How to cut a trim at 45 degrees

Trim on the door: the easiest way to make a 45° cut even without experience

Often during repairs, you may encounter a situation where it is necessary to saw off a piece from the part, at an angle of strictly 45 degrees. Usually, it is needed to connect two parts at right angles, 90 degrees, such as: door trim, baseboard, furniture and more. An experienced craftsman, professionally engaged in repair work, can often do without special devices, and practically by eye is able to evenly and clearly cut the necessary part. But if you are a novice repairman, and you have a desire to do the job as efficiently as possible, without damaging expensive parts, then you just need to buy a plier. a special device that allows without any tricks to saw off the material at a given angle.

To work you need to have: a plane, a hacksaw, a protractor with a pencil, a piece of wood, an electric screwdriver with screws or a screw clamp.

How to make a proper butt joint

If after gluing a part of the baguette remained some distance to the corner, you need to think about how not to make a mistake. a small margin will not hurt. At the beginning it is better to cut a piece with a good margin of about 10-15 cm. Then, having cut off a corner by any convenient method, make its fitting on a dry surface. To do this, place the bar to the ceiling and mark the point where the boundary of the shortening will pass. Trim it at a right angle.

Equally important is the correct joining of corners. Ready skirting boards are usually fixed at an angle somewhat less than 45 degrees, so there may be inconsistencies trimmed edges and the appearance of gaps. Here, the initial trimming of the corners is followed by a dry, as accurate as possible, joining of the skirting boards already on the ceiling itself. Problems usually arise with wood and plastic materials.

After completing the rough joints of the boards, they should be glued or screwed, and then, if necessary, use putty and then. seal all the existing joints.

Ways to cut a trim under 45 degrees without using a jig saw

The easiest way is to use an ordinary protractor, which is in every home, where there is a school-age child. With its help, it is not so difficult to make a marking.

Important: The sawing itself is also important. To avoid the formation of gaps, it is recommended to use a hacksaw not for wood, but for metal. Yes, this method requires more time, but for that the cut will be much more accurate and even.

When the markings using a protractor have been made, it is necessary to position the trim on a horizontal surface so that the front side is at the top. It is recommended to make a cut on the whole plane of the casing.

If there are no clerical devices nearby, you can use an ordinary tile, with which you can draw a 90-degree angle. Dividing it into two halves, we get a template for the 45-degree angle, which can be used for marking instead of the ruler.

If there is a ruler, the task becomes several times easier. You just need to take a sheet of A4 and draw a square, and then draw the bisectors of the angles. To make it more convenient, you can take a small plank and attach it to one of the corners, which will fix the construction. And then you need to attach the platband and start sawing.

How to Make a Jigsaw at Home?

If the above methods do not appeal to you. you can make a squeegee at home yourself. The ruler is a U-shaped device, reminding of a tray.

It is equipped with saw slots, designed to cut the material at a certain angle. The size of the parts is not very important, but the wider our home-made device is, the wider and more accurate we can saw wide bars.

Important: You have to do everything wisely, you should not overdo it either, because if the width of the saw is more than half the width of the hacksaw, it will be awkward to cut.

You can make a mark using the methods described above, and then use small pieces of plywood and a hacksaw. And in order to fix everything, you can use self-tapping screws or even super glue. However, all this is more complicated and will take much more time, though it will provide the most accurate result (of course, if you do it right).

Undoubtedly, the jigsaw is a handy and practical tool. It is sold in almost any construction store and has a low price that absolutely everyone can afford.

However, if for some reason it is impossible to get the tool as soon as possible. you can use improvised tools, such as a ruler, protractor, or even tiles, which can easily create a template with the desired layout or even recreate a jig at home.

Sometimes you need to trim an item or a product at a certain angle. As a rule, you need to trim baguettes, fillets, platbands, baseboards and other similar interior elements at an angle of 45 degrees. Anyone can do it. The main thing is not to hurry, not to be nervous, and everything will turn out.

Buy ready-made corner elements

Of course, the easiest thing is not to bother with trimming a particular part, and buy ready-made, not in need of processing and trimming. These parts and elements are now sold everywhere in large supermarkets or smaller stores.

For example, with regard to baguettes or fillets, there are special corner elements that fit perfectly into the corner and do not need to be trimmed. They just need to be glued in place and pressed down well.

Necessary tools

To properly and accurately carry out this procedure, you will need:

- Chisel. You don’t know how to cut platband at an angle of 45 degrees. with it. It helps to cut the piece at the right angle. It can be made of wood, plastic or metal. Looks like a box.

- Hacksaw. For metal, plastic will do for metal hacksaw, for wood. only wood. It must be properly sharpened, so that the cut is even.

- Nails/liquid nails.

If you can not use a jig, you can do with improvised materials: pencil, ruler, cardboard, a hacksaw.

How to cut the trim yourself without the help of a chisel

How to cut a door trim without using special equipment is a question that worries many beginners in the construction business. It is more difficult to do, but it is possible if you follow the instructions carefully:

- Take a sheet of cardboard, draw an even square, draw the diagonals, bring the lines of the sides of the square to the end of the sides of the sheet. It is an improvised ceiling, suitable for filing a right angle.

- Hold the platband against the bottom line of the square and saw where one of the diagonals crosses the platband. This is the lower border.

- Put another to the left side of the square, saw at the point of contact of the same diagonal.

- Do point 2 and 3 for the upper and right hand door trim.

Interior door trim installation: step by step instruction

How to eliminate gaps after installing doors and give them an aesthetic appearance? For this purpose, the specialists use cashier’s trim. Their main function. to hide the defects appeared during installation, cracks. Installation of interior door trim strips is a responsible process that requires the master’s experience, skill.

What are interior door trims

The construction market is represented by a wide assortment of overhead strips. They are differentiated according to:

- Functions performed: structural, decorative;

- color scheme;

- Shape: flat, rounded, shaped;

- texture: plain trims, carved frames, made according to templates;

- dimensions;

- The method of installation: overhead, telescopic;

- material: wood, metal, aluminum.

The trim should be chosen based on personal preferences, as well as taking into account the peculiarities of the interior, the exact place of installation. It is important to choose the right material when buying them. Every type of material has its pros and cons.

Wooden

Even ten years ago, this type was the only option for decorating doors. But despite the improvement of the construction industry, on DO today is in demand. The main advantage is versatility: wooden planks fit any type of door construction.

They may differ from others in their appearance. Depending on the consumer’s taste, the decor can be carved, with differently shaped figures.

The disadvantage of wooden door trims is the necessity of their renovation. But this is not a reason to refuse them. Modern platbands are made in such a way that they can be restored, putty, apply paint and varnish without any problems.

Most people compare this material to fiberboard. On the one hand, their properties are similar. On the other hand, the latest technologies are used in the production of wood-fibreboard, which gives the material a higher quality.

The wood fiberboard architraves are suitable for installation outside damp rooms

Wood-fiber board is a medium-density fiberboard. In terms of environmental friendliness it is the same as wood. And veneered fibreboard can hardly be distinguished from it even superficially.

Overlay strips of fiberboard are preferred because of low cost, durability. But when choosing it is necessary to take into account that it has poor moisture resistance. Therefore, it is not recommended to install it in rooms such as baths, toilets.

Methods of cutting the platbands

On how neatly the master will cut the components of the structure, depends on the appearance of the skirting. Cutting can be done using several methods:

To get the cut is as straight as possible, without splinters, roughness, experts recommend using a professional electric saw. In this case, the device must be in good working order. If the saw blade is crooked, blunt or even a small amount of bearing run-out, the result will be far from the desired one.

Using a professional saw it is possible to get a perfectly straight cut

However, it is necessary to know that even the high-tech equipment of famous brands allows for small errors. There are certain tolerances for them: cutting angle. 0.3-0.7 degrees, inaccuracy of joint. from 0.1 to 0.5 mm.

Those who refuse to buy an electric saw can use the factory-made power saw. It is a tray made of metal, plastic or wood. With this tool products are cut at different angles: 90, 45, 30 degrees.

Craftsmen at home most often use a plier

For overlapping strips of different materials select the appropriate hacksaw. Metal and plastic frames are cut with a hacksaw for metal and wooden frames are cut with a hacksaw for wood. The quality of the work performed depends on the right tool.

Ways of fastening the trimmers

Installation is carried out by finishing, liquid nails, self-tapping screws, “beaks”.

Using finishing nails

This type of fastener is widely used because of several advantages:

To work take fine nails about 4 centimeters long, with a diameter of up to 1.5 millimeters. The distance between them must be 50 cm. On the laths mark points with a simple pencil.

After fixing, the nails can be putty in the color of the wood, so that the nails will not be visible

At the marks, nails are hammered in such a way that they enter into the box by 20 mm. If the nail heads are narrow, they can be left on or, if desired, trimmed with side cutters. Formed small depressions mask with a wax pencil of a suitable color.

The disadvantages of working with finishing nails are:

- Difficult to remove. Due to the unique shape of the nail heads, it is almost impossible to remove the nails.

- The joint is less strong than that of common nails.

- If you choose this method of fastening, keep in mind that these nails are designed for finishing where there is no bending load.

Liquid nails

This method is ideal for fiberboard framing. It is performed quite simply, does not require certain skills and dexterity.

Installing the fiberboard panel trim is done with liquid nails

Liquid nails are applied on the underside of the decorative element and attached to the wall. Hold for a few minutes to allow the glue to set, and then secure with duct tape.

This type of fastener is good because it does not leave marks on the outside of the laths. However, the strength of attachment is not as high as when using conventional nails.

Fastening with self-tapping screws

This method is characterized by reliability. It is used for wooden products.

Wooden architraves are fastened with self-tapping screws

Even complete beginners can work with self-tapping screws. For this, you just need to follow the instructions:

- Find self-tapping screws 6 millimeters in diameter, 2 centimeters long.

- On the face of the strips, place the marks 50 cm wide apart.

- Drill small holes in the marked places, and then bore them out a little. This will allow you to hide the screw heads.

- Screw in the self-tapping screws. If you want, you can mask them with putty or decorative trim.

Installing the Platbandings on the doors with your own hands: step by step instruction

Trims play a decorative role, giving the door opening a complete look. The strips differ in material, shape, color and fastening method. Installation of interior door trims is performed after finishing the walls, but before laying the floor plinth.

Tools for the job

In order to successfully install door trimmers the following tools should be prepared beforehand.

- To make an accurate marking you will need a pencil, a tape measure, a plumb line, an angle and a level.

- To saw a perfectly flat billet at an angle of 45 degrees will help jigsaw.

- It is better to cut the slats with a mitre saw. If it is absent, you can use a metal saw. The fine teeth of the blade will not leave chipping on the product.

- To hammer the nails or to pound the elements of the trimmer use a hammer.

How to cut a platband?

After a marking of an angle of a cut and length of a preparation it is necessary to cut a platband with a crosscut saw. The adjustable table, which is set at the required angle, is a feature of the power tool. To saw off the door trim properly and without splitting off, the side edges of the workpiece is pressed tightly against the stops on the base. In case of a gap the cut will be uneven.

In the absence of an electric saw to cut under 45 degrees of an edge of a platband will help a plane. It is better to buy a quality tool. Cheap plastic has deformed thrust elements, distorting the size of the angle. A hacksaw is used for cutting with fine teeth, which do not leave any chips.

How to fix strips on the interior doors?

A simple fixing of flat shaped platband performs at an angle of 90 degrees. Vertical laths are joined tightly to the horizontal lath at the top. When mounting wooden or fiberboard elements of complex shape at the ends make a notch at an angle of 45 degrees. There are 4 methods of fixing strips.

Attaching with tongs

The method does not require the use of a self-tapping screw, nails or adhesive. Trim has a beak-shaped lock. The joining spike is inserted into the recess on the box and pressed until it clicks into place.

The advantage of the method in the ease of installation and invisibility of the mount. The negative point is the delamination of fiberboard platbands during disassembly. Over time, the spontaneous destruction of the joints can be observed, which requires additional processing of the joints with glue.

How to install the interior door trim?

When installing interior doors with their own hands to fix the wood or fiberboard trim glue, nails or self-tapping screws are used. However, take into account the evenness of the walls and the shape of the slats. No gaps must be left at the joints. If the walls adjacent to the end of the door frame are uneven, then it is better to refrain from gluing.

Mounting strips begin on the side where the interior door opens. This is due to the presence of hinges that prevent flush fixing of the slat with the frame element. You will need to make the same indentation, and on all three sides for symmetry. Where there are no hinges, there is no need for mandatory indentation.

If the door is in the corner, the installation is made in a letter “G. If you wish it is possible to saw an element vertically and use a narrow trimmer.

Trim on one side is installed in the case when the slopes on the other side are decorated with tiles or other wall materials.

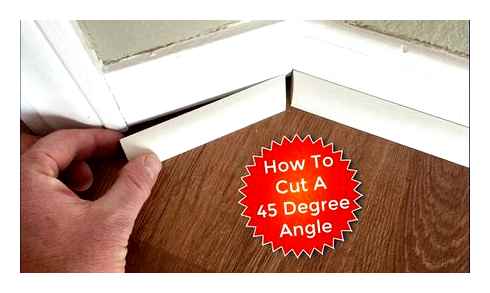

Mating at a 45 degree angle

When you want to install the platband on the door at an angle of 45 degrees, for marking use a plier. Such joining of elements is usually used for boards of figured and rounded forms. If you do not have a plane, the marking can be made with a protractor.

The order of installation consists of the following steps:

- The height of the vertical elements is measured from the floor. Planking from below is placed on the flooring, why the joints between the skirting boards and door trims are on the side. When installing the strips on the door on the hinge side, take into account the width of the indent. The indicators are measured on the workpiece and put a mark. This will be the lower point of the corner of 45 degrees.

- Having inserted a plank into the jig, mark out from the put point a line for a trimmer cut at an angle. The surplus part is sawed off.

- First press the pieces in two places, so that they can bend at the top. Remove the nail heads with wire cutters and hammer into the door frame: one nail is slightly higher than the floor and the other is hammered into it at a distance of 1 meter.

- The length of nails without nail heads must not be greater than the thickness of the slats. It is optimal to make the ledge of pins 5 mm. Place the architraves on the door frame. At the location of the nail to the workpiece is attached a wooden bar, wrapped with a cloth, and light blows of the hammer to plant vertical strips on the pins.

- To make the right side trim on the whole door, it is necessary to shape the corner properly. Bend the upper, loose parts of the architrave and put a horizontal component under them. On both ends of the workpiece with a pencil mark a line at an angle of 45 degrees, then cut off the excess part.

90° joint

Fix the 90-degree angle of the architraves with horizontal or vertical seams. The choice depends on the owner’s preferences. When installing the door trim with their own hands at a right angle, blanks use only a flat shape. The cut areas are treated with varnish or acrylic-based paint.

To install on the interior doors the strips with imitation of the lintel, the upper element is lengthened. The joint is obtained at an angle of 90 degrees with horizontal joints. The upper slat protrudes beyond the vertical ones.

Telescopic trim

Telescopic architraves are fixed on interior doors without nails. Decorative elements are equipped with a special lock, consisting of a slot and a groove. The fixation is made to the box face. The main requirement for the proper installation of the casing is the presence of the ledge. It is formed when the door frame is already the thickness of the room divider. The adjoining walls must be even, otherwise you will get an ugly gap.

Elimination of defects

Unpleasant point is the visibility of a nail or screw head. They are pushed into the body of the trim, and then covered with sealant of the required color. You can use a wax corrector.

Baseboard plank file

A carpenter’s saw is a device for making cuts at a certain angle. It is used with a hacksaw. In principle, you can make a chair yourself by assembling a guide made of boards and making cuts in the walls. On sale, however, there are various models costing from 15 to several hundred dollars. They differ in capabilities, materials, although they are all called a “plinth saw”. Professional models are made on the basis of a good hacksaw and have a scale that allows you to set the saw just right. With such a tool, it is no problem to set any desired cutting angle to cut the skirting board properly for a perfect junction.

Professional carpenter’s plane. a tool with a wide range

The simplest jointing tool is a plastic U-shaped profile, with slots in the walls. These slots are used as a guide for the hacksaw. They do not allow the blade to deflect. In any variant there are two cuts. straight and at 45 degrees. Some may have a couple more options.

How to fix a skirting board at 45 degrees? One way to do this is to use a jigsaw

Sometimes a hacksaw comes with the kit, sometimes not. Usually the ones in the kit aren’t too good. You can use any hacksaw, selecting the blade for the material you plan to cut. It is important that the canvas moves freely in the slots.

How to cut the baseboard in the inner corners: a plan of action in steps

Start the installation of the skirting boards in one of the corners. If this is your first experience, choose the part of the room in which there will be something to stand. The first pancake is not always a bad one, but still it’s better to play it safe. To make the corner on the baseboard neatly, work without haste. One sawed off, checked, fit. Move on to the next. It is better to mount after two adjacent corners are assembled. But it is not worth putting off assembly too much either.

Trimming the baseboard in the corners requires some skill. But by making a few joints yourself, you can beautifully decorate complex corners

How to use a wire cutter to cut baseboards? Position the device in front of you, preferably on a table, but it can also be on the floor. Which way you turn it doesn’t matter, it’s symmetrical. You insert the slat into the profile, rotate it as it will stand against the wall. When filing a skirting board in the jig, the “wall” is the wall that is further away from you. Once again: press the skirting board firmly against the back wall in the position in which it will be installed. Insert a hacksaw into the necessary slots. You can start sawing.

The first joint in the room

The first baseboard plank must be cut as close to the edge as possible. Carpenters have their own jargon and they say “cut” a corner. It does not matter what they call it, it is important that the plank is exposed in the jigsaw to make a cut at the beginning. For a fishing line for the trimmer of the cut we extend the bar on a small distance, to begin with it is possible on 1-2 cm. Cut a smaller piece is more difficult, so the economy leave “for later” when you have at least some skill.

Position the skirting board in the direction of the far wall, facing in towards yourself. This is easier to check if you are cutting/sawing properly

Next, do the corner on the baseboard as follows:

- Place the baseboard in the jig, press it against the opposite wall from us. We put it in a mounting position. how it will stand against the wall.

- Insert the hacksaw into the correct slots (see picture below).

- Move the bar so that it extends slightly beyond the line for the trimmer of the cut.

- Cut it off.

- Take the second piece of skirting board and repeat the same operations, but reverse the position of the saw on the cross-head. Insert the strip from the other side. Here be careful, otherwise you will have to redo several times, as the connection will not work.

How to cut a skirting board in a jig saw: for outside and inside joints

We got two pieces sawed to join in the inner corner. To make a perfect joint, try on parts in place. Most likely, there are some flaws. We take sandpaper with a medium grain, remove everything that prevents docking. Then with a fine grit achieve a tight joint without gaps and gaps.

When connecting the baseboards in the corner, use a transparent silicone sealant. Before installing the fasteners, a layer of silicone is applied to the cut. Immediately after the skirting board is fixed, remove the excess that has appeared on the outside. Remove until the surface is completely clean. This method of connecting baseboards in the corners looks more accurate, no dirt and dust is not hammered into it.

How to file the corner of a skirting board on the necessary distance

The second and all other corners of the skirting boards must be done at a certain distance. If the next corner is again internal and the distance to it is less than the length of the strip, we use the same fragment, which already has a notch. Measure the distance with a tape measure. strictly from corner to corner. Then this distance is marked off on the strip using the same tape measure. The beginning of the measuring tape coincide with the ledge, we measure the required distance, we make a pencil mark. This will be the starting point for the cut.

It is important to know how far to cut

The skirting board with a mark is put in a chair, and the necessary direction of sawing is chosen. The line can be aligned with the blade of a hacksaw or with the slot in the jigsaw. Who is comfortable? Cut off. This piece should be “tried on” in place. If both cornerstrips are against each other or the gap is only 1 mm, that’s OK. A second slat can be cut from the new piece to create the joint. And again we remove the imperfections with sandpaper.

If the length of the wall is longer than the length of the baseboard trim, take a new trim. We will cut the second corner on it. It is important not to mistake which direction to saw. Having established both slats along the wall, on one of them to mark the place of connection, make a straight cut. For a straight cut in the jigsaw, there are also slots. So there will be no problems.

How to connect two skirting boards in a straight line

But the joint in a straight line does not always look ideal, and in operation it often diverges, forming a visible gap. If there is a desire, it is possible to cut at an angle (any) the two slats.

To do this, first cut off the edge of one plank at an angle, mark on the second the place of connection. The mark is put on that side of a plinth which is pressed against a wall. On this mark we saw off other piece, without changing the position of the saw relative to the jigsaw, but having inserted a plank from the other side. The joint appears to be diagonal. It is more accurate. The difference is especially visible on wooden skirting boards and wood-fibre board. The cut, again, is finished “up to the mark” with sandpaper.

Making the outside joint

In apartments or houses, you find not only inside corners, but also outside corners. In this case, first trim the nearest inside corner, finish it. When it is ready, you can make the outer corner on the baseboard. Put the plank in the corner, as it should be. At the place of the outer corner with a pencil make a mark exactly at the place of the turn.

How to make the outer corner of the baseboard

Next, we transfer the plank to the jig, and choose the appropriate position. To avoid mistakes, all the time imagine how the plinth stands at the wall and what you should get.

Features and Recommendations

Experts and connoisseurs advise doing this kind of work with electric jigsaws, already because the usual hand saw is too rough. It does not allow you to cut the material evenly enough.The correct sequence of steps is as follows:

Preparing tools (ruler, electric jigsaw, measuring tape, awl or other sharp device for drawing by Woodchip board);

addition of these tools (if necessary) with an angle piece for laying right angles;

Measurement of the desired part (with a reserve of 0.2 cm to be able to adjust);

The actual cutting along the mowing line;

Finishing of a place of a saw cut by means of an emery paper;

Sawing along (telescope)

If the quality of the end face is very poor. mashing it with a crayon, similar in tone to the chipboard.

Two ways to file the trimmer, easy and simple!

Hello, dear friends! In this article I will tell and show you how you can easily saw 90 degree nudolichniki, for finishing doors or anything else. Interesting, then let’s go!

Hacksaw (preferably with a fine tooth, the cut will be thin and accurate)

The first method is using a coping saw.

I’ve divided our trim into four equal 30 cm parts. I put a piece on the trimmer table, switched on the laser line for the trimmer, rotated the saw 45 degrees and made the cut. With the second piece, I do the same but, the saw I set to 135 degrees and I make a saw cut, finished.

The second way of sawing without a coping saw.

I think this method will be more interesting to you, as not everyone has a crosscut saw. Up to some time and I did not have it, did not cope with anything by all means! So we take two pieces of our trim (preferably them ottorzivat their pre-marked square), put them on top of each other and overlap them by side and angle, so it was all flatness depends on it evenness of our sawing. We put, aligned and marked with a pencil

Next, we take our square and hold a straight line for a trimmer from the corner to the mark

All the marking is ready, half the job is done! Now we take a hacksaw with a fine tooth (I once sawed with a hacksaw on metal, tired of course, but the cut was so clean), and slowly make an incision along our line, keep everything tight and the hacksaw will play and can leave scrapes. Try to cut at an angle as sharp as possible, the cut will be smoother.

After sawing, we do the same with the second piece. All combine two pieces into a single corner and enjoy what we see! That’s how easy and simple, without trimming you can make a 90 degree angle. Thank you for your attention, have a successful repair and see you again!

The way to connect the architraves without trimming

Platbands today often do not trim at an angle to then dock with each other, and make the joint at right angles. This method of connecting the platbands does not require any special trimming, which is very convenient. In addition, this method looks more modern and attractive.

If it is still necessary to trim at an angle to one or another part, it is worth stocking up on a wire cutter. the simplest device, which looks like a small box. The chair has slots, which are designed for a saw or a long sharp knife. Of course, these cuts are made so that they form an even and accurate angle of 45 degrees.

However, the plinth cutter can have many slots at once, at different angles. It is convenient, because with the help of one device, it is possible to cut any details at different angles.

There are adjustable jigsaws on sale. Slots in such a chisel can be adjusted, allowing the master to set exactly the angle that is required at the moment. In particular, it is quite easy to translate the slots of such a jig to a position of 45 degrees.

Now the workpiece can be trimmed elementary. A baguette, platband or plinth is placed in the chair, and then the saw is inserted into the slots, and the excess is cut off elementary. The angle turns out as a result perfect, exactly 45 degrees.

What to do if there is no jigsaw?? Very simple. You need to make a template, which will not be difficult to transfer to the workpieces the necessary markings. As a template, you can choose thick cardboard or anything else that will be appropriate in this case.

Trimming “on the spot”

The walls, floor and ceiling will not always be perfectly flat in practice. Most often they have irregularities. For this reason there is no need to trim blanks at precise and accurate angles, because they do not fit perfectly anyway.

Instead it is sometimes convenient to trim the same ceiling plinth on the spot. That is, first glue one plank of the baseboard, trim it in the corner, and under it trim the second plank.

Of course, it is hardly possible to perfectly cut the workpiece. However, if there is a small gap in the corner, it can always be sealed with putty or plaster. No big deal.

How to cut a corner of a plinth or a baguette without a chisel

Plinth. an overlay frame, inherent in a door or window opening. This is a decorative detail, made in the form of shaped slats. There are also carved platbands, their difference is that they are made of wood and are often decorated with abundant carvings. The role of the frame is not only decorative, it allows you to slightly exclude such undesirable blowing in the area of the gap between the wall and the window or door frame, by overlapping.

How to cut a skirting board in the inner corners: a plan of action in steps

Begin installing baseboards in one of the corners. If this is your first experience, choose the part of the room where something will stand. Not always, of course, the first pancake, but still better to be on the safe side. To make the corner on the baseboard neatly, work without haste. Sawing off one, checking, adjusting. Move on to the next one. Fix it better after the two adjacent corners are assembled. But you should not put off assembling too much either.

Trimming the baseboard in the corners requires some skill. But by making a few joints yourself, you can beautifully decorate complex corners

How to use a baseboard tool to cut baseboards? Position the device in front of you, preferably on a table, but you can also on the floor. It doesn’t matter which way you turn it, it’s symmetrical. In the profile, you insert the bar, turn it the way it will stand against the wall. When sawing a baseboard in the jigsaw, the wall is the wall that’s farthest away from you. Once again: you press the baseboard tightly against the back wall in the position in which it will be installed. You put a hacksaw into the necessary slots. You can start sawing.

How to saw the right trim on the door?. Doors, partitions

We will demonstrate you how to install the door trim, how to work with the gun and explain the different nuances of work.

Marking and trimming of the architraves

First of all you need to tear off the ledgers before installation. We take the four trim strips and end them. You can determine the center of gravity of the trim by placing it on a finger. When the lath is balanced, we determine its center of gravity. Cutting and carrying the trim to the door.

Every door has a radius of curvature. There are straight casings, but very seldom.

Here we put the casing flush, even shifting it slightly inside the door to hide what’s underneath.

It is necessary to install the casing from the place where the radius ends:

We put two marks above the door. We do it by eye, but you can measure with a tape measure.

The angle will be 45°, that is the mark will be at a distance of 5-7 mm from the edge. Closer you can not, because here is the hinge, and closer the beginning of rounding it will not let you make a mark. Orienting on the radius, make a mark with a knife.

On the other side there is a mate and you can’t move it any closer either. Do not forget to number the platbands.

We remove garbage from under the architraves so we won’t cut off more than it is necessary.

Where the radius ended, put a mark. Similarly we measure the other side.

On the side of the architraves everything is much easier. Again, we do it not flush, but with a little displacement. We put a mark not along the boarding, but slightly below.

Accordingly, the same on the other side. 1 mm lower:

In the same way we make marks on the casing. not flush, but with a small offset. We carry out trimming of trim at 45 degrees.

There are situations when the wall is not quite flat. in some places it protrudes, and then you get mismatch when installing the architraves. Sometimes it happens that the trim must be a little fall when they are not flush, and shifted inward. What to do in such cases? Imagine that we have a wall on the right and a door on the left. We have to nail the platband to it.

If we cut it flat, when we nail it down, the corners will come apart. How to fight it?

Here we have an opening of about 2mm. If we do so, we must also cut it off, that is, to make some kind of lining.

Our wall goes up 2 mm, and we have to put some support under the corner of 2 mm high.

If you get a gap at the back, you get a platband without a gap at the front. This is the case if the door is sunk into the opening and gets on the ledge. In such cases, you have to take into account the back gap. the wall overhang. Next, we saw off the long slats.

Installing the trim

Now we will work with a pneumatic microscrew. a gun, the air in which is fed from a compressor. With its help we will fasten the laths to the wall with special nails. studs.

Dried foam should not be torn off, and cut with a knife.

Apply foam to all the other trims:

The foam will create a certain layer, and the casing will not dangle. Since the wall is not completely flat, all the irregularities must be compensated with foam. You can wait up to three minutes for the foam to form. A little foam will allow the batten to adhere more quickly.

The orientation is a rounding on the casing. At the corners of the top batten it is of course better not to nail at first, but to put long battens, and by them determine the position of the top batten. where to lower, where to raise. We have a small bump under the casing, but it is barely visible and the discrepancy between the casing is small.

We nail one nail at the bottom. Next, we have cured foam, which does not let the lath hang out, but where it hangs out, there and fasten. We advise nailing at 20 cm intervals. It’s better not to hammer them at eye level, otherwise such a nail will be too visible. In our case it is a micro stud, it can be waxed, and then it won’t be visible at all. It is desirable, of course, to fasten the platband from the ends.

However, there is one important point here. since the gun uses a lubricant like oil, then when shooting on light-colored wallpaper is air release, and the oily stain will get on the wallpaper. So when nailing, put a piece of paper underneath. The good thing about a microspike is that it breaks easily. If the microspike is not pressed properly when firing, the gun goes away when recoil and, accordingly, a cap is left, which is not blocked because it is very thin and bends.

In such cases, we clamp it with pliers and pull it off with rotary movements.

There is no point in taking it out, because you are left with a hole and you will never drive a stud in that hole again.

The nuances in installing the platband

Here we have either a little different trim, or the master did not set the angle exactly. Such irregularities can be rounded off with a hammer. but it’s good that the client doesn’t see it.

This is how the corner is rounded, so that the tip is not visible. That’s why it’s better first to file the angle, measure 90 °. If you get a little less, finish sawing.

Let’s say a few words about the oily stain on the light-colored wallpaper. You can’t see it on dark wallpaper, but you can see it very well on white wallpaper. Suppose this is our wall, we shoot. and here is our oily stain:

Now let’s talk about the nails on the nailed-up casings. This nail is almost not visible, but it is there, and some people do not like it. In such cases, you take acrylic putty, match the color of wood and apply it to the nail. It is desirable then to remove acrylic, and completely, as it may slightly whiten when drying.

In fact, all of these holes are visible at the time of acceptance, and after using the door in 1-2 months you simply do not see these holes. Try to remove the acrylic immediately, otherwise it will later be difficult to wash it off. One more thing from practice. Wooden trim is certainly cool, but not practical. It’s better to have fiberboard on your door trim.

Wood has one peculiarity. the change in humidity makes it twist.

If a wooden platband nailed on Dobor without foam, over time, after six months, especially in the off-season, it begins to twist and starts spreading the corners. Trim on the fibreboard to such climatic changes do not react. they will not hold.

Another point with regard to the nails. For white doors, never put Hi-Gear or any other kind of grease in the gun. Shoot the gun somewhere so that all the grease comes out, otherwise the white and light doors will have a black spot which will be very noticeable on the contrast.

How to properly saw the casings

Carrying out repair work in the apartment. The owners are often faced with the need to renew doors. It is worth noting that the replacement of the door unit is in any case a significant expense. But replacing the door trim is much cheaper. The quality in this case will remain at the appropriate level. Installation of door trims is not too difficult a job.

How to saw the architraves for the door

Platbands play a decorative role, making the doorway look complete. The strips differ in material, shape, color, as well as the method of attachment. Installation of interior door trims is performed after finishing the walls, but before laying the floor plinth.

In order to properly install the casings on interior doors, you must first select the appropriate elements. First of all, pay attention to the material of manufacture:

- Natural wood products are considered universal. The strips can be painted to match the door color. Fasten the wooden elements with nails without nails. If the walls are well aligned with the door frame, then the boards are put on the glue compound. “liquid nails”.

- Laminated chipboard slats have a look reminiscent of real wood. Decorative elements can be matched to the door color. Fix the trim strips with glue or flat-free nails, pre-drilling the holes without nails.

- PVC trim is more suitable for plastic doors. Glue or mount the boards on a mounting profile.

- There are also aluminum and steel trim, but it is usually put on entrance doors.

Most of the slats are given a standard flat, rounded or shaped shape.