Do-it-yourself Lawnmow Repair. Lawn mowing construction

DIY lawn mowing repair. Lawn mowing construction

The trimmer consists of three parts: a gasoline engine, a rod with a shaft inside and a cutting element. Torque is transmitted through the shaft from the motor to the cutting head. In trimmers with a curved rod, the role of the shaft is played by a cable. The rod itself is attached to the gearbox of a gasoline engine. There is engine control on the bar, a belt can also be attached, for convenient use of the trimmer. The cutting element in lawn mowers is a fishing line wound around a trimmer head or a special knife used to trim large weeds.

The main and most complex unit in the trimmer is the engine. In domestic and semi-professional lawn mowers, two types of engines are used. 2 or 4-stroke. Depending on the type of gasoline engine, its refueling and maintenance are different.

- 2-stroke engines do not have their own lubrication system, so they do not work on pure gasoline, but on a mixture of gasoline and oil. The latter, entering the ignition chamber, lubricates the moving components of the engine.

- 4-stroke engines are lubricated with oil in the crankcase. They work on pure gasoline without impurities.

Do-it-yourself lawn mowing and trimmer maintenance can be done without outside help. If replacement of motor spare parts or its adjustment is required, then it is necessary to contact a repair shop.

First launch at the beginning of the season

In late spring, when the active use of lawn mowers begins, before starting work, you need to do an inspection and a test for the performance of your tool. Be sure to lubricate the rotating parts, inspect and, if necessary, replace the cutting elements (knife or fishing line). Check for fuel mixture in the tank. If you drained fuel at the end of the previous season, do not forget to pump fuel into the engine using a suction (if it is in the engine).

If this is your first time using a trimmer, be sure to read the instruction manual. Such instructions should be attached to each lawn mowing ground.

Starting most two-stroke engines is quite simple. Use the procedure described in your trimmer instructions if it differs from the following:

- Move the choke lever to the open position. Position the trimmer on its side so that the air filter is on top.

- Hold or lock the throttle in the on position (the throttle must be held until the engine warms up).

- If the device has an on / off switch, move it to the on position (usually indicated by “I” rather than “O”).

- Make sharp, quick jerks with the starter handle until you hear the engine try to start. This should occur between 1-6 jerks, but no more.

- Close the throttle halfway and restart the starter. The engine should start after 2-6 additional jerks. If not, move the throttle lever to the full position and pull the starter handle again. Return the lever to half the throttle and pull another 3 times.

- After starting the engine, keep the start button pressed and let it warm up for 10 seconds, then turn off the start system.

- When the lawn mower warms up, it must restart with the throttle in the closed position.

Snow blower repair. How to do it yourself do it yourself

Snow blower is a type of equipment that becomes very popular in the winter season. Particularly in need of it are summer residents and owners of private housing construction. To prevent your equipment from failing during heavy snowfalls, it must be prepared in advance for winter. Preparation consists in a routine inspection of the unit to identify possible malfunctions. If they are found, then in most cases repairing a snow blower with your own hands is quite possible. Below we will consider typical malfunctions of a snowplow, and methods for their self-removal. But first you should familiarize yourself with the internal structure of the equipment.

- Ladle;

- Rotor or auger;

- Exhaust trough;

- Tracks or wheels;

- Control knobs;

- Control panel (not on all models).

Engine

2 types of engines are installed on snow blowers: gasoline or electric. The engine drives the snow removal unit, which includes either a screw or a rotor. Also, if the unit is self-propelled, then the wheels and tracks are driven by a drive connected to the engine.

It is also called a casing. It is installed in front of the unit and serves as a housing for the snow removal mechanism. The bucket can be made of sheet steel or durable plastic.

Gutter

The main purpose of the gutter is to direct the ejected snow from the unit in the right direction. Also, on some gutters, it is possible to adjust the ejection range. The part can be made of durable plastic or metal.

The main working body of the snow blower is a screw. It is made on the principle of the Archimedes screw and is designed to capture and move snow to the center of the bucket. The screw is made of metal. The edge of the auger can be either serrated or smooth. Toothed augers do better with icy and packed snow.

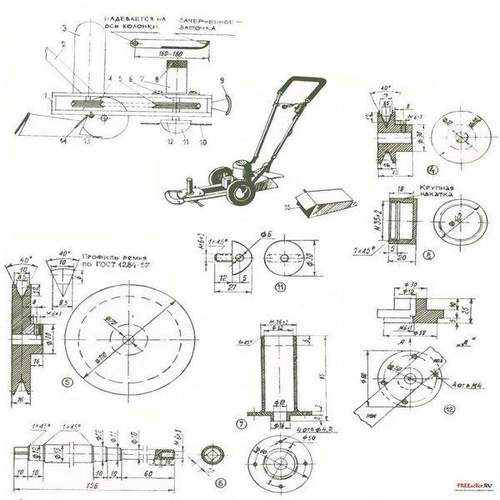

Below are drawings of auger snow removal mechanism that can be used to repair this unit.

Rotor

Just like a screw, the rotor is the main organ of the snow blower, but only of the rotor type. This part is made of metal and has the form of a disk with two / several blades or the shape of a propeller with several impellers deployed inward.

The following is a diagram of a rotary snow blower.

Important! There are two-stage snow blowers in which both screws and rotors are installed. In this case, the auger feeds snow onto the rotor, and it already throws it out.

Wheels

The snow blower chassis has a standard design: a metal rim and a rubber tire.

For better adhesion of the wheels to the surface and to reduce their slippage, the tires have a “winter” tread pattern.

Caterpillars

To increase the patency of heavy snow blowers, as well as medium-weight aggregates, tracks are used instead of traditional chassis.

Thanks to the tracks, the unit becomes more stable, which allows it to be used on terrain with difficult terrain, for example, on slopes, steep descents and ascents.

Control knobs

To move the snow blower (not self-propelled) and to perform various maneuvers, long handles are used.

On the handle can be placed the start button (if the unit is electric) or the gas lever in the case of a gas snowmobile.

Control Panel

On some self-propelled snowblowers, you can observe a full unit control panel.

On the panel can be placed: ignition switch, control levers for a wheel or caterpillar drive, speed switch (forward-backward), tilt lever, auger control, engine controls, halogen headlight on / off button.

The following is the electrical diagram of the ignition system of a gasoline unit, which is not difficult and is standard for this type of apparatus. It can be useful in troubleshooting a ignition system with your own hands.

Replacing brake pads. Replacing the front brake pads (disc brakes)

The front brake pads experience a greater load when braking than the rear. Front brake pads have to be changed much more often. Keep in mind that you need to change the pads only in pairs. Both front or both rear. Consider the algorithm for replacing the front pads on disc brakes.

Before replacing the pads, the car is installed on a flat surface, put on the parking brake. Having opened the hood, remove the brake fluid reservoir lid to facilitate the movement of the piston of the working cylinder. After installing wheel chocks under the wheels and loosening the wheel bolts, the car is lifted with a jack.

Now proceed to the basic replacement operations:

1. Turn out a wheel as it will provide good access to a support. Inspect the brake disc, assess its condition.

2. Turn out completely guides of a support, top and bottom. Remove the guides. Lift the caliper cover.

Important! Secure the caliper with improvised materials, such as wire or strap, to the suspension parts. This will prevent damage to the brake hoses.

3. Press in the piston with a large, flat-blade screwdriver.

4. Pry off the old pads with a flat screwdriver and remove them. Separate the anti-creak plates. Lubricate the plates with a thin layer of grease.

5. It is advisable to remove and staples in order to lubricate them. Coat them with grease on all sides.

6. Clean the seat from dirt.

7. Prepare new pads. Apply grease to the ears of the pads and the places where the anti-creak plates are attached.

8. Following the instructions for the car, install new brake pads. Remove excess grease with a rag.

9. Grease the piston perimeter. Replace the caliper. Be careful not to damage the caliper guides.

10. After preparing the guides, which consists in applying a thin layer of grease, install them by tightening them well.

11. Now repeat all operations on the second wheel.

12. After replacing both pads, check the brake system for leaks by repeatedly depressing the brake pedal.

Important! Remember to close the brake fluid reservoir cap, since hygroscopic brake fluid does not tolerate prolonged contact with air.

Trimmer repair. Repair of petrol and trim tabs.

Repairing trimmers is a rather fascinating and complex process. Benzo and electric braid repair can be divided into two categories:

- Repair of trimmers with natural wear, i.E. This is such a trimmer repair in which it is necessary to replace one or more spare parts that have failed as a result of prolonged and, most importantly, correct operation. This type of repair of trimmers is banal and uninteresting, since it does not bring any surprises to the employees of the service center. Repair of trimmers is carried out by professionals of the service center after the work of professionals.

- Much more interesting is the second type of trimmer repair, associated with an oversight and a complete lack of understanding of what a person is holding. This type of trimmer repair in the service center is the most interesting thing in the work of trimmer repair mechanics. Let us dwell on the most interesting points identified in the process of repairing trimmers or, as they are also called, braids.

So, trimmers are divided into two main types: an electric trimmer (it’s just an electric scythe) and a gasoline trimmer (they are often called a lawn mower or lawn mower).

Let’s start with the main points in repairing electric trimmers. It seems to be, what can be done with the trimmer so that it breaks? Plug in and mow yourself until you get tired. But there it was, there will always be a neighbor who has been working with the same mower for 100 years and who will tell you a bunch of ways how to mow faster and better for your health. And if suddenly something broke, your neighbor will immediately repair the trimmer and, even though you have a guarantee, will disassemble the trimmer and throw away some unnecessary, in his opinion, spare parts,

And collect it back. Of course, you will thank the neighbor for such a good attitude and spend several hours, or even days, with him, will joyfully praise the trimmer repair and the golden hands of the economic neighbor. But, as most often happens, the day after the trimmer’s repair carried out by a neighbor, you are going to mow the grass in a cheerful mood ……. And then it turns out that the braid is not working. You immediately run to a neighbor, they say, so damned broken, help. But, a strange thing, the neighbor will not recognize you and sends you to the service center to repair the trimmer, as he has a sick mother-in-law’s cat and he has no time.

And now we give examples of such repair trimmers:

- In the trimmer head, there is a very thick fishing line and there is no protective casing. In this case, the motor simply cannot unscrew its head and burns out due to overvoltage. Repairing such a trimmer in a service center will cost a very large amount comparable to the cost of the entire trimmer.

- The network cable is cut off, and instead of it, an extension cord is connected (why turn the cable on and off all the time into the socket) is thin, but very long. In this case, due to the fact that the cross-section of the wire does not correspond to its length, the motor suffocates from a lack of electricity, and repair of the trimmer in the service center will again be to replace the motor.

After hearing the verdict of the service center for repairing trimmers, you decide not to mess with the electric trimmer and go buy a gas trimmer. Hurray, the trimmer is bought and you, pleased with yourself, come to fight the evil grass. After several hours (or days) of struggle, the grass is defeated. You are in good health, after the righteous labors, sit on a freshly cut lawn and your soul sings. Then a neighbor comes up to you and repents, they say, the demon has beguiled that this will not happen again, etc. Etc. To celebrate, you forgive him, reconcile for several hours or days, and in the process of reconciliation give your gas trimmer to a neighbor, his mother-in-law, a cat in tall grass, got lost and mother-in-law, because you need to cut the grass and find a cat, and his trimmer is broken. After a while, the neighbor returns the trimmer, and you mark this event for several hours, or even days. There comes an hour of re-battle with the evil grass that has captured your entire site and threatens neighboring sites. You take your trimmer and. It does not start. You are to the neighbor, and the neighbor is on vacation to care for the pregnant cat of his beloved mother-in-law. And you again go to the trimmer repair service center.

Lawnmowers repair. Do-it-yourself lawnmowers repair. The main breakdowns to eliminate them

Lawn mowing is one of the most important tools of summer residents, and indeed, owners of private houses. The main purpose of this unit is to mow grass on a personal plot, turning it into a beautiful, soft ideal lawn. But before you start working, the device needs to be lubricated, that is, those parts that rub in it among themselves, it is also necessary to replace the cutting parts, and pour fuel into the tank. If problems with the motor are identified, it is necessary to repair the lawn mowings with your own hands, and for this you need to thoroughly understand its structure and essence of operation. This is usually described in the user manual, which is attached when you purchase a chainsaw.

How to repair a lawn mow if the engine does not start

In this case, check whether there is fuel in the tank. Be sure to use only high-quality A-92 gasoline for your device so that it does not break and lasts for a long time. You can buy fuel at any gas station. For example, in the same place where you refuel your car. If you save and purchase cheap fuel, the cylinder-piston group may be broken as a result, and its repair is very expensive for owners of mowers! It can make up a third of the total price of the unit. It is also very important that the mixture of oil and gasoline is properly prepared. In the manual of the unit, the proportions in which this mixture should be prepared must be indicated. Do not prepare fuel mixture in too large volumes. The thing is that if you store it in this form for a long time, it will lose most of its properties. Therefore, pour fresh mixes into the lawn mower.

Lawnmower repairs may be required if the fuel filter is dirty, making engine operation difficult. If you encounter a startup problem, check the condition of the fuel filter. If necessary, it should be replaced. The inlet pipes must never be without a fuel filter!

The air filter must also be checked. If it is too dirty, it must be removed, washed with fuel and installed again. If you are at home or at your own cottage, this filter, of course, is washed with water, you can even use detergents. Next, the filter must be rinsed well, squeezed and dried. When it has dried, moisten it with a little oil that you use to prepare the fuel mixture. If you put too much oil, it’s okay, you can remove the excess by squeezing the filter thoroughly with your hands, as if to squeeze. The removed cover must be replaced and secured.

The engine may not start if all of the above methods are tested and done. In this case, it is worth adjusting the idle speed while tightening the carburetor screw. At

How to quickly start a lawn mowing

And so, we will tell you about the ways to start the device, if you already need to do the work!

1. Carburetor repair lawn mowers. Lay the device on one of the sides so that the air filter faces up. If this is the position of the unit, the mixture falls into the carburetor (or rather its bottom). Before starting the engine, you should remove the air filter, and then literally pour a little mixture into the carburetor, and then install the parts back. In this case, the engine will start literally very quickly.

2. If the 1st option still does not work, then the essence of the breakdown is in the candles. They should be checked by unscrewing how efficient they are. Dry the combustion chamber thoroughly. A candle that does not show any sign of performance should be replaced.

3. This method is also possible. It is necessary to close the air damper and pull the handle once. After that, open the shutter and pull the starter a couple of times. So it is necessary to repeat up to 5 times.

Some people pull the handle so hard, as a result, it is necessary to repair the starter’s lawn mowers.