How To Correctly Adjust The Valve On The Tiller

Valve adjustment on the Neva Tiller

Let us take the Neva MB-23 model as an example and analyze sequentially how to correctly adjust the valve clearances (the principle is the same for all tillers of this company). You will need 12mm and 14mm wrenches, 10mm socket wrench, 0.15mm and 0.2mm styli.

- Remove starter by unscrewing 3 bolts.

- Carefully remove the muffler, belt and protective cover of the gasoline engine.

- Using a socket wrench, remove the valve cover.

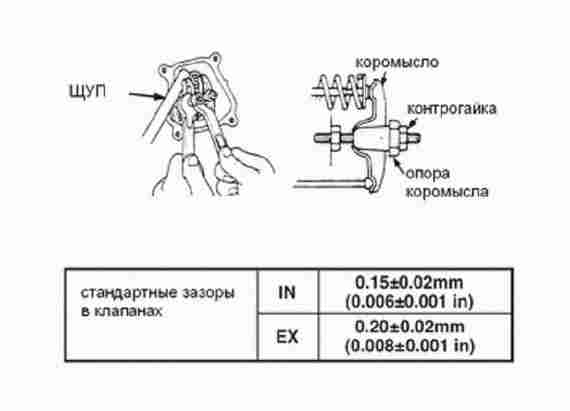

- Make sure what the valve clearance is on the tiller by looking at the instructions. For the Neva MB-23 engine, this is 0.15 mm for the intake and 0.2 mm for the exhaust valves.

- Adjust by measuring the gap with feelers and tighten the nuts, if necessary. When properly adjusted, the dipstick should fit between the valve and the rocker arm.

- Reinstall the valve cover, belt, guard, muffler and starter.

Step by step instructions for different models

Required tools

To adjust the carburetor valves, a minimum list of handy tools is required:

- razor blade or dipstick;

- minus screwdriver;

- box key.

Tarter How To: Correctly shorten a PTO Shaft

With these simple tools, you can adjust most carburetors.

People have invented snowmobiles that allow you to drive on snowy roads as quickly as possible without much effort. Ermak snowmobiles are quality, speed and reliability.

Gardening, caring for plants and trees have always been considered one of the most difficult types of work, as they required considerable time and effort. Sprayer Morolex. the perfect solution for your garden.

Time-consuming gardening work can now be done with a tiller. Learn how to plant potatoes with a tiller here.

It is important to understand that adjusting the valves means setting the optimal clearance, which is directly spelled out in the operating instructions for each specific model.

Engine UMZ. 341 for Tiller Agro. technical specifications, instructions, spare parts catalog

Setting gaps

Adjusting the engine valves means setting optimum clearances. Their norm is indicated in the technical passport of the tiller. Each model has its own permissible parameters, which depend on the brand and type of machine motor.

The permissible valve clearance on the chiller for a standard unit is as follows:

- for the inlet valve. 0.10-0.15 mm;

- for output. 0.15-0.20 mm.

To configure them, you need the following tools:

- spanners;

- styli for 0.10 mm, 0.15 mm and 0.20 mm;

- flat screwdriver.

The algorithm of actions for setting the optimal clearances is as follows:

- The engine must be cold during operation.

- Disconnect the oil bath cup from the air filter and filter element.

- Take the key, unscrew the 4 bolts around the protective cover.

- Remove the starter, then the tiller flywheel guard.

- Fix the “dead center” on the end of the flywheel. The mark on the rib of the cylinder blowing must correspond to the zero mark of the flywheel.

- Carefully remove the valve cover with a paronite gasket, having previously unscrewed 3 bolts.

- Check the clearances:

- there is an inlet valve near the filter;

- near the muffler. day off.

To check the interval, insert a dipstick between the rocker arm and the valve. If the distance is more or less than the permissible, using a spanner wrench and a screwdriver, adjust the elements.

If the valves are adjusted correctly, the engine will run without noise, jerking or malfunction.

How to adjust the valves on the tiller: adjusting and adjusting the diesel Lifan and Neva MB-2 with an American engine

Tillery as a means for plowing land has been known to many since Soviet times. This means of small-scale mechanization perfectly copes with this task, greatly simplifying the work of a person.

If we consider that additional attachments can be installed on this unit, then in fact all the work on the site is within his power.

However, in order for the tiller to work optimally, without failures, it needs constant care, which consists in timely maintenance.

In addition, the adjustment of the various components that are responsible for performance plays an important role. In particular, we are talking about adjusting the carburetor valves, on the correctness of which the stability of the engine will depend.

Engine UMZ. 341 for Tiller Agro. technical characteristics, instructions, malfunctions

In 1999, OJSC Ufa Engine-Building Production Association “started manufacturing a new generation carburetor engine UMZ. 341, developed by factory specialists. This single-cylinder, four-stroke engine produces 8 hp. in all respects it corresponds to the best world analogues, and in Russia it simply has no equal. It was originally created for the “Agros” tiller.

The official website of the engine manufacturer UMP 341. www.umpo.ru

Engine for Tiller Agro UMZ-341. operation manual download

Spare parts catalog for UMZ-341 and UMZ-341E engines. download

To convert the engine to AI-92 gasoline, replace the A11-3 spark plug with the A17B spark plug and adjust the ignition timing by moving it 2 degrees counterclockwise.

Guidelines for the transfer of the UMZ-341 engine and its modifications to AI-92 / AI-80 gasoline from the manufacturer download (this information is from the manufacturer’s site)

Setting gaps

Valve adjustment consists in setting the optimum clearances. This procedure is mandatory in carrying out maintenance. The clearance rate is presented in the technical data sheet of the device. Each model differs in permissible parameters, which depends on the brand and type of machine motor.

How to adjust the valves on the tiller, clearances

Adjusting the valves on the chiller is the main job that is carried out during the maintenance of this unit. THAT is necessary to ensure the safety of the tiller, to check the reliability and strength of all nodes and connections. Below we will consider the question of how to adjust the valves on the chiller, since they are the most important elements for ensuring the efficient operation of engines. Tiller reviews are presented on the youtube-channel of the AgroMotoCentre company. They also often publish reviews on agricultural machinery and its functional properties. You can see the video data at the link.

Clearance adjustment

The steps to adjust the clearances are as follows:

- before starting any action, check the engine: it must be cold;

- then disconnect the oil bath cup from the air filter and filter element;

- using a wrench, unscrew the four bolts from the protective casing;

- after these actions, it is necessary to remove the starter and the flywheel protective cover;

- then fix the dead point on the flywheel. It needs to match the zero mark;

- with careful movements, remove the valve cover with a paronite gasket, before that it is necessary to unscrew the three bolts;

- it is important to check the clearances. Remember that the inlet valve is located near the filter and the outlet valve is located near the muffler. To check the intervals, you need to insert a dipstick between the rocker arm and the valve. If the distance deviates from the allowable, you need to adjust these elements with a spanner wrench or a screwdriver;

- Valve clearances for gasoline tiller engines. Inlet valve 0.10-0.15mm; Exhaust valve 0.15-0.20 mm.

- after which it is necessary to wipe all connections with a clean rag, completely assemble the structure and turn on the tiller to check its working condition.

With correct valve adjustment, the engine will run quietly, without any jerking or malfunctioning.

Using the proposed algorithm of actions, you can correctly adjust the valves on the tiller, while ensuring the effective operation of the device!

About the device of tillers and valves

Tillery Cayman, Patriot, Texas, Foreman, Krosser, Viking, Forza, Sadko, Don are a rather complex technical device, consisting of several main working units: engine, transmission, chassis and controls.

The very understanding of the tiller design is very important, because the correctness of the repair and adjustment work depends on it.

Let’s consider each node in more detail:

- Engine. Depending on the configuration, 2-stroke and 4-stroke motors can be used. At the moment, the most widespread are 4-stroke ones, because they have higher performance indicators.

- In addition, engines are divided into diesel and gasoline. The former are most suitable for large-sized units, and the latter are most suitable for small and medium-sized tillers.

For more details on the operation of the tiller engine, see the given

- Transmission. The torque that is transmitted from the engine to the wheels is carried out precisely by the transmission. It includes a gearbox, gearbox, clutch system and differential (for some models).

- Depending on the type of gearbox and clutch, not only the cost of the tiller is formed, but also the principle of operation of these components.

- Chassis. Most tillers have in their presence a pair of wheels of various types. pneumatic or metal, equipped with grousers. In addition, the chassis includes the frame itself, on which all the other elements of the tiller are located. the engine, gearbox, etc.

- Control system. All control of the tiller is located at the distance of the operator’s outstretched arm, i.e. on the handle and in the immediate vicinity of it. This includes the clutch lever, shift and travel buttons, emergency engine stop, etc.

As for the carburetor, it is part of the engine power system. It acts as a kind of mixer that mixes liquid fuel with air to obtain a fuel mixture, which then enters the engine cylinders. Structurally, it looks like this:

Step by Step. How to measuring & adjust valve clearances

- float chamber;

- diffuser;

- spray;

- throttle and air dampers;

- mixing chamber;

- jet, etc.

This is a description of the standard carburetor, but different tiller models such as Huter, Profi, Plowman, Champion, Carver, Husqvarna may use different carburetors, respectively, and the adjustment will be different.

After a certain period of operation due to heavy loads, the clearance of the intake and exhaust valves may change.

The reason is the wear of the elements. A small gap changes the valve timing. The engine is not running at its rated power. Mechanical vibrations occur with large clearances, which lead to deformation. Due to the short opening of the valves, the cylinder is not completely filled. This leads to crashes and crashes, reducing performance.

Tiller valve adjustment is a must for maintenance.

How to set up on the Tiller Agro

The valves on the Agro tiller are adjusted as follows:

- We warm up the engine, after which we give it some time to cool down.

- Remove the oil bath of the air filter.

- Next, you need to unscrew the flywheel casing, mounted on 6 bolts.

- The flywheel has marks. 0 (top dead center), 5, 10 and 20 (fuel injection). We compare the dead center of the flywheel with the mark located on the cylinder so that they are opposite each other.

- Next, remove the valve cover.

- There are two valves under it. Loosen the lock nut, then insert the razor blade under the valve. The blade must pass freely between the piston and the valve.

- Having achieved this, we tighten the nut back. Then we put back the valve cover and flywheel housing.

It is worth noting that identical adjustment steps are carried out to adjust the valves on the Patriot tiller. tiller Agros and its valve adjustment also correlates with the tiller mb 1.

So, if necessary, you can use the identical scheme.

the tiller can perform a very wide scope of work, but this requires certain efforts on the part of the owner of this unit. We are talking not only about replacing failed parts and components, but also about timely adjustment of some units of the device.

In particular, the correct operation of the tiller engine will depend on how correctly and on time the valves are adjusted.

And it doesn’t matter whether we are talking about a Honda tiller, or we are considering a tiller knight 8 hp and its correct adjustment, we are talking about adjusting the valves on a diesel tiller, or adjusting the valves on the Forte tiller gasoline.

In any case, you should pay close attention to this action and carry out the adjustment as accurately as possible.

It is advisable to do this after each season, but there are times when such an adjustment is required at least twice during a given period of work. The main indications for this are atypical noise in the carburetor area, tapping. in general, uncharacteristic sounds during the operation of the tiller.

If this is found, and if the valves do not keep the dz adjustment in the tiller, then you need to immediately inspect and decide on the actions, especially since this procedure is quite simple and doable at home.

The tiller cart is a useful tool that you can assemble with your own hands.

Lifan 6.5

Adjusting the valves on the Lifan 6.5 tiller consists in setting the correct clearance under the valves. The sequence of actions will be as follows:

- Remove the cover to get to the flywheel.

- Remove the valve cover. There are two valves under it. intake and exhaust.

- To check the inlet valve clearance, you need a 0.15 mm dipstick, for the exhaust valve, 0.2 mm. If adjusted correctly, the dipstick should pass freely under the valve.

- To adjust, loosen the fastening nuts with a wrench. We insert the dipstick between the valve and the piston so that it does not slip, but is tight enough in this position. We wrap the nut.

- We put in place the valve cover and the flywheel cover.

Required tools

To adjust the carburetor valves, a minimum list of handy tools is required:

- razor blade or dipstick;

- minus screwdriver;

- box key.

With these simple tools, you can adjust most carburetors.

People have invented snowmobiles that allow you to drive on snowy roads as quickly as possible without much effort. Ermak snowmobiles are quality, speed and reliability.

Gardening, caring for plants and trees have always been considered one of the most difficult types of work, as they required considerable time and effort. Sprayer Morolex. the perfect solution for your garden.

Time-consuming gardening work can now be done with a tiller. Learn how to plant potatoes with a tiller here.

It is important to understand that adjusting the valves means setting the optimal clearance, which is directly spelled out in the operating instructions for each specific model.