How To Cut Wood Patterns With A Router By Hand

Router templates

Templates are very widespread. They are made for the production of specific products. That is why the question of how to make a template for a router with your own hands has become quite widespread.

The milling template has the following features:

- Some versions are designed for milling a workpiece along a straight contour, others at an angle or round shape. A very common template for milling round corners of various radii.

- Some models of the equipment in question are equipped with rings or bearings. They are suitable for hand routers. If a ring is used, it should be borne in mind that it should not come into contact with the installed cutting tool during milling of the workpiece.

- Creating grooves of an unusual shape can be called a rather difficult task. Recently, the milling of grooves has been carried out when using the particular equipment in question. For example, you can quickly make a stencil for woodcarving with a router or to create a groove that fits door hinges.

DIY templates for a router are often made of wood. This choice can be attributed to the fact that such a material is characterized by a high degree of workability. That is why it is much easier to obtain patterns on wood with a hand mill, since the template will completely repeat the geometry.

On sale you can find a variety of templates, for example, dovetail. However, almost all craftsmen are faced with the fact that they have to create such a product with their own hands when making unique parts for furniture or other products.

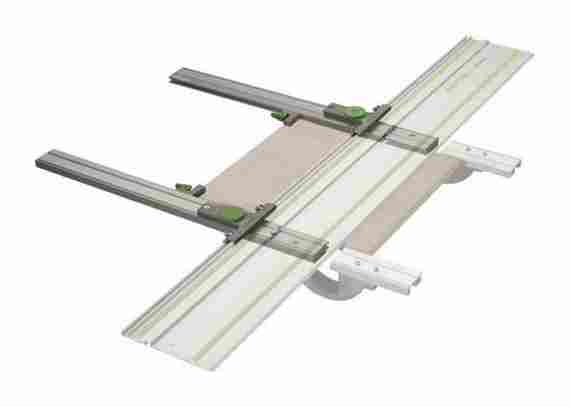

Guide rail

When processing wood, it is important to control the position of the tool used. The guide bar, like the previous equipment, is designed to ensure the movement of the router along a strictly straight path. All milling devices for wood are made so that they can be used in certain jobs. The following points can be called the distinctive features of this device:

- The guides for the hand router can be positioned at any angle relative to the edge to be machined. Due to this, the device provides accurate movement of the tool in any direction within the horizontal plane.

- Often, plywood is processed with a milling cutter in order to obtain holes that are located relative to each other with a certain pitch. The considered design may have additional elements that allow you to get holes with specified parameters.

- A special clamp for a milling machine is used to fix the device. If the delivery set does not include clamps, they can be replaced with conventional clamps.

- Some models come with a dedicated milling table adapter.

Router guide rail

The simplest homemade design can be made from a long bar that will be attached to the workpiece with clamps. In order to make it comfortable to use, you can equip the bar with additional side stops.

The above proposal is not always comfortable to use. The following homemade design is more popular:

- The fixture is represented by a combination of two boards that are parallel to each other and a plywood sheet.

- The design in question is used only if milling cutters of the same diameter are used.

- Due to the use of two boards, processing accuracy and template stability during milling are significantly increased.

In the case when cutters of different diameters are used, it is advisable to use a slightly different design. It is characterized by the presence of a folding board, which is fastened with hinges. The purpose of this structural element is to fix the template. After fixing it, the board leans back and you can use cutters of various diameters.

It should be borne in mind that clamps are used to fasten homemade templates in almost all cases.

They provide reliable fixation of the equipment. During operation, the fixture will be pressed against the surface of the template, due to which the accuracy of processing is ensured.

Parallel stop

The rip fence can be used for straight and curved cuts. This device is very popular today, it is included in the delivery of many tools. This milling attachment includes several structural elements:

- Guides made in the form of rods for niches formed in the body of a wood router.

- Locking screw, used to fix the device in the desired position.

- Screw designed for precise spacing between axis and workpiece surface.

- Contact sponges. They are required for the router stop to be based on the surface.

The side stop for the router is applicable for a wide variety of work. You can prepare it for work as follows:

- As previously noted, there are holes in the base of the wood fixture for placing the rod. It is inserted into them and fixed in the required position with a locking screw.

- After fixing the device, the locking screw is slightly loosened, the adjustment changes the position of the stop.

Knowing the design features of the device, you can make it yourself. To do this, you will need bars and metal elements, as well as screws. There are quite a large number of different models of parallel stops on sale, which are selected directly for the features of a router designed for working with wood blanks.

Copy ring

A wide variety of accessories for a hand router can significantly simplify the process of processing various workpieces. A copying ring for a router is a kind of product that acts as a side. During the work, the ring slides along the used template, setting the position of the router on the tree. Machine versions can be produced in a wide variety of materials. At the same time, various fastening mechanisms are created:

- Screw.

- Threaded hole.

- When using special antennae.

It should be borne in mind that the rings used must have a diameter that is close to the mill. However, during processing, it should not touch the ring, as this will damage the cutting tool.

Copy ring for router

The attachment of the copy ring can also be carried out using common clamps. The rings are made of steel designed to withstand the application of force. Soft alloys are not used due to the fact that they can deform, and this will lead to serious errors.

DIY wood router accessories

It is possible to significantly expand the functionality of the milling equipment with the use of special devices. Serial accessories that can be found on sale are quite expensive. That is why many craftsmen decide to make accessories for a wood router with their own hands. Most of the manufactured elements are intended for the correct positioning of hand tools in spaces. In addition, accessories for a wood router can significantly increase the processing accuracy. Some instruments are supplied with ancillary accessories initially. However, they are not highly specialized equipment, they are often not suitable for the assigned tasks. Let’s consider the most common snap-in in more detail.

Router compass

When working in a home workshop, you may often need hand router attachments to make it easier to mill a round surface. An example is a special compass, which you can make for a router with your own hands. The main recommendations for the work are as follows:

- To create the simplest design, you will need: a bolt with a nut, a small piece of plywood, several self-tapping screws and a wooden lamb. In the manufacture, the router itself is used, as well as a saw with a screwdriver.

- On the surface of the used piece of plywood, a platform is marked with a width of about 50 mm and a length of 150 mm. Note that the width must be larger than the router platform, the length must be larger than the machining radius.

- After marking the working part of the platform, holes should be made for the fastening bolts. You can drill with a perk, the diameter of the holes obtained should be 20-30 mm.

- A through groove is created along the central mowing line. Its width must be less than the width of the axle bolt.

- On the reverse side of the created platform, a recess is created for a nut with a washer, the second nut is fastened in a wooden wing.

- The central axis is being assembled. As a stud, you can use a bolt of the required length, from which the head is sawn off.

After creating a homemade compass, it is attached to the router and you can check the device in operation.

#274 Cutting Shapes With Your Router. Carving An Address Sign

Wood attachments

Depending on the complexity of the work being carried out, the equipment of a router for wood may differ significantly. An example is the case when the task is to milling grooves on narrow surfaces. Standard attachments for milling machines in this case may be less effective, and then special attachments are used.

Wood router bits

The key features of the applied nozzles include the following points:

- Milling cutters for hand-held milling cutters when using special attachments will carry out processing in a strictly limited area. That is why it is possible to significantly improve the quality of the resulting grooves.

- The design is represented by a base, which can have a wide variety of shapes.

- Two pins are installed on the base. It is they who provide the linear movement of the cutter during the processing of the workpiece.

Considering nozzles intended for wood processing, it should be borne in mind that the main requirement for their design is the location of the guide pins on the same mowing line with the center of the cutter used. When this condition is met, the groove will be located strictly in the center of the end surface.

DIY router table

Milling cutters for hand router

Milling cutters are a cutting tool that processes and shapes a surface. They consist of a cylindrical part, which is clamped by collets in the unit holder, and a cutting part. The cylindrical part can be of different diameters. Choose a collet for which your device has. The shape and location of the knives of the cutting part determines the look that the wood receives after processing. Some cutters (for edges) have a thrust roller. It sets the distance from the cutting surface to the workpiece.

Working with a manual router for wood requires a certain number of cutters. This is a small part of what exists

Cutters are made from different metals and alloys. For processing softwood. pine, spruce, etc. use conventional nozzles (HSS), for hard species. oak, beech and others. from hard alloys (HM).

Each cutter has a certain resource and maximum speed at which normal operation with minimal runout is ensured. Do not exceed the recommended speed. this can cause damage to the router. It also makes no sense to sharpen the cutter if it is dull. This is done on special equipment (costing about 1000), where you can set the required sharpening angle. Nothing good will come of it by hand. So blunt ones are easier (and cheaper) to replace, since they cost relatively little.

Securing the cutter

Next, the cutter is installed. Most branded cutters have marks on which you can navigate. If they are not there, then the minimum must be clamped at least 3/4 of the length of the shank (cylindrical part). Insert the cutter to the required depth (if necessary, having previously installed the collet. adapter cartridge for different cutter diameters), fasten the shaft, tighten it with an open-end wrench until it stops (but do not overtighten).

Work with a manual router for wood and other materials begins with the installation of a router

If the model is simple, two keys are needed. They do not provide for a shaft locking mechanism; you will need to hold it with the second key. The middle class devices have a lock button. Clamping it, tighten the cutter with an open-end wrench. In expensive models, in addition to blocking, there is a ratchet by which you can navigate.

Preparation for work and care

To understand the principles of working with a hand router, it is advisable to have at least a general idea of its structure and the purpose of the parts.

Self-milling wood and wood

Processing lumber, cutting in loops, making technological holes and recesses, wood carving. all this can be done by such a device as a router. over, this can be not only professional equipment, but also relatively inexpensive manual copies. But working with a manual wood router requires knowledge of some techniques and rules. All this is in the article.

Edging. Working with a Template

Edging an ordinary board is easier and faster to carry out on a thickness gauge, but if it is not there, a hand router will also cope, but it will only take more time. There are two ways: without a template and with a template. If this is your first experience with a router, it is better to use a template. When processing the edges of the boards, straight edge cutters are needed, and, most likely, you will need two. with a bearing at the beginning and at the end of the cutting part (pictured).

For edging. make a flat surface

As a template, you can use an already processed board or, for example, a building rule. The length of the template should be slightly longer than the length of the workpiece. by 5-6 cutter radii on each side. This will make it possible to avoid the cutter “diving” into the material at the beginning and at the end. One important point: the horizontal plane (perpendicular to the workpiece) must be flat. In any case, its curvature should not be greater than the gap between the bearing and the cutting part, otherwise the cutter will touch the template, and this is very bad. it becomes imperfect and the applied irregularities will be displayed on other copies.

Popular types

There are a number of types of router bits that are most commonly used.

- Edging. Serve for processing the side surfaces of workpieces. With their help, you can make even or curly edges, you can form grooves and spikes for joining parts. It is this type of cutter that happens with a bearing at the end. it abuts against the part, setting the distance from the edge of the workpiece to the cutter.

Some types of edge milling cutters

Grooving cutters. for forming grooves anywhere in the part

There are simple cutters, formed from a single piece of metal, there are typesetting. Stacked ones have a shank. a base, a certain set of different cutting planes, a set of washers of different thicknesses. From these parts, you can independently form the required relief.

Inlaid cutter. a set of several cutting surfaces and washers, from which you can make a cutter of the required shape

These are the most popular types of cutters, but there are actually a lot of them. In addition to different shank diameters, there are different diameters of cutting surfaces, their heights, the location of the knives relative to each other, etc. In general, do-it-yourself milling usually requires about five of the most common cutters. They are usually present all the time, and the rest are purchased for specific types of work.

Rotational speed

Work with a hand router on wood, composite, plywood, etc. starts with setting the main parameters. First, you need to set the rotation speed. It is selected depending on the selected cutter and the hardness of the material and the characteristics of the cutter, so you should look for exact recommendations in the operating instructions.

Approximate processing speed when using different cutters

Pattern on wood with a router

The hand router is a versatile mechanical tool in the home workshop. To use it correctly, you need to learn the basic lessons of a wood router. There are many Chinese-made milling cutters on the market, all of them are of the same design and differ only in engine power. Experts recommend purchasing a more powerful tool, since the list of work performed will expand significantly. The craftsman will be able to cut a pattern, make a quarter sample, cut thorns and perform other operations related to the manufacture of furniture.

Useful DIY homemade products

In order to do something useful, for example, a casket, you do not need to have a whole arsenal of sophisticated equipment and expensive tools. You can get by with a minimum of tools and mechanisms. To perform carpentry work you will need:

- milling cutter;

- electric jigsaw;

- Sander;

- several clamps;

- set of cutters.

You can use absolutely everything as a material. for example, trimming parquet boards, pieces of plywood and chipboard waste, but always with a right angle. To simplify the work, you need to make a simple milling table. To machine workpieces, you need a straight slot cutter with a large diameter. The process looks something like this. On a homemade table, plan the ends of the parquet board scraps. Mark the sides of the box and use a jigsaw to remove all unnecessary.

The resulting blanks must be processed with a thickness gauge to maintain the size of all sidewalls. If you do not have a planer, you can use a milling table. To do this, set the stop to the size of the workpiece and move the part between the stop and the rotating mill towards you. Perform the next operation to calibrate the sides along the length with a jigsaw.

You can connect the sidewalls together on a mustache. To do this, you need to mill the ends of the sidewalls with a conical mill with an angle of 90 degrees. This can be done using a router. Thus, the ends of the sidewalls have the same bevels of 45 degrees. Next, you need to make grooves in the sidewalls for the bottom. For this, an end mill with a diameter of 6 millimeters is used, equal to the thickness of the plywood. Parts are connected with glue. The product looks neat and beautiful both outside and inside. What else can you do with a hand-held wood router? Anything: for example, a shelf for things, drawers for storing vegetables or tools, kitchen furniture.

Creativity without boundaries

Milling equipment is indispensable for woodworking. With its help, you can turn a wooden blank into an elegant decorative product. This equipment is most often used by professionals, but amateurs with experience will also be able to master it. The use of mechanisms is not an easy task, therefore, before you start working with their use, you need to ensure your comfort and safety. The organization of the workplace is very important. The home craftsman must remember that during work there is a possibility of damage not only to the cutter or mechanical device, but also to health.

Woodworking is not only work at the machine, but also the preparation of the workplace, planning the sequence of work performed. Before you start milling, you need to choose the right type of cutter for a specific task, taking into account its shape and size. It is necessary to choose the speed of the machine and the depth of cut, and do not forget that the processed material must be securely attached to the table.

Depending on the specific type of milling device, the rules for their use are different in many aspects. Today, vertical milling machines are widely used, in which the spindles are located above the work table. They have proven to be excellent in such operations as milling in wood, when processing the edges of shelves and round tabletops, making a groove, and connecting wooden parts. When processing round structures, an indispensable addition is a special compass with a base plate, which ensures processing accuracy.

When working with a router, it is necessary to learn how to lead it calmly, with smooth movements. Correct and safe handling of the processed material is key. Do not do this too slowly, as burn marks can appear on the wood, which can damage the material.

Chips appear when milling wood against the direction of the wood grain. In one pass, it is necessary to perform milling to a depth of 8 mm, some models provide the ability to adjust with an accuracy of 0.1 mm. Deep grooves and quarters need to be milled in several passes.

Processing of wooden parts

The first thing to learn is to set the milling depth correctly. For this, the zero point must be set. It is impossible to set it firmly, because it changes every time the cutter is changed. The zero point is the position of the tool when the end of the cutter touches the material and is fixed with a special device called a retainer.

Please note that each router has a different locking position. To control the depth of immersion of the cutting tool into the material body, a thrust pin with a coarse adjustment scale is used.

When milling with a face mill, the counteracting force of the cutting force pulls the mill to the side. To prevent this from happening, you need to use a parallel stop. The milling process is as follows. Place the cutter on the mowing line marking, fix the stop position with a special screw. Set the milling depth and switch on the machine. If the rip fence is installed on the left side, pull the router towards you, when on the right side. away from you.

In order to select a quarter on a bar, you need to set the cutting edge of the cutter along the very edge, fix it, set the depth of the quarter, turn on the router and pull it towards you (if the stop is on the left edge of the bar). Milling the surface of narrow bars has its own peculiarity. The problem is that it is very difficult to hold the router on the narrow side of the workpiece. If it sways during operation, the groove will be inaccurate.

To avoid this problem, the block must be clamped with a clamp, parallel to put exactly the same size block. Then the milling machine will acquire two points of support and will not stagger.

Working with a hand router can replace the work of a planer. This will require several attachments to the milling mechanism. It looks like this: fix the milling mechanism on two equal-sized rails and use it as a planer, where a large-diameter cutter is installed instead of a shaft.

Training

Once you have chosen the right block or board and decided on the method of threading, prepare the place for work. You may need a vise or clamps, pencil, jigsaw, chisel and router.

Create patterns for woodcarving with a router

Next, draw with a pencil a sketch of your drawing on a wooden canvas. Fix it securely and start working. Be extremely careful in the process of drawing a pattern, as the slightest miscalculation can ruin the entire workpiece.

At the end of the work, cover the resulting ornament with varnish and install it in the place where it will be located. As a result, you will receive an original product made with your own hands. Even if the first time the masterpiece does not come out, do not despair, a little practice, and your craft will become a real decoration of your home.

Through thread

Through patterns of wood for a gazebo

This is a very common method of creating patterns and is used most often in the process of decorating houses. It implies complete through removal of some elements of the wooden surface. If earlier all the necessary work was carried out mostly with chisels and chisels, now the task is performed mainly with a jigsaw.

Tip: It is recommended to use an electric jigsaw for wood. With its help, work will go faster, the main thing is to be careful.

DIY wood patterns using an electric jigsaw

Cheap and cheerful

Wood carving is always beautiful, rich and expensive. This is done by talented people, painters or sculptors. But there are carving methods that anyone can do. For example, it is very easy to cut patterns with a hand-held wood router. The work is carried out with a small-diameter end mill along the contour of the drawing. To do this, you need to pick up a board of hard rock, nail in a stencil cut out of cardboard, and mill according to the template.

A milling machine of any power is suitable for work. It is desirable that it be light and comfortable, then it will be easier to copy the drawing. Therefore, you do not need to bother about which router to choose for beginners, the main thing is to choose cutters with a diameter of 2 millimeters or more. When working, you need to be diligent in order to smoothly pass a thin cutter along the contour of the drawing and not break it. The next step is to deepen the background, for this, a large-diameter flag mill is used.