How to cut a 45 degree profile pipe

Pipe cutting at an angle of 45 and 90 degrees

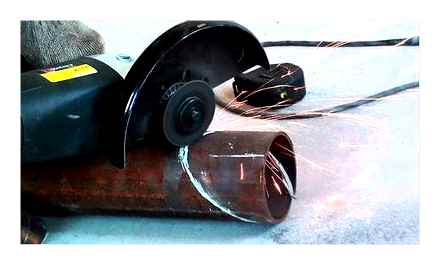

If you need to cut the pipe at an angle of 45 degrees, which is more often required when laying water, heating pipes. Steel, cast iron pipes that are cylindrical in shape are often used. In installation work, rectangular or shaped pipes are used. However, you should properly cut the pipe with an angle grinder, so that later it can be easily connected. Therefore, you should carefully mark the pipe.

Some craftsmen try to mark the place of the cut using a tape measure, but we warn you that the result is likely to be negative. And for a positive result, consider the following professional recommendation.

Take a sheet of paper or cardboard, preferably A4, fold it diagonally and wrap it around the pipe where you plan to cut it evenly. The edges of the paper should be exactly aligned with each other. And the side of the paper that is closer to the end of the pipe was perpendicular to the axis. Then mark the cut line in a circle.

If you need to cut exactly at an angle of 90 degrees, then solve the problem quickly using paper or masking tape again. Wrap around the pipe so the ends match. Make even lines and saw off.

Masters advise using a square when cutting a profile pipe. To do this, apply the square in turn to the sides, and turn and mark with smooth movements. After action, fix the pipe and cut. Prepare yourself a template that will come in handy in the future and save time. It is better to do the action with an angle grinder, so the cut will be smoother.

When working with a cast iron pipe, keep in mind that it is a brittle material. Therefore, we will point out a method with which it will be possible to cut such a metal without damage.

Before starting work, make notes for the cut, just like with steel pipes. Place a piece of wood for support. Run an angle grinder around the circumference of the pipe making small cuts. Then take the chisels, insert into the groove and hit hard with a hammer. Note that bakelite-based cutting discs are used to cut cast iron pipes.

If you do not have an angle grinder at hand to cut a cast-iron sewer pipe or other purposes, use a metal hacksaw, chisels or special pipe cutters.

Cutting a gas pipe is dangerous, so it is best to entrust it to professionals. But if you are confident in your strength, then to cut the metal, take an angle grinder, welding, hacksaw, gas welding.

- Shut off the gas riser before work. Then release the rest of the gas from the pipe. To do this, set fire to the gas in the burners and wait for it to go out.

- After the actions taken, cut. Using the welding method, the metal base burns out when exposed to high temperature. The result is fast and effective. But remember that cutting or rooting gas pipes again requires experience.

Methods for cutting large diameter pipes

There are a number of reliable tools available for cutting large diameter pipes such as sewers. Next, we will consider some of them in detail:

- An angle grinder is an inexpensive and affordable option, but it is not considered the safest when working with such materials. Once you decide to use this method, then be careful and use protective equipment.

- A roller machine (pipe cutter) is such a tool adapted for such manipulations. The device is attached and material removal begins. The clamping force is adjusted using mechanical devices. It is important to note that the models of the machine differ in shape, therefore, before use, consider the ratio of dimensions to the pipe.

- Flame cutting is the most popular option for cutting larger diameter pipes, sheet metal. The cut occurs due to the action of a high intensity flame, the metal melts and leaves the cut zone with a gas flow. This method is convenient and effective.

A quick way to cut a pipe lengthwise with an angle grinder:

- Focus on the markup.

- Use for such a case the painter’s thread, which has found distribution when marking walls.

- Before starting work, fix the pipe and with small movements, carefully saw the pipe.

- Better not to rush, but delicately and slowly process the parts of the pipe, so the cutting disc does not jump off the marking lines. Remember safety.

Thin-walled pipes are made of non-ferrous metals: aluminum, copper. Such work should be done delicately, since there is a high probability of material deformation. Fillers such as sand are used for cutting. Actions can be carried out using an angle grinder, a special machine.

Summing up, we emphasize that cutting metal pipes is a complex process, but anyone who wants to enhance it can enhance it. With the advice of a professional, you can easily cut pipes in a variety of sizes and materials. Also remember to file or sandpaper the edges of the pipes after cutting. And the most important thing to remember when starting such actions is safety precautions. Wear a special suit (casing), mask or goggles when getting started. Hands should also be reliably protected from sparks, so use thick gloves.

If high cutting accuracy is required, it is better to contact a specialized workshop, where it can be done at any angle on a pipe cutter or the required squeegee can be made. Bends with angles of 30º and 45º can be purchased in the construction markets. The bends should then be butt welded to the pipes of the required length.

There are computer programs that allow you to make sweeps and patterns for cutting cylindrical parts at arbitrary angles. The pattern is drawn on paper using a printer.

You can get a special miter box that allows you to cut at any angle, but it’s not cheap. You can make it yourself. Two steel corners with a shelf width of more than the pipe diameter are attached to a wooden board in parallel. One is a workpiece support. In the second, 2 holes are drilled for bolts and nuts are welded. Bolts are used to fix the workpiece. A cut is made in the board at the desired angle, which is built using a protractor.

If the listed methods do not suit you or the work needs to be done urgently, you will have to use the materials at hand.

Large diameter pipe cutting

When a large diameter pipe needs to be cut, a variety of special attachments and tools can be used. This may be required if, for example, a pipeline needs to be repaired.

- angle grinder. The use of an angle grinder is justified from the point of view of the availability of the tool and the relative cheapness of work. However, in this case, you should not count on high productivity, in addition, carrying out work in this way is fraught with considerable risk.

- Roller machine. Such attachments are also often referred to as pipe cutters. In fact, such a device is the same angle grinder, but more adapted for this type of work. The machine includes a special bed, where the cut-off element is fixed, as well as a cage with installed cut-off rollers, which do the direct work. It is important to understand that each machine must be purchased for specific tasks, that is, for the size of the pipes.

- Gas cutting. This option is most often used when working with large diameters. Cutting is done using a high-intensity flame, and the waste produced is blown out by the pressure of the gas. The method can be considered the most practical and effective.

There are other options for the implementation of the task, such as the use of plasma, waterjet or laser cutting, but in private use they are practically not used.

Cutting at 45 degrees

One of the particular examples of this situation is the need to cut a metal pipe at an angle of 45 degrees. This cutting of material is often required when laying plumbing or heating systems. In this case, you have to deal with steel pipes. For these purposes, the usual cylindrical pipes are usually used. If we are talking about the installation of some kind of metal structures, then shaped pipes of rectangular or square cross-section are more often used. The main problem here is that in order for the connected elements to coincide, the cut must be as even as possible, which means that especially close attention should be paid to marking the material.

In the event that cutting at an angle is required, a simple square sheet of paper can be used as a marking template. It must be folded strictly diagonally, and then wrap the pipe with a template. In this case, it is necessary to carefully ensure that the side of the sheet, which is located closer to the end of the pipe, is perpendicular to its central axis. Next, using the marking material, a number of dotted lines are applied and after the marking is done around the entire circumference, the template can be removed.

If the profile pipe is to be cut, then it is advisable to make a special template from the same pipe, but with a larger section. In this case, you only have to use the measuring devices once. For marking, you will need to use a protractor or construction square. After sawing off the template, the pipes to be cut can simply be inserted into it and marked. This approach will significantly save work time and it will be convenient to cut a profile pipe at 45 degrees.

As for what to use when carrying out work, here it is worth choosing the most suitable and familiar. It can be a simple hacksaw for metal, and an angle grinder with an installed cutting disc.

How to cut a cast iron pipe

If the pipe is made of cast iron, then in order to cut it evenly, you will have to apply certain knowledge. The fact is that this material is characterized by high fragility, which means that before cutting off such a pipe, you need to determine an algorithm of actions.

- We mark it in the same way as steel pipes.

- At the place where the cut is made, you need to put a wooden beam as a support.

- Next, you need to cut a few millimeters around the entire circumference.

- After that, a chisel is inserted into the groove and a sharp and strong blow with a hammer must be applied.

As a result, it will split along the mowing line, forming a fairly flat cut point, which, if necessary, can be additionally processed.

How to cut along

Another frequently asked question is how to cut the pipe straight lengthwise with an angle grinder. Here the algorithm of actions will be approximately the same as for cross-cutting. It is important to pay attention to the marking. You can, for example, use a painter’s thread, which is usually used when marking walls. In this case, it is necessary to rigidly fix the pipe. The sawing process itself must be done carefully and slowly, since when sawing long elements, there is a high probability of the cutting disc slipping off the mowing line of the marking.

How to cut a profile pipe straight

You can cut a profile pipe in much the same way, but here it will be easier to use a square. The device is alternately applied to each side, for which the cut element will need to be rotated, and the markings are applied. Next, the pipe must be fixed immovably and you can start work.

Any suitable tool can be used for sawing. If you have to cut a lot of pipes, then it is advisable to make full-fledged templates from scraps. In this case, the measuring and marking work will have to be done only once.

Root welding

- Boil the seam under the following conditions:

- minimum current;

- reverse polarity;

- short electric arc;

- dry electrodes;

- no wind in the chimney.

- Cook vertically, the electrode is perpendicular to the plane.

- Melt the edges with an electrode. a jumper will appear between them, called a weld pool. There is a so-called technological window in front of the lintel.

- Pay close attention to the size of the technological window: throughout the entire process it should remain the same diameter.

- Make the root joint no more than 1 mm high. The reverse roller should also not exceed this value.

- Clean the beginning and end of the seam, the area of transition between the electrodes to avoid the formation of pores in the metal, the presence of which will sooner or later lead to a loss of pipe tightness.

Cutting profiled sheet and metal tiles

Quite often, in practice, one has to face the need to cut a profile sheet or metal tile. These materials are made of steel, which is coated with zinc and polymer protective layers, painted.

There are different opinions on the possibility of using an angle grinder for cutting them. The installation instructions say that the profiled sheet cannot be sawed with an angle grinder. To do this, you need to use other tools. But they need to be purchased, which is not always justified by the amount of work to be done, and also requires additional financial investments. When there is no tool other than an angle grinder, you should know the possible negative consequences before sawing with an angle grinder.

- If you cut a metal tile or corrugated board with an angle grinder, then the protective coating in the saw cut area and a little near it will be destroyed, and the cut edge will begin to rust.

- Material is removed from the warranty.

- Flying sparks can ruin not only the appearance of the rest of the sheet (burn out the paint), but also damage the polymer coating.

- The cut edge may be torn.

All considered negative consequences can be minimized if you cut corrugated board or metal tile with an angle grinder, observing the following recommendations:

- do all the work just before installation;

- treat the sections with anti-corrosion compounds;

- cover the trimmed edges with a primer and paint;

- use discs for metal with a minimum thickness (up to 1 mm);

- to keep the edges neat, you need to cut pretty quickly;

- sand torn edges gently.

Before sawing, as usual, the sheets are marked.

If you need to cut a square, then proceed as follows:

- draw it on the surface of the sheet;

- cut the material along the marked contour with an angle grinder;

- at the end, carefully cut out every corner.

Circles or other shapes are cut out using the same pattern.

The use of an angle grinder for cutting metal tiles and profiled sheets facilitates the work. It becomes more convenient to carry out it, because you can adjust the sheets to the size directly on the roof.

Cutting metal with an angle grinder is a cheap, practically affordable and quite effective way of sawing it. In this case, the appropriate discs should be used for each material without defects. Not only the quality of the result will depend on this, but also your own health. It is imperative that when sawing metal, it is required to follow safety rules and use personal protective equipment. It should always be remembered that when working with an angle grinder, any shortcomings and inattention can result in injury.

Therefore, you need to work with concentration and caution.

Pipe cutting at an angle of 45 and 90 degrees

If you need to cut the pipe at an angle of 45 degrees, which is more often required when laying water, heating pipes. Steel, cast iron pipes that are cylindrical in shape are often used. In installation work, rectangular or shaped pipes are used. However, you should properly cut the pipe with an angle grinder, so that later it can be easily connected. Therefore, you should carefully mark the pipe.

Some craftsmen try to mark the place of the cut using a tape measure, but we warn you that the result is likely to be negative. And for a positive result, consider the following professional recommendation.

Take a sheet of paper or cardboard, preferably A4, fold it diagonally and wrap it around the pipe where you plan to cut it evenly. The edges of the paper should be exactly aligned with each other. And the side of the paper that is closer to the end of the pipe was perpendicular to the axis. Then mark the cut line in a circle.

If you need to cut exactly at an angle of 90 degrees, then solve the problem quickly using paper or masking tape again. Wrap around the pipe so the ends match. Make even lines and saw off.

Masters advise using a square when cutting a profile pipe. To do this, apply the square in turn to the sides, and turn and mark with smooth movements. After action, fix the pipe and cut. Prepare yourself a template that will come in handy in the future and save time. It is better to do the action with an angle grinder, so the cut will be smoother.

When working with a cast iron pipe, keep in mind that it is a brittle material. Therefore, we will point out a method with which it will be possible to cut such a metal without damage.

Before starting work, make notes for the cut, just like with steel pipes. Place a piece of wood for support. Run an angle grinder around the circumference of the pipe making small cuts. Then take the chisels, insert into the groove and hit hard with a hammer. Note that bakelite-based cutting discs are used to cut cast iron pipes.

If you do not have an angle grinder at hand to cut a cast-iron sewer pipe or other purposes, use a metal hacksaw, chisels or special pipe cutters.

Cutting a gas pipe is dangerous, so it is best to entrust it to professionals. But if you are confident in your strength, then to cut the metal, take an angle grinder, welding, hacksaw, gas welding.

- Shut off the gas riser before work. Then release the rest of the gas from the pipe. To do this, set fire to the gas in the burners and wait for it to go out.

- After the actions taken, cut. Using the welding method, the metal base burns out when exposed to high temperature. The result is fast and effective. But remember that cutting or rooting gas pipes again requires experience.

Centering and joining the pipe

- Centering and joining small-diameter products is carried out by fixing with the help of improvised means or using assistants.

- Center pipes of large size (from 60 mm) with special equipment. a centralizer: internal or external. Both have an electrohydraulic drive. Internal ones are more preferable due to the fact that when they are used, the joint remains open. This allows the use of automatic machines for welding, and also does not limit the manipulation of manual connection.

- Avoid deviations with manual alignment. It is unrealistic to dock perfectly without a centralizer, but try to minimize deviation.

- Having connected exactly the pipes, proceed to welding the root seam.

Methods for cutting large diameter pipes

There are a number of reliable tools available for cutting large diameter pipes such as sewers. Next, we will consider some of them in detail:

An angle grinder is an inexpensive and affordable option, but it is not considered the safest when working with such materials. Once you decide to use this method, then be careful and use protective equipment. A roller machine (pipe cutter) is such a tool adapted for such manipulations. The device is attached and material removal begins. Clamping force is mechanically adjustable

How To Make A Template To Cut A Profile Pipe To Create A Triangle

It is important to note that the models of the machine differ in shape, so consider the ratio of dimensions to the pipe before use. Flame cutting is the most popular option for cutting larger diameter pipes, sheet metal. The cut occurs due to the action of a high intensity flame, the metal melts and leaves the cut zone with a gas flow

A quick way to cut a pipe lengthwise with an angle grinder:

Pay the main attention to the markup. Use for such a case the painter’s thread, which has found distribution when marking walls.

Before starting work, fix the pipe and with small movements, carefully saw the pipe. Better not to rush, but delicately and slowly process the parts of the pipe, so the cutting disc does not jump off the marking lines. Remember safety.

Thin-walled pipes are made of non-ferrous metals: aluminum, copper. Such work should be done delicately, since there is a high probability of material deformation. Fillers such as sand are used for cutting. Actions can be carried out using an angle grinder, a special machine.

Metal-plastic pipes: how to cut?

The simplest equipment that you can use to cut a metal-plastic pipe is plumbing scissors. Cutting with such scissors can be easily controlled, and the process itself does not require much effort. This method allows you to properly cut pipes lengthwise. Scissors are designed for cutting pipes with a diameter of no more than four centimeters.

Other tools are used to cut pipes with a large diameter. For example, craftsmen often use an angle grinder.

When processing such pipes, some recommendations should be followed:

45 degree cutting trick | secret profile cutting trick | pipe cut 90 degree

- always use a disc that is intended for processing metal products.

- when cutting, do not put too much pressure on the tool.

Features of cutting various angles

We have disassembled the general technology of how to cut off the ceiling plinths. But it also has some nuances of cutting different corners of this product.

Paper mold for pipe

One of the most common ways to make a pattern for pipes with a round surface is a method for which you will need a lined sheet of paper, a ruler and a pencil. To obtain a paper pattern, proceed as follows:

- Draw a circle on a piece of paper with the diameter of the pipe to be cut, break the circle into 16 equal segments, each time dividing large segments into two equal.

- Measure the circumference by multiplying its diameter by the number Pi, equal to 3.14. Set aside this size on both sides of the axis of the circle in equal segments, each of which is divided into 8 equal parts.

- Draw from segments on a straight line vertical mowing line up and horizontal from the points set on the circle.

- The places of their intersection are connected with a smooth line and, as a result, a template applied to the paper is obtained, which is cut out and glued to the trimmed surface. For trimming, it is better to use an angle grinder with a small diameter disc. the surface will be curved and when using a large disc, the error will increase.

How to cut a cast iron pipe

The main difference between cast iron and ordinary steel is its high brittleness and large wall thickness; its accurate cutting must be performed in the following sequence:

- A marking corner is drawn according to the template using a scribe, for

supports under the part put a wooden shield or board.

- Perform a shallow cut of the surface with an angle grinder along the entire perimeter.

- Further, the groove is deepened in several passes until the two parts are completely separated.

Cutting at 45 degrees

Usually, in order to turn the pipe by 45 degrees, fittings are used, bends with a 45-degree rotation angle, made of the same material as the pipes themselves, if the pipes are steel, then the turns are welded from steel. For HDPE pipes, there are electrically welded or cast bends at 45 degrees (note that it is almost impossible to find compression fittings with such an angle of rotation in Russia).

But, if you still need to cut a round pipe made of steel or various types of plastics, then for this you need a piece for cutting pipes at an angle, the shape of which is calculated manually or by machine. The task is greatly simplified if at an angle of forty-five degrees it is necessary to cut a metal profile of a square cross-section.

For a quick cut, you can use a regular sheet of paper folded diagonally to mark the surface for the future cut. Using folded paper, proceed as follows:

- carried out on a straight surface of the profile in the place where the cut is made, strictly perpendicular to the line;

- apply a diagonally folded sheet of paper to the side surface with the sharp end to the mowing line so that the top edge of the paper triangle is flush with the top side of the metal profile.

- draw the line with a pencil along the side of the sheet at an angle of 45 degrees, after which the paper corner is applied to the other side and outlined with a pencil (it is better to use a thin marker).

For sawing, you can use an angle grinder with a disc for metal, drawing a thin line at the beginning along the markings, and then gradually deepening it until the edges are completely separated.

When working with an angle grinder, the following factor must be taken into account. if the edges are completely cut off, the disc can be damaged by an acute angle, which will lead to its failure, and in the absence of protection on the angle grinder, even to employee injury. Therefore, it is advisable not to cut the corner edges to the end, but to leave a narrow groove and then break off, subsequently grinding the protrusion.

How to cut 45 degree pipe with high precision at home

When carrying out work on the installation of gas or water mains, it is often necessary to change the direction of the mowing line, while the pipeline is cut and then welded at the desired angle. Most often, the direction changes by 90 degrees, and the question arises. how to cut the pipe at 45 degrees in order to accurately connect the joints when welding.

It is possible to cope with the problem with cut edge angles of 45 or 90 degrees with the appropriate knowledge and techniques that will help save not only time, but also materials during work. At other angles of rotation, it is impossible to solve the problem with a ruler and a sheet of paper. you will have to call computer equipment for help.

DIY pipe miter box

Using the template is not very convenient. you have to make a cut along the mowing line, keeping the angle grinder suspended, which leads to large errors. If you have a welding machine, you can make a simple miter box. guides for the disc of an angle grinder, which do not allow it to go to the side.

For this, a previously made template is used, in the side of which a hole is drilled and a nut is welded. When working, a homemade miter box is put on the profile, a bolt is screwed into its nut and the device is pressed against the profile surface. An angle grinder with a disc for metal makes a cut, slightly pressing the disc to the side surface of the device. It is clear that with long-term work, the edges in the miter box are gradually grinded, and although the process occurs simultaneously on all edges, some errors will appear over time. Therefore, it is better to make the device from hard wear-resistant metal in order to increase its service life and get a more accurate tool.

Cutting at 90 degrees

To cut straight across a round pipeline or rectangular metal profile, use a sheet of plain paper. They wrap the workpiece in such a way that the edges of the paper sheet coincide, after which it is fixed on the part with tape or glue. with an angle grinder, a thin line is carried out next to the edge of the paper sheet, after which it is gradually deepened until it is completely cut.

A metal profile or a round pipe can be cut using a template, putting on them an evenly cut element with a large inner diameter.

Some tips for cutting pipes

Households sometimes require cutting to connect the pipeline at different angles or axially. The main tool for these works is a universal angle grinder and discs for metal.

Pipe marking at different angles

For cutting pipes at an angle of other values, you will need patterns with the corresponding values. You can prepare a template using Excel or other computer programs by entering the values of the pipe diameter, the desired angle, etc. in the appropriate interface.

In the calculation programs, you can calculate the cutting of pipes of any diameter and at any angle. But most often this method is used to create a pattern for cutting pipes of small and medium diameter. For cutting large diameter pipes and in large volumes, it is preferable to use programmable cutting machines.

How to cut a pipe at 45 degrees

Gaining popularity

The main stages of work

At the next stage, we cut off a sheet of paper and wrap it around the workpiece.

Press firmly and smooth with your fingers so that the place of the cut is “imprinted”. We wrap the edges of the sheet inside the pipe.

Then we remove a sheet of paper from the pipe, unfold it and draw a pencil around the resulting contour. Cut with scissors.

The result is a reusable template that can be used to mark up other workpieces.

In the same way, you can make a paper template to cut round tubes for welding at an angle of 90 degrees.

For more information on how to make such simple templates and how to use them, see the video below.

Making decorative balls with your own hands

Precision cutting machines

Among the branded devices that could be used in everyday life to perform an angle cuts, you can pay attention to the technique of Italian production.

The Mini Cut band saw from the MASS company is a small-sized device with a hand clamp, for working not only with pipes, but also with corners, rods, and profile elements.

The machine supports setting the cutting angle from 0 to 45º. The procedure is carried out using a tape belt at a speed of 45 reciprocating movements per minute. The device is equipped with a 370 W electric motor, which is powered by a household network. The maximum permissible diameter of the cut round pipe. 65 mm.

Numerous machines with electromechanical and electrical drives have been developed on an industrial scale for pipe cutting. Technically sophisticated devices allow high precision thermal, oxygen and plasma cutting:

latest Комментарии и мнения владельцев

How to cut a pipe at 45 degrees

When installing the pipeline, it is quite often necessary to cut the pipe at an angle. over, the angle should have just the degree that is needed for the structure. If the corner is made incorrectly, it is unrealistic to make exactly the dimensions of the pipeline that were supposed to be made. For example, the pipe will rotate 45 degrees during installation, therefore, you need to know how to cut the pipe at 45 degrees. To do this, we need marking tools, an angle grinder or a hacksaw for metal.