How to put a spring on a lawn mower starter

Device

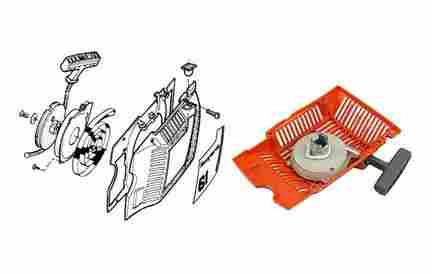

The chainsaw starter device includes the following elements:

- ignition system screw;

- return spring;

- coil of the starting system;

- deflector;

- cap;

- magneto;

- drum;

- spark plug;

- the electronic unit;

- wiring;

- power button;

- handle and cable.

The main parameters of the chainsaw start system:

- power. from 2000 to 2500 W;

- the maximum number of revolutions per minute. 3000;

- weight. 0.5 kg.

After pressing the power button, the flywheel begins to rotate along with the magnet that is on it.

An electromotive force appears in the system. The resulting current is converted by an electronic unit into electrical signals, which are transmitted to the driving elements. A spark is formed, which provokes the ignition of the fuel-air mixture.

How to fill a spring in a chainsaw starter

Spring repair

Procedure for repairing the starting system spring:

- Remove the starter from the tool body.

- Remove the protective cover.

- Wind the cord from the end of the pulley to avoid twisting the mechanism.

- Pass the other end of the cord through the hole in the protective cover.

- Pull the cord 17-20 cm to check the rotation of the spring mechanism pulley.

- Check the operation of the spring after pulling out and releasing the mechanism.

- Unscrew the pulley circle from the side of the generator by removing the 3 mounting bolts.

- Dismantle the pulley and cord.

- Check the condition of the parts for wear and damage or breakage. If the spring break is small, then the defect can be eliminated by welding.

Diagnostics

Diagnostics of the tool triggering system is carried out as follows:

- Unscrew the fastening screws and remove the cover.

- Remove the screw that attaches the mechanism to the protective cover.

- Smoothly start the starter by removing the spring and clamps from it.

- For inspection for wear and defects, dismantle the cable reel.

- Check the fuel system for water. If there is water inside the system, then the fuel fluid must be replaced.

- The power unit is inspected for overflowing with fuel fluid. In this case, you need to unscrew and dry the spark plug, pull the starter, dismantling the air damper.

- Check the spark plug for a spark.

The device and principle of operation of the chainsaw starter

Most well-known chainsaw manufacturers equip their products with starters that work on almost the same principle. Its essence is as follows: in the groove of the saw body there is a handle through which the cord is passed. When the handle is suddenly lifted, the cord is pulled out, which engages the drum, which is in the ratchet mechanism. This drives the spitz drum, which is located on the shaft. During this, the crankshaft makes a couple of revolutions, which leads to compression of the fuel mixture, which at this moment is located between the cylinder head and the piston. When the handle is lowered, on the contrary, the ratchet and the spitz loses their contact, which leads to a stop of the shaft.

With an increase in the power of the chainsaw, the amount of the fuel mixture increases, which should ignite when the chainsaw is started. In such a case, the number of jerks of the starter cord must be increased to start the engine. To speed up the return of the drum mechanism, manufacturers use a special steel starter return spring with excellent elasticity. Leading brands are using other methods to make it easier to start a chainsaw:

- Pre-enrichment of the fuel mixture using a separate flap;

- Installation of an automatic decompression valve, which reduces the pressure inside the cylinder of the chainsaw;

- Installing a primer designed to pump fuel before starting the engine.

The use of one of these technologies significantly facilitates starting and extends the life of the starter, which is especially noticeable at low temperatures.

Chainsaw starter. design and principle of operation

Chainsaws, although they have different names, are structurally similar. The trigger mechanisms of gasoline units, with the help of which the engine is started, also have a similarity. The mechanisms for starting the internal combustion engine are suitable for chainsaws of various brands Stihl, Husqvarna, Dolmar, Makita and others. Structurally, a starter for a chainsaw consists of the following elements:

- The drum on which the cable is wound

- The cable with which the crankshaft of the tool is driven

- Handle for ease of use of the mechanism

- Spring frame that winds the cable around the drum (returns to its original position) when the sawman starts the motor

PushMowerRepair.com. Briggs 3.5HP Recoiling a Starter Spring

The principle of operation of such a device is simple. With a sharp lift of the handle of the mechanism, the cable is pulled out. The cable engages with the ratchet, transferring motion to the spline drum. This is how the crankshaft moves, which makes several revolutions. At this moment, the working mixture is compressed in the cylinder. As soon as the handle returns to its original position, the splined ratchet connection is disconnected and the shaft stops rotating.

With each subsequent jerk of the cable, the amount of the fuel-air mixture in the cylinder increases. In order for the cable to return to its original position, return springs are used in the design of the trigger mechanism. They are made from resilient steels. It is this spring that often causes a malfunction of the starter of the unit, which can be repaired.

How to fix a starter on a chainsaw

The cause of a malfunction of the chainsaw starting system can be:

- Drive pulley. This part is subject to high axial and radial loads, therefore it is recommended to inspect the pulley for damage and cracks on the back of the housing before starting work. If necessary, repair the part or replace it with a new one.

- Spring mechanism. If it has lost its properties or has cracks or breaks on it, it is necessary to replace this element. It is also recommended to inspect the attachment points for defects.

- Rope launch system. The rope should be inspected for wear and damage. If necessary, replace the part and install it on the pulley.

How to fix a starter on a chainsaw

The cause of a malfunction of the chainsaw starting system can be:

- Drive pulley. This part is subject to high axial and radial loads, therefore it is recommended to inspect the pulley for damage and cracks on the back of the housing before starting work. If necessary, repair the part or replace it with a new one.

- Spring mechanism. If it has lost its properties or has cracks or breaks on it, it is necessary to replace this element. It is also recommended to inspect the attachment points for defects.

- Rope launch system. The rope should be inspected for wear and damage. If necessary, replace the part and install it on the pulley.

Typical breakdowns and repairs of the chainsaw starter

The appearance of various malfunctions of the starter leads to the inability to start the chainsaw. The most common starter breakdowns include:

- The starter pulley is completely burst or cracked;

- The spring has burst;

- Starter rope broke.

To fix each of these faults with your own hands, you will need certain tools. You must have a set of screwdrivers and a spare cable with you. It is necessary to remove and inspect the starter for the chainsaw in the following order:

- To find the cause of the breakdown, the starter will need to be removed from the chainsaw. To do this, unscrew the screws with a screwdriver, with which the protective cover is held with the starter attached to it;

- After removing the cover, you must carefully unscrew the screw by means of which the starter is attached to the protective cover;

- Then you need to try to smoothly start the starter. for this, remove the spring and clamps from it;

- Further, a coil with a cable is removed from the starter for inspection.

As a result of inspection, you can find a number of typical malfunctions. These include:

- Various damage to the pulley in the form of ruptures or cracks, mainly in the rear of the part. they interfere with the normal operation of the entire starter;

- Damage to the starter spring of the lightweight start. in such cases, not only the spring itself can be faulty, but also the place of its fixation. this is the most vulnerable part of the spring;

- Damaged starter flywheel dog.

Chainsaw starter: device, breakdowns and DIY repair

In the design of the chainsaw, the starter is responsible for the proper starting of the tool’s engine. Over time, owners of chainsaws are faced with the need to repair this important unit. And the sooner it is possible to eliminate the malfunction, the less other important parts and mechanisms of the tool will succumb to wear.

Replacing the cord

If the cord is pulled, the rope starts to rub against the starter housing. Replacing the cord begins with disassembling the body of the assembly, during which the ratchet drum is gently lifted so that the return spring does not slip from its seat. It is more correct and more convenient to do this together, where during the replacement of the cable the second will hold the spring! After the cable is successfully fixed in the grooves of the drum and the handle, it is wound on a roller with the subsequent assembly of the body.

Chainsaw starter device

As standard, the chainsaw starter consists of a number of parts.

These include:

- coil;

- cable;

- the frame to which the return spring is attached;

- a pen.

A protective cover is installed on top of all elements of the starter. The original principle of operation of most of the triggers is also almost the same. In a special groove in the chainsaw body there is a handle that holds the cable. When the handle is raised sharply, the latter is understood. At this moment, a ratchet is triggered, which, through the drum, transfers the force to another drum with splines located on the engine shaft.

When pulling out the standard cable, the chainsaw motor shaft begins to rotate, which leads to compression of the existing fuel mixture located at this time between the cylinder head and the standard piston.

With an increase in the volume of the internal combustion engine cylinder, the amount of consumed fuel mixture, which is required for its future ignition, also increases. Consequently, the operator of a powerful saw needs more jerking strokes than the owner of a low power tool. Powerful chainsaw manufacturers use resilient return springs to increase the speed at which the drum returns to its original position.

Chainsaw starter: DIY tool work and repair

A quick start of any chainsaw is not complete without a starter. During the operation of the tool, due to the accelerated cranking of the crankshaft, the fuel-air mixture is fed into the engine, compressed and ignited. Based on this, a well-chosen starter for a chainsaw is able to guarantee a long and trouble-free operation of the entire mechanism.!

How to put a spring on a chainsaw starter?

Fitting the spring into the correct groove is a tricky task. First of all, the part will need to be twisted, returning it to its previous dimensions. After that, it must be inserted into the cavity of the standard drum hub. To fill the spring in the chainsaw starter, you need to proceed in this order:

- The outer end of the spring used must be fixed in a special stop lug. In this case, the second end with a screwdriver will need to be installed opposite the standard hole inside the lock;

- Next, the loop located at the inner end of the standard spring should be aligned with the hole. It is better to use a screwdriver for this. When the ends are aligned, the disc will need to be lowered;

- After mounting the disc, you need to check that the dog of the factory ratchet mechanism of the chainsaw is in its original place. Then you can assemble the ratchet in reverse order.

To wind the spring on the chainsaw starter, you need to take into account all the holes and notches available. After installation, you will need to tighten the spring. As soon as the slack is eliminated, the spring will remain to be wound a few turns. this is necessary to maintain the required tension of the installed part.

Chainsaw starter device

As standard, the chainsaw starter consists of a number of parts.

How to fix a pull starter recoil spring and replace a stuck or limp pull cord

These include:

- coil;

- cable;

- the frame to which the return spring is attached;

- a pen.

A protective cover is installed on top of all elements of the starter. The original principle of operation of most of the triggers is also almost the same. In a special groove in the chainsaw body there is a handle that holds the cable. When the handle is raised sharply, the latter is understood. At this moment, a ratchet is triggered, which, through the drum, transfers the force to another drum with splines located on the engine shaft.

When pulling out the standard cable, the chainsaw motor shaft begins to rotate, which leads to compression of the existing fuel mixture located at this time between the cylinder head and the standard piston.

With an increase in the volume of the internal combustion engine cylinder, the amount of consumed fuel mixture, which is required for its future ignition, also increases. Consequently, the operator of a powerful saw needs more jerking strokes than the owner of a low power tool. Powerful chainsaw manufacturers use resilient return springs to increase the speed at which the drum returns to its original position.

Chainsaw starter

The starter is one of the most important mechanisms in any modern chainsaw. It is on him that the engine start of the tool depends on all weather conditions. The chainsaw starter stands out for its simple design, it is easy to maintain and repair it yourself. However, in order to fix the breakdown, you must first find its cause. For this, most often it is required to completely disassemble the standard mechanism.

How to put a spring on a chainsaw starter?

Fitting the spring into the correct groove is a tricky task. First of all, the part will need to be twisted, returning it to its previous dimensions. After that, it must be inserted into the cavity of the standard drum hub. To fill the spring in the chainsaw starter, you need to proceed in this order:

- The outer end of the spring used must be fixed in a special stop lug. In this case, the second end with a screwdriver will need to be installed opposite the standard hole inside the lock;

- Next, the loop located at the inner end of the standard spring should be aligned with the hole. It is better to use a screwdriver for this. When the ends are aligned, the disc will need to be lowered;

- After mounting the disc, you need to check that the dog of the factory ratchet mechanism of the chainsaw is in its original place. Then you can assemble the ratchet in reverse order.

To wind the spring on the chainsaw starter, you need to take into account all the holes and notches available. After installation, you will need to tighten the spring. As soon as the slack is eliminated, the spring will remain to be wound a few turns. this is necessary to maintain the required tension of the installed part.

How to assemble a starter on a chainsaw?

After replacing the faulty elements of the starter, it is the turn of its reassembly. In this case, maximum accuracy must be observed, since the slightest discrepancy can lead to damage to the trigger. The assembly of the assembly should be performed in the following sequence:

- The standard cable will need to be tucked into the factory hole of the reel. At the same time, the cord does not need to be wound;

- Next, you will need to insert the coil into its base place. At this stage, many beginners make a common mistake. There are 2 slots on the surface of the coil. One of them should get the regular hook of the coil spring. To do this, the coil will need to be installed in such a way that it fits snugly into its original place, and the existing hook fits exactly into the slot. The correctness of installation must be checked by turning the coil in the direction of the clock hand until resistance appears;

- Then you need to install a device for easy starting of the chainsaw. In this case, the protrusion of the latter should be located in the recess of the installed coil;

- After that, you will need a screw and washer to fix the device;

- Next, the other end of the cord must be tucked into a special outlet;

- In the next step, you will need to thread the cable into the starting handle. To this end, you will need to tie a medium-sized knot at the end of the cord. If it is too small, then the cable will slip, which is why it will quickly wind up on the trigger drum;

- Then you need to release the loop inside the starter. Immediately after this, you should start rotating the trigger in the direction of the clock hand. In this case, the cord does not need to be wound. Next, you need to fix the coil with your hand, and pull the loop out by the handle;

- After that, you need to check the operation of the trigger;

- If the unit is working properly, it remains to install it on the tool, and fasten with three screws.

Starter repair is not a complicated procedure if you follow the correct procedure. As a rule, replacing the starter cord will take no more than 20 minutes. The main thing is to correctly position the pulley and drum in relation to each other. Otherwise, the trigger will not work.