How to correctly install the blade on the angle grinder

How to change a disc on an angle grinder? Step-by-step instructions

I think the author is most likely interested in the question “which side to put the disk on the angle grinder (angle grinder)?”which many people are interested in.

As for the sequence of actions to replace the disk, questions rarely arise, here that is called all in sight. special key or a gas key and forward. It’s hard to miss the size of the disk, because the size of the housing is a criterion here. Not unimportant parameter is the number of revolutions specified on the drive, here you need to choose in strict accordance with the manual angle grinder, disk what speed can be operated on it (speed specified on the disk should be either equal or greater than the spindle speed, but in no case less than!)

I will not comment on cup-shaped discs. there is no other way to put them. Diamond disks and disks for cutting hard alloy stone, have the direction of rotation, or pronounced tooth profile, in addition, they have a metal base. and it is metal on both sides.

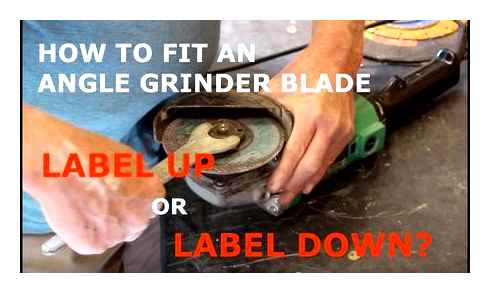

But not everyone knows which way to put the cutting wheel label when installing. outward or toward the gearbox with the paper.

Some people are just convinced that there is no difference. But this is not so. The disc is always mounted with the label facing outwards. Yes, someone will tell that the direction of disc rotation is not regulated strictly by the drawn arrow, this arrow is almost always absent, at least on abrasive discs (cutting) and also will be right.

This is not the case, the arrow is not needed, at least according to the following several logical conclusions.

There is a wide metal washer on the label side. This is exactly what it should be facing the moving flange nut, that is outward (even if the disc is unlabeled). In case of disc jamming and breakage, the sliding nut will be easier to unscrew if it slides on the metal washer. If you put the disc the other way around (with the washer facing the gearbox), the moving outer nut will be very difficult to unscrew on the abrasive part.

Because of this seemingly obvious thing, the structure of some cut-off discs. They are less prone to kinking (and wear) if installed correctly. with the label facing outward (and therefore a wide washer toward the nut being clamped and not toward the gearbox)

P.S. Well, of course, to all of the above, to work you need to arm yourself with a suit of thick cloth (I have for this purpose an apron) and safety glasses!

What to use for installing the disc?

In fact, the process of installing the disc in the angle grinder is not that complicated. However, in order to perform such work, you must take into account certain rules and use certain tools.

In particular, to install it, you may need:

- A wrench with which to unscrew the nut.

- Next, the disc itself is needed.

- You may need a hole or a chisel. These tools should be used if the disc is jammed and you have to remove it by popping it open, which means that the remains in the gap can be removed exactly with a chisel. These tools may not be needed, but it is better to have them handy.

What you need to use to install the drive

The operation is quite simple and will not take more than a few minutes, if you choose the right guide. But to produce this type of work, you must follow the basic rules and use special tools.

- A special wrench that can be used to unscrew the nut that holds it to the angle grinder. It comes with the equipment, and in case of loss the key can be bought in a construction store.

- The abrasive itself to replace the old one.

- In some cases it is necessary to use a chisel or other similar hard object. This tool is needed if the cutting disc was jammed during work. In such a situation, there is nothing left but to crush it to make the replacement. Abrasive residue can get into the gap, so you need to remove them so that the new disc does not interfere with the splinters. In most cases you do not need to use these tools, but it is advisable to always have them nearby.

Determined with the tools that will be needed for replacement, you can proceed directly to the installation:

- There is a metal ring on top of the abrasive disk for its fixation. The ring has two holes and the key has two pins that match the dimensions.

- The wrench must be put on top, in the holes of the ring, and turn counterclockwise. If the disk has not been changed for a long time, the ring may stick (not move from the operator’s effort). In this case you need to extend the key with any pipe and try to unscrew the ring again.

- After removing the old abrasive, you must put a new one in its seat. Put a metal ring on top and turn it clockwise with the wrench. It is advisable to press the key one more time to check if the abrasive has taken hold.

Important! Do not use too much force when tightening, otherwise there is a risk of damaging the disc.

Which side to put the disk on the angle grinder

In most cases, the abrasive for the angle grinder is set only in one direction, but in the situation when working with stone or concrete, the process changes. Therefore, we need to consider these cases separately.

Depending on the situation, the disc is mounted in different ways

For metal

How to properly place the wheel on the angle grinder. two factors affect it:

- On any abrasive glued a special label that shows the side on which it should be attached to the angle grinder. If the angle grinder works away from the operator, as it should in most cases, then the disc should be mounted with the label inward. When the angle grinder is working in reverse, the label is on the outside.

- Of course, you can put the abrasive on either side without paying attention to the label. But in this case you should expect unpredictable results, for example, disk breakage.

Important! Experts assure that if you do not observe the disc installation requirements, the angle grinder will one day jam, the disc may break, injuring the operator working with the tool.

For other materials

When working with concrete or wood, the angle grinder should rotate the disc toward the person holding the angle grinder. In this case, the label must be directed outward. These are isolated cases, and in most other cases, the grinder works away from the operator.

What will be needed to install the disc?

Installation of the disc on the angle grinder, as a rule, is a fairly simple process in which you need to follow a few rules. In order to produce it, it is necessary to arm yourself with the appropriate tool. a wrench, which will be needed to unscrew the nut. The next step after unwinding it will be to replace the angle grinder’s disc, or its initial installation. If it happens that the disk is jammed in the angle grinder, to remove it you will have to crush it and extract the remains from the gap between the supporting flange and the nut with a flat screwdriver or chisel.

In order to determine which side to put the disk, you need to consider a few basic factors.

- It is possible to pay attention to the label. If the angle grinder works on its own, namely rotates to the side of the manager, then in this case, the drive must be installed with the label inside. In the opposite direction of rotation, it means that the label must be installed outward.

- You can install it without paying attention to the label. But then you can expect the most unpredictable results, such as the usual failure of the disk and angle grinder. In this case, experts argue that such negligence can lead to the fact that the angle grinder simply jam, and about the safety of talking in this case is not necessary.

In order to determine in what direction should rotate the angle grinder, it is necessary to refer to the information on safety. Concrete in particular must be cut on itself.

In this case, the sparks will fly from the side, namely from the control. In general, cutting materials in the direction from yourself is not safe, because in the case of jamming, the angle grinder with a disc will fly precisely to the one who drives it. This has to be taken into account.

How to change a disc if it is jammed?

What to do if the wheel on the angle grinder becomes jammed? This can happen, for example, when pieces of the workpiece to be cut sharply clamp the rotating disk as a result of operation. This frequently results in destruction.

It may be very difficult to unscrew the nut that has been driven in if the wheel is jammed.

- One of these ways is to use two gas wrenches at the same time. The remains of the disk must be chipped with pliers. One wrench should clamp the part of the rod under the disk, and the other. unscrew the flange.

- Sometimes, in order to access the gas wrench to the stem of the “angle grinder”, you have to disassemble the gearbox.

- There are reviews on penetrating grease: a nut treated with such a composition should turn in a few minutes.

- There are more exotic methods. For example, warming up a jammed nut with a gas torch. A heated nut will be easier to turn as a result of expansion.

- Sometimes, in order to avoid unnecessary impact on the parts of the “angle grinder”, it is better to crush the rest of the disk completely, remove the protective cover and saw out all the remnants of the circle between the clamping devices with a hacksaw.

- From the problem of a jammed nut is saved by a simple device. cardboard or tin washers. They are often sold with an “angle grinder”. But over time may be lost or fall into complete disrepair. Making homemade washers is not difficult at all. However, it is better not to neglect them.

In an extreme case, the flange can be sawed with a hacksaw for metal and then replaced with a new one.

Tips that do not stand up to criticism

On some cutting-off wheels, for example, those designed to work with stone or tile, there is a special arrow. It indicates the direction of rotation. In this case, to advise the opposite would be foolish, which is quite logical. As for the abrasives for metal cutting, as a rule, no arrows are put on them. This is where the “superprofessionals”, giving out advice left and right, get their imagination on.

The first logical chain of pseudo experts might be as follows. In the middle of the circle, on the side where the drawing is applied, there is a metal washer fixed by rolling. That’s right, there’s no arguing with that. But this is not the point. What follows is an explanation. “Look at the washer of the angle grinder where you put the disc, it has pimples on it. If you place the circle so that it is in contact with these irregularities in the metal washer, the defects are leveled. In the process of clamping roughness will press against the ring, thus ensuring the best and most reliable connection. No biting of the abrasive during work, it will not rotate.

Logic chain number 2 from pseudo-specialists. “Small bumps form on the lap as it is cast. The clamping nut of the grinder has a backlash on the threads. It is at the expense of it when clamped smooth out the irregularities”.

Now for the most interesting part. According to the “experts”, if you look at the petal disc for grinding, the inner metal ring is on the side of the petals. Accordingly, this part to the gearbox and set the abrasive on the grinder.

Carefully analyze the above advice and proceed to a complete rebuttal. Otherwise, more and more people will adopt false information, which will not only create problems in the work, but can also cause injury.

The main difference between the two sides of the circle

On any angle grinder disc, you can easily spot the differences in the two sides of the wheel. One side is single-colored, it is coated with abrasive materials (to work with different types of metals). The front side has a special label on which they write information about the characteristics of the cutter.

But the main difference between the two sides of the wheel is the metal ring. This is an important design element that affects the safety of use, and therefore deserves a separate mention.

The main difference between the two sides of the circle

On any disc for angle grinder you can easily notice the difference in the two sides of the wheel. One side is single-colored, it is covered with abrasive materials (for working with different types of metals). The front side has a special label, on which they write information about the characteristics of the cutter.

But the main difference between the two sides of the circle is the presence of a metal ring. This is an important design element that affects the safety of use, and therefore deserves a separate mention.

What are the discs for angle grinder? What wheel to cut with?

For angle grinder (angle grinder), you must first adhere to the established for a particular model of cross.

This is although a very fundamental point, as it is often possible to increase the depth of cut or area of the surface treated, some craftsmen remove the protective cover and set the circle size standards.

All, because of this, the tool itself is even more likely to burn out (gearbox breaks), and with, there are quite a lot of injuries. There is a disc for the angle grinder has a limit on the maximum speed of rotation of another, to put it simply, at a speed of rotation.

The wider the cross-section of the wheel, the lower the speed. It is this error is a huge disc at high speeds are often simply broken, and taking into account the fact that in all this lack of protective casing, the consequences can be the most pitiable.

What are the discs for angle grinder in the cross-section

There are a total of 5 main modifications:

Very popular are considered an angle grinder, and therefore the disc ∅ 125 and 230 mm. At home in most cases small models are used, while the professional work uses a more powerful and productive tool.

How to choose a disk on an angle grinder to work with different materials

Versatility angle grinder is that it can not only cut virtually any material, but also to grind different surfaces, and otherwise conduct grinding tools. The main thing. to choose the right disc. So what are the discs for angle grinder? The main groups look like this:

Again, there are several varieties in each group. Cutting discs are abrasive, diamond and wood. 1-you are designed for cutting metal, although there are also abrasive circles on concrete.

They differ in the components used in the manufacture, and the customer can distinguish them by the color on the information label (for metal. blue, for concrete. greenish), by the inscription (metal. “Steel,” concrete. “Concrete”) as it is also called by the schematic representation of a particular material.

Diamond cutting discs are designed for use with stone, concrete or clay products only. A more common question that arises from home masters, which disk to cut tiles with an angle grinder? In general, for this purpose recommended circles with a solid coating without segmentation, grooves and slots, because they leave like a movie chipping on the enamel.

The main difference between the two sides of the circle

Two surfaces are clearly distinguishable on any cutting disc. One of them (back) is single-colored, formed by the abrasive material. The second (front) side has a label with basic information about the features of the disc. But the main difference between these two surfaces is the metal ring on the face.

The metal washer (ring) is designed to protect the integrity of the disc when it is tightened by the moving flange nut and also to increase the support surface area. In addition, the metal washer prevents the cutting wheel from “sticking” to the nut surface, making replacement much easier.

Advantages of mounting a disc with a ring on the angle grinder

Cutting-off wheels have no pre-programmed direction of rotation. Therefore, it does not matter which side you install them. But as mentioned above, the installation of the disk face outward, facilitates the process of its replacement (on the abrasive side to unscrew the nut is much harder). There are several other advantages to mounting a ring sander.

Ensure smooth installation on the shaft

The metal ring increases the support area. So when the disk is mounted on the shaft and the nut starts to tighten, the pressure is evenly distributed. It ensures a straight fit of the cutting disc and reduces the risk of damage due to misalignment.

Comfortable installation of the disc

Installing the abrasive wheel face outward provides yet another advantage. you can always visually see exactly what attachment (for metal or stone) is installed at the moment on the angle grinder. They are not interchangeable and a mistake can have serious consequences. For example, when attempting to use a metal cutting disc to cut through concrete, it is possible for the disc to break and injure the craftsman with the resulting chunks. Therefore, the installation of the abrasive wheel with the label outward will ensure not only convenience, but also the safety of work.

Instruction manual

The instructions for many angle grinders, e.g. the Metabo WP 850, clearly state that “the metal flange of the abrasive cut-off wheels must be in contact with the supporting flange”. Manufacturers do not give such recommendations for nothing, as they ensure safe work with the tool, reduce the risk of serious injury to the master.

What you need to use to install the disc?

In fact, the process of inserting a wheel into an angle grinder is not that complicated. However, in order to perform such work, you need to consider certain rules and use certain tools.

Specifically, you may need to install it:

- A wrench with which to unscrew the nut.

- Next, the disc itself is needed.

- You may need a hole or a chisel. These tools should be used when the disk is jammed and you have to remove it by popping it open, which means that the remnants in the gap can be removed exactly with a chisel. These tools may not be needed, but it is better to have them handy.

Which side is suitable for mounting

In order to determine which side to mount the disk, there are several basic factors to consider.

- It is possible to pay attention to the label.If the angle grinder works on its own, namely spinning away from the driver, in which case you need to install the disc with the label inside. In the opposite direction of rotation, so the label must also be installed outward.

- Can be installed without paying attention to the label. But then you can expect the most unpredictable results, such as the usual disc and angle grinder breakage. In this case, experts argue that such negligence can lead to the fact that the angle grinder simply jam, and about the safety of talking in this case is not necessary.

In order to determine in which direction the angle grinder should rotate, it is necessary to refer here to the safety information. In particular the concrete should be cut on itself.

In this case, the sparks will fly from the side, namely from the manager. In general, cutting materials in the direction away from yourself is not safe, because in the case of jamming, the angle grinder with a disc will fly exactly to the one who operates it. This should be taken into account.

Is there a significant difference from the direction of rotation

The direction of rotation of the cutting wheel can be either “on” or “off”. Each of them has its own advantages and disadvantages. So when you rotate the disk “away” on the operator flies dust and sparks, which creates additional difficulties in the work associated with possible burns eyes, skin, flashing clothes. Turning the disc “on itself” does not have this disadvantage. But in this case there is also a higher risk of injury. Because if the disk is jammed, the tool will fly with force into the operator’s face. There is no single rule in which direction the cutting wheel must rotate. If this is important, the information is necessarily indicated on the tool. In all other cases, the direction of rotation is chosen by the operator, taking into account the type of work surface, convenience and experience.

Installing the disc on an angle grinder is usually a fairly simple process in which you need to follow a few rules. In order to perform it, it is necessary to be armed with the appropriate tool. a wrench, which will be necessary for the unscrewing of the nut. The next step after unscrewing it will be to replace the disc of the angle grinder or its initial installation. If it happened that jammed the disk in the angle grinder, to remove it will have to crush it and extract the remains from the gap between the supporting flange and nut with a flat screwdriver or chisel.

How to remove a jammed disc from an angle grinder

Using new nuts solves the problem of removing the disk, but what to do with a bent disk?? Even if the disk has been installed correctly, it is not always possible to remove it. Practice suggests different ways of solving the problem. It is possible to clamp the clamp and strike through the superstructure into the holes of the nut in the direction of unscrewing. This is only possible if the retainer is intact. But a clamp can not withstand such a solution and break.

The second method is more logical. Under the clamping nut and bottom support washer is the gearbox shaft with the chamfers. The lower support washer is put on them. You can’t fit a standard wrench in there, it’s very narrow. But you can take an ordinary open-ended wrench for “17” and turn it on both sides.

The sharpened wrench will enter the gap, place it on the chamfers of the shaft, and lock it. Now with any wrench any nut will be unscrewed, and the disk or its remnants removed from the angle grinder.