How to cut ondulin across the wave

How and how to properly cut ondulin?

Onduline is a sheet roofing material with a core of compressed cellulose (cardboard) impregnated with bitumen and polymers. It has a wavy profile, a rough surface, covered in several layers of paint. Euroslate has flexibility, so cutting and processing it at home does not present any special problems.

- construction knife;

- hacksaw for wood;

- hand circular (disk) or reciprocating saw;

- angle grinder (angle grinder);

- jigsaw.

Euroslate cutting rules

To obtain an even cut when cutting, the following rules must be observed:

Since the composition does not include substances harmful to human health, no protective agents are used during processing.

Apply the markings with a colored pencil using a 220-230 cm long wooden lath or trim the sheet. The pencil is selected in a contrasting shade in relation to the color of the roofing material.

Marking and cutting should be done on a flat, flat surface. It is not recommended to do this on the roof. there is a high risk of damage to the supporting elements of the roof, it is impossible to firmly fix the product.

Before cutting the ondulin, it is necessary to securely fix it, otherwise it is impossible to achieve good quality.

It is advisable to control the cut in a straight line with a staff or trim.

It is better to cut in the shade, as in the sun this material heats up and becomes soft, which makes processing difficult.

Becomes brittle at temperatures below 5 ° C.

The bitumen, which is part of the euro slate, inevitably sticks to any cutting tool. To quickly clean the canvas, it is periodically moistened in kerosene, toluene or solvent, you can wipe the surface with a cloth soaked in them.

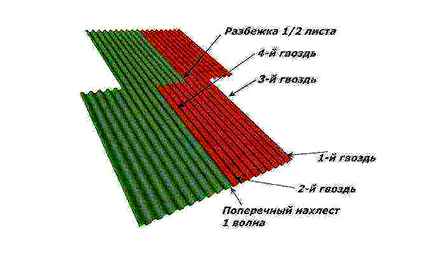

The sheets that will be at the joints are not cut at a right angle, but at an angle so that the gap between them is minimal. The seam is closed with one wave of ondulin. There are special decorative parts on sale, but they look worse.

Cutting tools overview

If you need it to cut a small number of elements only along or to fit them on small fragments of the roof, then you can use an ordinary construction or office knife with a retractable blade. The incision is made from the front side, then the sheet is bent in half and finally cut.

We cut with a hacksaw on wood and a jigsaw.

It is good to cut the euro slate across the wave using a hacksaw. For working with ondulin, tools with a blade length of 350-400 are suitable, with fine teeth and a thin cut. In the process, the sticking of small particles on a hacksaw is inevitable, so it is pre-lubricated with oil and periodically lowered into cold water.

First, markings are applied to the sheet, then all the tops of the waves are cut to a depth of 1.5 cm. After that, they are turned over, the upper points of the depressions are cut and broken along the cut. The method is suitable for small volumes.

An electric jigsaw cuts far and wide according to the same principle as a hacksaw. The saw is chosen for wood with large teeth, preferably from well-known manufacturers. Bosch, Makita. Since ondulin sticks to the jigsaw blade faster, this tool is used less often.

Circular or reciprocating saw and angle grinder.

According to experienced builders, the best option for cutting large volumes is a hand-held circular (circular) saw. It provides a perfectly straight cut, quickly processes a large volume of material. It is better to choose a disc with the largest number of teeth. You can clean it from adhering particles by cutting a piece of wood. It is convenient to cut off the euro slate yourself both along and across. It is recommended to periodically lubricate the disc with machine oil.

Less commonly, a reciprocating saw is used instead of a circular saw. With both circular and saber tools, you can independently process several sheets at once. To do this, they are pre-fastened into a pack and aligned. Thickness depends on the diameter of the blade or the length of the file.

You can use an angle grinder (angle grinder) with the thinnest disc. Cut with an angle grinder very carefully. When operating at high speeds, there is a high risk of edge melting.

- When choosing a color, it should be borne in mind that euro slate is prone to fading in the sun.

- The smaller the size and number of waves, the more overlaps there will be between the elements of the roof, which means the higher the strength of the roof.

- If the installation will be carried out by one person, then again it is better to choose sheets of the smallest dimensions and weight.

- When buying, be sure to pay attention to the thickness. If it is less than 3 mm, then the material is of poor quality.

Classical. It has 10 waves with a height of 36 mm, the pitch between them is about 95 mm, the dimensions are 2000×950 mm. Most often used for finishing flat and vaulted roofs.

Smart. It differs from the classic Onduline Smart by the presence of markings for fasteners-nails and a smart lock-hydro-barrier. It has a slightly smaller dimensions. 1950×950 mm, the thickness and number of waves are the same as in the usual one. The weight of one element is about 6.3 kg. Smart lock prevents slanting rain or melt water from entering. Especially suitable for roofing of residential and public buildings.

DIY. Already classic, its dimensions are 2000×750 mm, the number of waves is 8. Standard thickness is 3 mm, weight is about 5 kg. Most often used in areas with difficult climatic conditions. This is due to the large number of overlaps between the sheets, due to which the roof is stronger.

Compact. It has the smallest dimensions. 1000×750 mm. Thickness. 2.6 mm, weight. 2.5 kg, number of waves. 8. Suitable for finishing the roof of a small area or complex shape. The greatest number of overlaps compensates for the smaller thickness.

The price depends on the manufacturer, type, batch size, color.

| Ondulin type | Price, rub / sheet |

| Classical | 450 |

| Smart | 370 |

| DIY | 300 |

| Compact | 170 |

Euroslate of the same manufacturer and brand, but different colors may differ significantly in price.

Layout sheets

To avoid waste of material and difficulties during installation, markings are made before cutting Ondulin. To complete it you will need:

- construction tape;

- long wooden lath (2.2. 2.3 m);

- colored marker or pencil (the color is chosen so that it is clearly visible on the surface of the material).

Instead of a slat, a scrap of Ondulin sheet is often used as a template. Marks must be applied carefully and clearly so that they are clearly visible. If the marking is done transversely using a long ruler, the line of the cut is indicated by risks on the crests of the waves.

depositphotos

How to cut ondulin quickly and evenly

Ondulin is a roof covering made from environmentally friendly raw materials. Unlike slate, this material does not contain asbestos hazardous to health and is easy to process.

The choice of a suitable tool for cutting Ondulin sheets depends on the amount of work and the direction of the cut. All manipulations are carried out on the ground, then the material of the required size is fed to the roof.

Tool selection

In order for the cutting part of the tool to easily walk over the surface of the roofing material, it is moistened with water or lubricated with machine oil.

- Construction knife. for cutting along the wave, fitting in places with difficult abutment;

- A hacksaw with medium-sized teeth and a blade of 35. 40 cm. for a small amount of work and cutting material at an angle;

- Electric jigsaw (file with large teeth). allows you to speed up the process and make a cut both along and across the sheet;

- A circular hand saw with a large number of teeth is suitable for high volume jobs.

The recommendations for work largely depend on the tool used. When cutting Ondulin, the teeth of the tool are clogged with bitumen particles, therefore, it should be periodically cleaned:

- the hacksaw is cleaned in a bucket of water or a brush is used, which must first be moistened in white spirit or kerosene;

- to remove bitumen between the teeth of a jigsaw or circular saw, take a wooden block or board, on which several cuts are made.

To speed up the work, it is allowed to cut several sheets at a time. The amount depends on the size of the cutting head of the power tool. To avoid deformation and displacement, the sheets must be fastened together with clamps.

Ondulin is an easy-to-use material. It is not difficult to cut it yourself, you just need to follow the manufacturer’s recommendations and do the job carefully.

What material is ondulin made of?

So, in order to correctly select a tool and understand the features of working with it, let’s first consider the structure of a modern ondulin:

What are such sheets, in essence? It is cellulose impregnated with bitumen and formed into a ten-wave sheet. Modern ondulin has a multilayer structure, compressed enough to guarantee safety against impact and deformation.

Metal scissors: for cutting corners

Let’s start with the smallest jobs. So, there is one method that allows you to save a lot on trimming. If you do this, then the side slopes are perfectly flat, and the sheets do not have to be cut in half at all.

The whole secret is that here ondulin is cut only at the corners, and not half the entire leaf. What’s the problem? Why is it generally bad to cut ondulin? He does not suffer from corrosion.?

The fact is that such seams do not always turn out to be neat and accurate in geometry. And all this then affects the appearance of the roof and the tightness of its joints.

In the classic installation of ondulin, so-called thickened seams are formed at the intersection of the longitudinal joints. They are obtained when the sheets lie one on top of each other. And it is here that there is a possibility that in this place water will begin to flow and snow will blow out.

But trimming the corners in this case significantly reduces the thickness of this overlap, by at least 50%:

In short, everything can be solved simply. The outer sheets, which are joined at the corners, must be cut with metal scissors or a hacksaw, while slightly tilting the blade at a certain angle.

And close the junction with one cut-off wave of ondulin or a special additional element, which manufacturers produce today. The dimensions of the trimming itself depend on the size of the overlap, and it depends on the selected brand of ondulin and the parameters of its sheet.

Cutting corners, by the way, is often practiced with a router. But thanks to the use of metal scissors and patience, the cut is especially smooth and clean.

Chainsaw and angle grinder: for a perfectly straight edge

Alternatively, an angle grinder with a conventional metal wheel is also suitable for cutting ondulin:

At the same time, the sheets are cut quite well. The only negative is that the angle grinder smokes, so you have to take breaks. Plus, not everyone takes up this tool, tk. fear that unpleasant splashes of molten ondulin will begin to scatter, which is akin to driving on fresh asphalt.

But the chainsaw is suitable for cutting at an angle, across and along. Only it will need to be constantly lubricated with oil. And this method has its drawbacks: the cut itself turns out to be rough, shaggy. In addition, you still need to be able to work with a chainsaw, this tool is not one of the unsafe.

You can also use circular cutters with carbide tips for cross-cutting. Remember that each sheet should only be cut along its grooves. As well as the fact that when working with power tools, be sure to wear protective clothing.

The circular is good because it is not clogged with bitumen. And if the sheet is fed carefully, slowly, the cut is of high quality, almost indistinguishable from the factory one.

How to cut ondulin for the roof? Overview of suitable tools and work technology

Ondulin is an amazingly light and durable material that is used to cover absolutely everything today: the roof of a house, and the roof of the veranda, and an intricate gazebo. Working with him is a real pleasure if you know the technology and do not be too lazy to do everything right. Particularly pleasing is the safety of handling it and the small amount of waste. That’s why they love ondulin, because you still have to try to spoil such material in the process!

In this article we will reveal to you the secrets of professional roofers: how to cut ondulin and what are the best tools, what is the difference between each of the methods and how to achieve a neat, even cut without splashing everything with oil.

There are many nuances in this process, and knowing each of them will help you make the sheet fitting process quick and accurate. Neighbors will consult with you!

Construction knife: for small tasks

If you still have to fit the sheet onto the ramp and cut it completely, then let’s start with the simplest tools. So, an ordinary construction knife quite easily cuts ondulin along the waves.

Just try not to rush so that the edge is even, and do not be lazy before doing the markup:

But abroad they like to cut ondulin with a thick clerical knife. The good thing about it is that it has a sharp, periodically replaceable blade:

Will you try this method? Then this venture you will need a clerical knife, level, marker and tape measure. And then everything is step by step:

- Set the extreme points of the distance of the desired line.

- Take another sheet of ondulin, attach it to the points and trace along the wave with a marker.

- Make an incision.

- Turn the sheet over and cut to the end. Break.

Note that such an almost office tool is quite convenient, especially if you do not need to cut a lot. Just be careful in your efforts, because the blade of such a knife can suddenly break off and bounce.

Jigsaw: for fast cross-cutting

The jigsaw is recognized as the most convenient for cross-cutting of ondulin sheets today. Only use a long file with a large tooth. In this case, the cut is clean and tidy.

Here is the process of cutting the ondulin using a jigsaw:

Be sure to run a straight line before cutting. See how quickly and easily everything turns out in working with such a tool:

And then to quickly clear the knife of bitumen, just cut some wooden block. that’s all.

Ondulin sheet sizes

The dimensions of the ondulin sheet for the roof are always the same and have strictly specified values (the working size of the ondulin):

Length 2000 mm

Working width of ondulin. 950 mm

Of course, as in any technical matter, there are tolerances or errors declared by the manufacturer, that is, the deviation of the actual size from the nominal.

For ondulin, these tolerances are as follows:

- In length. 2 meters Tolerance. more by 10 mm or less by 3 mm

- In width. 95 cm plus or minus half a centimeter.

- The deviation in thickness is allowed in two tenths of a millimeter, 0.2 mm.

So, we now know the dimensions of the ondulin for the roof, now we will figure out what is the useful area of the sheet and the height of the wave of the ondulin.

Useful area of ondulin (size of the ondulin sheet, taking into account the overlap)

How to calculate the dimensions of the ondulin for the roof? The total area of the ondulin leaf is standard and equals 1.9 sq. M. The usable area is the one that is visible, we do not count overlaps and layering. There may be overlaps in one wave, there may be in two.

And from top to bottom, the overlap of sheets on top of each other can also differ depending on the value of the angle of inclination, or, as it is also called, the roof slope. In this article, all the most important about the installation of ondulin.

It is believed that the working area of an ondulin is from 1.3 sq.m with a very steep roof, when there is a need to use large overlaps of sheets on top of each other and interlayer in two waves, and up to 1.6 sq.m.

How To Pivot & Swing To Catch A Wave | Detailed Surf Tutorial

Although the masters claim that if you count the number of sheets and divide the value of the roof area by one and a half, you will not be mistaken.

There is a special program for calculating the number of sheets. It’s called ondulineroof, you can easily download it on the Internet or use our online calculator.

In fact, you only need to know the dimensions of the roof and calculate its area. If it has a simple geometric profile that can be divided into separate rectangles, triangles, or at least trapezoids, the area of which is found according to known formulas, then it becomes easier.

The area of the roof is found, summed up from the areas of the geometric figures that make up it, and then the number of ondulin sheets can be calculated by dividing either the resulting value by 1.5, or by 1.3 with a very steep roof, or by 1.6 with a flat roof, up to 10 °.

How to cut ondulin

During the installation process, ondulin often has to be cut, sometimes into small pieces, in order to lay the material around the chimney or other difficult sections of the roof. Often you need to cut off the excess if the overlap is excessive.

Remember: cut the ondulin from the “front”, that is, the front side, which is placed on top to the sky. And they also cut not along the wave, but along the hollow between the waves.

How to cut ondulin? The cutting technique is as follows:

- An incision is made. That is, cutting begins with a cut from the face. Then the sheet is bent, turned over, and it is cut further.

- How to cut ondulin? For these purposes, an ordinary stationery knife is perfect. It allows you to make a straight cut without leaving “chipped” edges, everything will be clear and even.

- This is if it means cutting along the sheet. If across, then there is nothing better than a classic hacksaw for a tree. But there are certain peculiarities here. This cutting also goes on the front side. But you must first make high-quality markings in order to cut exactly along the mowing line.

- If you need to cut a lot of sheets, you can use a “circular”, that is, a circular saw. The circular saw gives a straight, correct cut.

- As for cutting with an angle grinder, you can use it, but be careful. Care must be taken that the edges of the cut do not melt, because when cutting with an angle grinder at high speeds, friction increases the temperature of the material at the cut from the circle.

Cons of ondulin

- The material is absolutely fireproof, but at the same time, not fireproof. When heated to 250-300 degrees, it spontaneously ignites.

- It is for this reason that at the roof of kindergartens, hospitals, social facilities and institutions, it is laid in sections so that in the event of a fire situation, the fire would not spread to the adjacent sections of the roof.

- It can also change color from exposure to sunlight and has a tendency to fade. It can also fade depending on the fall of the sun color, where it is more, where it is less, turning into a variegated canvas.

- Bitumen stains can appear on the surface of the sheet. This is considered the norm and is not a marriage.

How to cut ondulin and its characteristics: sheet dimensions, thickness, useful area and weight of one sheet

Roof insulation is an important stage designed to reduce heat loss at home.

How To Ride Along the Wave Face. a short cut to the green face.

The roof must be weatherproof and windproof.

Among the variety of materials, there are several that are most widespread.

One of these is the material of French origin. Euroslate.

This material is already being produced in Russia.

Ondulin, and what are its advantages and disadvantages

Ondulin consists of cellulose impregnated with bitumen, with the addition of resins and minerals.

Ondulin is ideal for outbuildings due to its low cost.

When laying a roof, the question always arises: “How to cover the roof beautifully, efficiently and inexpensively?” Ondulin took its rightful place among the materials claiming to satisfy all three requirements at the same time.

This material is sometimes called euro-slate. It’s warm, pretty, and relatively inexpensive. What he really is?

Before dealing with its consumption when laying on the roof and questions of its usable area, we will consider the advantages and disadvantages of ondulin.

Tool for working with ondulin

Ondulin soft roof is both durable and lightweight product. To divide sheets into parts, a construction knife, hacksaw, circular saw or jigsaw is most often used. The choice of the right tool will depend on your capabilities and scope of work.

- If during the installation process you have to cut the material only a few times, then in this case you should not bother too much, use a special knife.

- In the case when the volume of material is large, but it rarely has to be cut into pieces, you can get by with an ordinary hacksaw for wood. For such work, a saw with a blade of 350-400 millimeters, with small teeth, is best suited. If you do not have such a tool in your arsenal, then perhaps your neighbor has it. In this case, the main thing is not to take large teeth, as you will get uneven cuts. A suitable alternative is a jigsaw, it not only makes it easier, but also speeds up all the work.

- The hand-held circular saw is used when working on large areas. A disc with the maximum possible number of teeth is used as a working blade, only then a high-quality saw cut will be obtained.

IMPORTANT: Carrying out the work yourself is a commendable thing, but if you doubt your abilities, then remember that you can always invite specialists or experienced assistants to the object.

Metal scissors: for cutting corners

Let’s start with the smallest jobs. So, there is one method that allows you to save a lot on trimming. If you do this, then the side slopes are perfectly flat, and the sheets do not have to be cut in half at all.

The whole secret is that here ondulin is cut only at the corners, and not half the entire leaf. What’s the problem? Why is it generally bad to cut ondulin? He does not suffer from corrosion.?

The fact is that such seams do not always turn out to be neat and accurate in geometry. And all this then affects the appearance of the roof and the tightness of its joints.

In the classic installation of ondulin, so-called thickened seams are formed at the intersection of the longitudinal joints. They are obtained when the sheets lie one on top of each other. And it is here that there is a possibility that in this place water will begin to flow and snow will blow out.

But trimming the corners in this case significantly reduces the thickness of this overlap, by at least 50%:

In short, everything can be solved simply. The outer sheets, which are joined at the corners, must be cut with metal scissors or a hacksaw, while slightly tilting the blade at a certain angle.

And close the junction with one cut-off wave of ondulin or a special additional element, which manufacturers produce today. The dimensions of the trimming itself depend on the size of the overlap, and it depends on the selected brand of ondulin and the parameters of its sheet.

Cutting corners, by the way, is often practiced with a router. But thanks to the use of metal scissors and patience, the cut is especially smooth and clean.

Chainsaw and angle grinder: for a perfectly straight edge

Alternatively, an angle grinder with a conventional metal wheel is also suitable for cutting ondulin:

At the same time, the sheets are cut quite well. The only negative is that the angle grinder smokes, so you have to take breaks. Plus, not everyone takes up this tool, tk. fear that unpleasant splashes of molten ondulin will begin to scatter, which is akin to driving on fresh asphalt.

But the chainsaw is suitable for cutting at an angle, across and along. Only it will need to be constantly lubricated with oil. And this method has its drawbacks: the cut itself turns out to be rough, shaggy. In addition, you still need to be able to work with a chainsaw, this tool is not one of the unsafe.

You can also use circular cutters with carbide tips for cross-cutting. Remember that each sheet should only be cut along its grooves. As well as the fact that when working with power tools, be sure to wear protective clothing.

The circular is good because it is not clogged with bitumen. And if the sheet is fed carefully, slowly, the cut is of high quality, almost indistinguishable from the factory one.

A circular saw

It is a suitable option especially in cases where it is necessary to cut many sheets in a limited amount of time. The advantage of a circular saw is that when using it, you can simultaneously cut a stack of sheets, however, when working in this way, it should be borne in mind that the edges are less neat.

Construction knife: for small tasks

If you still have to fit the sheet onto the ramp and cut it completely, then let’s start with the simplest tools. So, an ordinary construction knife quite easily cuts ondulin along the waves.

Just try not to rush so that the edge is even, and do not be lazy before doing the markup:

But abroad they like to cut ondulin with a thick clerical knife. The good thing about it is that it has a sharp, periodically replaceable blade:

Will you try this method? Then this venture you will need a clerical knife, level, marker and tape measure. And then everything is step by step:

- Set the extreme points of the distance of the desired line.

- Take another sheet of ondulin, attach it to the points and trace along the wave with a marker.

- Make an incision.

- Turn the sheet over and cut to the end. Break.

Note that such an almost office tool is quite convenient, especially if you do not need to cut a lot. Just be careful in your efforts, because the blade of such a knife can suddenly break off and bounce.

Jigsaw: for fast cross-cutting

The jigsaw is recognized as the most convenient for cross-cutting of ondulin sheets today. Only use a long file with a large tooth. In this case, the cut is clean and tidy.

Here is the process of cutting the ondulin using a jigsaw:

Be sure to run a straight line before cutting. See how quickly and easily everything turns out in working with such a tool:

And then to quickly clear the knife of bitumen, just cut some wooden block. that’s all.

How to cut correctly?

After deciding what is the best way to cut ondulin, it is important to understand the rules and features of this process. For this, numerous recommendations of professionals are taken into account:

- it is advisable to carry out the process exclusively on a flat and perfectly flat surface;

- usually for this, next to the house on which the covering is created, a site is cleared from the ground;

- it is necessary to lift ready-made sheets to the roof, which have smooth and high-quality cuts, since cutting on the spot usually always leads to a poor-quality work result;

- cutting and marking are done directly on the ground, which ensures the evenness of the procedure;

- for marking, it is advisable to use a long and even rail or building level;

- to speed up the procedure, it is recommended to periodically lubricate the instrument with machine oil;

- it is allowed to cut ondulin into several sheets, but only when using an electric jigsaw or circular saw;

- before cutting several sheets at the same time, it is necessary to securely and firmly fasten them to each other so that they lie perfectly even in the bundle;

- straight mowing lines are quite simple to do, but it is advisable to control the process with a rail;

- if you need to get unusual and zigzag cuts, then it is important to proceed carefully and slowly.

Important! It is not allowed to use an angle grinder or other similar tools that help to heat the material to cut ondulin, since such a process can lead to a significant violation of the protective coating of the sheets.

If a person is engaged in the process for the first time, and at the same time is not sure of their own strengths and capabilities, then it is advisable to practice in advance on inexpensive sheets or use the help of a specialist.

Thus, the process of cutting ondulin is not considered difficult, but it is important to choose the right tools for these purposes. Also, the procedure is performed only after the markup has been made. It is advisable to prepare a site for this process in advance, and to raise ready-made sheets to the roof with optimal dimensions and high-quality cuts.