Goose feet for power tiller with their own hands

Types of tillers for a power tiller

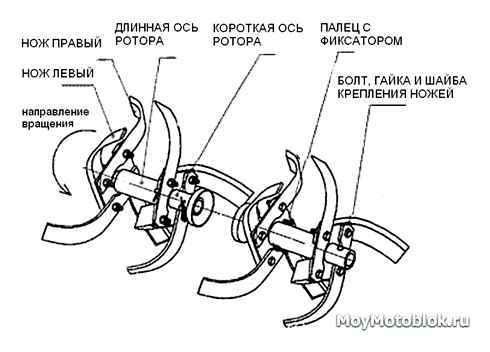

Structurally, a tiller is a set of tillage blades placed on a rotating axis. Such module consists of two parts, which are installed on the drive shafts of the wheels on either side of the power unit. Due to such arrangement, single axle tractor is able to move independently during cultivation.

You can also distinguish the type of power tillers with attachments, the rotary motion of which is ensured by the power take-off shaft. The power take-off is behind the power unit and does not participate in the movement. MtZ, Neva, Proab, Sich, Agro power tillers are produced in various modifications, with and without PTO.

There is practically no difference in the construction of both mounted and conventional cutters. But for a tiller with independent rotation the module with PTO drive and angular double-sided gearbox is made additionally.

Active (saber)

Blade blocks on such cutters consist of four cutting elements, located 90˚ from each other. There can be 2, 3 or more such blocks on one side of the drive. Number of blades and module width depend on the weight of the power tiller and its power.

The blades are curved strips of high strength alloy steel. Steel springs, type 50ХГФА, are well suitable for self-treatment and quenching. Blade bends have alternating directions.

Active shearer design enables to cultivate areas with stones and roots without danger of breaking blades. But it is reasonable to use this type of equipment on light soils.

“Goosefoot

The cutting elements of these machines are in the shape of a rugged steel triangle on the end of the leg. This arrangement is the reason for the extravagant name “Goosefoot”.

As with active power tillers, blade module width and number of blades are determined by the weight and power of the power tiller. Number of cutting elements arranged around the circumference in the knife block, from 4 or more. blades means better shredding, but you need a more powerful engine.

These types of tillers are designed for working heavy soils and virgin lands. The presence of branched root systems in the soil leads to frequent clogging of the module.

FARMING WITH LOCAL POWER WEEDERS 918341000131 \power tiller \power weeder|KISANTV TELUGU

How to assemble an active tiller

This type of homemade tillage equipment is the most common because of the simpler manufacturing technology. The cutting element and the stand in such a layout form a single whole and are made from a single piece of high-strength steel strip.

It is also possible to make homemade all-terrain vehicles from a power tiller.

You can read about the reverse gearbox in this article.

Up to the “axial tube with flange” stage, the process is identical to making a gooseneck tiller for a single-axle tractor. For this reason, consider making the cutting elements directly.

The pre-sharpened strip is bent 90˚ when heated. The length of the bent part usually does not exceed 80 mm. It is advisable to combine the cooling of the workpiece with its tempering for comfortable drilling of the mounting holes. It is finished by hardening and mounting it on the axle tube flange.

When cultivating soil with a milling cultivator of any type, you get some scattering of the ground, which makes it a little difficult to determine the boundary between cultivated and uncultivated soil. To avoid these problems, marking discs are placed on the edge of the tiller.

Tips for routing cutters

The mill to be installed on a single axle tractor is a part with an uncomplicated design. Before you start assembling, you should get acquainted with the existing cutters. This will allow you to take into account the design features of this or that type of tool.

A suitable drawing can be found in thematic publications. Once the model of the future cutter has been selected, it is necessary to prepare all the materials that will be required during assembly. If the design includes shaped parts, it is better to order them from a master or forge them with your own hands if you have forging equipment. The other parts can be made or bought in a store.

When assembling a tiller for a motor-block, special attention should be paid to the correct assembly. Possible tolerances in the construction of the machine must be avoided. The consequence of inattentive assembly can be a violation of the axis of the power tiller: it will be pulled to one side or the other.

It is important not to reverse the direction of rotation of the tines when mounting the tiller to a single axle tractor.

Specialists advise to make elements with a diameter of no more than 500 mm. These limitations are caused by the fact that the tool with the specified parameters is able to enter the soil by 260 mm. It is possible to capture about a meter of soil at a time.

A sabre-shaped cutter is safer and reduces the risk of injury to the operator in case he falls on the tool. Thanks to the alternate arrangement of the blades, they enter the ground consistently, without hitting or jerking.

For homemade cutters to last a long time, you need to adhere to the rules of operation. When starting the power tiller, they must be above the ground. After that it is necessary to start revolutions, slowly lower the blades into the soil and start tilling the ground.

Homemade tillers for the power tiller. the order of making the equipment

The simple design of tillers for power tillers allows you to make this kind of equipment with your own hands. Below we will consider the correct order of action when making different types of equipment for plowing the soil.

How to assemble properly cutters on a single-axle tractor. making saber-shaped equipment

Immediately before making saber-shaped rotary devices, we advise you to study the drawings, which will prompt you the correct order of action when assembling the equipment.

Any sabre cutter to a power tiller consists of two interconnected blocks, each of which contains 12 cutters. The design of one separate block includes 3 units, each equipped with 4 cutting blades. The latter, in turn, are positioned at 30° to each other.

The assembly of the saber fixtures is carried out as follows:

- To begin with, make a stand using a 6.3×4 cm corner;

- Weld one end of the stand to the flange so that you can then join the 4 cutting blades together;

- Connect all the cutting elements of the cutter with each other by means of flanges and bolts with washers.

The rotary cutter made in this way is very strong and stable, which will allow you to use it to process soils of any density.

Making goosefoot cutters

Immediately before the assembly of this type of devices you will need to prepare carefully for the work. With tools and materials you will need:

- steel tube, 4.2 cm in diameter;

- steel plates for making cutting blades;

- welding machine;

- angle grinder with a set of discs.

The active goosefoot cutter is assembled in the following order:

- To make the cutting elements you can use the springs from a car. Cut them into equal pieces, and then weld them to a steel tube, which plays the role of the base;

- The edges of the cutting elements are carefully sharpened and welded to the base to be used;

- After assembling the machine, start it up and make any necessary adjustments. After starting the power tiller the blades of the machine should be hanging in the air, not touching the ground.

Read also: Propane and oxygen gas welding

In order for the goosefoot cutter to last as long as possible, it should be lowered slowly to the ground. Otherwise, the equipment may break.

Mounting the burrs to a single-axle tractor by yourself

Self-installation of equipment on a single-axle tractor is carried out in exactly the same way, both for sabre and goose-foot type attachments.

In either case, the procedure is as follows:

- Mount the manufactured milling cutters on a special wooden “trestle”, about 0.5 m high;

- Carefully tilt the single axle tractor at a 45° angle and rest it on the coulter;

- Place the “goosenecks” under the handlebar of the power tiller;

- Dismantle the standard wheels of the agricultural machine, and install the self-made cutters instead;

- On the left and right outer end of the cutters securely fasten the cutter plates. they will significantly improve the running of the power tiller and make it smoother and more stable.

After completing all of these steps you can start tilling. During work, do not forget to monitor the reliability of the fastening of the plates that fix the main and additional cutters on the power tiller.

Reviews

I built my first single axle tractor in 1985. Cutters made by the principle of “goose-foot. Since then, four more modifications have been made. Cutters, which are on sale, do not meet my requirements. When I bought a modern single-axle tractor, I adapted my old “legs” to it. Perfect result.

Pavel Stepanovich

I made a mistake when making the cutter, thinking that I can do everything “by eye”. This has caused parts to be reworked several times. In order to avoid my problems, study the materials. I regret, that this article came to me after manufacturing.

Grigory

Diagram and structure of a tiller for a power tiller

Thanks to the saber shape, tillers for power tillers are safe to work. If a single-axle tractor hits a root or a stone, the cutters lift it like a car wheel, while continuing to work. If the cutters are straight, they can catch on an obstacle and overturn the single-axle tractor. This can cause the operator to lose his balance and possibly fall on the cutters.

The blades are attached to plates that are welded at different angles to the shafts. This allows the tillers to dig smoothly into the ground one at a time. This has a positive effect on the tiller’s transmission. Carbon steel is used to make the blades. If you have access to a forge, using a spring, you can make such blades. For the manufacture of other parts the following steel grades are used: St-25, St-20, St-10, which are easy to weld.

The purpose of the cutters for the power tiller

Regardless of the type, tillers are designed to perform agricultural work:

- Loosening and leveling the soil;

- Grinding land lumps;

- Mixing layers of soil;

- fertilizer agitation;

- weed control.

Originally, power tillers only came with universal, collapsible cutters with saber-shaped blades. They cope with almost all types of work on soft soils.

Goosefoot tillers for power tillers are new. This solid implement is well-proven for hard tillage, thanks to its unique shape and mechanical strength of the material and the entire construction. What sets them apart from sabre-toothed tillers is that they pull weeds out with the roots.

Often they are used to cultivate areas during the first frosts to kill weed sprouts and pest insects that have laid down for the winter.

Disadvantages of industrial goosefoot mills:

- Roots and weed stems are constantly wound around them. Since a power tiller has an indestructible design, it would be difficult to clean it after cultivation.

- Power tillers are often made from low-quality material, so they often break while working.

Classification of tillers

The tiller is a soil blades fixed on the axle, which, rotating around it while the power tiller is in motion, crushes the soil and weeds. Cutter designs vary, so in order to choose the best option, it is worth to understand their varieties. First of all, tillers are classified according to the type of aggregation:

Outboard tillers are installed as a driving unit and essentially replace the wheels, but are powered by their drive shafts. So they drive and cultivate the machine at the same time.

Rear-mounted power tillers are mounted on the back of the power tiller and are operated by the PTO and perform only the function of cultivation. These are the cutters equipped with the Neva (MB 1 and MB 2), Celina and some others.

In addition to the type of installation, milling cutters differ in the type of blades:

In this video, let’s look at tillers for the power tiller:

Active sabre-shaped

The name of the cutters is determined by their appearance. the blades are large and have an elongated curved shape. On milling machines of this type there are several sets of four knives, located relative to each other at right angles.

Usually there are two or more sets of blades on one axis. This fairly powerful piece of equipment is highly durable and perfectly copes with the processing of heavy soils and virgin lands, not afraid of stones, roots.

“Goose legs.”

“Goose legs” on a single-axle tractor. another variant of equipment, the name of which is also determined by the shape of the knives. triangular, similar to goose legs, and located at the ends of the cutting element posts. As with the previous version, the number of blades determines the quality of cultivation and varies depending on the power of the machine.

There are three-row and four-row goosenecks with different axle diameters. Three-row tillers on axle diameter of 25 mm are installed on power tillers Texas, Neva, Krot, Caiman, and four-row fit units of brands Salyut, Farmer, Favorit. The equipment on the axis of 30 mm is combined with the devices Cascade, Master Yard, some models of power tillers Neva and a number of others.

“Goose-foot”. cutters for power tillers, which show high efficiency when processing heavy, clay soils and virgin soil, but can be clogged when working in areas abundant with roots.

Cutter Classification

A tiller is a soil blades fixed on the axle, which, rotating around it during the movement of the power tiller, shreds the soil and weeds. The designs of milling cutters vary, so in order to choose the best option, it is worth to understand their varieties. First of all, tillers are classified according to the type of aggregation:

Sideways milling cutters, installed as a running gear, essentially replace the wheels and work from their drive shafts. So they both drive the machine and cultivate the soil at the same time.Rear-mounted power tillers are different. they are installed behind the tiller, run from the PTO and perform only the function of cultivation. Exactly such cutters are equipped with units Neva (MB 1 and MB 2), Celina and some others.In addition to the type of installation milling machines differ in types of blades:

In this video we will look at cutters for a power tiller:

Active saber-shaped

The name of the cutters is determined by their appearance. the blades are large and have an elongated curved shape. On cutters of this type, there are several sets of four knives, arranged relative to each other at right angles.Usually two or more sets of knives are placed on one axle. This rather powerful equipment design is highly durable and perfectly copes with the processing of heavy soils and virgin lands, not afraid of the rocks, roots.

“Goose legs”

“Goose legs” on a single-axle tractor. another version of the equipment, the name of which is also determined by the shape of the blades. triangular, similar to goose legs, and located at the ends of the cutting element posts. As in the previous version, the number of blades determines the quality of cultivation and varies depending on the power of the machine.There are three-row and four-row “goose feet” with different axle diameters. Three-row tillers on axle with diameter of 25 mm are installed on power tillers Texas, Neva, Krot, Caiman, and four-row fit units of brands Salyut, Farmer, Favorit. The equipment on the 30 mm axle is compatible with Cascade, Master Yard, some models of Neva motoblocks and a number of others.”Goose feet“. cutters for power tillers, which show high efficiency when processing heavy, clay soils and virgin soil, but can be clogged when working in areas abundant with roots.

A flange is welded to the axle tube to hold the blade struts. It can be turned on a lathe, or can be made from metal strips at least 5 mm thick.