How to cut a polypropylene pipe without scissors

How to cut polypropylene pipe If you do not have scissors?

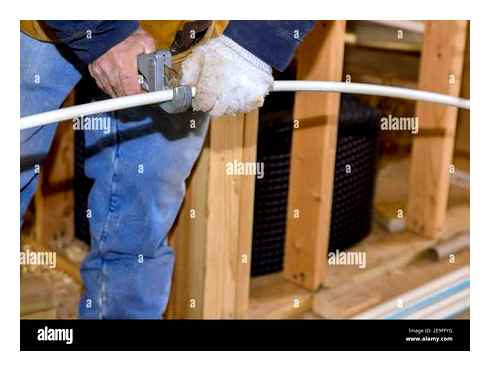

No special scissors, you need to cut a polypropylene pipe (water pipe), than to cut it without scissors? hand shears. True, the diameter of the pipe must be considered, as well as the thickness of its wall. If the pipe is reinforced with aluminum you need to buy a shaver for the scissors, if the reinforcement is made of fiberglass you don’t need a shaver.

When working with these tools your hand gets tired, it is very difficult to cut a lot of material quickly. You can not use them to cut thick pipes, the maximum diameter is 42 mm. If you use an angle grinder, you need to prepare a disc for metal. When working, it is important to accurately distribute the force. you can not push hard on the angle grinder.

What you can cut a plastic pipe with?

Band saws and jigsaws are most effective for cutting polymer materials in the form of rods, sheets and sleeves with a large diameter / thickness. Band saws for cutting plastic are convenient, because they dissipate heat from the cutting zone better than, for example, with circular saws.

What tool can be used for cutting plastic pipes

If we consider that the people in our country artisans, then to cut the pipe, he manages to use the most unimaginable of improvised means. But do not think that such a cut contributes to the excellent quality of the coming pipeline. Therefore, let’s consider tools that allow you to cut plastic pipes more perfectly:

- Metal hacksaw;

- self-sharpening knife (with small teeth);

- scissors for cutting plastic pipes;

- The pipe cutter is of the roller type;

- Cordless pipe cutter;

- guillotine pipe cutter.

Cutting pipes with a hacksaw or a knife is not worth taking seriously, because using them makes the pipe flapping and the burrs appear, which need to be removed with emery paper or scraping with a knife.

In any case, the quality of the cut is poor.

These methods can be used to make single cuts. If the pipeline has a complex configuration and many joints of separate sections, it is better not to use these tools. Pipe scissors are mostly used to cut plastic pipes.

the sharp-ground blade of the knife is fixed only on one side of the tool. In place of the second blade, there is a rather large base with a slot designed to receive the cutting plate. Work with such scissors is done only by human muscle power. between the handles of scissors is arranged serrated rack round shape, which after the closing of the handles of scissors pushes the blade in the direction of the base. The process of cutting the pipe is as follows:

- A distinctive mark is put on the surface of the pipe and marks the place of the cut;

- the base is placed over the given mark, controlling its position through the slot in the base;

- then plunge into the pipe, apply force, and with steadily increasing force, create the final cut in the pipe.

The advantages of the scissors are high enough efficiency and low cost of construction.

The disadvantage is considered to be a direct link between the effectiveness of the tool and the physical strength of the person working with it. In addition, while cutting one should look for the smooth movement of the hand, otherwise the blade can simply slip off the toothed rack.

It is clear that one’s hand gets tired quickly when making many cuts, that is why the speed of the works is reduced. In addition, it is unrealistic to use scissors to cut pipes of large cross-section. The biggest cross-section of the pipe that can be cut is 42 mm.

The pipe cutter is not worse than the scissors in terms of efficiency. But unlike them, there is practically no physical effort at work here.

The cutting process itself is carried out as follows:

- mark the place of the cut with a marker;

- the screw is unscrewed from the clamp, and the bracket is brought to the place of the cut;

- then the screw is tightened smoothly (so as not to break the pipe);

- after the necessary cutting force is felt on the cutting wheel, the clamp is rotated around the pipe, smoothly tightening the tensioning screw.

This way the pipe is cut in a circular manner, and the end of the pipe comes out extremely flat, without any burrs.

the only hazard when working with the pipe cutter is the cracking of the pipe due to the very strong clamping force of the screw.

Guillotine pipe cutter is used for pipes with a diameter of 63 to 350 mm. The possibility of deformation or destruction of the pipe walls is reduced to almost zero. The process of cutting looks as follows:

- mark the place of the cut on the pipe and insert it into the guillotine, fixing it in a sector of 30 to 60 degrees;

- The guillotine blade, which is mounted on wheels, swings around it;

- after the first cut of the plastic, plunge the blade into the pipe with the rotating screw handle, and thus finish the pipe.

That way the cut is extremely smooth and burr-free.

Guillotine blades are easy to replace. In modern guillotines blades are additionally covered with teflon.

Guillotine pipe cutter

A guillotine type mechanism is well suited for trimming plastic workpieces. Such a cutter is used to cut products with a diameter of fifty to seventy millimeters.

- Make a mark on the place of the future cut.

- Pull the handle apart and wrap it around the workpiece.

- Close the handles and touch the cutting component to the mark.

- Press down on the cutter grips so the cutting component goes all the way around the perimeter of the workpiece.

Make the cut with high precision. Make a serious physical effort to solve this problem. This will ensure a straight cut. The guillotine has one drawback. If it is used, there is a possibility of deformation of the pipe at the inner diameter. But this happens very rarely.

In general, this tool is well suited for cutting medium- and large-diameter sewer pipes. The operation of the guillotine is comfortable and easy. Even inexperienced craftsman can work with the tool.

Features of the material

When choosing the method of stripping, you need to consider the end of the pipe. In the standard distribution for cold and hot water, heating, reinforcing layer is in the middle, between the outer and inner layers. In older models it is located closer to the outside, protected from external influences by a thin layer of polymer. Its main function is not to increase reliability but to reduce the thermal expansion of the pipe.

On this basis, we can highlight the following features of stripping for polypropylene pipes:

- The inner reinforcing layer is not removed, but only the ends are deburred. This is necessary for soldering polypropylene.

- In the case of the outer layer of aluminum, complete stripping of the surface to a depth of up to 2 mm is necessary. The foil layer at the connection to the socket is completely removed.

- Pipes that are not reinforced do not need to be deburred or chamfered.

Removal of part of the aluminum foil is necessary for all types of coatings. homogeneous and with peoria. The reason. metal heats up and cools down faster than plastic. In the contact area there can be nonuniform crystallization at the boundary with aluminum that will lead to loss of mechanical strength.

Tip: Before stripping pipes should stand in the room at room temperature for 5-6 hours.

The main types of tools that cut propylene pipes

All modifications of equipment manufactured for cutting thermoplastic polymer polypropylene pipes are subdivided into several design variants.

Precision scissors. have a fairly simple, reliable ratchet-cutting mechanism. This tool can be used to cut and fragment items with a diameter of 3.0-41.5 mm. Cutting tool has a steel blade (alloy grade) with a serrated bar that allows for fairly light, even cuts in propylene tubing.

One-handed use of the precision scissors is possible without difficulty, but the muscles of the hand, forearm and shoulder fatigue quickly increase with larger amounts of material fragmentation. Buying a tool involves registration of a one year warranty, valid only with the competent use of scissors.

Other tools for cutting plastic pipes

They are used occasionally when there is no pipe cutter under your arm:

- Angle grinder. for cutting plastic pipes you will need an alloy cutting disc. The main point when working with an angle grinder is a clear regulation of the effort, you can not put too much pressure on the tool.

- The electric jigsaw is a more successful method in the absence of special scissors.

There is a high chance of getting an oblique cut, so the pipe must be rotated several times while working for better accuracy.

What is categorically not recommended to cut pipes:

- The bandsaw blade moves very slowly and if it is not otsrozuboe it can damage the inner cross section of the pipe, which leads to chipping and cracking.

- Circular machine. Since plastic pipes are flexible, pushing them into the machine often causes displacement of the pipe and shock, which is not safe for the person making the cut.

Polypropylene pipes are sold in coils or straight sections, whose length reaches 12 meters.

It is clear that during installation it is often necessary to cut them with scissors for cutting polypropylene pipes, as such huge sections for the creation of plumbing and heating systems are not suitable. The pipe of suitable length is cut off and then the welding goes on.

Comfortable and common in use when working with one hand, but if cutting is intense, the hand will quickly get tired;

Cutting polypropylene pipes with this tool. a pleasure, because the cutting speed is quite high. from 4 to 7 seconds. But there is a disadvantage. limited range of pipe cutting. This tool can only cut pipe up to 42 mm.

This cutter for polypropylene pipes can cut pipes with a cross-section of 63 and up to 350 mm. It has Teflon-coated blades that cut at a ninety-degree angle, leaving an even, burr-free cut. Blades can be simply changed or sharpened.

This way of cutting has a huge advantage.

It is not necessary to surface finish the pipe before welding after sawing, because the cut goes out smooth and even, there is no deformation.

The process of cutting with the guillotine. The guillotine blade, mounted on wheels, swings around the tube, fixed in a sector from 30 to 60 degrees. After the cut the blade goes deep into the pipe by the action of a rotating screw handle, so it finally cuts the pipe to the full depth of the cross-section.

What is the best tool to choose?

When choosing the type of pipe cutter for polypropylene pipes you should be guided by how intensively you will use it.

If you need it for one time, then both roller shears and precision scissors are suitable for this. And if it is necessary to cut pipes often, the battery scissors are the best for this purpose. Also for this you will need and guillotine pipe cutter, especially if you are dealing with pipes of large cross-section.

Read more: What is better: metal or polypropylene, which pipe is better for heating systems

But all the scissors suffer from the same flaw, when cutting the blade may go a little to the side. At the small cross-section it is not so awful phenomenon, but when working with pipes of huge cross-sections such a cut requires additional processing. That’s why for pipes with large cross-sections it is better to take a guillotine pipe cutter.

Mounting

Installation of indoor and outdoor sewers are largely similar. The difference. in the materials used. For indoor sewage systems colored gray collectors are used. The outer ones have an orange hue. This is due to the difference in external loads:

- Products located indoors are exposed to its own weight and, occasionally, the load from the flowing fluid. Thermal heating up to 60-90°C with a parallel chemical attack by the components of the effluent is added.

- Parts located outside the building are exposed:

- to the pressure of the weight of the covering soil;

- The collectors can be installed in a way that allows them to be stressed by the weight of the passing traffic;

- Are experiencing forces from the overhead buildings;

- are exposed to external temperature variations, from negative to positive.

Hence, the installation of domestic sewage is carried out with the predominance of polymeric materials:

PVC products are most in demand. Installation of internal collectors made by joining the narrowed part of the pipe and the expanded (bell). additional elements. fittings (transition fittings, tees, 45° and 90° angles, elbows). are used.

Installation of sewer pipes is made with the obligatory observance of angles of inclination:

In the process of installation or repair work, there is a need to saw a plastic part. Polymers are not as hard and durable as metal products. Therefore processed by most locksmith and mechanical tools. It is possible to cut a plastic pipe by:

- Hacksaw for metal or with a fine hardened tooth;

- triangular file;

- with a jigsaw (for diameters not exceeding 50mm);

- A circular or saber saw;

- Angle grinder and other tools.

Installation of sewer systems is performed according to the rules based on the requirements of SP 30.13330.2012. In addition to observing the gradients, it is necessary to properly distribute the points of fasteners, joints. If technically possible, it is recommended to perform hidden wiring.

Installation of sewer pipes inside the premises begins:

- With the drawing up of a work plan;

- Performing a sketch or drawing;

- Determining the necessary dimensions of the collector;

- The preparation of the necessary material;

- Preparation of the tool, which can be used to cut the plastic part.

At the end of the installation phase, the device of the internal sewer is checked visually. Next, it is necessary to flush the system with water in order to detect possible defects in the product or the presence of leaks.

Cutting technique

Self-cutting can be done with items from 5 to 30 cm in diameter. So if the product does not fall within these boundaries, it is best to contact professionals.

When carrying out any such manipulations, it is important to remember the basic rules:

- Metal-plastic products are very sensitive to temperature, so that in hot or cold weather, there may be some problems. The material is easily compressed and expands, making it difficult to determine the true dimensions.

- Metal-plastic, as well as polypropylene pipes, can be cut with any improvised means. But to avoid various negative effects it is best to do it with special tools.

- An excellent tool is a special self-sharpening knife. But if you plan to work on replacing one section with another, it is better to abandon the tool in favor of scissors.

- The material is quite fragile. Applying too much force is fraught with the appearance of cracks or specific deformations. The allowable load can be seen in the passport of the product, which was issued at the time of installation of plumbing.

- The type of cutting directly depends on the proportion of metal and plastic in the product. If there is more metal, then when cutting there should be as little friction as possible. Otherwise, a large proportion of plastic implies a high intensity of work with a lot of friction.

- Before you start work, make sure that there is no water or gas flowing through the pipe. It is necessary to turn off all taps and wait a little.

- After completing the work it is necessary to properly clean the inside from debris that can lead to clogs or break the specialized equipment.

The use of electronic tools for cutting is not considered reasonable, because the specifics of the material is not designed for it. You can handle with hand tools.

How to cut polypropylene pipes without scissors

In the section of Construction and Repair on the question METALLOPLASTIC PIPE-need to cut with special scissors? The best answer given by the creator of Eurovision is that I used an alloy hacksaw. But it wasn’t straight all the time.

Answer from the Right[guru] You can also use a hacksaw.

I still use a knife handle to flatten it. but keep in mind that this is somewhat incorrect.

Answer from Lowbrow[guru] There are different methods on one website looked at 2) 2) 2. knife with teeth, or as it is also called a self-sharpening knife. It is more difficult to cut with it, because in the middle there is a part of aluminum. But in the absence of other tools, you can cut it. The disadvantages of such methods of cutting pipes is that when cutting the pipe, the plastic gets hairy, at the junction of the pipe there are pieces of plastic, which can later get into the pipe and clog the filters. We don’t need that. Therefore, the most correct method of cutting plastic pipes, this cutting scissors. 3) Cutting with special scissors.

I have already mentioned them in an article with polypropylene pipes. At this point I would like to show again. Such scissors are sold at least any hardware store. supermarket, they are not so expensive and are always needed in the house, especially if you themselves conduct and serve water or heating pipes. Cutting plastic pipes, this method is really easy, just clamp the pipe and cut. The pipe is cut extremely evenly and without any jagged edges and it can be installed immediately.

Answer from Bidon Coons[guru] No. You can do it with.

Answer from VASILIY [guru] need to make an even end without tilting, and cut it with whatever you can, even an angle grinder

Answer from Victor Ivanov [guru] metal hacksaw.

Striving to make an even cut with a hacksaw, you can make an even cut, only in small cross-section. 16-25mm. For installation. a device for chamfering is obligatory! ! Calibrator (flare)

The answer from Fire is not to be found?[guru] Even scissors give a straight cut only when the pressure on both parts of the pipe is similar, and it happens rarely, so they cut with a roller pipe cutter for thin-walled pipes.

Answer from KERK[guru] They write horror stories!

You can even use a pipe cutter to cut plastic. Kinky. It’s great when you’re quietly at home, cutting a pipe, but not to assemble the entrance. You’ll be working until the second coming of Christ! You can cut it with anything! And an uneven cut isn’t armageddon either. The main thing is to use Kalibr (as mentioned above by Kot). Although the edges can be flared with other tools at hand. Burrs can also be removed with a sharp knife. The point is that when shoving the pipe in the fitting its edges do not pucker rubber o-rings in the fitting. That’s all as they say.

We have already written about polypropylene pipes in this article for us. Personally, I think these pipes, in fact, the most common, so as the pipe itself, and fittings, connections, for them are significant kopecks.

Since they are very common, I will try to tell about them as much as possible. And now a light article on how to cut polypropylene pipes. It seems like an easy question, but not almost all newcomers know about it

In contrast to iron and plastic pipes that can be cut with an alloy hacksaw, polypropylene pipes are much softer. And to cut them with a hacksaw for alloy, it is, excuse me for the expression, “pure perversion”.

But if you do not have anything at hand, you can cut with an alloy hacksaw. In general honestly cut these pipes you can do anything, even a knife, it’s plastic. But there is a small disadvantage of cutting polypropylene with, say, a hacksaw for alloy. The thing is that in the place of cutting, there will be chips, which remain in the pipe and will interfere with a water clot, and this is not good.

So when cutting polypropylene pipes, I advise you to use special scissors.

Scissors for cutting polypropylene, come with almost all soldering tools polypropylene pipes.

The scissors have a special extremely sharp knife, which is on top, as well as the bottom holder, where the pipe lies.

Just mark the appropriate size pipe, we put in the scissors and cut a suitable amount of pipe. Everything is extremely simple. It should be announced polypropylene is cut extremely easily.

After such cutting there is no burrs or crumbs, only an extremely smooth surface, you can immediately solder.

Cut polypropylene scissors, if you do not have them then buy, they are not cheap, 100. 400, but they are worth it.

Tools for cutting: classification and features of application

Pipe cutters for plastic pipes can be divided into manual tools and equipment with an electric drive. Regardless of how the tool is driven, all pipe cutters are classified by the mechanism of their action.

Pipe cutters for polymer materials are divided into several types according to configuration, principle of operation, cutting tool:

Aside from the operating principle, there are also size categories.

Notice! When speaking of size, here we do not mean the size of the pipe cutter itself, but the maximum and minimum diameter of the pipe that the tool can cut.

Most hand tools are limited to a maximum diameter of 110-150 mm, which is enough for the installation of any household communications.

Pipe cutters for larger pipelines are professional tools, they are manufactured with an electric drive. Such equipment is expensive, it is inexpedient to buy it for a single installation.

The pipe cutters differ in the material of the tool itself. The cutting part is made of alloy steel. The thicker the blade, the longer the tool will last. Handles and body can be made of metal, metal can be combined with plastic. It is preferable to choose a manual pipe cutter with aluminum handles. These shears will be lighter and easier to work with than steel ones.

Guillotine pipe cutters

The guillotine pipe cutter is a stationary frame over which the blade walks. The manual version involves smooth lowering of the blade into the body of the pipe due to the screwing in of the threaded rod, to which this blade is attached. Professional guillotine pipe cutter with hydraulic drive works like a gun.

Guillotine pipe cutter

The advantage of this type of pipe cutter is that the blade enters the pipe strictly perpendicular to its axis of guidance, applies pressure evenly. The guillotine blade is shaped like a blunt angle, which eliminates forceful impact. cut is even, without cracks, chips and burrs. Significant advantage. low price manual guillotine and simplicity of design.

The disadvantages include the labor-intensive nature of working with hand tools. Here you need to screw the rod in completely first, then unscrew it completely. If a large number of pipes have to be cut, it is worth considering a more convenient version.

Roller tool

Roller tube cutters for plastic pipes are hook-shaped tools, with a wide pipe bed and movable metal cutting discs or rollers. The configuration may differ depending on the manufacturer, but the principle of operation is the same.

The tool for installing cross-linked polyethylene pipes

Please note! Disc (with a cutting part in the form of a metal disc) pipe cutters are designed for cutting plastic pipes only. Roller (cutting part in the form of rollers) pipe cutters are universal tools.

To cut plastic pipe lay the pipe on the bed of the pipe cutter, lower the roller blades and use a rotary motion around the pipe to cut. The process is carried out by uniform pressure from several points, depending on the number of rollers. For plastic sheet metal pipes up to 50 mm in diameter one cutting wheel is sufficient.

On inexpensive tools the depth of the cutting rollers is increased manually after each lap. It creates a jerk in pressure on the pipe and causes it to shift slightly each time. Repeat until it separates. The cut may be burr-faced, so another chamfering is needed. Many models of the manual pipe cutter are equipped with a chamfering tool. However, the operations are performed alternately. first the cut, then the beveling.

Ratchet cutter or scissors

Scissors for cutting plastic materials is a secateurs with one blade and a semicircular stop, which is equipped with a ratchet mechanism to prevent reversal. It is easy to work with a ratchet cutter because only one hand is used.

Cutting is performed by repeatedly pushing on the handles and there is no return action. The principle of operation of plastic pipe scissors is similar to the guillotine pipe cutter, but the blade here performs lateral, not so uniform impact. The ratchet hand pipe cutter is used for installation of communications up to 32-50 mm in diameter. Power-driven tools cut thicker plastic pipes.

Electric chain saw

The chain saw is a pair of pliers with an attached, flexible chain of cutting rollers. There is a special clamp on the moving handle to secure the chain. Cutting is performed in a rotational and reciprocating motion with a gradual tightening of the chain until the segments are completely separated. This type of pipe cutter is convenient for cutting large diameter plastic materials or fixed sections in hard-to-reach places.

Chain saw

Please note! Chain pipe cutters are divided into tools with moving rollers (for plastic materials) and tools for metal pipes. In these pipe cutters, the rollers do not rotate, and the cut is made only by the clamping force.

Electric sabre saw

Electric saber saw is a professional tool. Used for installation of large diameter utilities. In domestic piping, its application area is sewer systems.

Electric cordless chain saw from Bosch

Sabre saw resembles an electric jigsaw, but has a quieter stroke and teeth for plastic materials. It has a flexible blade that enables it to cut flush cuts in wall-mounted sections. A big advantage of this tool is unlimited size of communications, high speed of work.

Features

On the construction market most often you can find polypropylene pipes in lengths of 12 meters. When installing a water supply system or underfloor heating it is often necessary to cut the products into shorter sections. A special tool is required for these applications. The speed and ease of installation depends on a comfortable and quality cut.

There are many types of devices for cutting PPP. Specialized tools are equipped with a sharp blade, as polypropylene is a strong material. Using a poor quality tool can severely damage the pipe. In addition, an uneven line for the trimmer cut will negatively affect the quality of installation.

When joining the elements of the water supply system back to back, it is important to ensure that the sealing of joints was at a high level. Otherwise this can lead to leaks. For this reason, it is recommended to use special scissors for cutting pipes.

Instead of special tools, polypropylene pipes can be cut with a hacksaw for metal. However, this way of cutting is more labor-intensive and of lower quality, since the edges of the cut remain rough, and the line itself for the trimmer in most cases turns out uneven.

There are many modifications of tools for cutting polypropylene pipes. Each type has its own design features and technical characteristics.

It is possible to distinguish the following types of devices:

- Precision cutters;

- hand-held roller tube cutter;

- device with a ratchet mechanism;

- cordless pipe cutter;

- pipe cutter.

Precision tools have a fairly simple design. Can be operated with one hand. These shears are suitable for cutting pipes with diameters of 3 to 41.5 millimetres. The instrument is equipped with a blade made of alloyed steel. Suitable for small jobs.

The roller-type pipe cutter is an arc-shaped housing with a handle, rollers, and a flat, round blade. The rollers rotate the pipe and the blade is a retractable mechanism. This model is inexpensive. However, the roller-type tool is easy to operate and makes even cuts at a 90-degree angle.

How to mark and cut pipe cleanly. Marking pipes.

Tools with a ratchet mechanism are a more convenient modification of roller shears. These devices are easy to use: the support and the cutting rail with the blade allow easy opening and closing with little effort. The wide tube support securely holds the tube in place in the unit. The sharp blade cuts through the material easily and does not allow it to change position. It can be operated with one hand, without great physical effort.

Cordless scissors feature high cutting speed. This is a tool mainly used by craftsmen when laying water supply systems. The device is equipped with a small electric motor. It allows you to quickly and effortlessly cut the pipe into a large number of sections.

READ How to Cut Polypropylene Pipes

The pipe cutter is used to cut large diameter pipes (from 63 to 350 millimeters). The cutting tool has a sharp, Teflon-coated blade. When cutting with such a device edges of the received sections of the pipe are perfectly flat and smooth.

It is worth noting that different modifications of scissors vary depending on the diameter of the pipes that they can cut. Models for small items (up to 42 mm) cost less than devices for cutting pipes with a diameter of 75 millimeters and more.

How to Cut PVC Panels Properly?

When cutting, place the panel on the front side To successfully cope with the task, it is worth knowing some secrets of cutting plastic. This will significantly reduce the number of rejected and spoiled panels, and save the novice craftsman from wasting time, money, and above all. from injury.

- If you carry out finishing work in the cold season, do not cut panels that have just been brought in from the street. Let them warm up to room temperature. The best option is for them to spend at least 1 night at room temperature. Otherwise, the plastic, which in the cold becomes brittle, will break off in large pieces, and cracks may occur along the entire length of the panel.

- Regardless of which method of cutting you have chosen, it is necessary to place the panel face up (photo above), otherwise the panel may deform and its installation will cause difficulties. In addition, if you make the cut on the wrong side, the front side can be covered with microcracks, which will manifest themselves only over time, finally spoiling the design. It will not be superfluous in advance to mark the line for the trimmer cut, for this will work a simple pencil or felt-tip pen (which can easily be erased from the surface after the work) and a student ruler.

- To cut several PVC-panels at a time, you need to stack them and make this stack two-point support, so the panels do not sag. worth to keep the opposite edge of the pile in the wall, otherwise during the cutting the panel will move and you will end up with parts of different lengths.

Briefly about the drainage system

Sewer design. a description of all the components and how the system works as a whole and by individual nodes. Subdivided:

Internal

- Sanitary appliances (sources of dirty water): toilet bowl, bidet, washbasin (kitchen sink), bathtub (shower cabin), washing machine and dishwasher.

- Traps and connecting elements (transition sleeves).

- Sewage pipes Ø 30-50mm. For toilet bowl 100 mm.

- Transition elements: fittings and couplings, non-return valve, revision valve.

- Main riser. the element that collects in one sewage pipe, the effluent from all sources. The diameter of the manifold should not be less than 100 mm.

Installation of indoor plumbing is regulated by regulatory documents: SNiP (Sanitary Norms and Rules) 3.05.01-85 “Internal Sanitary Engineering Systems.

Outdoor

- Drainage line of pipes Ø 100-200mm (for individual housing).

- Overflow (observation) wells.

- Couplings, fittings.

- Wastewater receiver (cesspool, septic tank, biological treatment plant).

The installation of sewers outside the building is regulated by SNiP 2.04.03-85 “Sewerage. Outdoor networks and facilities “.

Technology for cutting plastic pipes with precision scissors

There are no special rules when cutting propylene pipes. Cutting tools, especially precision scissors, have special recesses in which the material to be cut is positioned strictly perpendicular to the sharpened blade.

Careful! When pressure is applied to the handles, the straightness of the pipe can be compromised. This should be prevented in every possible way, otherwise the cut will be uneven or the tool will break!

It is very important for welding, fitting and other kinds of connection, to watch the angle of cutting. it should be only 90 deg.

When the tool is uncomfortable to hold in the hand because of the large handles, it can be clamped in a vise. You can do the same when cutting pipes with a large diameter, as there may not be enough force to normal pressure on the lever.

It is clear that it is not possible to cut a large number of pipes with these methods, but if the repair is small, you can do without large, expensive cutting tools.

Turn the tube into a chisel case and adapter

PVC pipe becomes very ductile when heated strongly. You can use it to make two things you often need.

If one end of the heated pipe is flattened and the other left round, the PVC pipe will turn into a sheath where you can store, for example, a chisel.

When the pipe is well heated, not only its shape but also its dimensions can be changed without difficulty. This makes it easy to make adapters from it, allowing you to connect pieces of equipment with different diameters.