How To Cut Tiles With A Glass Cutter

Preparation for work

Before you start cutting the tiles, you need to get ready to work. In addition to the cutting process itself, you need to clarify some points about the work.

How to cut

If you know how to cut glass, then these skills will certainly come in handy when cutting tiles or ceramic tiles, since these processes are essentially the same.

They differ only in how the marking is done and what efforts need to be made when breaking.

Cutting the tiles is not difficult, but it will take some time to, as they say, “fill your hand”. To do this, you can use unnecessary pieces of tile to work out or adapt to the force that will be required for a particular material. Do not neglect the “little tricks” that every experienced craftsman has in stock. Step by step, the cutting process looks like this:

- Prepare your desktop. It must have a flat and solid surface.

- Place the tiles face up on the table. Using a ruler, mark the line to cut with a marker. (Use a water-based marker, then it can be easily removed with water).

- Place a ruler along the line you have drawn and run the glass cutter across the tile from the far edge of the product towards you. Use a metal ruler as a guide and try to distribute the force equally when pressing the cutter. The cut is ready!

- Place a block of wood under the tile (along the mowing line of the cut) and press on both sides. The tile is easily split into two halves at the cut.

- Look at the end of the cut line. If large chips are visible on them, then sand the edges of the tile with medium or coarse sandpaper. This will give the details a complete look.

It is worth clarifying some important points:

- Do not cut the tile material in advance, but do it during installation. With this option, the minimum amount of scrap of tile material will be obtained, since very few people manage to accurately calculate the distance between the tiles in advance.

- Try to apply even pressure to the handle of the glass cutter while cutting. Remember that if you press harder, the surface of the tile will be covered with small cracks. And if you don’t push it, the scrapping line will come out with chips or even break not along the mowing line.

- It is better not to use a glass cutter if you need to make a cut of less than 1 cm.A short piece of tile can break off unevenly during the cutting process and ruin the entire tile as a whole.

- And now about the “little trick”. Experienced tilers advise to soak the tile for 3-4 hours in plain water before cutting. After such “water procedures” the tile material becomes more plastic, and this allows high-quality cutting.

Additional tools

To perform a high-quality tile / tile cut, you need the following set of tools:

- The glass cutter itself (roller, diamond or with automatic oil supply);

- Mowing line marker, preferably water-based, so that the markings can be easily removed without leaving marks.

- A metal square or ruler used for measuring and guiding when cutting tiles / tiles;

- Table with a stable horizontal surface;

- Wooden block (pencil) for lining in the place of the break;

- Sanding paper for medium and coarse grain size;

- Protective gloves;

Safety engineering

Before starting finishing work and, in particular, cutting tiles, you need to take care of your workplace.

The table or any other surface must be well fixed.

Check working equipment and necessary equipment.

If the room is not sufficiently lit, it is necessary to use portable lamps operating from 12-42 V sockets. Pay attention to cleanliness in the workplace. unnecessary tools and debris lying under your feet can lead to injury.

An employee according to safety standards must be provided with overalls and personal protective equipment. about this:

- Suit made of dense fabric. protects the body from possible cuts and injuries when working with a cutting tool;

- Glasses. protect your eyes from fragments and dust particles. The glasses in them must be made of plastic or shatterproof material;

- Respirator. protects the respiratory system from dust that is formed when cutting tile material. This protector is used when there is a lot of work.

- Gloves. Protect fingers from cuts on sharp tile edges. In some cases, rubberized is used if the surface of the tile material is glossy or has been degreased.

When performing work on cutting tile material, you need to be extremely collected and careful, use a work surface, and not break the tile along the cut line of the cut on the weight or on the knee.

Advantages and disadvantages of a glass cutter

Summing up the above, we come to the conclusion that it makes sense to use manual roller and diamond tools for small-scale facing and in the case when buying a more expensive professional tool. an angle grinder or tile cutter, is financially unprofitable for one-time cutting.

Instructions: how to cut tiles with a glass cutter

Tiling at home. kitchen, bathroom, floor in the hallway. Who among us has not faced similar tasks? What tool is needed for this? How to cut tiles? The answer is simple. manual glass cutter. For small volumes of tiling, it is the ideal choice. Manual glass cutter will allow you to realize all your ideas to improve the interior of the room, while not driving into debt after home repairs.

Glass cutter selection

If you settled on a glass cutter as your main tool for cutting ceramic tiles, then there are three models to choose:

- Roller-type glass cutter;

- Oil-type glass cutter;

- Glass cutter with diamond tip.

By far the simplest and easiest to use is the roller type glass cutter. A small roller (also called a roller) as a cutting tool provides a thin line of the cut without chipping at the edges. As a good alternative, an oil-type glass cutter is suitable, the principle of which is the same as that of a roller.

Only it is equipped with an automatic fluid-oil supply to the cutting mechanism. The oil is in the cylinder of the handle shaft and provides lubrication when cutting, making the job much easier. Both of these models of a roller glass cutter do not require special training, a novice master can easily handle them.

A diamond glass cutter requires an “experienced” hand. Only a specialist who knows firsthand how to use it and has “adapted” to a diamond cutter can undertake to cut ceramic tiles with such a tool. Otherwise, a lot of tile material will be spoiled.

Don’t worry if the cut edges don’t immediately come out as sharp as you want them to be. Uneven cut depth can depend not only on lack of experience and ineptitude in using the cutting tool, but also on the poor quality of the ceramic material itself.

Before getting started, carefully study the technology of cutting ceramic tiles. Analyze the tile material you have and think about which type of tool is best for you. It is not always worth buying a professional tile cutter or angle grinder if you have little work and can easily cut tiles or tiles with a hand-held cutting tool. Throw out of your head the thought that you will not cope, take a glass cutter in your hands. you will succeed!

How to cut tiles with different tools

When carrying out facing works of any premises with the help of tiles, it is necessary to lay not only whole tiles, but also their parts. This raises the question of how to cut the tile so that the edges are smooth. It is even more important not to break the entire tile, the cost of which is quite high. Both tasks are achievable only if the craftsmen use special tools in their work, among which there are professional expensive equipment and cheap fixtures. When performing one-time work, you can use inexpensive tools.

Cutting tiles with a glass cutter

A direct cut of a tile with a glass cutter is quite simple to make, but you will have to tinker with curly cutting.

The operation is performed as follows:

- First, outline the line with a felt-tip pen or pencil, along which the cut will be made;

- With one hand they hold the tile, and with the other they confidently hold the glass cutter along the intended mowing line, while the tool is directed “towards you”; the glass cutter must be kept strictly at right angles;

- The cut tiles are placed on a wooden glazing bead and hit with the palm. This breaks the tiles exactly along the mowing line of the cut.

How to cut tiles with wire cutters

Nippers are indispensable for cutting holes in tiles for water pipes, platbands. Hoods, fireboxes and other structural obstacles. Better fracture is done with a pair of pliers fitted with two carbide clamps. The upper clamp cuts through the glazed surface of the tile, while the curved lower clamp holds the tile from below. Before work, a contour is applied with a felt-tip pen, along which it is necessary to make a cut. Rather, in this case, the tool does not cut, but bites off fragments of the tile until a groove of the desired size is obtained.

Safety engineering

- Work must be carried out in goggles and a respirator.

- The area around the workplace must be clear to avoid the possibility of injury from the saw blade.

- It is advisable to work with a partner who, using a vacuum cleaner, will remove construction dust.

Electric tile cutter

This tool, equipped with a diamond blade, is the most ideal device for cutting any kind of tile. At the same time, using the circular saw of the tile cutter, perfectly even cuts are obtained, the edges of which are slightly smoothed and rounded.

Electric tile cutting machine copes with any amount of work, no matter how large they are. The design of the perfect tool is able to provide a high level of safety for the person working with it.

The marked tiles are laid on the working platform of the tile cutter and slowly advanced under the diamond saw blade. At the same time, they try to hold the tile tightly, pressing it to the platform with both hands.

Manual tile cutter

The manual tile cutter allows you to take tiles that are less than 6 mm thick. It is an affordable tool that allows you to quickly cut fragments of tiles according to measurements. Such a tile cutter is convenient for those amateur craftsmen who perform cladding work with their own hands. Professionals use an electric tile cutter, which we’ll talk about a little later.

Handle a manual tile cutter as follows:

- Marking is done on the surface of the tile with a felt-tip pen;

- The tiles are laid on the base of the tool in such a way that the wheel coincides with the markings;

- Pass the wheel over the mowing line of the marking once, controlling the handle of the glass cutter;

- With the help of “wings” the tile is fixed on both sides of the cut for even division into two parts;

- With a light movement of the hand, they hit the handle, while getting the desired fragment for laying out the cut row.

Safety engineering

- When working with a power tool, use protective goggles that protect eyes from small fragments of tiles.

- The manufacturer recommends to monitor the level of water in the pan and responsible for cooling the cutting blade.

- Periodically, the water in the sump should be changed, as it heats up and becomes clogged with tile chips.

How to cut tiles

Manufacturers offer to use a different tool for cutting tiles, which can be selected depending on the volume and characteristics of the material chosen for the manufacture of tiles. The tile is cut:

- Roller glass cutter;

- Electric tile cutter;

- Manual tile cutter;

- Tile cutters;

- Angle grinder (“angle grinder”).

Let’s dwell in more detail on the features of the application of each of the above tools.

Using the “angle grinder

A diamond disc mounted on an angle grinder allows you to quickly cut tiles according to the markings made. With this universal tool, both straight and curved tiles can be cut. The advantage of an angle grinder over an electric tile cutter is its mobility. But it loses in terms of the quality of the cut obtained, after which the edges of the tiles need additional processing (grinding).

Benefits of tile

The tile has many advantages. it does not burn, does not emit toxic substances, it is resistant to temperature extremes and chemicals, does not conduct electric current.

Quite often, tiles are used for interior and exterior decoration of premises. This is due to the fact that it is a highly durable material. Correctly laid tiles are able to withstand a pressure of about 30,000 t / m², which makes them even more durable than reinforced concrete. Consequently, the tile is practically not subject to deformation. Another important advantage of the tile is its hygiene, ease of maintenance, dirt is easily removed from it, its surface does not contribute to the development of bacteria. The tile is not afraid of moisture. That is why it is often used to decorate bathrooms, showers, toilets.

Tiles are non-flammable, do not emit toxic substances when heated, do not undergo destruction upon contact with highly toxic chemical elements. The tile is resistant to different weather conditions. snow, rain, direct sunlight. this makes the tile an excellent material for exterior decoration. A particularly significant advantage is that it does not conduct electric current, so its use is safe in any conditions.

The disadvantage of tiles, perhaps, is their high thermal conductivity, making them cold when touched. It is unpleasant to walk on a tiled floor with bare feet. However, this drawback is easily corrected when combining tiles with a warm floor.

How to cut tiles with a glass cutter

To cut tiles, you will need a glass cutter, pencil, ruler.

A glass cutter is a tool designed to cut or, more precisely, to apply a groove on the surface of glass, followed by controlled breaking. It is used for small volumes of work or for one-time use. In other cases, they resort to using professional equipment. For household needs, the most convenient and popular is a roller glass cutter. The roller wheel is usually 5 mm in diameter and is made of hardened steel or tungsten carbide with a V-shaped edge. Each roller has a certain reserve of strength, indicated in the instructions. how many meters of glass they can cut. as a rule, in the region of 350 running meters. With the wear of the roller, the percentage of scrap increases. There are glass cutters that provide for the replacement of the roller with a new one, otherwise, if the roller is worn out, you need to purchase a new tool.

To work with tiles, it is advisable to use a glass cutter with a new roller. A roller glass cutter pushes a small groove on the surface, along which glass, mirror or tiles of the required size are very carefully broken off afterwards.

So, for cutting with a glass cutter, you need the following tools:

- Roller glass cutter,

- Marker or simple pencil for marking,

- Carnation or match.

The tiles are laid on a flat surface, marking is done with a pencil. And make an incision, pressing evenly, hold it with a glass cutter from the far edge towards you, so that a groove appears.

To get started, the tiles should be placed on a flat and non-slip surface, such as plywood, to prevent damage to the floor or table on which you plan to cut. If there are irregularities under the tiles, the tiles can be damaged. The enamel of the ceramic tiles should be moistened with water and marked with a marker or soft pencil. Next, an incision should be made. For accurate work, you need to put a ruler or a metal level on the marking line, which will not allow the glass cutter to wiggle to the side. There is only one incision to make, so you need to focus and make it carefully. Pressing evenly, move the glass cutter from the far edge towards you so that a groove appears on the surface. To break the tile exactly along the mowing line of the marking, you need to put a match or a nail under it and press lightly on both sides of the groove. Some cutting professionals use the technique of tapping at the site of the future fracture. From blows, the crack deepens, thereby facilitating the break.

How to cut tiles with a glass cutter

Tile is a wonderful finishing material, common in renovation work. When laying tiles, whole tiles are not always required; from time to time, only parts are needed. To obtain them, the tiles must be cut. This can be done in different ways: on special professional machines, an angle grinder, a tile cutter, using a glass cutter, or by simply breaking it off the edge of the table. Learn more about how to cut tiles with a glass cutter.

If you do not have special tools for cutting tiles, you can use a regular glass cutter.

Cutting tiles with a glass cutter requires the least material costs and professional skills. However, using a glass cutter, you can only cut glazed tiles with a low degree of strength. Information about the strength of the tiles can be found on the packaging of the tiles. The wear resistance of tiles is expressed in arbitrary units from I to V on the P.E.I. scale. So how to cut a tile with a glass cutter?

A few secrets

If you need to cut the tiles along a curved mowing line or in thin strips, special pliers are used.

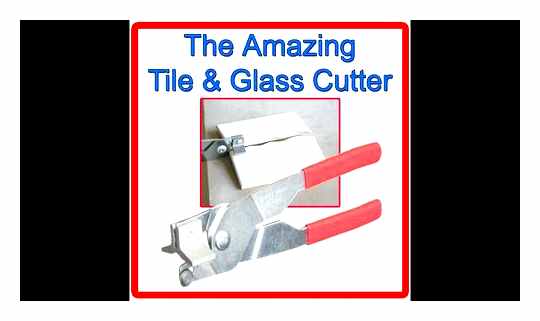

It is convenient to use a glass cutter for household one-time work, with a large scale of work and if you need high accuracy, you need to use other cutting methods, for example, a tile cutter. It works on the same principle as a glass cutter, only it has a larger cutting roller. The tile cutter is a hand tool, the principle of which is similar to the principle of the glass cutter. The difference is that the tile cutter has restrictions on the thickness of the material being cut. First, an incision is made in the enamel with a cutter, and then a tile break is made along the mowing line. The tile cutter is a tile clamp similar to a plier with a glass cutter built into it.

A glass cutter is more versatile than a tile cutter, but both are only suitable for home use.

Benefits of tile

The tile has many advantages. it does not burn, does not emit toxic substances, it is resistant to temperature changes and chemicals, does not conduct electric current.

Quite often, tiles are used for interior and exterior decoration of premises. This is due to the fact that it is a highly durable material. Correctly laid tiles are able to withstand a pressure of about 30,000 t / m², which makes them even more durable than reinforced concrete. Consequently, the tile is practically not subject to deformation. Another important advantage of the tile is its hygiene, ease of care, dirt is easily removed from it, its surface does not contribute to the development of bacteria. The tile is not afraid of moisture. That is why it is often used to decorate bathrooms, showers, toilets.

Tiles are non-flammable, do not emit toxic substances when heated, do not undergo destruction upon contact with highly toxic chemical elements. The tile is resistant to different weather conditions. snow, rain, direct sunlight. this makes the tile an excellent material for exterior decoration. A particularly significant advantage is that it does not conduct electric current, therefore its use is safe in any conditions.

The disadvantage of tiles, perhaps, is their high thermal conductivity, making them cold when touched. It is unpleasant to walk on a tiled floor with bare feet. However, this drawback can be easily corrected when combining tiles with a warm floor.

How to cut tiles with a glass cutter

To cut tiles, you will need a glass cutter, pencil, ruler.

A glass cutter is a tool designed to cut or, more precisely, to apply a groove on the surface of glass, followed by controlled breaking. It is used for small volumes of work or for one-time use. In other cases, they resort to using professional equipment. For household needs, the most convenient and popular roller glass cutter. The roller wheel is usually 5 mm in diameter and is made of hardened steel or tungsten carbide with a V-shaped edge. Each roller has a certain reserve of strength, indicated in the instructions. how many meters of glass they can cut. as a rule, in the region of 350 running meters. With the wear of the roller, the percentage of scrap increases. There are glass cutters that provide for replacing the roller with a new one, otherwise, if the roller is worn out, you need to purchase a new tool.

To work with tiles, it is advisable to use a glass cutter with a new roller. A roller glass cutter pushes a small groove on the surface, along which glass, mirror or tiles of the required size are very carefully broken off afterwards.

So, for cutting with a glass cutter, you need the following tools:

- Roller glass cutter,

- Marker or simple pencil for marking,

- Carnation or match.

The tiles are laid on a flat surface, marking is done with a pencil. And make an incision, pressing evenly, hold it with a glass cutter from the far edge towards you, so that a groove appears.

To get started, the tiles should be placed on a flat and non-slip surface, such as plywood, to prevent damage to the floor or table on which you plan to cut. If there are irregularities under the tiles, the tiles can be damaged. The enamel of the ceramic tiles should be moistened with water and marked with a marker or soft pencil. Next, an incision should be made. For accurate work, you need to put a ruler or a metal level on the marking line, which will not allow the glass cutter to wiggle to the side. There is only one incision to make, so you need to focus and make it carefully. Pressing evenly, move the glass cutter from the far edge towards you so that a groove appears on the surface. To break the tile exactly along the mowing line of the marking, you need to put a match or a nail under it and press lightly on both sides of the groove. Some cutting professionals use the technique of tapping at the site of the future fracture. From blows, the crack deepens, thereby facilitating the break.

How to cut tiles with a glass cutter

Tile is a wonderful finishing material, common in renovation work. When laying tiles, whole tiles are not always required; from time to time, only parts are needed. To obtain them, the tiles must be cut. This can be done in different ways: on special professional machines, an angle grinder, a tile cutter, using a glass cutter, or by simply breaking it off the edge of the table. Learn more about how to cut tiles with a glass cutter.

If you do not have special tools for cutting tiles, you can use a regular glass cutter.

Cutting tiles with a glass cutter requires the least material costs and professional skills. However, using a glass cutter, you can only cut glazed tiles with a low degree of strength. Information about the strength of the tiles can be found on the packaging of the tiles. The wear resistance of tiles is expressed in arbitrary units from I to V on the P.E.I. scale. So how to cut a tile with a glass cutter?

A few secrets

If you need to cut the tiles along a curved mowing line or in thin strips, special pliers are used.

It is convenient to use a glass cutter for household one-time work, with a large scale of work and if you need high accuracy, you need to use other cutting methods, for example, a tile cutter. It works on the same principle as a glass cutter, only it has a larger cutting roller. The tile cutter is a hand tool, the principle of which is similar to the principle of the glass cutter. The difference is that the tile cutter has restrictions on the thickness of the material being cut. First, an incision is made in the enamel with a cutter, and then a tile break is made along the mowing line. The tile cutter is a tile clamp similar to a plier with a glass cutter built into it.

A glass cutter is more versatile than a tile cutter, but both are only suitable for home use.

The best way to cut tile at home

When carrying out home renovations, when, as a rule, there is a small amount of work, you should choose a tile cutting tool that allows you to work quickly and accurately. The main features of working with tile-cutting tools are that the use of an electric cutter at home is, as a rule, economically impractical. As a rule, this tool is best used for cutting large volumes of tiles or for work where increased precision and aesthetics of the finish is required. Using tongs or nippers, the craftsman breaks the ceramic tiles if it is necessary to bite off small pieces of material, for example, to create oval holes for pipes, etc.

A number of cutting tools, such as a glass cutter, an “angle grinder” and a manual tile cutter, allow you to cut tile materials only in a straight mowing line, but curly cutting is carried out using an electric cutter, as well as using tongs and nippers.

Convenient tile cutting with a tile cutter

How to cut a tile with a manual tile cutter. a manual tile cutter or tile cutter is used to cut tiles in the same way as a glass cutter. With this tool, the cutting process is speeded up because the cutter has a larger diameter cutting wheel than the glass cutter and a platform for fixing the tiles.

Tile cutting with an electric cutter has the following features:

- The device itself is expensive, it requires working skills and knowledge of the rules for operating the tool, for example, when cutting tiles, it is necessary to regularly replace the water in the barrel of the tool, etc.

- The electric cutter is suitable for cutting high hardness porcelain stoneware tiles and also allows cutting pieces up to 5 mm wide.

Electric tile cutter is a professional tile-cutting equipment, the use of which is advisable for industrial volumes of finishing work or when carrying out finishing work with increased requirements for aesthetics.

A glass cutter is unsuitable for cutting tiles of significant hardness, for example, porcelain stoneware, etc. In addition, using a glass cutter, it is often impossible to get even cut edges and you have to saw and trim the edges of the tiles using a jigsaw.

Features of manual tile cutter

Trimming tiles with a hand-held tile cutter is one quick, inexpensive and practical way to resize tiles. Features of cutting tiles using a manual tile cutter, you need to know.

Namely:

- The tile cutter disc knife allows you to cut the material smoothly and quickly.

- With a manual tile cutter, it is impossible to cut a strip of tiles of small thickness (for example, 0.5-0.6 cm).

Tongs or pliers are often used to break small strips off the tile. In addition, small oval cutouts in the tile required for pipes are also cut out in small pieces using tongs or nippers.

If the pipe will be placed in the center of the tile, then the tile is cut in half in advance, and then with pliers or tongs they bite out the oval cutouts in the two halves. After that, the halves of the tiles are installed so that the seam is not noticeable.

Tile cutting tools and accessories

It should be noted that various types of tiles are produced for interior finishing works. ceramic, glass and polystyrene. The most popular and practical are ceramic glazed tiles of different colors, which can have a glossy or matte surface, as well as square or rectangular. In the process of repairing when facing walls, it is often necessary to adjust the size of ceramic tiles, therefore it is necessary to provide tools and devices for cutting operations in the arsenal.

In order to cut the tiles, the following tools are useful:

- Glass cutter;

- Electric angle grinder (“angle grinder”);

- Electric tile cutter;

- Tile cutter, or manual tile cutter, etc.

In addition, during repair work, it is often necessary to use tongs and pliers in order to break off a corner or cut a tile in a semicircle. The choice of one or another tool (device) for cutting tiles depends on the type of cut and the properties of the tile (thickness, strength, etc.).

Cutting tiles with an angle grinder is the best option for home renovations. Preparing tiles for laying, especially on uneven surfaces, involves adjusting the thickness and other dimensions of almost every tile, and using an angle grinder, this can be done efficiently and quickly.

What equipment and how to cut tiles correctly

So, tile cutting should be done using the necessary tools. And since tile materials are cut with different devices, the main methods of size correction are also different.

In this case, the line of the notch should be parallel to the tiled edges in order to avoid obtaining an oblique seam. Then the tiles must be laid on a solid and even and with a glass cutter, under the ruler, make an incision in the glazed layer. In this case, the glass cutter must be pressed with constant force, since it is undesirable to carry out the manual glass cutter 2 times along the same mowing line. The reverse side of the tile can additionally be scratched with a nail. Next, the tile must be broken against the rail or the edge of the table. for this, you must first knock along the mowing line of the notch on the back of the tile with the handle of a hammer or glass cutter.

We use an electric tile cutter. when working with a tile cutter:

- First, the tile cut line is marked;

- Then the tile must be fixed on the bed;

- Cut with a tile cutter.

Sawing tiles “angle grinder” with a diamond disc. this method is the most common when correcting the size of tiles, because it allows you to cut the facing material quickly, although this produces a considerable amount of fine dust, therefore it is better to work with the “angle grinder” outdoors or using a respirator.

Basic ways to cut tiles: 4 tools to help

How to cut tiles with a manual glass cutter

For the correction of tile sizes at home, the most optimal equipment is such as a manual tile cutter and an “angle grinder”. The choice of a tile cutting tool depends on several factors. The decisive factor when choosing this equipment is the volume of work, the presence of high requirements for aesthetics and the strength of the tile as a finishing material.

Stage 2. performing cutting of ceramics

Cutting tiles with a glass cutter is similar to cutting glass with the same tool. The soaked and marked ceramic sheet should be placed on a flat hard surface with the glossy side up. It is best to wear work gloves to avoid injury to your hands. On the mowing line, the markings are required to be drawn with a glass cutter, pressing on it. For the accuracy of the line, it is best to use a ruler, angle or template as a guide. It is recommended to guide the cutting tool in the direction from the far edge of the ceramic towards you. The pressure on the cutter should be of medium force in order to both cut the tile and not crush it.

When cutting ceramics, the main thing is to cut through the strong outer layer. You will get an even, thin line of the groove, weakening the strength of the tile. For a thick plate, you need to make a groove on the back side. The groove from the glass cutter remains shallow, it is impossible to cut the tile with a glass cutter. Therefore, a refined clay product must be broken into two parts along the mowing line of the cut.

In order for the tile to be of high quality after cutting, without cracks, it must be able to break correctly. There are several ways to separate pieces of a clay plate:

- Position the tiles on the table so that the notch line and the edge of the furniture match. With one hand, you need to hold the edge of the tile left on the countertop, and with the other hand, gently press on the free part of the ceramic. Thanks to such manipulations, the tile should gently break along the mowing line of the groove.

- Place a match or a small nail along the mowing line of the cut under the tiles and lightly press on both sides with your hands. If the cut is made correctly, the tile will split along the mowing line of the groove.

- If it becomes necessary to break off a narrow strip of tile, then it is better to disconnect it with pliers.

To break evenly, you need to evenly distribute the force along the entire mowing line of the cut. When separating the parts, do not raise them high, otherwise they may fall and break. If irregularities have formed after cutting, then they can be broken with carpentry scissors. If necessary, cut off the tile not straight, but in a circle, you need to make a marking with a pencil, make a notch with a cutting tool and carefully bite small pieces with pliers, forming a depression.

At the end of the work, it is advisable to grind the cut place with coarse sandpaper or a grinding stone. You will get a beautiful smooth surface, the cut will look neat and aesthetically pleasing.

Cutting tiles with a glass cutter in 3 steps

Before starting repairs in the bathroom or kitchen on your own, it is better to learn how to cut tiles with a glass cutter, because this is a very simple and cheap way. After all, resorting to the help of a master is expensive, as well as purchasing special equipment for cutting tiles. Therefore, with a small front of work, it is better to do everything yourself and with a simple tool. The only thing that is necessary in this case is to be careful not to chip the edges of the ceramic product with a glass cutter, and everything will work out.

Stage 1. preparation for work

If the necessary technology for cutting ceramic tiles is not observed, you can get ugly chipped products. Therefore, you should carefully prepare for work. You should also take into account the factor of future marriage and purchase additional 5 tiles in reserve in case a high-quality cut does not work out and the processed tiles burst crookedly.

Before you start cutting tiles, you need to take care of the availability of the necessary tools in advance. For cutting you will need:

- Glass cutter;

- Metal ruler or corner;

- Pencil for mowing line marking;

- Sandpaper or emery stone for polishing chipped edges;

- Work gloves to protect hands from damage from sharp tiles.

The glass cutter comes in two variations:

- Roller;

- With diamond tip.

A diamond tool is not suitable for separating ceramics, therefore, only a roller should be used. The tool must be of high quality. A bad cutter will not cut a groove of the desired thickness on the tile, and the break of the product will be uneven.

To prevent the tile from cracking during the cutting process, it must first be soaked in plain water. Moisture will fill the porosity inside the clay product, and it will become more flexible and lose its fragility. The minimum time for such “water procedures” is 1 hour, but it is optimal to keep it for 3-4 hours, especially if the tile is large.

To successfully cut a tile, you need to correctly calculate its future size. Take into account the distance between the tiles and the gap in front of the wall by 3 and 2 mm, respectively. Therefore, from the distance from the edge of the last laid canvas and the wall, you need to subtract 5 mm. this will be the required width of the future product.

On a tile soaked in water, measure the required size of the future product with a ruler. On the glossy side, where the glaze is applied, it is necessary to outline with a pencil or felt-tip pen, which can be easily removed, marking the future incision. It should be noted that you can only break off the edge of the tile, which is not less than 1 cm. Otherwise, you can easily split the ceramics not along the mowing line of the cut. Therefore, in such a situation, it is better to grind off the excess with an emery stone.

Stage 3. the nuances of cutting tiles with a glass cutter, advantages and disadvantages

Special power tools and electrical appliances are much more convenient for cutting ceramic products than glass cutters. But such special devices are much more expensive. Therefore, if tile cutting is carried out at home with small amounts of work, it is more practical to use a glass cutter. After all, it is completely inappropriate to use expensive tools when you only need to cut a few tiles.

Glass cutter has some advantages over other devices for cutting tiles:

- Affordable price;

- Ease of use.

But the use of a glass cutter also has significant disadvantages:

- It is not suitable for large volumes of work;

- The tool is not capable of cutting through dense tiles;

- There is a possibility of spoiling the tiles.

Using such a tool is not very convenient. The glass cutter has a small roller that makes shallow grooves. Therefore, you have to break the tiles by hand, which gives rise to the risk of cracking the tile or its uneven break. Because of these sequential procedures of marking, notching and breaking, the entire process of cutting the clay plate is rather long and tedious. Therefore, it is not recommended to use a glass cutter for large volumes of work.

Another glass cutter with its small roller is not able to cut through heavy-duty porcelain stoneware. It is also unlikely to scratch thick floor tiles to the depth necessary for breaking. The tool is capable of cutting only thin wall tiles. Therefore, for large volumes of work or cutting powerful products, it is better to purchase a special tile cutter.

Subtleties of the process: how to cut a tile

Tips: how to cut floor tiles

When cladding a bathroom or a bathroom, you may definitely need a curly cut for mounting tiles near a toilet, bath, sink, etc. Therefore, it will be interesting for craftsmen to learn how to cut a floor tile at home. For this purpose, it is possible to apply an original method. a drill with a nozzle. It allows you to make a round or perfect hole for the floor.

As an attachment to cut, it is possible to take:

- Ballerina. A nozzle that is fixed in the center with a foot.

- Crown. Round tips of different diameters with a straight or serrated edge.

- Tubular drill. Small diameter straight carbide tube.

- Traditional sharp drill.

To flatten the cut when using the drills, you need to use a wire cutter. It is necessary to work slowly and very carefully, then the rounding of the tiles on the floor will turn out to be of high quality.

How to cut floor tiles at home: tile cutters and angle grinders

Tongs will cost the master about 400 rubles, and they can be used exclusively for small amounts of work with thin tiles at home.

Cutting is done like this:

- It is necessary to carry out the marking, taking into account all the gaps and seams, minus 5 mm.

- Then you need to attach a metal ruler to the marking and draw it once with a cutter. It is not necessary to press hard so that the result is a strip. It is recommended to lead from the far edge towards yourself.

- The pliers should be positioned with their feet along the break line close to the edges. The sponges are located on top of the glaze, and the straight part is on the bottom. the break line should be straight from the middle between the edges of the sponge on top. Next, do not press the handles sharply, the cutting will be done. Do not lift high, otherwise the tile will split.

The cutting methods are different, for example, you can use an electric tile cutter. An ideal solution if the volume of work is large. The highest quality cut is obtained from the electrical tool. Here a diamond wheel is used and water is supplied to the place of the notch, due to which cooling occurs and there is no dust. The most inexpensive devices cost about 4,000 rubles.

Here it is necessary to draw a line of a break with a pencil and perform a wash down using an angle grinder with a diamond disc. But if you do not wash down, then during cutting a narrow strip will break off in pieces. Therefore, you need to carefully, slowly walk the angle grinder along the markings to make a cut of about 2 mm.

It is necessary to walk the disc along the mowing line, and not directly along it, then the width of the strip will be as necessary, it will not decrease. Cutting is performed in the same way, after several times. Now you can work with the device faster, but you need to try to press the angle grinder to the opposite side, then chips will not form. It is better to cut on weight, so vibration can be avoided. When it becomes noticeable that a narrow strip is about to fall, it is necessary to put a soft matter, then it will remain intact.

Glass cutter for ceramic tiles

If you need to cut just a few tiles, then it is irrational to buy a tile cutter.

It is possible to use the tools at hand for work:

- Glass cutter.

- Drill. You need to take a product with a victorious tip, since it is more effective.

- Nail.

- Construction knife.

It’s not hard to work. The ruler must be applied to the cut site and walked once with a glass cutter or drill. You should get a well-visible scratch on the glaze. If we are working with a knife, then it will be necessary to walk on the surface 2-3 times. Then the tile must be laid with a cut at an angle and sharply broken. The cut must be perfect, and you don’t have to spend money.

Cutting ceramic tiles with a tile cutter

To simplify the process of cutting tiles and make the necessary breaking line, you need to loosen the glaze layer. that is, cut it, and then break it.

There are 3 main techniques:

- Electric tile cutter or special tongs;

- Angle Grinder;

- Other sharp tools at hand.

The instruction looks like this:

- The tile must be inserted into the device, and the markings on the tile must be combined with a special mark.

- The handle must be lowered and held away from you. It must be driven at the same speed. You should also press evenly so that the roller cuts the glaze to the same depth. The must be run once. If you drive more often, the breakage will be of poor quality.

- Next to the roller there are special paws, which, as soon as they go down, will immediately break the tile into 2 neat parts. This happens after sharply pressing the special lever. At the same time, all devices are based on a metal tubercle, and along the edge there are special non-rigid pads. When you press the edges of the material with your paws, in the place where the cut is made, maximum stress is obtained, and the tile breaks evenly.

High-quality tile cutters make it possible to cut without problems even ceramic material, the thickness of which is 1 cm. And it does not matter at what angle the material is cut: it will be at least 45 degrees or even 30 degrees. And how to cut a tile with the letter “G”?

Many will also be interested in how to cut porcelain stoneware? It is believed that porcelain stoneware tiles are more rigid. It is possible to cut it in the same way as ceramic. Sometimes standard floor tiles are more difficult to cut than porcelain stoneware. There is a hardened material on which, after working with the tile cutter, it is almost impossible to see the notch. And even a diamond disc angle grinder cannot cope with it. the notch is crooked. Here you need to use an angle grinder, and file a 3 mm groove on the back side, thereby marking the place of the break.