Chainsaw Problems And Troubleshooting

Adjusting the carburetor of the Partner 350 chainsaw

This is the most frequently performed self-service maintenance procedure for your chainsaw and is worth learning. It is similar to adjusting the carburetors of most chainsaws and is described in sufficient detail in the proposed video:

It is important to complete it by adjusting the idle screw, which ensures the immobility of the chain when operating in this mode. If the chain does not stop at the lowest steady speed, this indicates that the clutch needs to be repaired and it is not safe to use such a saw.

Partner chainsaws. features

Many sources claim that it was this Swedish company that produced the first serial household chainsaws in Europe. And it happened in 1949.

It is generally accepted that these are good Chinese saws, and this is partly true. most of the Partner chainsaws sold in our market are assembled in China, which is honestly written on their nameplates. But besides China, the saws of this brand are also produced in America, Italy, Norway and England, and you can also buy them in Russia.

For more than 10 years, this brand has been owned by the Husqvarna concern, one of the leading manufacturers in this segment, which affects not only the design features of the saw, but also the widest network of service centers that can quickly and efficiently service it.

Few people know, but for the first time the chainsaw chain brake and the handle heating system were applied precisely on Partner chainsaws, so they should not be underestimated.

There are about 30 modifications of this brand’s chainsaws. From the smallest Partner 340S saw on the market today with 1.44 kW of power at 13,500 rpm to the most powerful Partner 842 with 1.6 kW at 12,000 rpm.

But, perhaps, the 350th model remains the most bought in Russia.

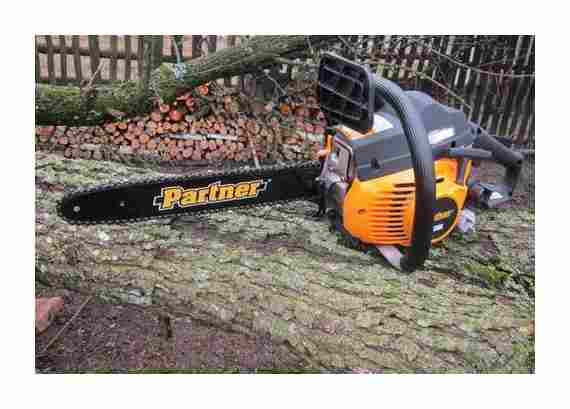

Chainsaw Partner 350 S. features, troubleshooting, operating instructions

One of the most popular household chainsaws in Russia is the 350th model of the Partner saw. This can be explained by a number of advantages of this model.

The most important qualities of such saws, which characterize them on the positive side:

- compactness and light weight with sufficient power;

- relatively affordable price;

- durability;

- excellent repair facilities.

Saw Partner 350 overview

We will consider it in more detail.

Specifications:

- power 1.52 kW;

- working volume 36 cm3;

- idle speed 3000 rpm;

- the maximum recommended speed is 13000 rpm;

- saw bar length 40 cm;

- chain pitch 3/8 “.

The use of saw bars with a length of 45 cm is allowed, but for this length the saw is still rather weak.

The saw is equipped with a hand chain brake, an easy start system, a primer for pumping fuel, a carburetor air damper regulator, chrome-plated cylinder walls and a cyclotron air preparation system. It is assembled quite qualitatively and, yielding in class to more eminent classmates from Husqvarna and Shtil, surpasses almost all other chainsaws in the household segment in terms of its consumer characteristics.

Chainsaw Partner 350: malfunctions and their elimination

One of the main features of this saw, its users note the durability of operation with a minimum number of failures. And yet they do happen. To determine why the saw stopped working, you need to make an elementary diagnosis.

If the saw does not start, then:

- there is no spark on the candle;

- no fuel is supplied;

- no air coming in.

First, check for the presence of a spark: by unscrewing the spark plug, connecting it to the high-voltage wire and placing it on the cylinder, pull the starter. If there is a spark, then clean and adjust the spark plug gap (0.5. 0.65 mm). If it is not there, then you need to change: either the flywheel or the coil (magneto). In addition, the candle itself may fail or the high-voltage wire may break.

The next step is to check the fuel supply. To do this, disconnect the supply hose from the carburetor and check for its presence. Absence may mean that the fuel filter or supply system is clogged. And the carburetor itself may become clogged.

If you have no experience in repairing and cleaning it, entrust this work to specialists.

If the air supply deteriorates, the saw should start, but it will not work well. Remove and wash the air filter. Put it back in place only after it is completely dry.

If the saw starts well, runs at idle speed and stalls when gas is applied, the muffler is most likely clogged. Take off, disassemble, wash, put back and work on.

Easily do it yourself, you can also change the bar and chain, carburetor, starter, oil pump, ignition and clutch.

Here is a video of the complete disassembly of this saw:

And you will be quite capable of replacing the torn starter cable after watching this video:

We recommend that you entrust more complex chainsaw repairs related to replacing the cylinder-piston group or crankshaft with specialists, although if you are familiar with two-stroke engines, then this work will not be difficult for you, and spare parts for Partner chainsaws are not in short supply in Russia.

To enlarge a picture, click on its thumbnail.

We advise you to regularly monitor the health of the safety group: brake and chain catcher. Remember that the saw must be thoroughly cleaned of small chips. It can not only clog the technological holes in the oil pump and other places, but also interfere with the operation of the brake.

Operating instructions for Partnerа 350

In this manual, you will find not only a detailed description of the saw, but also the basic techniques of working with the tool. We would like to draw your attention to the fact that this chainsaw can operate on AI95 or AI92 gasoline with the addition of oil for two-stroke engines in a ratio of 1:50.

Disadvantages of the saw

On the Russian market, you can find not very high-quality counterfeits of the Partner 350 chainsaw, which is not only additional evidence of its popularity, but also harms the brand as a whole. And other models of this brand are also popular with summer residents and farmers.

If you are ready to consider Partner 350 as your home tool for sawing thin trees, pruning branches and other not-so-voluminous work, then you should also know the disadvantages, most often called by their owners:

Not a very high-quality vibration damping system, as a result of which the hands get tired quite quickly. But, given that this is a household tool that requires 15. 20 minutes of rest every 20. 25 minutes of work, you can put up with this drawback.

Leakage of oil from the chain lubrication system, which, however, suffers from most chainsaws equipped with it, including the more eminent relative of Partner chainsaws. Husqvarna. (Link)

Lack of visual control of the oil level, which is not very convenient in operation, and operating the saw without lubrication will lead to rapid stretching, overheating and wear of the chain.

Of course, you can use this saw to cut a tree up to 30. 35 centimeters thick, but its main purpose is to work on the site. Therefore, we offer you the most objective video review of this model:

Dear readers, if you have any questions, ask them using the form below. We will be glad to communicate with you;)

Chainsaw malfunctions and how to fix them

Carburetor adjustment

Incorrect adjustment of the carburetor will cause the chainsaw to not develop full power. It will be difficult to start, or not at all. The carburetor setting directly affects the quality of the air-fuel mixture, which is necessary for normal starting and further engine operation.

If the carburetor is incorrectly adjusted, the mixture of fuel and air will contain more or less gasoline than required, and the mixture will not ignite even with normal sparking.

An excess of gasoline in the mixture is called overflow. A characteristic sign of overflow is a wet spark plug, after several unsuccessful attempts to start the chainsaw.

The gap between the ignition coil and the flywheel

An incorrectly set gap between the flywheel and the contacts of the ignition coil affects the quality of sparking, which in turn is responsible for normal start-up and stable operation of the engine.

Chain lubrication problems

If no lubricant is supplied to the chain, then this threatens the development of the following events:

- Rapid chain wear (blunt teeth, stretching, tire wear)

- Engine wear due to heavy loads placed on the tool

- Wear of the drive sprocket, which also needs lubrication

Malfunctions of the chain lubrication system and their elimination by hand

If oil does not flow to the chain, then the reason may be an insufficient amount of lubricant in the reservoir, a malfunction of the oil pump, and damage to the channels. The breakdown can be eliminated only after determining the exact cause of the chainsaw malfunction.

Prevention

Improper care and use of the tool will shorten its service life. To extend its service life before the next repair, it is necessary to follow some preventive recommendations.

- Before each start, check the serviceability and tension of the chain, as well as the sharpening of the teeth.

- During the sawing process, allow the tool to rest periodically, especially when it comes to household or semi-professional chainsaws.

- After completing the work, clean the chain, tire, air filter, housing and other slots and grooves where sawdust could get.

- Flip the tire periodically to ensure even tire wear.

- Use only quality oils and fuels.

- It is impossible to store the fuel mixture for a long time, therefore drain the residues from the tool and dispose of them.

Work should be carried out only when you are sure that everything is in order. The implementation of such simple preventive procedures can significantly extend the life of the instrument.

Sparks on the spark plug

Checking the spark on the spark plugs is the first step in diagnosing the unit.

The most common reason a saw refuses to work is a malfunction of the spark plug electrodes.

The reasons why the ignition device stops working may be as follows:

- Incorrect carburetor adjustment.

- Increased oil level in gasoline (acceptable oil depends on the specific model of the chainsaw).

- Contamination of the air filtration system that interferes with their operation.

- Excess fuel in the spark plug channels.

- Disconnecting the high-voltage cradle to the end of the candle.

- Breakdown of the ignition block.

Expert opinion

Kulikov Vladimir Sergeevich

All of these factors lead to the growth of charred clumps on electrical conductors. Deposits prevent spark formation. Therefore the instruments cannot function cold. Lack of maintenance of the filtration system and engine power system assembly leads to the gradual spread of corrosion. Excessively narrowing or increasing clearance makes the saw malfunction.

Excess gasoline

Filling the spark plug channel with gas is another common cause of chainsaw malfunction. The owner of the tool is able to cope with this problem on his own.

To prevent breakage, the following manipulations are performed:

- The candle is unscrewed with a specialized key.

- The candle is wiped with a sterile and dry cloth.

- The part is thoroughly dried for half an hour.

- Carbon deposits are removed from the electrodes using a file.

- The distance between electrical conductors is corrected.

- Residual fuel fluid is drained from the spark plug channels.

- The saw is assembled and re-started.

If the problem was an excess of fuel, then the listed procedure will return the cutting tool to “life”.

It so happens that the saw stalls due to improper operation of the ignition unit. This part cannot be repaired, no matter who does it. an amateur or a specialist. The only way to combat this factor is to replace the block.

Chainsaw design and general classification of faults

Correct diagnosis is essential for a successful repair. Therefore, in order to determine why the chainsaw failed and, most importantly, how to make it work again, you first need to know the features of its design.

It should be noted that it does not differ in particular complexity, since it includes:

- engine (two-stroke gasoline);

- functional part (saw bar and chain);

- systems that ensure the joint operation of these two units (ignition, filtration, lubrication, etc.), that is, the tool as a whole.

In order to simplify the diagnosis of malfunctions, it is customary to distinguish them into two main categories:

- engine malfunctions;

- malfunctions of other parts of the chainsaw.

Most often failures occur in the engine systems, however, the rest of the tool, due to intensive use or improper care, can fail at any time. How to determine exactly where the breakdown occurred? Simple logic will help us with this.

If the problem is in the engine, it will:

- do not start;

- stall;

- work unstable;

- overheat;

- smoke;

- develop insufficient power.

As for all other malfunctions, as a rule, they manifest themselves with a normally operating motor.

Calibration algorithm and safety precautions when troubleshooting chainsaw carburetor

Carburetor adjustment is carried out in two stages:

- Basic (carried out with the engine off).

- Finishing (carried out with a running, pre-warmed engine).

For basic adjustment, screw in screws H and L as far as the stop and back out 1.5 turns. Final adjustment requires the engine to warm up for 5-10 minutes at low revs.

The final calibration is performed by unscrewing the idle screw until the minimum engine speed is reached (in this case, its operation must be stable, and the chain must be stationary). If the engine stops at idle speed, the screw must be returned back, and if the saw chain is still in motion, continue turning counterclockwise.

Calibration check is performed by test:

- Acceleration (with a smooth press on the accelerator, the engine should quickly pick up speed to the maximum indicator).

- Maximum speed (if there is an ignition interruption, screw H should be slightly loosened).

- Idle work (the chain should not move, and the engine should pick up speed as quickly as possible).

If the owner of the chainsaw is not familiar with the carburetor device and does not have the necessary tool to calibrate it, contact a specialist. The carburetor is a very complex unit, so any wrong action can lead to irreversible consequences, for example, complete engine failure.

Repair of the cylinder-piston group (CPG)

If the engine of the chainsaw does not start or cannot develop normal power, it is likely that sufficient pressure does not build up in the engine cylinder for combustion of the fuel mixture. The reason for this may be the wear of the elements of the cylinder-piston group. the piston, rings, bearings, etc. In order to assess the condition of this unit, it should be visually inspected, having previously removed the muffler.

For a more complete diagnosis, a compression meter is placed in the spark plug hole of the two-stroke engine of the chainsaw. It measures the compression in the engine. According to the results of the check, one can judge the state of the CPG, however, the exact facts can be obtained only with a complete disassembly of the unit.

If the piston is chipped or scratched, it will obviously need to be replaced. The same applies to deformed or broken piston rings. for normal engine operation, they must be completely intact and free of carbon deposits.

Troubleshooting muffler problems

If at low speeds the engine of the chainsaw works normally, but at high speeds it starts to stall and smoke, the problem may be hidden in the muffler.

To check the quality of its work, you should do:

- dismantling (with the obligatory closing of the outlet);

- disassembly (if the muffler is collapsible);

- cleaning from carbon deposits using special detergents or dry method;

- drying (with a hair dryer);

- reassembly and assembly.

Dry cleaning without respiratory protection is not recommended. The carcinogens in the soot will be released into the surrounding atmosphere as dust, which is extremely hazardous to health if inhaled.

To prevent clogging of the muffler during the operation of the chainsaw, you should carefully monitor the composition of the fuel mixture and the quality of its components.

The main malfunctions of chainsaws and their DIY repair

The chainsaw is a worthy replacement for hand saws and axes. Today, this tool is available in almost every household. it is indispensable for setting up a personal plot, construction and repair work. Intensive use and improper care of the tool can lead to premature failure. However, the owner of the chainsaw does not have to go to the workshop right away. many of the faults that can happen to her during operation are quite realistic to eliminate on their own.

Checking the carburetor and signs of need for adjustment

A correctly working carburetor guarantees maximum efficiency of the chainsaw, that is, it is possible to develop full power with the most economical consumption of the fuel mixture. The adjustment of this unit is usually carried out by the manufacturer, but its design provides for the possibility of adjustment already during operation.

The fact that such a setting will have to be performed by the owner of the chainsaw is evidenced by:

- Strong vibrations or damage to the protective cap.

- CPG wear.

- Carburetor clogged.

- Inability to start the engine or its spontaneous stops after starting.

- Increased fuel consumption and exhaust emissions while decreasing engine power.

Chainsaw carburetor adjustment is carried out in strict accordance with the manufacturer’s instructions using three special screws, which are responsible for the maximum (“M”) and minimum (“L”) revolutions, as well as the engine idle (“T”). In order to exclude unwanted intervention by an inexperienced user in the operation of the carburetor, some manufacturers install only one idle screw.

DIY chainsaw repair: fuel supply system

If the fuel mixture does not flow into the cylinder, but the spark plug is working properly, this may mean that:

- Clogged fuel filter.

Top Reasons Chainsaw Running Rough — Chainsaw Troubleshooting

To clean this unit, remove the fuel hose and check the jet. If it is weak, the filter must be removed through the filler hole of the fuel tank and cleaned or replaced if completely worn.

As a preventive measure, it is recommended to replace the fuel filter at least once every 3 months.

This is nothing more than a hole in the fuel tank cap, which is cleaned with an awl.

- Fuel mixture not supplied or not supplied in sufficient quantity.

There may be several reasons for this:

- the air filter is clogged (in this case, it must be removed, rinsed with water, dried and replaced);

- the carburetor settings are out of order (which means this unit needs to be re-adjusted);

- the integrity of the carburetor membrane is broken (must be replaced);

- the channels of the carburetor are clogged (it must be disassembled and all parts and assemblies must be cleaned).