How To Drill A Concrete Wall Correctly

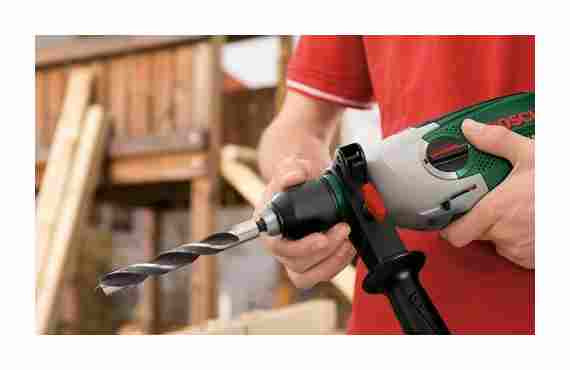

Ways to drill a concrete wall with a drill

When preparing for renovations in the house, you need to be prepared for the fact that you will have to drill the walls. For example, to fix a profile for drywall sheets. At this stage, some difficulties usually arise, since in many houses the walls are made of concrete. In addition to high strength, the material can be combined with reinforcement, which makes the work doubly difficult. To drill a concrete wall with an ordinary drill, you need to familiarize yourself with all the nuances of the workflow in advance.

How to properly drill a concrete wall

The process of repairing an apartment includes many works related to the creation of holes in the walls: for this, a tool of various designs and power can be used. Many craftsmen and those who are going to carry out repairs on their own want to know how to drill a concrete wall with an ordinary drill, and whether it is possible at all. For such work, a perforator is usually used, but it is not always suitable for this, besides, if the tool is to be bought, then its cost is much higher than that of a drill.

Surface preparation

Before you start drilling, you need to make sure that there are no wiring, pipes, electrical cables in the selected overlap location. A metal detector will help to cope with this task, as it reacts to non-ferrous metals, iron and steel.

If you ignore this condition, you can stumble upon fittings, damage the drill, or cables / pipes that were hidden in the ceiling. If this section satisfies all of the above requirements, then a point is marked on the wall, and after that a small depression is made in it at a slow speed using a drill. It is also worth remembering that the surface of a concrete wall is looser than subsequent layers.

A little about the drill device and drill installation

The classic drill consists of a power cable, a button, a capacitor wire, a reverse, brushes and springs, an armature, a stator, a gearbox and a chuck, bearings, a key and fastening screws. Correctly inserted drill improves the quality of drilling, and is able to secure it.

The first thing to check when starting to work with the drill is whether there is any dirt on the drill itself. When cleaning drills, a rag will be an excellent assistant. If the drill is loose, there is a risk that it will fly out and injure the master. Accordingly, it is necessary to immerse the drill as much as possible into the chuck (all the way!).

Do not under any circumstances try to “lengthen” the drill by incomplete immersion in the chuck.!

It is important to ensure that the drill in the tool is fixed strictly along the axis. If this rule is not followed, drilling in concrete will be of poor quality, the shape of the hole may be unpredictable, and the cause of all these misunderstandings will be the elementary beating effect of the drill.

Features of the work: expert advice

Drilling a concrete wall with a simple drill has some nuances:

- At the moment the drill is in the wall, the drill cannot be stopped: the tip will get stuck and it will be problematic to remove it. They stop pressing the key only after removing the drill from the wall.

- During operation, the drill is periodically wetted so that it does not overheat.

- Do not push the drill too hard: this will lead to deformation of the rod or destruction of the chuck.

- If a hole is drilled through a layer of plaster, a plan for the location of communications is first studied. Otherwise, there is a risk of damaging, for example, hidden electrical wiring.

IMPORTANT. Do not drill through decorative wall trim!

Compliance with the technology of work and safety rules when drilling holes in concrete with an ordinary drill will help not only to do without the involvement of highly paid specialists, but also to avoid injuries.

Features of the choice of tool

In most cases, it is better to use a perforator for drilling concrete: it has increased power, is designed for punching hard surfaces, and allows you to make holes large in diameter. The use of the tool is impractical in the following cases:

- the need to drill the wall to a depth of 10-12 mm;

- work with foam concrete, which crumbles when processed with a perforator;

- in work it is required to make no more than 10-15 holes.

Concrete drill

Before drilling a wall, it is important to choose the drill itself: it should not be hammerless, since this type is ineffective when drilling concrete, the nozzle and cartridge become unusable almost immediately. The nozzles themselves must be victorious, intended for concrete work, the tip. with a carbide coating.

In some cases, a good solution would be to purchase a drill-perforator: the device is more expensive than the classic model, but it has increased power, which can be adjusted.

How to make a hole with a drill

First you need to prepare a drill, attachments and other related items. Then, in the process of work, you will not have to be distracted and spend time looking for the right things.

Drilling is often necessary in cases where it is required:

- rough finish;

- laying of wiring;

- plumbing installation;

- concreting of communications.

In this case, the concrete wall (if drilled correctly) should remain without severe damage and large chips.

When working with a drill with a victorious bit, sometimes you need to use a metal punch. It is selected in accordance with the size of the hole. This tool enables the drill to not jam when the drill is buried. To do this, the punch is driven into concrete and hammered into pieces in order to split a solid obstacle into pieces. This process can take quite a long time, so it is better to use a diamond core bit. In addition, a drill with such a nozzle will never get stuck in concrete.

Drilling sequence:

- Examine the tools carefully. The drill must be in good condition and the drill must be intact.

- Start carefully drilling a hole in the concrete with a drill, stopping the continuous operation of the tool 10 minutes after the start of action.

- The process can be continued only after the motor has cooled down.

- Before drilling the next hole, moisten the nozzle with water. This will protect the metal from bending.

Using such simple methods, you can drill a concrete wall without a punch.

Sometimes there are times when the drill gets stuck in the wall. It is not advisable to use force in this case, otherwise it will break off, and the edge of the nozzle will remain in the concrete. To free the drill, you must first disconnect it from the drill, then put on a crown of a smaller diameter and get the stuck part.

To perform drilling on your own and at the same time to avoid various injuries and unpleasant incidents, you need to follow safety precautions and follow the recommendations of specialists.

Which is better to choose?

First of all, it is worth deciding on the following criteria:

- the depth and diameter of the proposed holes;

- type of drilling tool used.

You should not give preference to cheap options, since drilling concrete strongholds requires the use of quality products.

It is better to opt for well-known foreign (Bosh, Metabo, Makita) or domestic (“Zubr”, “Enkor”, “Interskol”) manufacturers.

General recommendations

Drilling load-bearing walls and concrete partitions is not an easy task. To complete the intended work quickly and efficiently, you need to know some secrets and tricks. And also it does not hurt to listen to the opinion of experienced craftsmen who advise:

- Use a concrete drill bit for the same material as well as stone and ceramics. They are absolutely not suitable for metal and wood.

- Drill steel reinforcement caught in the wall only with a drill for metal, then change it again to a drill for concrete.

- Break hard stones in concrete by hand with a sledgehammer or using an old drill.

- Monitor the condition of the packing when working with hard concrete. It should not overheat, so you need to take breaks from work every 10 minutes.

- To maintain the integrity of the wall on the back, you need to sometimes slow down.

- You can drill a ceramic tile with a drill on concrete, but do not press hard on the drill so as not to split the finishing material.

Concrete drill bit for a drill: structure, varieties, how to drill a concrete wall

Features of the choice of tool

In most cases, it is better to use a perforator for drilling concrete: it has increased power, is designed for punching hard surfaces, and allows you to make holes large in diameter. The use of the tool is impractical in the following cases:

- the need to drill the wall to a depth of 10-12 mm;

- work with foam concrete, which crumbles when processed with a perforator;

- in work it is required to make no more than 10-15 holes.

In some cases, a good solution would be to purchase a drill-perforator: the device is more expensive than the classic model, but it has increased power, which can be adjusted.

Drilling tips

There are several basic rules with which you can perform drilling extremely efficiently:

Distinctive features

In order to determine when looking at a drill for concrete that this is exactly the option that is needed for working with high-strength structures, you should know its main features.

Tip type:

- wood drills have a sharp tip, which, when working, plunges into the surface of the material;

- products for drilling metal have a cone-shaped tip;

- drills for concrete are blunt at the end and equipped with flake soldering from pobedit.

How to drill through a wall

By color:

- black metallic color is typical for metal drills;

- products for wood drilling have a lighter metallic shade;

- white color. a sign of a drill for concrete.

Drills for drilling concrete can be roughly classified based on two parameters: the diameter of the holes to be drilled and the type of tool used.

For the manufacture of small diameter holes, it is possible to use both impact drills and perforators, in which drills with T-shaped or cruciform solders are installed.

Making large holes in concrete is done with cylinder-shaped diamond core bits.

Drill types:

An overview of popular brands of tools for drilling holes in concrete

Drills used for concrete work are produced by foreign and domestic manufacturers. The cost of the tool depends on the brand awareness.

How to choose the right drill bit for concrete?

Good and durable tools are produced by foreign and Russian manufacturers. The best drills for concrete are presented in the table:

Manufacturer Features of tools High quality, durable and wear-resistant drills are carbide-tipped, retaining their properties even under prolonged loads, which are accompanied by heat generation. Each drill is sandblasted and coated with titanium nitride for increased wear resistance. They are distinguished by high elasticity, have resistance to bending and shock loads. The special sharpening of the soldering facilitates the drilling of the drill into concrete, and the spiral groove removes construction dust from the hole. For the manufacture of the drill, high quality metal is used, and a special treatment protects the product from damage by corrosion. Has high strength and wear resistance, reliable protection against deformation. With a long service life, it retains its original shape. High quality, hard soldered, robust concrete drills. They have special heat resistance, very durable, and have special grooves for quick removal of drilling waste. It is usually produced in a set of eight drills, of different diameters from 3 to 10 mm, packed in a cardboard box. High quality tool steel is used for manufacturing, and special treatment protects against corrosion. Has high strength and durability. Does not undergo deformation with frequent and long periods of work. U-shaped spiral on the tools helps to efficiently evacuate dust when drilling a hole. The cylindrical shank securely secures the drill in the chuck of the equipment. Tools with a four-helix shape. This significantly reduces the time and effort required to remove concrete residues from the hole. Feature of the tool:

- Using a VK8 carbide insert, significantly increases the drilling speed and increases the wear resistance of the drill;

- The presence of a U-shaped spiral accelerates the removal of unnecessary material and reduces the heating of the tool;

- High class of cleanliness of cutting edges;

- Sharpening angle. 130 °;

- Hexagonal shank, which serves as a reliable fastening of the drill in the chuck, ensuring safe and quality work.

The presence of a victorious tip allows drilling concrete and other building materials. The best option is to work in electric shock drills. They have an optimal ratio of price and quality, a long service life. Products are manufactured in China. Equipped with durable carbide inserts that do not break even if the drill hits the steel reinforcement when drilling concrete. However, you cannot drill the reinforcement with this drill. But when purchasing such a tool, you need to pay attention to the soldering of the carbide plates. they must be even. It is used for rotary hammer drilling.

- Made of tool alloy steel;

- The milled spiral is U-shaped;

- Cylindrical shank.