Miter saw what you can do

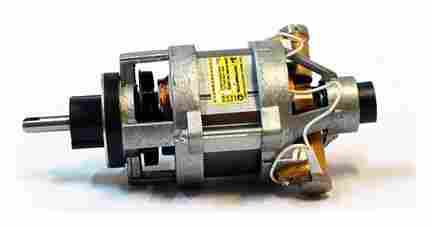

Collector motor

Brush motors look much more attractive from the point of view of the ratio of dimensions and power. With a comparable mass, the torque of a collector motor is several times greater than that of an induction motor. It is capable of delivering up to 5-10 thousand rpm, and the organization of the control system and speed stabilization is much simpler.

It is not surprising that despite the disadvantages of collector motors (high noise level, the need for regular maintenance, which consists in replacing collector brushes), most miter saws are equipped with them.

Additional accessories

Almost all modern models of miter saws have some kind of additional devices and functions aimed at facilitating work and increasing safety. At the stage of selection, the future user of the tool will have to figure out which of them are really necessary to solve the typical tasks facing him, and which will be an unjustified waste of money.

The dust extraction system consists of a branch pipe and a dust bag or hose of an industrial vacuum cleaner connected to it. The second option is preferable because it allows you to more effectively capture the fine dust of the material being processed, which is formed when performing an accurate cut when the saw operates at high speeds and / or with discs with an increased number of teeth.

The dust extraction system should not be considered as an additional, optional function, even if you are faced with the task of choosing a miter saw for your home, i.e. low-intensity episodic work on it is assumed. Working without a dust extraction system, you risk not only the safety of the equipment available in the workshop (and first of all the saw itself), but also your own health.

The blade guard completely covers the saw blade until it is immersed in the material being cut, significantly reducing the risk of accidents when using the miter saw.

Cutting depth limitation is used to perform work on grooving or trimming profiles.

The laser “draws” the guide line on the workpiece where the saw will cut. The presence of this option increases the accuracy of the cut (especially when sawing at angles other than 90 degrees), facilitates the work, reduces the time for preparatory work.

Illumination of the working area is useful when working in workshops or workshops with insufficient general lighting.

What Can You Do With a Miter Saw? Should You Get One? | WOODWORKING BASICS

Smooth start provides a gradual set of revolutions by the engine when turned on, which prevents the tool “jerking” at the start, reduces the risk of saw failure due to a sharp current surge and the likelihood of equipment jamming at the beginning of work.

Automatic shut-off when the saw blade is jammed is another useful feature to increase safety when working with a miter saw.

Adjusting the number of revolutions allows you to vary the cutting speed. Most miter saw models do not have this function. However, it allows you to better tailor the sawing process to the characteristics of the material being processed. Recommended for those who intend to work not only with wood, but with various materials based on it, plastic, plexiglass, etc.

Maintaining constant rpm during load increase. With this function, the engine speed does not drop with strong pressure, since the electronics make their own adjustments to the speed. As a result, the cut is neat and clean.

Varieties and choice of motor for trimming

Most often, the miter saw motor is located to the right of the blade. However, on some machines, it is shifted back to maximize the view of the working surface (regardless of which hand the operator is using) and not create obstacles when cutting an oblique cut. such saws, as a rule, have a tilt of the working head in both directions.

Two types of electric motor are installed on the end faces. asynchronous and collector.

How to choose a miter saw. tips and advice

Saw blades

Often, novice craftsmen who do not have sufficient knowledge, but have a great desire to acquire a new tool, ask the question: “How to choose a miter saw for wood?” This question is not entirely correct. Any trimming will cope with sawing wood, because for this it was created. But how much you like the result of the work depends not so much on the tool itself, but on the equipment installed on it. the saw blade.

Technological slots.

2. Rim diameter.

3. Outside diameter.

Outside diameter value.

5. Maximum rotational speed of the disk.

6. Cutting disc for 96 teeth.

Disc thickness value.

8. The value of the rim diameter.

Asynchronous motor

An induction motor is considered to be more economical, reliable and quieter. There are no contacts in it, which means there is nothing to make noise, overheat and fail under the influence of external factors. dust, humidity, vibration. In addition to bearings, there is simply nothing to wear out there, so such units can serve without any special complaints for decades.

However, not all manufacturers of power tools strive to equip their products with such seemingly ideal motors, since they have asynchronous motors and their significant drawback. low power with a sufficiently large weight.

For example, a 2-kilowatt motor of this type weighs over 20 kilograms. Agree, it is rather difficult to manually move the working unit with such a makeweight. In addition, when powered by an industrial frequency current, an asynchronous motor, in principle, is not able to reach a speed of more than 2850 rpm. Of course, the use of modern materials and power supply of the motor with a high frequency current to some extent neutralize these problems, but do not completely eliminate them.

Types of gearboxes, their advantages and disadvantages

The connecting link between the electric motor and the saw blade is a gearbox that transmits and converts the motor torque. On miter saws, two types of gearboxes are used. with a gear or a belt drive.

The cogwheels, which provide a rigid connection of the shafts, seem to be more reliable. They do not slip or fly off like a belt, and there is nothing to break there. It would seem that manufacturers of miter saws should give preference to such a reliable system. However, in practice, the belt drive on these tools can be seen more often than the gear.

What is the reason? There is also a downside to the reliability of the gear train. In the event of an emergency situation, the gear reducer may fail, and then it will need to be completely replaced or seriously repaired in a specialized service center.

The “unreliability” of the belt drive can also be looked at with different eyes. Yes, sometimes the belt flies or even breaks, but in order to install it in place or replace it with a new one, special knowledge and skills are not required. an ordinary user can also cope with this task. In addition, the belt provides some damping of radial and axial vibrations, which helps reduce wear on bearings and other engine components.

In the event of an emergency overload of the tool (for example, when the saw blade is jammed), even a well-tensioned belt will slip, which will save the metal parts of the motor from destruction. And the saw with a belt drive produces incomparably less noise, which is also a rather significant factor.

Belt Drive Miter Saw.

By the way, some manufacturers (including such reputable ones as Bosch and DeWalt) have completely excluded the gear unit from a number of their models by installing the saw blade directly on the motor shaft. This solution also has its pros and cons. On the one hand, the load on the bearings increases, on the other, the noise emitted by the tool decreases, the reliability of the structure increases, and maintenance and repair are simplified.

Miter saw: device, selection principles and discs used for work

Cutting finishing materials at an angle is, frankly, not an easy task, and almost all people have problems with its solution. Meanwhile, most of the finishing materials require just such an approach to their installation, for example, lining, skirting boards, baguettes and even metal structures assembled from a profile pipe. In general, there are many such materials, and their diagonal cutting has to be solved, sometimes even with very high accuracy. In this article, along with stroisovety.org, we will explore a tool such as a miter saw to help you tackle the task of diagonal trimming. We will familiarize ourselves with the device of this tool, the evaluation criteria, which will allow us to purchase a model suitable for work and we will deal with the saw blades used with this tool.

Electric miter saw photo

Miter saw: device, purpose and capabilities

A hand-held miter saw has a narrow purpose, and you are unlikely to be able to unfold boards with its help. Her tasks are slightly different. she can perform extremely short cuts. With its help, you can cut the board in half, align its end, or cut the end of the board at a certain angle. That, in principle, is all that she can, but, believe me, this is a lot. other saw equipment copes with such tasks much worse. Oh yes, I completely forgot that in addition to wood, depending on the equipment used, the miter saw can work with soft metals, plastic and, if necessary, with thin sheet iron, or rather with a profile made of it.

Miter saw capabilities

The universal miter saw has a rather complex design. it consists of two main units, which are not at all simple in design. This is a bed on which a rotary table and a movable cutting head with a powerful electric motor attached to it are fixed.

- Bed with a rotary table. As a rule, these two parts cannot do without each other. There is a guide on the bed itself, which ensures a fixed position of the workpiece. The miter saw table itself can rotate relative to the guide within 90˚ (45˚ in one direction and 45˚ in the other direction), thus providing a simple trimming of the workpiece in any direction without reinstalling the part.

- Cutting head. Installed directly on the turntable. it changes its location with it. For convenience in work, a graduated scale is applied to the side of the rotary table on the bed. by combining the table mark with a certain degree value, you can make cuts at any angle. And that’s not all. the head itself, or rather its cutting part, can be tilted left and right, thereby providing an oblique cut. In most cases, this tilt is performed in one or two fixed positions (30˚ and 45˚ to either side). Also, some models can be equipped with a special broaching mechanism. The miter saw with a broach allows you to cut workpieces much wider than its ordinary counterpart.

What is the design of the miter saw

Electric miter saw: nuances and selection criteria

The question of how to choose a miter saw can be solved by adhering to five small rules.

-

To begin with, you must decide on its purpose and operating conditions. What do you need it for? What kind of work, and most importantly, how much do you plan to do with it? If you are purchasing a miter saw for home use and do not plan to perform complex operations, then it is quite possible to get by with a simple tool with a basic set of additional functions. If we are talking about the professional use of the miter saw and its daily use, then, of course, you need to choose the extended version of this tool with a full set of additional options. You can consider the option of purchasing a so-called combined miter saw, which is equipped with an additional work table in the upper part of the cutting head, allowing it to be used as a stationary circular saw.

Miter saw for wood photo

How to choose a miter saw

Naturally, when choosing a miter saw, it will not be superfluous to take into account the power of this tool, as well as the speed of rotation of the blade. In most cases, these values are calculated by the manufacturer and are optimal. A household tool will have a lower power than a professional one, but the rotational speed of the disk is almost always the same, which is due to the need to make a clean and even cut.

Miter saw universal photo

Miter saw blades: what is the difference between them

There are not so many differences between the discs used on the miter saw, and the main ones are the fit and outer diameter, as well as the geometry of the cutting tooth. If everything is more or less clear with the size of the discs (the bore can be either 25mm or 30mm, and their outer diameter is 210, 250 and 305mm), then the geometry of the tooth should be dealt with in more detail.

- You should pay attention to the size of the tooth. the larger it is, the rougher the cut will be. A disc with a large tooth is unlikely to be able to cleanly cut laminated, varnished or painted workpieces. for these purposes, you need to purchase a disc with a fine tooth. Also, a small tooth showed itself well when working with an aluminum profile. In general, in this respect, saw blades for a miter saw can be divided into three types: for longitudinal cuts, for cross cuts and for fine cuts, which, as a rule, are universal.

- When it comes to mass production or working with thick workpieces, you need to pay attention to the presence of thin slots on the disk. in fact, these are temperature compensators, whose task is to maintain a stable disk size when it heats up. In addition, such discs are less noisy.

Miter saw blade photo

And a few words about the enterprises that produce miter saws for wood. Bosch and Makita are leaders in nearly all power tools, and their miter saws are no exception. The tools Metabo, Hitachi, DeWalt also showed themselves well in practice. If we talk about domestic miter saws, then here we can note the Corvette tools. In general, there is plenty to choose from. the main thing is just not to miscalculate the possibilities.

That is, in principle, everything you need to know about a tool such as a miter saw. Buy, use it and remember that this tool is quite dangerous. do not forget about safety precautions and when working, always be extremely collected, and most importantly sober!

Sliding miter saws.

The disadvantage of the tool design is the small length of the cut. The disc descends vertically onto the workpiece by about a third and the cut length is much less than the diameter.

This parameter can be increased by installing a broaching mechanism on the angle cutter, when the saw unit rests on two horizontal guides, and they move inside the rack, which is performed not vertical, but slightly tilted back.

Such a device allows you to increase the cut from 80-200 to 240-340 mm (maximum 430 mm). Having installed a wide material, the worker simply pulls the saw head towards himself.

For high-quality work, the manufacturer must ensure sufficient structural rigidity and the absence of backlash, which is not easy to do due to the large number of movable joints.

Combination tool with saw table.

On both feed-through side saws and standard models, a die-cast aluminum platform can be installed at the top. The disc coming out of its slot allows you to create a mini circular on the base of the angle cutter for opening the boards along the length.

The saw unit locks in the down position. The power button is fixed after pressing. Pushing short workpieces is carried out with a plastic pusher.

Miter saw 255mm with wire Worcraft MST20-255

Miter saw 254mm with wire JET JSMS-10L

Combined miter saw 250mm Einhell Home TH-MS 2513 T

Miter saw 250mm Virutex TM43L

End saw for wood 210mmProton PDT-210

Miter saw Stark MS-1820

Cross cut with 305 mm broach and laser Yato YT-82175

Types of trims

First of all, I would like to divide the whole variety of types of miter saws by design into:

- standard;

- multifunctional.

In the multifunctional version, the saw has a movable cover or table, which easily transforms it into a miniature circular saw. This is a more professional type of tool, which we do not recommend purchasing for home use because of the significantly (2.5-3 times) overpriced.

Secondly, miter saws can be divided according to functionality. advanced versions have a retraction. a very popular feature that allows ripping cuts to be made much wider than the saw blade diameter. Or the ability to cut at different angles. The most inexpensive miter cuts are usually only sawed perpendicularly.

What is a miter saw for?

The main task of trimming is to make a very accurate and perfectly straight cut at a given angle. This can be a horizontal cut at 90 ° or at an angle of 30 °, 45 ° and so on. Most often, a miter saw is needed in woodworking and furniture enterprises, often its use in finishing work. She is an irreplaceable assistant in the manufacture of door and window openings, furniture. Cross-sections have also found their application wherever it is necessary to work with polymeric materials or soft non-ferrous metals. To do this, they replace the saw blade with a cutting blade for metal. Sometimes a miter saw is called a cutting saw, because it is directly involved in the installation of something.

If you do not need to use frequent trimming or the cutting accuracy does not need to be so critically accurate, then we recommend that you pay attention to a cheaper and easier-to-use circular saw.

What you can do with a miter saw

What is a miter saw for? What can be done by trimming. What types of saws are there and how they fundamentally differ. The most popular miter saw manufacturers in the world.

In the household, you rarely find a miter saw due to the peculiarities of its scope. It is also worth noting that the cost of this construction device is quite high compared to the more common angle grinders. So let’s figure out why a miter saw is needed and for what work it is bought.

Most popular manufacturers

- Metabo. German quality speaks for itself. The company has been developing and supplying power tools worldwide for almost 100 years.

- Bosch is the second proven manufacturer from Germany, which has been known and loved by professional builders for almost 150 years.

- Makita is a Japanese quality that is not inferior to German in anything. than 160 countries use this manufacturer’s electric and gas powered tools.

- DeWalt is a North American manufacturer with factories on three continents.

If the information was useful to you, rate it.