What you can do with a hand router

How a hand-held milling machine is designed

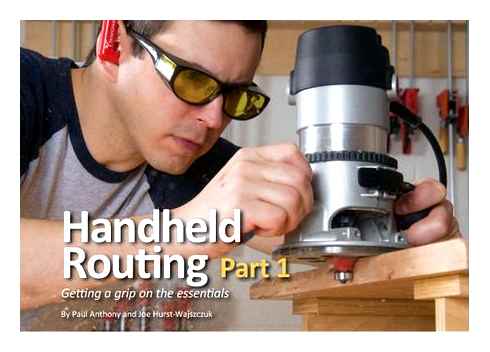

The design of a hand router for wood is quite simple. The machine has a housing in which the key assemblies and elements are located. The most important of these is the driving force. the motor. Directly from the body protrudes the holder. in it will be inserted collets. These are special adapters into which cutters with different diameters can be inserted and fixed.

Separately worth mentioning the platform, which is usually made of metal. It can be attached by bars to the body separately. The lower part has a sliding plate of smooth material. this will help the instrument go smoothly from point to point. Platform stability is important. It is better if it is made of cast (expensive models) or stamped (low-end versions) material. This will ensure a better adherence to the surface. The lower part of the platform is covered by a plastic cover, often removable, so it is easy to replace.

On the body there are buttons to turn on and off. It is good, if they are accompanied by a button for locking. It is comfortable to use the parallel stop when working.

For the hand router, these settings are used:

All parts and components require proper care. For a newly purchased product, this role is performed by the factory-applied lubricant. However, in the future, this duty already falls on the user: it will be necessary to clean the dust and manually lubricate the moving parts.

It is not recommended to use thick mixtures, as dust and shavings settle and stick to them, which makes it difficult to work. There are no such problems with spray versions.

What you need a wood milling machine for and what you can do with it at home

The article tells in detail about the kinds of work that can be done with a router at home. Describes all the steps. from adjusting the parameters of speed and processing depth to step-by-step technologies to perform milling. There are also a number of rules for the safe handling and subsequent care of the router.

How to make a router for wood with your own hands a step-by-step instruction

Carpenters, joiners, model makers, carvers, turners and other manufacturers of wooden products sometimes have to make their own cutters for processing wooden workpieces. It’s not so much an opportunity to save money, as the need to get a cutting tool with a given geometry. Self-made cutter for roughing all types of wood is made in tens of minutes or a few hours.

What an ordinary hand router can do

Let’s try to figure out what features a hand router has. First we should determine the power of the power tool.

Making small things like dishes or caskets. Low-power devices with power consumption up to 1,200 W are sufficient here. This milling machine is also suitable for craftsmen who use it occasionally. Usually these are fans to spend a weekend in the garage or a mini-workshop, making various shelves or stools for themselves or as a gift. Cutter diameter here does not exceed 32 mm, and the length of the shank is equal to 0.8-1.2 cm.

If you want to use milling cutters with a longer shank, equipment with a power of 1.2-1.9 kW is used. This power mill can also be used for more professional work. However, an increase in power entails an increase in weight.

If there is a need to produce furniture or other facades, work with large-sized parts, as well as the operation of equipment for a long time using high-powered equipment. 1.9-2.4 kW. Such power tools are used in small furniture production.

The main functions of hand routers

With the help of a hand router, the following operations, which are basic, can be performed:

- issue the ends and edges of workpieces, with the help of a shaped cutter to remove the bevel;

- Cut out patterns of any complexity;

- Make various grooves;

- make fronts for cabinets;

- Drill holes of a given depth and diameter.

However, there are a few other features that some home craftsmen not only do not use, but do not even know about them.

From theory to practice: learning how wood routers work

The greatest difficulty for the novice “self-made” is the creation of a rotary cutter. The best machine is the one that can process wood, both straight and curved. Here it is important to choose and fix the blade head itself, which is the main working body of the mill. It is fixed on the spindle, which is located on the shaft of the electric motor. Most often this part is vertical. The entire structure is mounted on a bed that can move on two axes. There are different types of machines, each of which has its own design features. If you plan to engage in shape carving in wood, then you will be suitable for a manual milling machine with a movable cutter. As a basis, you can take the technology used in handheld cutters.

These machines have a simple structure. Key components are hidden in the housing. The driving force is provided by a motor. It is “hidden” in the body and fixes the holder for adapters or collets, in which different diameter cutters are inserted and fixed.

But not every craftsman will be satisfied with a handheld cutter. For more complex tasks, it is better to pay attention to stationary milling machines.

The cutter can not only work with flat surfaces, but also create recesses and grooves

Unlike the manual method, products machined with electric machines look much more spectacular. Yes, and significantly saves time. Separately, it is worth mentioning the platform, which is usually made of metal. It can be attached with bars to the body separately. The lower part has a sliding plate of smooth material. this will help the tool to go smoothly from point to point.

Tip! When choosing a unit, pay attention to how conveniently arranged the on and off buttons of the device, whether they do not interfere with the comfortable work on the machine.

An important parameter. the stability of the platform. Better if it is made of cast (expensive models) or stamped (budget versions) material. This gives the tool a better surface contact. Submersible models are considered more professional, they will help to create not only notches, but also to mend grooves and holes of the desired shape and depth.

The power of the cutter is directly proportional to the weight of the machine. This is important to consider when choosing a hand tool

Edge machining using templates

To obtain complex profiles. roundings, perfectly flat or with a specific curvature. it is more convenient to use templates. Edge machining on such workpieces is usually carried out on a pre-cut plywood or chipboard edge contour. Using a roller cutter for this purpose.

Workpieces the width of which is less than the length of the cutting part

Components which are smaller than the cutter’s cutting part can be processed by means of a template set so that it touches only the roller. Base plate height adjustment is then carried out so that the cutter only touches the workpiece. With the roller positioned over the cutter body, the template is positioned on top so that it touches the template.

This method is quite difficult to perform, especially if the edge cut must have a certain profile. For this purpose it is recommended to use a cutter with the lower arrangement of the supporting roller.

Another option of workpiece plane machining with the help of template can be setting the shank so that its edge touches the template. This technique is used when there is no support roller on the cutter. Machining of workpieces with width exceeding the length of the cutting surface

In this case the process is carried out in two steps. During the first step, a pass is made by the cutter with the help of a template. The second milling is carried out without the help of a template, because the result of the first pass will act as a template for the work.

Edge machining of complex shapes

Getting a nice edge of the workpiece with shaped cutters depends largely on the quality of pretreatment of the workpiece. Uneven edges, bevels or cracks are copied by the cutter as it passes over the edge. Regardless of the quality of the machine and the sharpness of the working edge, all imperfections will remain, only already milled.

If there is a need to process a curvilinear workpiece, then it is necessary to make the first run roughing, simply approaching the profile to the desired template. The second time the processing of the edge is done finishing, using a template and with the utmost care.

Wood carving with a hand router

Wood carving with a router is a fascinating activity that requires certain skills and craftsmanship. Dozens of woodworking operations can be performed with this tool. Artistic carvings on furniture elements look very beautiful. Woodcarving can be used to create decorations and other design elements for an interior. Using a hand-held router, you can “revive” old things with figure carving. For this purpose, furniture, parquet tiles and other wooden objects amenable to processing are suitable.

Creativity without borders

The router is indispensable for woodworking. With its help you can turn the wooden workpiece into an elegant decorative product. This equipment is most often used by professionals, but amateurs with experience will also be able to master it. Using mechanisms is not an easy task, so before you start working with them, you need to ensure your comfort and safety. Workplace organization is very important. The home handyman must remember that during the work there is a possibility of damage not only to the cutter or mechanical device, but also to health.

Woodworking. it is not only the work at the machine, but also the preparation of the workplace, planning the sequence of works performed. Before you start milling, you need to choose the right type of cutter for the specific task, taking into account its shape and size. It is necessary to choose the speed of the machine and the depth of cutting, and not to forget about the fact that the material to be treated must be securely attached to the table.

Depending on the specific type of cutter, the rules for their use are different in many ways. Nowadays, vertical milling machines, in which spindles are located above the work table, are widely used. They have proven to be an excellent choice for operations like wood milling the edges of shelves and round table tops, grooving, or joining wooden parts. When working on round constructions a special compass with a bearing plate is an indispensable addition that ensures the accuracy of machining.

When working with a router, you must learn to guide it calmly, with smooth movements. Proper and safe movement of the material being worked on is key. You shouldn’t do it too slowly, because burn marks can form on the wood and damage the material.

Chips appear when performing wood milling work against the direction of the wood fibers. You have to mill up to 8 mm in one pass, some models allow you to adjust it to 0,1 mm accuracy. Deep grooves and quarters need to be milled in several passes.

The milling machine can be used to make many household necessities and carry out any operations with wood or metal. Milling machines are needed for machining flat and shaped surfaces. These tools create recesses, grooves for various connections and even complex patterns that serve as ornaments.

What can you do with a woodworking router?

A distinction is made between stationary and hand-held milling machines. Machines, in turn, are differentiated by the type of operations performed.

Stationary machines are placed in large factories or plants, where a large number of similar parts must be produced. Their cutting head is fixed and the workpiece to be machined is moved.

Electric hand routers are considered the most universal and suitable for a wide range of tasks. When using a manual tool, the workpiece is fixed rigidly, and the tool itself moves. Cutters have the constructive ability to fix the tool, so handheld devices are recognized as more versatile.

Simply reposition or change attachments to change the application.

In particular, what can be done with a hand-held wood router that has the right tooling:

- Create straight or rounded edges on parts.

- Cut out places for door locks, dowels, hinges, furniture accessories.

- Make rebates.

- Polishing and sanding.

- Drill holes. plain and shaped. enlarge their diameter.

- Prepare workpiece edges for dovetail joints, microtips, T- or V-joints.

- Cut and trim parts to desired length.

- Roughly smooth flat surfaces.

- Thread wooden workpieces.

- Carve patterns, engrave on wood, metal, stone or plastic materials.

- Cutting straight or spiral grooves.

Wide possibilities of this tool allow its use both by professional construction or repair teams and by beginners at home.

Indispensable when making interior decorations, making furniture or creating various handicrafts.