades?

I’ll admit that I have not been great about cleaning my circular saw blades. Blades can get dirty with something called pitch, which I’ve learned is a thick resin that pine trees can produce. I don’t know much about it, but this explanation about what pitch wood is easy to understand. Blades can be expensive, at 25…40…or more apiece. They should be taken care of and not allowed to have gunky build-up. I’ll need to be more mindful of this when taking care of my blades!

Here’s an easy to follow tutorial that I found on YouTube that explains how to clean your blades (and your bits).

How Do You Store Circular Saw Blades?

If you check out YouTube, there are a bunch of neat ideas on how to store saw blades. I don’t have enough blades to actually feel the need to make a neat little organizer. I have my blades up on my pegboard. But if you’ve got a collection growing, it may be helpful to check out these tutorials on storing your blades. You don’t want them to chip or rust, so make sure they’re not banging into each other or stored in really humid conditions.

Help With Learning About Tools

If you’re a newbie with using power tools and you want to learn more about them, definitely check out my tutorial on How to Use a Jigsaw. You can also watch the YouTube tutorial (29 minutes!) and learn everything you need to know about using this versatile tool to make a variety of projects (and I also cover my favorite jigsaw blades, too!)

Hopefully, this guide on circular saw blades, specifically, which blade to use for wood and metal (depending on your project), and how to change the blades, will be helpful for your next project!

Now let me know in the Комментарии и мнения владельцев section: Do you already know how to change circular saw blades, and do you have multiple blades in your DIY toolbox? Leave a comment below and let’s chat about it!

Download the 5 freebies!

Thrift Diving inspires women to decorate, improve, and maintain their home themselves. using paint, power tools, and thrift stores! Use these 5 printables, checklists, and ebooks to get started!

Success! Now check your email to confirm your subscription.

Scroll Saw Blades

When you start looking for the answers to your questions, this subject can start to get very confusing. I hope this will make it less confusing and help to answer these and other questions that you may have about the different types of scroll saw blades.

When I first got my scroll saw several years ago, I just picked up a few packages of blades that were on the rack at the store. My saw also came with a few assorted blades in the box, so I used them. These blades worked okay for the first few days; however, the more research I did, the more I realized that I should get some better blades. So I ordered some good blades and while I waited for them to arrive, I continued to use the stock blades until I eventually broke them all. When the new blades arrived, it was surprising how much better they really were. They were so much better I never went back to the cheap blades.

In this article, I have included links to several of the websites that have been very helpful to me with this hobby. These are links that I have used to find the information that I am sharing with you.

Two Styles of Scroll Saw Blades

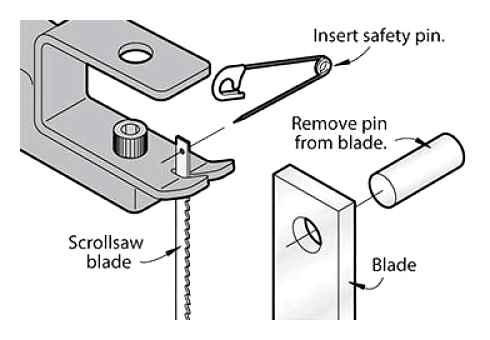

The first thing you need to determine is what kind of blade your scroll saw requires. There are two different styles of blades that are available: “Pin End” and “Plain End.” Some higher-end scroll saws do not accept pin end blades and some older scroll saws do not accept plain end blades. Some scroll saw can use both.

Pin End or Pinned

Pin end blades use a pin at each end of the blade to attach it to the blade holder. A limiting factor of using pin end blades is how small of an internal cut you can make because the hole may be smaller than the pins on the blade.

Most modern higher-end scroll saws do not accept pin end blade types. Also, some older or lower end scroll saws only accept pin end blade types.

If you have a scroll saw that only accepts pin end blade types and you want to do some of the work that requires a plain end blade, do not worry. The Olsen company has created the AC49610 conversion kit. This conversion kit allows most older 16-inch scroll saws to accept plain end blade types.

Plain End or Pinless

Plain end blades lack the pins that attach it to the blade holder. Because there is no pin, they must be held in place by clamping each end to the blade holder. This type of blade is much more popular than its pin end cousin and there are more blade configuration options available. Since there is no pin you can use it in very small internal cuts as long as the hole is slightly larger than the diameter of the blade itself.

Types of Scroll Saw Blades

There are several types of blades that perform different roles. Scroll saw blade manufacturers make their blades with different configurations and will call some of them by different names. They all will be some variance of the following types:

- Spiral – Spiral blades have teeth on all sides of the blade due to the blade actually being twisted. Because of this twist, they are sometimes difficult to attach to the blade holder. For this reason, some blade manufacturers design them with flat ends, making it easier to attach to the blade holder. Spiral blades are very useful for multi-directional scrolling since it allows you to cut in any direction without turning the piece of stock. This is a great benefit for people who have smaller scroll saws if they want to cut a larger project. I find these types of blades hard to use. There are many people that prefer spiral blades over the straight blades because of the maneuverability they provide. If you look at it closely, it resembles barbed-wire. Spiral blades are only plain end or pinless type.During my research, I have found that pin end spiral blades may have existed at one time, however, they appear to be very rare and mostscrollsaw blade manufacturers do not make them. I was unsuccessful in finding them.

- Standard – The teeth all point downward. This is how scroll saw blades were originally configured going back to the 18th century.

- Skip Tooth – Skip tooth blades will have a gap between each tooth. This allows the sawdust to be extracted which will keep the blade running cooler and will help prevent burning.

- Double Skip Tooth – Similar to a skip tooth blade except it will have two teeth and then a gap between the next two teeth. This allows even more sawdust to be extracted allowing the blade to run cooler and prevent burning. This added benefit of a smooth cut with less burning does come with the cost of a slower cut.

- Reverse Tooth – The teeth on the top portion of a reverse tooth blade point downward, and the teeth on the bottom portion of the blade point upwards with a blank space in between. This reason for this is to prevent tear-out on the bottom of the project.

- Crown Tooth – Crown tooth blades have teeth pointing in both directions so it cuts on both the upward stroke and the downward stroke. This allows a smooth finish with less burning. Also when it starts to become dull, you can flip the blade over and use it just like a new blade.

- Manufacturer Specific – Ultra reverse is an example of a manufacturer-specific type of blade. It is similar to a reverse tooth blade, except it adds more teeth pointing in both upward and downward directions. For instance, it will have several teeth pointing down, then every third tooth, pointing up. It will repeat this pattern for the length of the blade. Another manufacturer-specific type is the Modified Geometry by Pegas and Mach Series blade by Olson.

- Puzzle – Puzzle blades are very thin blades and specifically designed to make jigsaw puzzles. Puzzle blades can usually be found where regular blades are sold.

- Sanding – Olson calls them sanding files. Sanding files look like regular blades however, instead of teeth, they have sanding material on it designed for shaping and sanding.

- Other – Some manufacturers produce blades that are specifically made for metal, glass, and other materials.

What Size of Scroll Saw Blade Do I Need?

The blade size that you need will depend on the project that you are doing. For instance, if you require an internal cut for a fretwork pattern, you may need to go as small as #3/0; however, for a larger project or thicker materials, you may be able to use a blade as big as a #12.

Wood species and material thickness will be factors in determining the size and type of blade that you will need for a particular project.

The blade characteristics will be the width of the blade (kerf), TPI (teeth per inch), length of the blade, and the blade configuration such as skip tooth, reverse tooth, crown tooth, spiral, etc.

Taking all of these things into consideration, you may settle on just one or two blades that you become familiar with for most of your projects. I have become very used to a size #3 blade on probably 95% of the projects I do, including thicker hardwood.

The different types of blades come in a variety of sizes ranging from as small as #3/0 to as large as size #12. You can also get sizes that are outside of this range; although they are not very widely available.

Manufacturer’s Recommended Size of Scroll Saw Blades

There is a chart located on the Scroll Saw Woodworking Crafts website that shows the recommended blade size and configuration based on the project, the material, and thickness of the material.

Blade manufacturers will have different sizes for the different blade configurations as well.

For instance, at the following link, there is a chart available on Olson’s website that details the different blades they produce. You will see on page 1, the “PGT” blade size ranges from size 5RG to 9RG, while on page 2 the “Double Tooth” blade ranges from size 3/0 to 12.

Click the link below to view the Olson Scroll Saw Blade Selection chart. https://www.olsonsaw.net/wp-content/uploads/2016/01/2015-scrollchart.pdf

The chart in the link below is located at Bushton Manufacturing/Hawk Woodworking Tool’s website and includes three of the more popular brands of blades. They are Olson, Pegas, and Flying Dutchman. The chart lists the brand and the specifications of the blades such as TPI, pilot hole size, width, and thickness. Also listed in the chart will be the material and the pattern type that will be best suited for a particular blade.

Click the link below to view the Bushton Manufacturing Scroll Saw Blade Selection Chart.http://www.bushtonmanufacturing.com/ScrollSaw/ScrollSawParts/SS_BLADE_CHART_2-22-2013.pdf

The manufacture of the Pegas brand of blades has several downloadable charts for comparison available on their websites.

What Length of Scroll Saw Blade Do I Need?

Scroll saw blades are available in three, four, and five-inch lengths. Five-inch blades are the most popular with modern scroll saws.

Refer to the documentation for your scroll saw to verify which blade length may be required for your particular machine.

Brands of Scroll Saw Blades and Where Can I Get Them?

When I first began the scroll saw hobby, I only used blades from a handful of manufacturers. It was not until much later that I discovered there are many more brands of scroll saw blades available than I had originally thought.

In the link below I have listed all of the brands of scroll saw blades I could find. This list includes the website of the manufacturer if available and also where you can purchase that brand.

Some of the manufacturers make what they describe as fret saw blades as well. This is more common outside of the United States where scroll saws are sometimes known as fret saws. A fret saw can also refer to a hand-powered scroll saw that looks similar to a coping saw. The blades are usually interchangeable between the two tools.

Conclusion

Scroll saw blades come in either “pin end” or “plain end” style. Most modern scroll saws will accept plain end blades; however, to be certain, you will need to refer to the documentation that came with your scroll saw. Unless you have a specific need to use pin end blades, I would stick with plain end blades.

There is the AC49610 conversion kit if you require a plain end blade and your scroll saw only accepts pin end blade types.

There are a multitude of scroll saw blade manufacturers around the world. Scroll saw blades are available in a variety of configurations such as skip tooth, double tooth, and spiral just to name a few. There are even scroll saw blades for cutting metal and glass as well. Some manufacturers will have their own unique designs and names for their tooth configurations.

The type and thickness of material that you will be cutting are a few of the factors when determining the size and type of blade you will need.

An important thing to consider is that everyone has their own favorite blades to use. In order to find the right blade for your projects, you may want to experiment with some different types. This will help you determine which blades will be the best choice for you and your scroll saw.

I hope this has been helpful and you have enjoyed your visit. Let us know if you have any questions in the Комментарии и мнения владельцев section below. Subscribe to our blog so you will be notified by email when a new article is posted.

WEN Two-Direction Variable Speed Scroll Saw

DWYM is your trusted product review source. Along with our in-house experts, our team analyzes thousands of product reviews from the most trusted websites. We then create one easy-to-understand review. Learn more.

We looked at the top Jigsaws and dug through the reviews from some of the most popular review sites. Through this analysis, we’ve determined the best Jigsaw you should buy.

Update as September 4, 2019:Checkout The Best Jigsaw for a detailed review of all the top jigsaws.

Overall Take

In our analysis of 161 expert reviews, the WEN Two-Direction Variable Speed Scroll Saw placed 6th when we looked at the top 8 products in the category. For the full ranking, see below.

From The Manufacturer

Remember when your scroll saw could cut in two different directions? Take on the most intricate and artful cuts with the WEN 16-Inch Variable Speed Two-Direction Scroll Saw. The 9/16-inch stroke saws through hard woods up to two inches thick. Adjust the speed anywhere from 550 to 1600 strokes per minute with the simple turn of a knob. The cast iron base prevents vibration and walking during operation while the spacious 16-by-11-inch table bevels up to 45 degrees for angled cut. The adjustable air pump clears saw dust from your work area to give you a clear line of vision as you cut. This combined with the 1-1/2-inch dust port keep your work area clean so you can FOCUS on your woodworking. The saw also includes a hold-down foot clamp for securing your project in place along with a flexible work light that bends and adjusts to whatever position your heart desires. This unique blade holder accepts both pinned and pinless blades while also allowing users to change the direction of their cut to accommodate their particular workpiece. For pinned blades, simply pop the pins out of the front holder and turn the blade 90 degrees. Now, your cuts are no longer confined by the 16-inch throat of the scroll saw. On top of that, our removable pinless blade holder design tightly grips blades to prevent them from coming loose during operation. Onboard blade and holder storage creates simple organization solutions between jobs. And because its a WEN product, your scroll saw comes backed by a two-year warranty, a nationwide network of skilled service technicians and a friendly customer help line, all to make sure you remember WEN. Do not use power tools in the presence of flammable liquids or gases

Expert Reviews

What experts liked

The large cast-iron table with a throat depth of 16-inch is stable and solid. The scroll saw can also be easily bolted to a workbench for more stability.

The WEN 3920 has dual direction cutting capability. So you can cut both forwards and backward which will save you a great deal of time and help speed up your projects so you can get back to doing things that you love on your weekend instead of working.

The saw runs fairly quiet at different speeds, and is a great saw for a variety of small tasks such as cutting underlayment for purses. Even intricate designs are possible, if you know how to make them.

Quick assembly – It’s a fairly light saw and arrives almost ready to go, with just a few steps to set up.

The WEN 3920 is one of the most affordable scroll saws, but the manufacturer didn’t compromise on quality.

The support table is quite wide and has a tilt mechanism that allows you to tilt your workpiece at 45 degrees to the left and right for angular cuts.

The saw is extremely durable and stable thanks to its sturdy cast iron base. The fact that it supports both pinned and pinless blades put this saw in a class above the rest. From the look of things, this is a saw that every woodworker should have in their workshop.

The model is relatively lightweight – at 28 lbs – which means you can quickly move it from one workbench to the next. It also does not consume much space and can comfortably fit in the boot or back seat of a small vehicle.

The Wen 3920 includes a versatile tilting table that is 16 inches deep, allowing you to make lengthy cuts for large projects.

The package is great due to the fact you get a dust blower, blades and air pump. Most other saws come without these additions.

Perhaps the key selling point of the WEN, aside from its cutthroat price, is the proprietary design which allows it to accept blades in 2 directions. This means you can be even more creative when it comes to the designs you carry out with your scroll saw.

What stands out about this saw is its ergonomic design. This will allow the user to be more comfortable and therefore do better work for longer than with it. It’s large work surface also helps make it really versatile and able to handle pieces if different sizes.

Precision and accuracy are given priority, and this is evident with its accessible switch buttons coupled with its air pump and flexible light feature. The weight of the product is also a good point since it is quite light so it can be brought to different workshops.

An interesting part of this product is the way in which there is a line that blows away sawdust, allowing you to not feel overwhelmed by the amount of dust you are creating while sawing.

WEN 3920 Scroll Saw is easier to operate; it’s so simple that even a beginner can operate this device without facing any technical issues. The blade changing system is very easy to deal with and can be used with both pin-less and pinned blades.

There is a tension release switch that is situated right at the top of the machine for instant blade changes and which you can easily access. It can easily cut through a wood of up to 2 inches thick effortlessly.

One thing which we found pretty impressive in this purchase is that it comes with a clamp. Depending on the size of the material, you can move the clamp up and down. This clamp comes handy for keeping the material in place which eventually reduces vibrations to a certain extent.

There is one feature that makes it accessible, and best scroll saw, and that is throat depth. It includes 16-inches throat depth which means that you can quickly cut and handle more significant pieces.

The saw also comes with a 16” x 10” table that a great size; perfect for small pieces, but can support most projects. The table is also designed specifically to reduce vibration.

The WEN 3920 can be set to a range of speeds, from 550 to 1600 strokes per minute. It’s easy to change the speed for different cuts using a convenient knob located on the front of the machine.

It comes with a great table—the work surface is generally spacious (16 by 11 inches) and bevels at up to 45 degrees. It is also well-built—the cast iron base featured on this unit ensures that you’ll have a stable workspace and minimal vibrations.

What experts didn’t like

Vibration could be an issue but if you hold down the clamp and do not try cutting too fast, vibration should not be a noticeable issue.

Blade quality – The stock blades included aren’t the best, so you’ll probably want to buy better quality replacement blades.

However, cutting through metal, even after retrofitting with a carbide-tipped blade, will make this unit struggle.

Not possible to buy this scroll saw on WEN’s own website although you will still get that 2-year warranty.

According to some customer reviews, one aspect that may need improvement is the strength of the machine’s vibration. It is not very stable even when mounted on a thick surface and it causes crooked cuts as a result.

What turned me off about this tool was that even though it could be used on a table top, it is not possible to bolt it down which leads it to vibrate and bounce a lot.

The main disadvantage is weak blades. Therefore, we recommend you to purchase few extra ones just in case. And use protection while cutting for your safety.

There isn’t much, but one thing is the difficulty in finding this product at all. It seems to be in short supply. There have also been some reports of weak blades.

This tool is designed to handle smaller workpieces,not good for larger workpieces. Some users mentioned that the adjustable speed component doesn’t work properly.

Overall Product Rankings

SKIL 6.0 Amp Orbital Action Laser Jigsaw

DeWALT 20-Volt MAX Li-Ion Jig Saw

WEN Two-Direction Variable Speed Scroll Saw

An Overview On Jigsaws

If you were to take note of the most standard equipment to be found in the workshop of a handyman or woodworker, one tool that would show up quite frequently is a jigsaw. Jigsaws are generally operated by one hand and have thin blades that stroke up and down while allowing the user to make precise cuts around curves or areas that are tricky to reach.

When setting up a project to use a jigsaw, you have a few things to consider before turning the saw on to make a cut. Imagine you are building your own cornhole board, and you need to cut a large circle out of a piece of plywood without cutting in from the edge. You will want to mark your circle to be cut and then drill a hole in the center that is larger than your jigsaw blade. The jigsaw blade will then fit into the drilled hole, and you can start working the blade around the circle that you’ve drawn.

Not only do you want to go nice and slow during your cut to ensure you stay on the line neatly, but you will need to make sure the board you are cutting is not laying directly on top of your work table. The jigsaw blade will stroke down below the bottom surface of the board that faces the floor. So, take this into account and prop the board up in a secure fashion with something like a pair of sawhorses.

When making a cut with the jigsaw, you will be producing a noticeable amount of sawdust. You will quickly find out that the sawdust can impede your ability to see the line you’re attempting to cut, and you will be wondering how to best get rid of this sawdust. Some models of jigsaws like the Bosch Power Tools Jig Saws take this into account and have a built-in blower that will constantly blow the working area clean, allowing you to work with better vision and make your cuts more accurately.

To further enhance your ability to see well when you’re using your jigsaw, models like the Skil 6.0 Amp Orbital Action Laser Jigsaw have a built-in light that illuminates the path in front of your blade. This addition is a great perk due to the fact that the body position you use when operating a jigsaw is generally standing over top of it and blocking most of the ambient light with your body.

Like most handheld power tools, a jigsaw will send vibrations through the handle of the tool and into the hand and arm of the user. Thankfully,the vibrations in this specific tool aren’t overly aggressive. However, they can be enough to tire out the hands of the user if they’re making a lot of cuts in a short period of time. Products such as Porter-Cable Orbital Jigsaw take this into account by offering protracted grips that allow the user to make cuts for hours on end without wearing themselves down.

A common consideration in choosing any handheld power tool is whether or not to purchase one with a cord or to opt for the battery-powered option. As you would imagine, the cordless options give you the freedom to grab your jigsaw and go outside — all without the need for supplying power from a nearby outlet and some combination of extension cords.

The caveat is that the battery will die after some amount of use, and you’ll need to either wait for it to charge or have another pre-charged battery handy to swap in when you need it. The DeWALT 20-Volt MAX Li-Ion Jig Saw is a good example of a saw that has a big enough 3Ah battery to last almost an hour when cutting standard lumber. It can go closer to an hour and a half when cutting thinner materials like wood paneling.

Jigsaw blades vary greatly depending on the brand and their intended use. Like most saw blades, the type of metal used and the geometry of the teeth will determine which blade best suits your needs. It’s ideal as a beginner to purchase a multi-pack of jigsaw blades that have options to choose from to suit the material you’re cutting into.

The best thing you can do is to purchase a jigsaw that takes T-shank blades. T-shank blades have taken over as a nearly standard jigsaw blade style across almost every brand that makes the power tool. The T-shank blade allows for most saws to have a tool-less option for changing saw blades. This is a wonderful option since saw blades will become extremely hot during use and have the potential to seriously burn the skin of your fingers if you attempt to touch the blade right after use. Instead of maiming your hand, you can use a lever-action, like on the Bosch Power Tools Jig Saws, to remove the hot blade and insert a new one without having to wait for it to cool down.

Another useful function that you can find in a lot of modern jigsaws is the ability of the base to bevel, allowing the user to cut at a specific angle like 45 degrees. Having this option suddenly gives this tool a significant boost in versatility. With your saw blade angled to your desired angle, the base plate still sits flush on the board or other material that you’re cutting. As the user, you still just follow the line that you have marked, the blower still blows away the sawdust and the LED light still illuminates your cutting path. However, the final cut can be a nicely angled edge that both looks nice and softens the hard 90 degree edges that the board would have otherwise. This is highly advantageous to those using the saw for arts and crafts.

What Are Spiral Scroll Saw Blades Used For?

Home » Scroll Saw » What Are Spiral Scroll Saw Blades Used For?

Spiral scroll saw blades are unique in the way they are designed and they have a specific purpose. Unlike most scroll saw blades that have teeth on one side, spiral blades have teeth arranged in a spiral pattern. This pattern runs throughout the entire length of the blade. Why is this and what are they good for?

Spiral scroll saw blades are designed to cut in all directions. Rather than spinning your workpiece to cut a pattern line, you can simply push and pull your workpiece in any direction. This is perfect for large workpieces that can’t be spun easily or patterns with contoured lines in all directions.

These types of blades can be very helpful when cutting patterns that have lots of directional changes. Once you come to an area where a directional change is needed, you can simply push your workpiece into the new direction. This is faster and can be more accurate than having to reposition your workpiece in order to cut in a new direction.

So why wouldn’t you always use spiral scroll saw blades?

Spiral scroll saw blades are great when used in specific scenarios. They are best used when cutting detailed patterns such as portraits or fretwork. However, they have some downsides that you will want to consider before choosing to use them. Let’s look at when you’d want to use these blades and the pros and cons of using them.

When to Use Spiral Scroll Saw Blades

Spiral scroll saw blades are best used when cutting out patterns that have lots of multi-directional details. The following list includes cases in which spiral blades perform the best.

Fretwork

Fretwork is the perfect opportunity to use a spiral blade. These patterns have lots of areas that will have you turning your material constantly as you are cutting. There are lots of small details to contend with on a fretwork pattern. While you can use a standard blade, it would be much more work spinning your workpiece around to cut in different directions.

A spiral blade will make it much easier to deal with such areas and allow you to work faster and more accurately. When you come to an area that changes direction, you’d normally need to rotate your wood around so that the blade teeth are lined up. You won’t have to do this with a spiral blade as you will be able to simply push or pull your workpiece in the new direction without rotating it.

Portraits

Portraits require lots of small areas to be cut out similar to fretwork. It isn’t always necessary to be exact in these areas which makes a spiral blade perfect. Similar to fretwork, you’ll be able to cut out intricate portraits without spinning your workpiece around constantly.

Large Items

Some projects require you to do your work on a larger workpiece. Consider a rectangular sign. If you were to spin a sign like this around, it would likely hit the scroll saw arm, not allowing it to spin in the direction you need it. A spiral blade may solve the problem since it takes the act of spinning the workpiece out of the equation.

You can position a large item in your scroll saw and then cut in all directions without ever rotating the workpiece to move in different directions.

Cons of Using Spiral Scroll Saw Blades

There are some good reasons to use them but they aren’t always the best choice. Even when they are, they still have some downsides.

Spiral Scroll Saw Blades Don’t Work Well on Straight Lines

Spiral scroll saw blades are great for complicated patterns that require intricate cutting, but they don’t work as well when it comes to straight cuts. This is because the blade is designed to cut in all directions rather than a single direction like a standard scroll saw blade would.

The spiral design of the blade makes it difficult to make precise and consistent straight cuts and can lead to uneven edges or jagged lines along the cut.

This means that if you are making a project with predominantly straight lines, then a standard scroll saw blade is probably going to be more suitable for the job.

They Have a Learning Curve and Take Some Getting Used To

Using a spiral blade takes some getting used to because it doesn’t cut the way you would expect a traditional blade to cut. It tends to drift to one side or another and can be difficult to master. Usually, on a pattern that calls for this type of blade, exact results won’t matter as much as they might with other patterns that have straight lines and 90° angles.

It’s a different feeling when you first use a spiral blade because you will move the wood differently through the blade in order to cut. This can take some adjustment so you may end up with poor results in the beginning. It may take a little time of using it to get a feel for it and how it cuts through the material you are using.

They Leave a Rougher Edge Than Standard Blades

I love how a scroll saw leaves such clean edges. There isn’t usually much sanding to be done after cutting through wood. This is especially true if you are using reverse-tooth blades. However, if you are using a spiral blade, you will notice a finish that isn’t quite as smooth as you might expect.

Spiral scroll saw blades leave a jagged edge rather than a smooth edge like regular scroll saw blades do because of the nature of their design. A spiral blade has teeth that spiral all the way around, while regular scroll saw blades have teeth on one side and are designed to cut in one direction. The result is an uneven edge and a rougher finish than you would get with a regular scroll saw blade.

They Don’t Work Well in Thicker Materials

As good as spiral scroll saw blades are for patterns with lots of multi-directional lines and curves, they don’t work well in thicker materials. In my experience, the thicker the material, the harder they are to control.

Additionally, more breakages are more likely to occur when using thicker materials. If you are using anything over 1/2″ thick, you’ll need to move at a slower pace when using a spiral scroll saw blade. I have found that the small teeth usually present on a spiral blade don’t have the cutting power to cut through thick materials at a fast pace.

For these reasons, spiral scroll saw blades should be used primarily for thinner pieces of wood and other soft materials such as foam or plastic.

Spiral Blades Don’t Work Well in Sharp Corners

When it comes to scrolling, sharp corners can be difficult to navigate with a spiral scroll saw blade. This is because the spiraling teeth of the blade make it more challenging to cut straight lines and get tight corner edges.

The shape of the spiral blades also makes them drift slightly while cutting, meaning that you are less likely to get crisp and clean corners on your project. For these reasons, if you are looking for sharp corners in your scroll saw projects, a standard scroll saw blade may be better suited for the job.

They Produce a Larger Kerf

One of the biggest downsides of using these types of blades is that they leave a larger kerf than regular scroll saw blades. This is because the cutting width of spiral scroll saw blades is often larger due to their spiraling design. This means that more material needs to be removed in order for them to make a cut. As such, if you are looking for precise cuts with minimal waste then it might be better to use a standard scroll saw blade instead.

You’ll notice more waste and sawdust when using spiral blades, especially on thicker materials.

Bottom Line

Overall, spiral scroll saw blades are useful and a good option to have in your workshop. If you cut out a lot of patterns that require a lot of directional changes and spinning of the workpiece, they will make the job easier. They do have a learning curve that can be difficult to get used and they have a different feel while using them as compared to standard blades.

Some people swear by spiral blades and others hate them. It all depends on your application and what you are trying to achieve. A combination of both traditional and spiral will usually work out best. Ultimately, you will need to decide which type of scroll saw blade is the best choice for your project. The only way to know for sure if they will work well for your needs is to test them out.

Hello there! My name is Dan and I’m a DIY fanatic! I’ve been building and fixing things most of my life and love to share my experience with others. This blog is my place to share DIY projects, answer common questions, and hopefully inspire others to tackle fun DIY challenges. Learn more.

Legal Information

HomeDIYFun.com is owned and operated by Dan Collins. As an Amazon Associate I earn from qualifying purchases.