How To Test A Lawn Mower Ignition Switch Step-By-Step. Riding mower ignition switch

How To Test A Lawn Mower Ignition Switch [Step-By-Step]

The ignition switch of a lawn mower is the most crucial component which helps to start the engine. And if your mower fails to turn on, then there is a chance of having an issue in the ignition switch.

To figure out the fault in the switch, you need to understand how the switch works and it’s defective symptoms. And for that you must know how to test a lawn mower ignition switch.

That’s why today I’m here with you. In this article, I will guide you step by step of how you can test a faulty ignition switch. Also, I’ll be providing some symptoms of having a bad ignition switch as well.

Symptoms Of A Defective Ignition Switch

If you are facing an issue with your engine, there is a chance of having a faulty ignition switch in your lawn mower. So, if your mower’s ignition switch has any fault, you will notice the following signs.

Key Won’t Turn On

If the key gets stuck and doesn’t turn on to the start state of the engine, then there is a fault in the ignition switch.

Overheating Issue

It’s another prominent issue where one end of the wire might become excessively overheated.

Lawn Mower Stalls

While starting or moving the lawn mower, it might stall after some time.

Engine Won’t Start

Another significant issue is that the engine attempts to start but fails every time. This might be due to faulty or broken ignition switches.

Steps Of Testing A Ignition Switch

Different types of procedure can be followed to test the lawn mower ignition switch with the help of digital and analog multimeter. You can follow any of the methods to test your mower’s ignition switch.

1st Method Of Testing The Ignition Switch

- Get the “fuse panel”, lying under the “steering”, and open it. Now, get the starter signal fuse from the panel and check carefully whether the metal strip is in good condition.

- Change the metal strip with a good one if it’s found to be damaged or defective. Make sure the new one comes with the same amperage as the damaged one.

- Connect the digital multimeter to the positive and negative terminal on the battery. Recheck whether the red lead of the voltmeter is connected to the positive side of the battery.

- The voltmeter marking should be at least 12.6 volt for moving the engine with its full speed. But if it becomes less than 12 volt, then probably the battery is dead.

- To check the ignition switch, start your engine by putting the key to the switch. If the engine fails to start and at the same time, you don’t hear any clicking sound, then the ignition switch isn’t working.

On the other hand, if you are hearing the clicking switch but the engine fails to start, then the issue is in the battery.

Lastly, if the engine starts successfully, both battery and ignition switch are okay.

2nd Method Of Testing The Ignition Switch

Replace the spark plug with an old plug to the end of the boot and power the engine placing the key to the ignition switch.

Now check the ignition switch by checking whether there is a continuous spark to the old plug. If there is no spark, surely the switch of the lawn mower is faulty.

Connect the voltmeter to the coil’s positive and battery’s negative terminal of the lawn mower. If the voltage of the battery is on the positive side, your ignition switch is okay. Otherwise for lower reading, there can be an issue with the switch.

3rd Method Of Testing The Ignition Switch

- For beginners, check the multimeter carefully and turn on the key. Place the multimeter’s positive end to the power supply and the negative end to the distributor’s base.

- Place the key to the running position in the ignition switch and inspect the voltage of the battery using the multimeter.

- If the reading of the voltage is lower than 90% of the main battery’s voltage, then there is a huge chance of having an issue in the ignition switch or wire.

Replacing The Ignition Switch

Once you have done testing the ignition switch, it’s time for taking the necessary steps, depending on the problem. Identify the underlying problem and replace the ignition switch if needed.

Replacing an ignition switch is complex work. However, if you have a good technical knowledge, you can simply change the ignition switch without any trouble. Otherwise, you can visit any nearby engine repair shop to take help from professionals.

Conclusion

In some cases, testing the ignition switch’s issue and resolving it becomes very frustrating and tiresome. But hopefully, following the above method will make your work easier.

Nevertheless, regular cleaning and operating the lawn mower will lessen the tendency of having technical issues in the inner components.

Lawn Mower Ignition Switch Problems ( How to Resolve)

One of the good things about having a ride-on lawn mower is that they have electric starters. Say goodbye to yanking on a pull cord! Unfortunately, even electronic ignition systems can go wrong from time to time.

The downside to ride-on mowers is that fixing an electric starter is not as simple as replacing a pull cord on a push mower. So, to figure out why your mower isn’t starting, you’ll have to take a closer look at the lawn mower’s ignition switch. Grab your multimeter, and let’s get to work.

Why Is My Lawn Mower Ignition Switch Not Working? (The Short Answer)

Lawn mower ignition switch problems can be caused by several issues. Problems such as worn-down connections, corrosion of the contacts, an internal short, and the ignition collapsing internally can all cause ignition failure. These ignition problems are usually due to the amount of use they receive and the environments they are subjected to.

Troubleshooting a Broken Lawn Mower Ignition Switch

I like to break down troubleshooting an ignition switch into two categories: external and internal ignition switch problems. Let’s take a look.

External Lawn Mower Ignition Switch Problems

External problems can be caused by different things like a build-up of grime, corrosion, and even the connection becoming loose because of the vibration the switch suffers.

So, first of all, check the connections are in place, and the connector is firmly connected to the back of the ignition. Next, remove the connector and take a look at the pin on the rear of the ignition. These should be free of any rust and not covered in grime, such as oil and dirt.

Finally, take a look at the connector itself. The connector contacts shouldn’t be damaged or have connectors spread open. If the connector can’t make a good, clean and tight electrical connection, then you will end up with a problematic lawn mower ignition switch.

Internal Lawn Mower Ignition Switch Problems

A lawn mower ignition is made up of several rotating metal plates, connectors, a spring, and, of course, the key. To complete different electrical circuits, these parts all need to move in a very specific order, over precise distances, and make firm connections.

They must also be wired correctly to complete their task. Problems with how the key turns between the different positions of the ignition is a sign that there could be a problem internally.

A quick test is to give the key a turn. If it’s either unable to move or moving too easily, it could have collapsed or cannot make the necessary connections.

So, let’s go over how to test a lawn mower ignition switch internally and see if the key is doing its job.

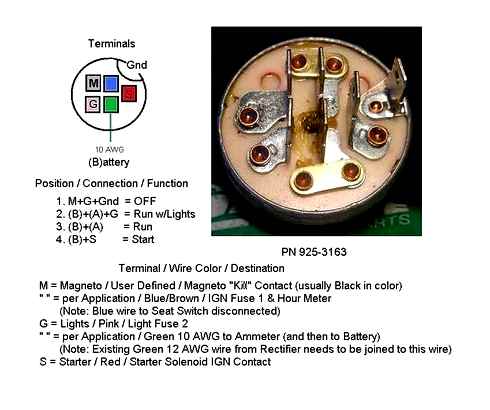

Understanding the Ignition Pins

If you flip over the ignition, you’ll find the 5 pins that connect to the lawn mower’s electrical system. If you take a closer look, you’ll discover that each of the pins is labeled with a letter. Now, the lettering can either be on the housing of the ignition or the actual pin itself. Here’s what the letters stand for.

Understanding the Ignition Positions

Next, let’s go over the different positions and the connections the ignition switch makes during operation. Here are the different internal tasks the ignition does while you turn the key.

How to Test a Lawn Mower 5-Pin Ignition Switch

To test your lawn mower ignition switch, you’ll need to have a multimeter that can test for continuity. This tests if there is a break in a circuit.

The meter I use makes an audible sound when a connection is made, which I find much easier than using a meter that just has a digital display. Also, a meter that has crocodile clips on each cable makes the testing much less fiddly. So, let’s have a look at the ignition switch test.

Ignition Switch Test Summary

Testing the OFF Position G-M

Connect one multimeter cable to the G pin M pin.

Key PositionExpected ContinuityFailed Test Results

Testing the RUN Position B-L

Connect one multimeter cable to the B pin L pin.

Testing the START Position B-S

Connect one multimeter cable to the B pin S pin.

Testing the START Position B-L

Connect one multimeter cable to the B pin L pin.

How to Fix a Faulty Lawn Mower Ignition Switch

Now that you have finished inspecting the wiring of your lawn mower ignition switch and testing the continuity, it’s time to look at the repairs you can carry out. So, here’s what you can do to get your lawn mower running again if you have a lawn mower ignition switch problem.

Corrosion Dirty Pins

The best product I have found to clean dirt and grimy ignition terminals is an electrical contact cleaner spray. Spraying the contact and then wiping it down with a rag is all you need to do to clean the pins.

For the connector itself, I find spraying the connector and connecting the switch in and out a few times works just fine. If you have some corrosion or rust, then a little piece of sandpaper or file is enough to remove the corrosion.

Tools Materials to Clean Up Dirty Corroded Ignition Pins

Damaged Connectors

If you have some loose connections, then try taking a pair of pliers and pinching the terminal. You’ll be looking to close the connector opening enough so that it will snuggly grip the pins of the ignition switch.

If the connector lacks space to pinch the terminals, then you can try pulling the terminals from the connector. If this isn’t an option and you can’t fix the terminal, then you might need to consider replacing that part of the wiring loom.

Tools to Repair a Connector

Ignition Failed the Continuity Test

Unfortunately, if your ignition switch fails a continuity test, there isn’t much you can do other than replace the switch. So, let’s go over how to wire a lawn mower ignition switch.

First, remove the positive cable from the battery or remove the battery main fuse, if your lawn mower has one. This will protect your new ignition from any shorts or arcs. Then, remove the switch from the dash and disconnect the connector.

Next, mount the new ignition switch into the dash and reconnect the connector. Finally, reconnect the battery or reinstall the main battery fuse.

Tools Parts to Replace an Ignition switch

Hot Wire a Lawn Mower & Bypass all Safety Switches!!

Are Lawn Mower Ignition Switches Universal?

The short answer is no. The first thing you’ll notice is that ignition switches are available with different numbers of pins. Also, the wiring of lawn mower ignition switches differs from mower to mower. Even if a new ignition switch fits onto your lawn mower and connects to the connector on your mower’s wiring, this doesn’t mean it’s the right switch.

This is why it’s so important to understand the lettering so you can match up a new ignition correctly. So, if your riding lawn mower ignition switch has gone bad, make sure that you either buy a new OEM part (Original Equipment Manufacturer) or check the pins on the replacement ignition.

About Tom Greene

I’ve always had a keen interest in lawn care as long as I can remember. Friends used to call me the “lawn mower guru” (hence the site name), but I’m anything but. I just enjoy cutting my lawn and spending time outdoors. I also love the well-deserved doughnuts and coffee afterward!

Leave a Reply Cancel reply

Copyright © 2010. 2022 LawnMowerGuru.com, All Rights Reserved.

Affiliate disclosure: As an Amazon Associate, we may earn commissions from qualifying purchases from Amazon.com. You can learn more about this here.

Lawn Tractor Won’t Start No Click – Fix it now!

Before we assume there’s a problem, let’s take a minute to check that we’re following the correct starting procedure. All mowers will have safety sensors fitted, and if the sensors are open, they won’t start.

So why won’t your lawn tractor start, not even a click? The most common reason for a no start, not even a click sound, is a totally flat battery, but other likely causes include:

A tractor mower won’t start if the blade lever/button is on, manual mowers need to be in Neutral gear, and some mowers won’t allow starting if the oil level is low or the hood is open.

If you are in any doubt about the correct starting procedure for a lawn tractor, check out – “How to Start Husqvarna Ride-on Mower.”

If you do hear a click sound when you turn the key, check out – “Mower Wont Start Just Clicks.”

Check Battery Connections

To test a battery, you need a voltmeter, but if you don’t have one, try this basic check. If your mower has hood lights or dash lights, go ahead and turn them on. If they light up and are bright, your battery is most likely not the problem.

Dash Lights are Dim

Check – Check the battery cables; they should be clean and tight. When connections are loose or corroded, it prevents available power from flowing to the starter.

Charge Battery – If your battery is completely flat, it will take a couple of hours and will require a battery charging hack, or check out this Smart battery charger the NOCO Genius1 on Amazon.com.

Jumpstart Mower – This is the fastest solution, but it may not be the long-term fix. (see Jump starting below)

Battery Check Hack

- Turn on the lights to check for power supply

- If they work – the battery is likely OK

- If lights are dim – check battery cables

- If cables clean and tight – charge battery

- If you have no lights – check battery with a volt meter

Volt Check – Need a voltmeter for this test. Check b attery voltage – 12.65v is 100%, 12.30v is 70%, and 12.05v is 50% charged. This battery needs a charge.

Very low volts indicate the battery is likely faulty, and it may not recharge. To test a battery, it must be charged, so a battery charger may be required. However, it is possible to jump-start the mower (see below), and given time, the mower’s alternator will charge the battery, assuming it isn’t faulty.

Once the battery is sufficiently charged (about 70%), try the crank test.

Battery Crank Test – Attach the Voltmeter and crank over the engine; if the volts read less than nine, replace the battery. (The battery must be over 70% charged for running this test)

Check out the Amazon link below for quality mower batteries delivered to your door.

Voltmeter – If the lights don’t work at all, you’ll need to use a voltmeter to check the battery’s state of charge. You may have blown a fuse (see below).

If you have very low volts, the battery is likely faulty. The average life of a battery is four years, more if well cared for.

Jumper Cables

If you don’t have a charger, you can still get it running, but you’ll need a set of jumper wires, and a car or any 12-volt battery will do the job. Follow this link for a more detailed guide to Jump Starting.

Jumpers – Use good quality jumpers.

If you are unfamiliar with jump-starting, you’ll find a complete guide here, “Jump starting riding mower.”

Add the cables in sequence 1, 2, 3, and 4 to start the mower, and while idling, remove jumper cables in reverse order 4, 3, 2, and 1.

Dash Lights Don’t Work

Main Fuse – If the battery is fully charged and still no go – check the main mower fuse. Some mowers will have the blade-type fuse; others will have the old-style bottle type.

When the fuse blows, all power is lost; changing it is simple. It is important to replace the fuse with the correct amp rating. If the fuse keeps blowing, the rating is too low, or there’s a short-to-ground wiring fault.

Fuse Location – Places they like to hide include under-seat, under the hood, behind the fuel tank, and control module incorporated. Modules are usually under the dash panel.

Replacing the fuse is simple, just pull out the old one and push the new one into place. It’s important to replace it with the correct amp rating. Otherwise, you can damage the wiring circuit and components.

Check Safety Sensors

Riding mowers are designed with safety features built in to protect us from operator error or accident. Safety features on mowers are controlled by sensors/switches, and most modern mowers will wire those sensors into a control module.

The sensors are a very simple on/off switch type and rarely give trouble; it’s more common for the striking plate that pushes on the sensor to be misaligned; when this happens, the sensor is open, and the engine won’t start or stops depending on where the sensors fitted.

Over-riding – Sensors can be overridden for test purposes, remove and join the wires, and some sensors are wired in reverse – meaning, just disconnecting them will override the sensor. You can check sensors for continuity using a voltmeter.

Starting Procedure

As you know, there’s a starting procedure that must be followed before your mower will start. You can check out the starting procedure here – “How to Start a Husqvarna Ride-on Mower.”

There are several sensors that must be engaged; the location and number of sensors are dependent on the make of the mower and differs between manual and hydro-static (type of transmission).

The main sensors are the brake pedal; seat; gear lever; blade engage control switch or lever, and some models, such as John Deere, will have one fitted to the hood (Hood open – no start).

Safety – For our safety, sensors are fitted to the seat, blade engages lever or button, transmission selector, brake pedal, and on some models, the hood. Any of these sensors will prevent your mower from starting.

On older manual transmission mowers, the gear selector wears, and although the selector points to the Neutral position, it’s often still in gear – confirm it’s in Neutral by pushing it forward or back; it should be easy to push.

Sensors – This older style Craftsman / Jonsered / Husqvarna blade lever causes lots of no-start problems.

Replacing Ignition Switch Huskee, MTD, Craftsman Riding Mower

The lever spring gets weak and leaves the sensor in the open position which prevents starting.

Sensors – The quick fix, hold down the lever to start the mower. The complete assembly is available and not too difficult to fit. Check that all sensors are working, and look to see if the striker plates are closing the sensors fully.

Check wiring to sensors for chafing and that the connectors are secure and corrosion-free.

Check Control Module

Most modern mowers will have a Control module; they are a printed circuit with relays and resistors – they do give trouble. Because the specs vary, I can’t be more detailed.

The function of the control module is to receive a start/stop command from the ignition switch and only output a start command to the starter (via the solenoid) if all the correct sensors have been engaged.

Offers Extra Power, Durability, Features and Comfort. []

You can visually inspect the module printed circuit for loose solder, scorch marks, or water damage. All modules will have an internal or external fuse, and as you know, the main fuse can blow, and if it does, it will kill the power to the ignition system.

Modules can be fitted anywhere, usually housed inside a small rigid plastic box. but not all mowers will have one fitted.

Replacement modules can be on the spendy side, so it may be time to access your old mower; if she needs a ton of love in the blades bearing and belts department, it may be time to look at a new set of wheels.

Module – Wires come loose, have a helper attempt to start the engine while you wiggle the wiring connectors.

Check also for damage, water, or scorch marks on the panel itself.

Check Ignition Switch

Ignition switches are an important part of the ignition system; bad connections here can cause lots of problems. Ignition switches – send commands to the control module if fitted.

If your mower doesn’t have a control module, then the safety sensors are wired inline to the ignition switch – meaning any sensor that is in the open position will leave the ignition switch with an open circuit (No start). These systems are basic and tend to be the most reliable.

Common Problems

Issues with ignition switches: loose wiring at the switch; corroded terminals; broken terminals; spinning ignition switches.

Wiring specs for ignition systems vary, so I can’t be more detailed. Check the ignition wiring for damage, corrosion, or loose wires. Have a helper sit on the mower and attempt a start while you wiggle the ignition wires and connectors.

- Check ignition inputs – ground and 12-volt supply.

- Check ignition outputs – 12v to the starter solenoid (or to the control module, if fitted) when the ignition is in the start position.

Switch – Spinning ignition switches cause damage to the wiring and pins.

Corrosion is another common failure. This usually causes unreliable starting and shutdowns.

Wiggle – Try wiggling the wires at the back of the ignition switch while attempting to start the engine; you may need a helper. Often wires simply come loose but do check them for corrosion.

Related Questions

Lawnmower ignition switch problems? Common Ignition switch problems include:

Hey, I’m John, and I’m a Red Seal Qualified Service Technician with over twenty-five years experience.

I’ve worked on all types of mechanical equipment, from cars to grass machinery, and this site is where I share fluff-free hacks, tips, and insider know-how.