How to cut a countertop for a round sink

How to cut a sink hole in a countertop

When you have experience in a particular case, then you do not notice the difficulties, everything seems simple and straightforward. But when you start some operation for the first time, even little things raise questions. How to cut a hole in the countertop for the sink, where to start?

To start with the designation of the place where the sink will be located on the surface, because there are at least three options:

- how the water will be supplied to the faucet;

- how the faucet will be installed;

- how the drainage is done;

- Will there be enough space for additional equipment (filter, soap dish, trash receptacle, and so on).

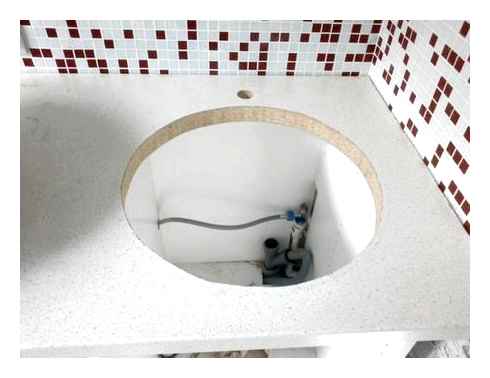

After understanding and presenting a complete picture, you can proceed directly to the question of how to cut the sink in the countertop. It is good if it is rectangular, but if it is round or oval, or even complex geometric shape, then how to cut a countertop for a sink?

The template will help you, or rather, you can’t do without it. Some manufacturers, in order to make it easier for the future owners of the sinks, offer a ready-made template in the package with the purchased product.

But if you are not lucky with this, do not get upset. Since you have already set up and imagine how to cut the countertop under the sink, it will not be difficult to make a template of the sink with your own hands.

Take cardboard or heavy Watman, and trace the contours of the future sink hole with a pencil on a sheet of paper. Then use scissors to cut out the necessary details. Please note that you must take the measurements on the outside, not forgetting the sawing gap.

So, when the template is ready, you can move on to the next step. marking.

Draw on the surface of the board with a simple pencil the line of the future sawing. To do this, place the template where the future sink will be located and trace the contours of the desired hole.

Some people fix the template to the surface and immediately start sawing. Specialists recommend abandoning this method and be sure to do the marking with a pencil. Why? Because how to properly saw the countertop under the sink, if the template is always moving? There is a chance of cutting along with the cardboard, which will distort the required dimensions.

You don’t want to make a template at all? You can turn the sink with the front side to the countertop surface and trace its contours with a pencil.

Now it is necessary to make apertures under a sink by a drill to enter a jigsaw for sawing. At the same time for:

- rectangular shape. 4 holes (in each corner);

- triangular shape. 3 holes (in the corners);

- oval or round. one hole (anywhere).

Thus, the surface is prepared directly for sawing. If there is a possibility and space allows, it is desirable to detach the plate of the future tabletop for the time of the sawing process.

So, how to make a hole for the sink in the countertop, depending on the material of the product? Let’s talk about that further.

How to embed the sink in the countertop: made of artificial stone at home, instructions

Inserting the sink into the countertop. Types of sinks by installation type, materials and form. Peculiarities of working with natural stone surface and step by step instructions.

Epochs are changing, and with them, so is life. Modern kitchen equipment differs significantly from the stereotypes established over the years, only some accessories remain the same. No kitchen room can do without a refrigerator, sink and stove, neither now nor a few decades ago. One of the key parts of the “working triangle” is the sink. And if previously it was, as a rule, an enamel surface-mounted design in white, now the variety has greatly increased. Modern kitchen sinks are made of different materials, have different shapes, sizes and design features. Installation of such elements may not always be under the power of the owner. Features of different models, their advantages and disadvantages, as well as tips on how to cut the sink into the countertop. below.

How to cut in a corner sink

The peculiarity of this kind of embedding is that it is necessary to saw a right angle for installation. It is done again with a jigsaw, and to facilitate the work, it is best to drill several holes in a row, then you will not go left-right.

The inner and outer corners of the sink must fit together and match the corners of the sink. Control this moment and it will fit perfectly.

You will learn how to choose a corner sink from our article.

How to cut the sink into the countertop. step by step guide, installation instructions

If you replace the sink or buy a new kitchen unit, you will need to remount the sink in the countertop. You can perform this work yourself or use the services of a master. The process is not difficult, but it requires attention and quality performance.

Incorrectly done mortise sink in the countertop will end up with water seeping into the piece of furniture, it will swell and deform as a result.

Necessary materials

Sealant serves to prevent moisture in places of contact of a sink and a table-top. Water can be very destructive to particle board. Different surfaces can be treated with different sealant. When working with artificial stone only silicone is used. Sealants containing alcohol are used more often on wood and plastic.

If it is decided to cut a hole in the countertop under the sink by your own efforts, you will need a special tool. “angle grinder” with a diamond wheel.

The use of sealant not only prevents unwanted penetration of water. This serves and additional strength of the connection.

If the sink is purchased separately and will need to install it, it is advisable to trust this work to professionals.

- electric drill

- electric jigsaw

- Wood drill 10 mm in diameter.

- wrench set

- Brush

- adjustable wrench

- a rasp

- An electric screwdriver

When buying furniture for the kitchen with such a surface, it is desirable to have a ready-made product, which will only require connection to the water supply and sewerage system.

Before sawing a hole in the countertop for the sink, the required hole is marked. For this purpose a template is made of cardboard or thick paper. Some manufacturers and manufacturers of sinks attach the template with the product itself. If you have chosen to use the countertop and the rims are wide enough, you can mark without a template. To do this, use the sink as a template. The upper surface of it is attached to the plane and a marker or pencil traced on the contour. For ease of installation it is desirable to remove the countertop. Allow 0,5 to 1 cm for the inside of the sink. From the drawn line, drawn a working contour, which is done and the cut.

It will look more solid, but it will be more difficult to install the sink into it by yourself.

Having marked the kerf line, the template is removed and you can begin the process of sawing out a place for the sink. Drill a place for the saw of an electric jigsaw, with a diameter of about 10 mm. For a square or triangular sink, holes are made in all corners. If the product has a round or oval shape, one will be enough to work.

Install the sink in a tabletop made of wood or particle board, having the required tools and simple skills of handling it, is not difficult.

The hole and kerf made from the side of the laminate, it will prevent it chipped. The jigsaw should carefully saw the required hole according to the drawn contour. The electric jigsaw must be pressed firmly against the surface. The saw blade must run straight at a right angle.

The sealing tape supplied with the product is applied to the sink.

When doing this job, it is important to maintain the inside of the sawtooth. Or to arrange a tabletop so that at the end of sawing this part will not fall down. If the remaining and the part to be removed are separated suddenly, the laminate flooring may crack. Or a part of the chipboard will break off.

You can use a drill with a special drill bit. furniture drill bit, just take such a drill bit of the required diameter.

If there is no space for this arrangement, or the countertop was not removed, use construction tape. In this case, sawing must be done intermittently. Making a kerf of 10-15 cm., which is then taped on both sides.

To the bowl is mounted drain and, if the design provides for it, a faucet (water faucet).

After sawing is completed, the sink is tried on beforehand. It must fit freely, but the gap must not be too big. If it fits too tightly, you need to enlarge the place of installation with a rasp or jigsaw.

Having marked the kerf, the template is removed and you can begin the process of sawing out the place for the sink.

Now it is necessary to carefully “sand” the inner face, to which the sink will adjoin. It is done with fine grit sandpaper. The resulting dust is removed, and a thin layer of sealant is applied to the point of contact with a brush.

For the convenience of installation, it is desirable to remove the countertop.

How to cut a hole for the sink in the countertop?

When you have experience in a particular case, then you do not notice the difficulties, everything seems simple and clear. But when you start an operation for the first time, even little things cause questions. How to cut a hole in the countertop for the sink, how to begin?

To begin with the designation of the place where the sink will be located on the surface, because there are at least three options:

- How the water will be supplied to the faucet;

- how the mixer will be installed;

- how drainage is done;

- whether there is enough space for additional equipment (filter, soap dish, garbage can, etc.).

After understanding and presenting a complete picture, you can proceed directly to the question of how to cut the sink in the countertop. It is good if it is rectangular, but if it is round or oval, or even complex geometric shape, then how to cut a countertop for a sink?

The template will help you, or rather you can’t do without it. Some manufacturers, in order to make it easier for the future owners of sinks, offer a ready-made template immediately with the purchased product.

But if you are not lucky with this, do not get upset. Since you have already set up and imagine how to cut the countertop under the sink, it will not be difficult to make the sink template on your own.

Take cardboard or heavy Watman paper, and trace the contours of the future sink hole with a pencil on a sheet of paper. Then use scissors to cut out the necessary parts. Note that it is necessary to be guided by the external measurements, not forgetting about the gap when sawing.

So, when the template is ready, you can move on to the next step. marking.

Draw on the surface of the board with a simple pencil the line of the future sawing. To do this, place the template where the sink will be located in the future and trace the contours of the desired hole.

Some people fasten the template to the surface and immediately begin sawing. The experts recommend to refuse such a method and to make the marking with a pencil. Why? Because how do you properly cut out a countertop for a sink if the template keeps moving?? There is a chance of cutting through along with the cardboard, which will distort the required dimensions.

You don’t want to make a template at all? You can turn the sink over to the surface of the countertop and trace its contours with a pencil.

Now it is necessary to make sink holes with a drill so that the jigsaw can enter for sawing. At the same time for:

- rectangular shape. 4 holes (in each corner);

- Triangular shape. 3 holes (on the corners);

- oval or round. one hole (anywhere).

The surface is thereby prepared directly for sawing. If there is a possibility and space allows, it is desirable to remove the plate of the future working table for the time of the sawing process.

So, how to make a hole for the sink in the countertop, depending on the material of the product? Let’s talk about that next.

Selection of the sink and preparatory measures

It is not necessary to understand step by step how the installation is performed. You also do not need to know the exact dimensions. You can probably do without the jigsaw.

But all this will be possible if you ask for help from specialists, who will take care of all these issues. But this service is not the cheapest, and the cost of installation sometimes exceeds the cost of the sink itself. So you can draw your own conclusions. But you will surely have to choose the product yourself. Experts and just experienced homemakers advise to opt for a sufficiently deep sink (sink) and not very high selected faucet. Still, the faucet also plays a role in this case.

Deep sink allows you to avoid splashing water, and dirty water, while washing dishes. Plus, a deep product gives the opportunity to stack quite a large number of dishes.

The last but not the least role is played by the fabrication material used.

The easiest sinks in terms of installation are rightly considered to be made of stainless steel. The alternative is enameled steel, but its durability is lower.

To install the sink itself, cut a hole under the faucet, fix it on the countertop under the wood. made of fiberboard or other materials, you will need to prepare a certain set of tools and materials.

- Jigsaw. Preferably electric. And buy several interchangeable nozzles at once, as beginners often encounter their breakage due to unsure movements;

- Self-tapping screws, screwdrivers or screwdrivers. Actually, fasteners and tools for tightening them;

- Fixings. Most often, the fasteners for sinks and basins are included. Make sure of this when buying;

- Sealant. Must be moisture-resistant to withstand the further strain of water and moisture.

Sealant treatment is made all around the perimeter of the landing place. This way you will ensure an effective watertight seal.

How To Cut a Hole For A Sink In A Laminate Countertop

If the countertop is made of particleboard or fiberboard, then it is doubly important to use a sealant.

Furniture and furnishings

The use of innovative technologies in the field of design has significantly expanded the range of interior solutions for the kitchen, where used equipment must be not only aesthetic but also functional. In accordance with current requirements, a modern kitchen must be equipped with a number of devices and appliances designed to optimize the cooking process. One of these devices is the kitchen sink, the installation of which only at first glance seems a fairly simple task. However, given the variety of models and the possible locations of its placement, it is important to choose the design and the procedure of its placement in the most responsible way. Despite the wide range of models, the most popular are sinks made of stainless steel and embedded in the kitchen countertop. Given the popularity of these products, it will be most appropriate to consider the design features of this product and find the answer to the question: How to install a sink in the countertop?

The principles of kitchen ergonomics: the role of the kitchen sink

Positioning your kitchen furniture and appliances is key to optimizing your cooking. Surely everyone is familiar with the concept of ergonomics and its basic principles, which may vary slightly depending on the type of room. The kitchen is no exception repair in this area is subject to strictly defined principles of ergonomics. According to them, the arrangement of furniture and equipment in the kitchen depends on the sequence of work, and in this regard, it is recommended to place furniture from left to right in a strictly defined sequence: refrigerator dishwasher (if any) sink stove. Between the named technical objects are recommended to place work surfaces with cabinets.

As for the minimum distances between objects, there are also certain requirements:

- The distance between the sink and the stove, as well as between the refrigerator and the sink should be 40 cm;

- The refrigerator and stove must also be located at a distance of 40 cm from each other.

What to consider when choosing a kitchen sink?

When choosing a kitchen sink, pay attention to the following factors:

- Functionality, which is determined by the type of work in the kitchen and depends on the number of additional bowls and draining wings. These compartments will be useful if you are accustomed to carrying out several manipulations in the kitchen at once;

- Capacity, which must be determined by the amount of dishes you wash daily;

- Stability and durability, to a greater extent depending on the material from which the construction is made;

- The design solution and design of the sink should be such that it fits perfectly into the environment and becomes a full element of the integral interior concept;

- Usability: the sink should be made to stand and work comfortably near it.

Constructional types of kitchen sinks: a brief overview

There are a number of requirements for the installation of a kitchen sink, so it must be carried out in accordance with a certain technology. The choice of the required technological solution, and, accordingly, and the method of installation depends on the design of the sink. Consider the most popular design types:

- Overhead sinks are the most budget-friendly option, the distinctive feature of which is the ease of installation. The principle of their installation is based on the fact that the sink is put on a separate cabinet, in connection with which they become a continuation of the countertop, as if, replacing it. Despite the described above undeniable advantage, for this type of sinks are characterized by disadvantages. relatively small thickness of the product and the formation of a gap between the sink and countertop, which leads to additional inconvenience;

Important! Experts recommend giving preference to overhead models if the kitchen set consists of separate sections. If the kitchen modules are combined under a common countertop, it is more appropriate to use recessed models.

- Inset sinks. are models, which are installed directly into the worktop, that is why it is necessary to begin installation measures with preparation of the corresponding hole in the worktop. Installation technology of inset sinks implies attaching the construction to the inner side of the countertop with special holders and brackets. Recessed sinks of this type are characterized by a solid appearance and ease of operation. Despite the fact that the cost of such models is somewhat higher, experienced professionals often give preference to them due to their practicality and the ability to avoid accumulation of moisture between drawers;

- Underbench sinks are innovative models, the high cost of which reduces their widespread availability and limits their widespread use. The principle of installation of these sanitary ware products implies their fixing below the countertop level, in connection with which they form a single whole with it. The advantages of under-bench sinks are their aesthetic appearance, high noise absorption and effective sealing of joints. These products are also hygienic and durable.

Materials for inset and overhead sinks

As for overhead and inset sinks, both are made of stainless steel with the same frequency, remaining at the moment one of the most popular. Sinks made of stainless steel can vary in appearance, and smooth sinks and sinks with a linen-like texture are the most common.

In addition to traditional stainless and enamelled steel sinks, built-in sinks made of stone and mineral-epoxy composite materials are no less popular. Artificial stone is also a popular material. Sinks made of composite materials have a spectacular grained structure, reminiscent of polished stone in appearance. Recessed sinks made of artificial stone constitute a vast group of kitchen accessories characterized by high aesthetic and performance characteristics, including resistance to scratches, abrasion and sharp temperature fluctuations.

The form of sinks is no less diverse along with single-cup, there are also models with several (two to four) bowls, which can be both shallow and deep, equipped with additional dryers.

The basics of mounted sinks

- Mounting overhead sinks is carried out on a separate module of the kitchen countertop so that it completely covers its top. This installation is simple enough fixing equipment is made with the help of L-shaped elements with an oblique slit. To fix a sink, you need to prepare at least 4-5 fasteners.

Important! Before you install the washbasin, you must hook up the faucet, which will reduce the installation hassle later on.

- Apply the pre-prepared fasteners to the inside of the cabinet and leave the appropriate marks;

- Prepare the shortest self-tapping screws (15 mm) and screw them in the marked places so that above the mark protrudes at least 5 mm;

- Treat the end of the cabinet with sealant, which will protect the furniture and increase the reliability of fixing the sink;

- Place the sink on the screwed-in self-tapping screws and move until it is fully seated;

- Install the brackets, remove the excess sealing compound, and then connect the sink to the water and drain pipes.

Inserting a sink into a countertop: a step-by-step guide

Let’s consider the principle of installation of a built-in sink in a countertop made of particle board, covered with plastic on top. If you wonder how to fix a sink in the countertop made of other materials, including artificial stone, carefully read the product data sheet, where the manufacturer should detail the recommendations for working with this material.

Preparation of materials and tools

Before proceeding to install the sink, check its completeness with fasteners. Most often these are special clips that are mounted on both sides. On the cut edge of the countertop and on the inner surface of the sink. In addition, the kit should include a tubular sealant, which will be needed to seal the joints. In addition, prepare the following set of tools:

- Electric jigsaw, which can be replaced by the usual hand tools, and a set of spare saws on wood;

- Drill with a 10 mm drill bit (for metal) and self-tapping screws;

- Standard set of measuring tools: a construction knife, level, angle, tape measure, Phillips screwdriver, ruler and pencil;

- Colorless silicone sealant, which is necessary for sealing the gaps and joints.

Making a marking: important nuances

- The marking carried out according to the following recommendations will be relevant in case of installation of a standard rectangular inset sink. If you are installing a round sink, familiarize yourself with the following additional installation steps.

- Using a pencil, in the place where you plan to install the sink, draw two perpendicular mowing lines, at the intersection of which the drain will be located;

- Turn the sink and put it on the countertop with the bowl upwards and align it according to the prepared marking (you can see the intersection of axes through the drain hole). Take a simple pencil and trace the outer edges of the sink along the perimeter. It is important to take into account the size of the mortise sinks, as well as the mutual location of the boundaries of the sink and the remaining free edge of the countertop, the presence of which is necessary for the rational installation of cabinet doors;

Important! The sink must be inside the drawer so that it will not be an obstacle for closing the doors of the cabinet.

- Next, measure the width of the edge of the sink and, according to the obtained value, draw the inner contour along which the cutting line will run. Although the width of the edge is individual for each sink, on average it varies within 12 mm.

Important! The size of the hole must be such that the sink will fit freely into it, with the allowable deviation from the markings not exceeding 3 mm.

How to cut a hole in the worktop correctly?

- This process is carried out with the help of an electric jigsaw, however, before the tool saw enters to the full depth of the material of which the tabletop is made, it is necessary to make technological holes that facilitate the process of work. The holes are made with a drill or an electric screwdriver at the corners of the internal marking.

Important! Corner holes should be located in the inner plane of the cutting area, and their edges only in contact with the cutting line.

- In order to avoid the formation of chips on the laminated surface all the cutting work should be performed on the front side of the countertop.

- After you have made the holes at the corners of the cut plane, jigsaw the hole along the inner mowing line of the cut. To prevent the cut part of the tabletop from falling off, screw self-tapping screws along the mowing line of the cut, which will ensure its fixation.

- After you have made the hole in the countertop, remove the self-tapping screws and the cut-off part of the countertop from the main plane, clean the cut from dust. Pre-install the sink in the resulting hole, which is necessary in order to verify that the product matches the dimensions of the hole.

Important! The sink should fit freely into the resulting hole (if there are difficulties, you need to trim the edges with a jigsaw).

Rules for processing the cut: tips from experts

- In the process of preparing the hole, all sorts of microscratches and roughness can form on the inner mowing line of the cut. In this regard, it is necessary to consider the rules of processing the cut, in case of neglect, which can cause problems of the following nature:

- It is practically impossible to completely seal an uncleaned particleboard surface;

Important! Insufficient sealing will lead to the ingress of moisture on the unprotected area of the countertop, which will cause the activation of processes of decay and the formation of fungal plaque. Subsequently, the cut edge will become brittle, which will reduce the stability of the sink and lead to its warping.

- Rotting of the countertop will soon lead to a decrease in its physical, aesthetic and operational characteristics, which will require replacing it.

- To avoid this, the end side of the cut is sanded with fine sandpaper;

- Thoroughly treat the entire cut area with sanitary sealant. Specialists recommend doing this work with a trowel, in the absence of which you can do it with your finger. By implementing these protective measures you will prevent the tabletop from becoming wet and swelling.

Important! If in the process you found chips in the plastic (the front side of the countertop) carefully dab them with sealant, while it is not necessary that the layer was thick in this case its thickness does not matter.

- There is another way to protect the end face of the cut. treatment with PVA glue. In spite of the fact that it is more labor-intensive it is not inferior to the previous one in its reliability, but for better protection the applied layer of glue must dry within 30-50 minutes.

- The next step involves gluing a sealant made of polyethylene foam (it was noted earlier that it should be included in the package of the sink). It is glued to the edge of the sink along its perimeter. If, after gluing the sealant, you find the edges of the material sticking out, carefully trim them with a knife. If you neglect this advice, you will find that the edges of the sink are loose against the countertop, and water getting into the gaps will lead to swelling and subsequent rotting of the countertop ends.

Due to the fact that the process of gluing the sealant directly determines the durability and performance of the future headset, we will consider it in more detail.

- Take the sealant and use a rag soaked in gasoline and solvent to degrease it;

- Apply sealant to the gasket in a continuous strip (the strip of sealant should be thin enough so that the adhesive does not come out during compression);

- Press the sealant to the outer edge of the sink.

How to secure the inset sink to the countertop?

- Apply a layer of silicone to the countertop (between the cut and the outer marking line);

- Place the fasteners on the inside of the sides of the sink and, making sure that they are not completely fixed, proceed to install the sink. It starts with a recess on the side where the faucet will be attached;

- Subsequently the rest part gradually becomes in the hole until the sides of the sink tightly touch the inner surface of the table top.

Important! While installing the sink, firmly press the entire surface of the structure, which will remove excess silicone from under the sides of the sink.

- Using a construction level, make sure that the installation is correct, and then proceed to the final stage of the final fixing elements;

- After completing the above steps, proceed to connect the utilities. To do this, connect the hot and cold water hoses to the water system, using a gasket.

After securing the hoses, the installation steps are as follows:

- Insert the siphon outlet into the sink (S-shaped design is recommended);

- Add a rigid corner or soft corrugated pipe to the siphon;

- Lead the pipe from the trap into the sewer pipe;

- Check all system connections for leaks.

How to cut a hole in the countertop if it is made of artificial stone?

- In most cases artificial stone countertops are ordered with holes, calculated for a particular sink, but if in the process of ordering such conditions have not been specified in advance, you can turn to specialists who, using special tools, will cut the hole of the required shape and size.

- If you want to carry out the work yourself, in accordance with the above technology, instead of a jigsaw, use an angle grinder (angle grinder), as well as a disk for cutting concrete with a diamond coating.

Peculiarities of installation of angular, round, as well as granite sinks

The process of embedding the corner and round sink is identical to the one described above, but for both varieties there are certain peculiarities of installation.

Types of sinks for a sink

The range of kitchen sinks is represented by a huge assortment of household appliances, differing not only in size and design, but also in the way of installation and fixing. So, according to the method of installation distinguish such models of kitchen sinks as:

- Desktop. These sinks are installed on top of the kitchen unit countertops, to which they are fastened at the level of the drain siphon. This type of sinks is seldom used in kitchens. In bathrooms, these sinks are found as premium appliances. Therefore, their price is appropriate.

- Overhead. Devices of this type are installed on floor pedestals. The sinks have sides, which function as a supporting plane. The appliance is placed on them, resting on the upper ends of the cabinet walls. Most often these models are made of stainless steel, hence the low price of the product.

- Built-in. Structurally, the device of this type is “sunk” into the countertop of the kitchen set, to which it is attached from the back side of the plane with special fasteners. The installation process consists in cutting a piece of countertop exactly to the sink’s dimensions.

- Pedestal sinks. These sinks are installed just below the front surface of the countertop. These models are usually placed in countertops made of stone (natural or artificial). To fix them, special brackets are used, and the ends of the appliances are treated with a special adhesive composition, which not only glues the sinks to the countertop, but also creates a tight connection of planes.

- Integrated. Basically, such sinks are made of synthetic stone, less often of stainless steel. The main condition for installation is a minimum clearance between the appliance and the countertop.

Attention! Only professional plumbers deal with the installation of pedestal and integrated models. This is due to the fact that the installation of such sinks is a complex process, based on precise adjustment to the countertop. Therefore, it is better not to carry out such installation yourself.