How to thread the inside of a pipe

I use a pipe threader or a clip to cut the threads on the pipe.

For threading a pipe with a diameter of 15 (aka 1/2″, aka half-inch), I usually use a lerk in a lerk holder, which I put on the prepared cut of the pipe, the side that has the edge, due to its length it serves as a guide, which is important for uniform meshing of the lerk. Slightly press the end with my hand and turn it clockwise with an adjustable wrench

It is not always possible to use the guiding side, it may be due to the fact that the cut pipe for some reason is made very close to the tapping into the riser, then enter doing the side of the line. In this case you need to be more careful, keep the turner perpendicular to the axis of the pipe, otherwise the thread could be crooked and on the fourth turn the pipe will break through. Actually if the bevel is cut evenly around the whole diameter, the approach will be straight, and consequently the whole thread.

It is also possible to thread with a crescent, but usually a pipe of this diameter is used for distribution, and using a screwdriver is not possible due to its weight.

On a pipe with a diameter of 20 (aka 3/4″, aka three-quarter inch), the thread cut with a clip, though just in case I have a three-quarter lerk in the lerko holder. From the same considerations as in the above paragraph.

And pipes with a diameter of 25 (aka 1″, aka one-inch) and 32 (aka 1 1/4″). I only thread with a ratchet and a quarter inch). This is solely due to the labor-intensive nature of the job. Using the tongs the process is much simpler, easier and faster.

On the photo besides clinches and klups with a collar, I presented that I use for hermeticity of the thread connection, namely the universal, sanitary sealant and sanitary flax. After the thread, apply sealant to it, trying to distribute evenly over all the coils, and after that winding linen, details about this tell (and show) in another article, the link will leave below.

Connections are not only threaded.

In my profession I have to connect polypropylene with cast iron, when installing sewage. Basically, this connection is made through the transition of the rubber sleeve that blotted with sealant put into the bell of a cast-iron pipe or fitting, and already in it you insert the fitting blotted with sealant or a pipe made of polypropylene. Due to this the connection is airtight.

The photo shows the kabolka, different in thickness, it is also used for installation of drainage systems, through ramming into the gap between the above materials. The fact that the bobbin is convenient in that it can be unbraid and select the strand of desired thickness. Its use is actual when the transition sleeve is not suitable in size, such cases are not frequent, but they still occur.

Perhaps these articles will be helpful to you:How to thread a pipe. 10 important nuancesHow to thread a pipe hermeticallyHow to thread a pipe easier to cut with an angle grinder

If you have any questions or additions, write in the Комментарии и мнения владельцев section. For today that’s all, good luck in your work, Sincerely Andrew.

Tired of looking for information from the practitioners? Subscribe (turn the page down), and the information will find you. Clicking on the social network icon is the best reward for my hard work.

How to thread a pipe: clips and dies

Let’s look at how to properly thread exterior and interior pipe with clups and taps. Metal pipe threaded connections are strong and airtight, and can withstand considerable pressure. And if you mount the pipes yourself, you will need to thread.

You will need tools and materials for the job:

- A caliper to accurately measure the diameter of the pipe.

- Vise when using one-piece dies or a tap.

- Machine oil or any grease.

- Rags or sponge.

- Protective equipmentglasses, gloves.

Threading tools (solid or sliding dies, electric tongs, ratchet clips, or taps) depending on the application.

The main ways of threading

Threading on pipes can be cut in one of two ways:

For domestic conditions, of course, the manual technique is more relevant. Threading on plumbing or other pipes by hand is often done with a die.

Tap. a simple device for threading pipes at home. The same tool is successfully used on industrial machines.

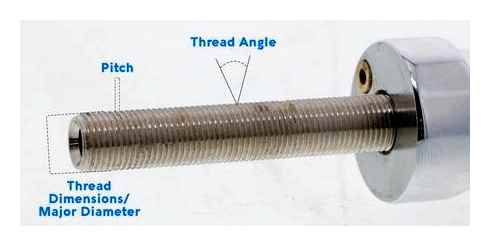

The tool looks like a disk, the inner diameter of which is drilled several axial holes. The edges of these holes form several cutters (usually 8-10). The material for dies is alloy steel or other hard alloys.

There are several types of such devices:

According to the form of execution die is available in the form of circle, square, hexahedron, prism. Circular tools are the most common. They are used for threading of water pipes up to 36 mm in diameter.

For the convenience of working with dies are used:

Threading (metric, tapered) of the best quality on pipes in the manual mode or on machines give solid dies.

However, this type of tool, due to the rigidity of its own design, has its own negative sides. Cutters wear out quickly.

The spring loaded (cropped) dies are of less rigid construction which makes it possible to thread the pipes and thus change the thread diameter in the range of 0.1-0.3 mm.

Such devices are characterized by high wear resistance of cutters, but do not provide high accuracy and cleanliness of threading.

Sliding dies consist of two working parts. They are designed to be mounted in a tool clamping module.

They are mounted in a clevis by a mechanism consisting of a sliding block and an adjusting screw. The screw adjusts the size of the diameter for threading. A set of dies for several different diameters is usually supplied with the clapper.

Method #1. making pipe threads with dies

The process of threading a pipe with a die or a clevis involves a locksmith performing some preliminary steps:

- The pipe surface in the threading area must be carefully deburred.

- The end part of the pipe must be filed (make the entrance chamfer).

- Apply a lubricant to the machined surface to reduce resistance.

If possible clamp the pipe vertically, e.g. in a bench vice. The strength of the fastener must be carefully calculated so that the pipe body is not deformed.

Then take previously prepared screwdriver with roughing cut of required diameter and suitable threading characteristics.

Hold tool horizontally and perpendicularly to the edge area of the pipe. Slide roughing die on the chamfer of the edge by the inner hole. Using light pressure and successive short turns of 25°-30°, make the initial cut.

This work has to be done carefully, taking your time, constantly checking the right angle between horizon of die and verticality of the pipe.

The first two or three threads are carefully threaded in this manner. Usually after the first two or three threads have been cut, the tool is firmly in its working position. You can no longer control the right angle after that.

But the cutting technique with short circular movements (without much thrust) should be kept until the end of the cut. We recommend that you periodically add grease to the threading point.

After the first pass, twist the device and then repeat it one or two more times with a finishing die

Technique #2. cutting with a club

Kupp is a variation of the same die for threading, including pipe threads. Peculiarity of the claw is possibility of setting of cutters.

There are clipping tools for hand use as well as similar tools with electric drive.

Variant #1. cutting with manual clevis. Manual cutting of pipes is usually done with a club, which is inserted into a ratchet holder. Such a holder makes pipe threading work more convenient and less complicated.

Of course, depending on the conditions of performance of locksmith’s work other kinds of handpieces can be used. For example, a standard double-headed fixing screwdriver.

The principle of making a thread with a crescent is almost the same as with traditional dies:

How to Thread Pipe; A Beginner’s Tutorial

- Clean the top surface of the pipe and make sure it is free from defects.

- Sand the cut area until it has a distinct metallic sheen.

- Grind the outer working part of the end edge at an angle of 45-60º (chamfer).

- Lubricate the prepared surface with petroleum jelly.

- Clamp the pipe in a mechanical vise or hold with a gas wrench.

After all these procedures you put the cutting tool (tongs) by its inner hole on the chamfer of the pipe and begin to rotate it by short reciprocating movements with moderate even pressure.

If a ratchet holder is used as a tool holder, only straight-threading is carried out. It’s good to use the ratchet clamp when working in confined spaces.

For example, when you want to work on a pipe that is installed next to a wall.

Option #2. cutting with an electric clevis. Along with hand tools, electrically powered tools are also commonly used. The obvious advantage for the locksmith is a significant reduction in labor intensity.

But on the other hand, not all electric machines are able to work in cramped conditions. Besides, when working with hand tools you can get better result.

To get similar results with electric clips you need a lot of experience.

- Preparation of the pipe surface in the area of the cut, cleaning, chamfering, lubrication.

- Fastening of the pipe with devices, which can provide a rigid fixation.

- Fixation in the starting point of the strip holder with a clamping screw that is included in the set.

- Checking the stroke and direction of the clincher.

- Threading the first two or three turns in jog mode.

Now the pipe threading is done automatically. The cutting length is considered optimal when the top edge of the clamping heads reach the front edge of the pipe.

At this point the action of the machine is stopped, the reverse rotation function is engaged and the claw is pushed off the pipe. It is imperative that the cutting area is periodically oiled throughout the process.

Way #3. using lathes

Large-scale construction and repair work generally excludes the use of hand tools. Here for the appropriate machining of the pipe a lathe is usually used.

Tapping functions are supported on many general purpose lathes.

Both internal and external pipe threads can be done efficiently and easily with the machine. The pneumatic (or mechanical) fastening module of the lathe ensures high-quality reliable fastening of the pipe, and the exact approach of the machined part to the cutter.

Different types of cutters are used to perform threading functions:

Work on turning machines is performed by specialists trained in this business with the appropriate qualifications. Without experience and professional skills to try to thread with their own hands on the machine is not recommended.

Home craftsmen who have decided to engage in locksmithing and make a thread on metal workpieces, the following tips will help in the work:

Threading by hand

All work is done with a die or lance. These are identical concepts and are synonymous. Depending on their design they can be:

- Adjustable or sliding. Usually there are several cutters in them, the distance between which can be changed. They are especially useful when the profile of a pipe is uneven because of a deformation or a factory defect, but threading is still required. Most often they are installed in clinches, which provide them with a good fixation. With such tools threads can be cut in several passes, which increases its accuracy and quality.

- Monolithic. Are made as a small cylinder with a hole in the centre. Such a tool is clamped in a special die holder. Usually held in place by one or more screws. Using this tool it is possible to make threading in one pass.

- Tapered. Suitable for tapping the threads mentioned above.

The tool is selected according to the diameter of the pipe to be machined and whether the thread is to be threaded to the right or to the left. All the markings are either on the packaging or on the tool itself. The whole process will be reduced to the following steps:

- Workpiece is held in place. If it is not fixed in any system, it is clamped in a vice. If the cutting will be done on a water pipe or a heating pipe, it is necessary to make pads to immobilize it.

- Apply lubricant to the end face of the prepared piece of pipe. If these components are not available, you can use what you have on hand. even lard.

- The tool bit surface should also be lubricated.

- Hold the flat-face tool with the cutter against the end of the pipe. It must be done accurately at right angles. It is much easier to do with a guide plate.

- At the same time you need to rotate the threading tool and press it against the pipe. There should be a grip. It is important to thread the first 2 coils this way.

- If you do not use a strip lock with a guide, you must always make sure that the angle stays at 90°. If this is not done properly then there is a risk of skewing. This threatens that the thread will be torn, the tool will be spoiled, or the required pitch will not be observed.

- It is not worth threading in one continuous pass. Metal chips are generated in the process. In order to remove it, it is necessary to make one turn in the direction of movement and half a turn back. This is how the accumulated waste is removed.

- You also have to add grease as you go along.

- When finished, it is necessary to unscrew the pick and go over it one more time to make a finish fit.

Threading with a crescent is done by the same mechanism. In addition, in some products it is possible not only to move the cutters, but also to turn them. In this case, you can use the same tool to perform both the finishing and roughing passes. When using a machine like this you need to be very careful during the initial phase. This is because more force can be applied with a ratchet handle than with a conventional ratchet tool holder. If you do not set the angle correctly in the beginning, you can ruin the entire workpiece without noticing it. It is inconvenient to use the cluppe in cases when the pipe is already installed and is close to the wall. It will need to either bend it with a wedge or hollow out some of the plaster, so that the nozzle fits well and does not shift.

How to thread a pipe properly?

To connect parts in systems of various kinds is often used threading or tapping. It provides reliability and durability of structures. Threaded fasteners are versatile, because they can easily be used to mount and dismantle pipes of different systems.

Using a die

Cutting dies are also called lerks. This threading tool is essentially a nut that has been fitted with holes. They form the edges for the cuts.

Depending on the shape, there are different kinds of threading lathes:

Using such a device as a pipe tongs, you can quickly prepare a pipe product of any kind for connection.

Tap needs to be aligned perpendicular to the face of the pipe. If skewed, there is a chance of stripping the thread, or the diameter of the thread could change. In either case the final result is not satisfactory.

It is recommended that all work with the cutter be done smoothly, without jerking. While operating with this device, from time to time it is necessary to lubricate the cutters and the surface of the thread.

After the final coil is complete, the pliers should be returned upward and the thread should be threaded again.

Threading with an electric club is similar to the usual process, but it requires more space and additional fixation. Its advantage is that it reduces the labor intensity of the process for the locksmith. With any type of slicing, it is recommended that lubricant be added to where the cutting edge is located in the process.

Threading can also be made with a lathe. This type of work is most often used for large production volumes. You can do both external and internal threading with this device, but you need a trained specialist to work with them. Without the appropriate knowledge working with a machine can cause injury

Performing work on threading, it is necessary to adhere to safety rules

It is very important to wear gloves and safety glasses to prevent cutaneous tissue damage due to sharp metal chips

Tapping a thread with a tap begins with selecting the right tool. After the first step is to drill the hole. This step is, in fact, the most important because if the wrong diameter is selected, either the bolt will be loose or the tap will break when threading from the overload. The best way to determine the diameter of the holes is to use the tables, but you can also make a rough estimate: subtracting from the diameter of the thread its pitch, you can get an approximate value of the required diameter of the hole.

For example, if the outside diameter of the thread is 18 mm, and the pitch is 1 mm, then you need to drill a hole of 17 mm. It is necessary to drill strictly perpendicular to the surface of the part (because of deviations possible defects in threading). It is desirable to make a small bevel around the drilled hole. Blind holes must have a greater depth than the length of the part to be threaded, so that the tool will go beyond the required thread length when cutting. If this reserve is not provided, the thread will be incomplete.

The part with the drilled hole is clamped in a vise. Tap is fastened in a collar (or in its absence a adjustable wrench is used) or in a machine chuck. The quality of threads, cutting speed and tool life are considerably affected by the right selection of cutting fluid (Coolant). To not spoil the tool, and to get a clean thread with the correct profile, it is necessary to use the following coolant:

diluted emulsion (one part emulsion mixed with 160 parts water);

linseed oil can be used for brass and steel parts;

for red copper. turpentine may be used;

Tapping should be carried out dry in cast iron and bronze.

Do not use mineral and machine oils. they contribute to a significant increase in resistance, which the tool to overcome in the process, have a negative impact on the roughness of the thread and lead to rapid wear of the tap.