How To Install Ignition On Lawn Mowers

Second way

If you cannot use the tester, there is another way to test. In this case, it is important not to touch the cylinder with the electrode, otherwise the coil will be damaged.

- Remove the spark plug cap. Do not unscrew the plug, as this will maintain compression.

- Then you need to pick up the nail with the removed cap and insert it tightly into the cap.

- Next, the cap with the nail should be securely tied to the cylinder with a dielectric. In this case, the electrode should be at a distance of 5.5-7 mm from the cylinder body, but not touch the mass.

- Then, using the starter, you need to simulate starting the engine with the ignition button turned on. In this case, you need to carefully monitor whether a spark appears, and try to determine its color.

Important! A strong spark of white or blue tinge indicates that the magneto is in good working order. If it is weak, or orange or yellow, the magneto is damaged.

There is one important point to consider when diagnosing: unheated magneto in any state can form a powerful spark. However, if it is faulty, then, after warming up, it stops creating current, and the trimmer will not start. Later, after cooling down, the coil returns to the operating level again, the tiller turns on and runs for some time at idle or under load, until the temperature of the magneto rises again. In this case, the part must be replaced with a new one.

On a note! In a number of situations, the problem with heating is not due to the fault of the coil, but due to the spark plug. This means that both parts must be checked.

The first way

You can check the performance of the magneto using a tester. To do this, you need to perform the following sequence of actions.

- Correctly configure the tester: use the resistance measurement function and set 200 Ohms to take measurements of the primary winding.

- Direct the first electrode of the measuring device to the “mass” of the magneto, and the second to the output contact. If the primary winding is in good condition, the indicators should be from 0.4 to 2 ohms.

- Set the tester switch to 20 kΩ to diagnose the secondary winding. Then direct the first probe to the candle cap, and the second to ground. If everything is in order, the figures will vary from 4 to 6 Kohms, depending on the trimmer model, whether it is a Patriot 547, a Husquarna 128 r or another brand of equipment. If the circuit is open, the tester will display an infinity value. And if there was a short circuit, the display will show zero.

Magneto diagnostics

Magneto is a key component in engine ignition systems. It is a core coil that is surrounded by a primary and then a secondary winding. If this part is defective, there is no spark on the spark plug and the fuel will not ignite.

Features of adjustment on different models of trimmers

The ignition system works in a similar way on different brands of equipment, so the process of adjusting it will look the same. Differences, if any, will be insignificant. They are mainly related to the disassembly of equipment. For example, removing the cover from the engine on different trimmers is done with some differences. So, on Patriot devices, you first need to unscrew the bolts and disconnect the air filter housing with a slotted screwdriver. After that, it will be very easy to remove the plastic cover. A detailed diagram and device of a trimmer of a particular model are usually shown in the instruction manual of the tool.

So, you can do the ignition adjustment for a gasoline trimmer with your own hands. This process is not difficult if you know the correct procedure. But first, you need to exclude possible malfunctions of other components and parts, for example, spark plugs or magneto, which may be the reason for the lack of engine start of the lawn mowers. However, disassembling equipment of different brands, you need to take into account the likely differences in design, which are described in detail in the user manual.

Operating principle

When the flywheel rotates, an electric current is generated in the magneto, creating a spark on the spark plug as the magnets pass under the coil.

Ignition adjustment procedure

Setting up the ignition system is simple and identical on different trimmer models, be it a Stihl FS55, AL-KO BC 4125 or another lawn mower. First you need to remove the casing from the engine, after unscrewing the fasteners that fix it. This disassembly step may differ on different mower models (described below). Next, you need to partially unscrew the fasteners that fix the magneto with a screwdriver, and turn the flywheel so that the magnets are in the upper part.

To make the optimal gap between the coil and the magneto, a special template must be used. It is impractical to buy it for a one-time use, therefore, as an alternative, you can use a business card or a small calendar, as well as an A4 paper sheet folded in four. A strip cut from a plastic bottle or other materials at hand that has the required thickness is also suitable. The optimal distance is usually indicated in the user manual. The selected item must be placed between the magnets and the coil.

The coil will then be attracted to the flywheel by the magnetic field. While holding the magneto in this position, you need to tighten the fasteners that fix it, and then pull out the business card. After that, you need to turn the flywheel several times to make sure that it does not touch the coil at all. The process is over. the lawnmower’s ignition is on. You can learn more about the process of adjusting the trimmer ignition system on the Internet, where there are many videos on this topic.

Trimmer ignition. principle of operation and possible malfunctions

If the owner of the lawn mower wants to adjust the ignition system on his own, he should understand the principle of operation of this unit. In an internal combustion engine, it consists of a flywheel and a magneto (coil). In turn, the flywheel includes an impeller that performs the function of cooling the motor and a number of permanent magnets.

When adjustment is needed

It is necessary to adjust the ignition system so that the fuel ignites in the combustion chamber at the right time.

Important! When the piston compresses the fuel and almost reaches dead center at the top, a spark is generated in the spark plug. Further, when it passes the maximum high point, the fuel ignites, as a result of the explosion, energy is generated and directs the piston down.

If the flywheel is displaced on the shaft from its original position, the fuel ignites faster than the piston crosses top dead center. As a result, the piston moves backward and the crankshaft rotates in the opposite direction. An early ignition of fuel can be determined by a broken starter cord, a broken starter assembly or other breakdowns.

Sometimes ignition is late. The piston compresses the unignited fuel, and then goes down, and only then a spark is formed. As a result, the engine either does not work, or its power decreases, and the speed is gained much slower.

Usually, the flywheel with magnets is set in an ideal position, precisely coordinated with the operation of the piston, and is carefully locked to avoid misalignment. This allows us to assert that incorrect installation of the part is impossible. But if the flywheel offset is a confirmed fact, then it is a malfunction or an accident. Thus, setting the ignition timing is not required, since problems with early or late fuel ignition are very rare.

Important! It is very easy to adjust the ignition system. There is no need to calculate the ignition timing. The most that needs to be done is to correctly set the clearance between the flywheel and the coil.

Installation

first of all, it is necessary to set the TDC. 4 cylinders (we look at the position of the slider), this must be done by turning the crankshaft ratchet to the mark on the pulley, we combine marks 4 and 3 in the figure);

dismantle the distributor, candles and the coil (remembering the color of the wires suitable for the ignition coil);

we lay new wiring;

install a new high-voltage ignition coil;

we put the distributor exactly as the old one was (the installation of electronic ignition of vaz 2106,2103, 2107 with engines of 1.5 and 1.6 liters is slightly different from other models. These engines have different cylinder block heights and, accordingly, different length of the distributor drive shaft);

we fix the switch (it is advisable to find a place on the shield of the engine compartment);

we screw in the candles and put on high voltage wires (operating procedure 1-3-4-2);

we connect the wiring as in the diagram:

How to install the ignition on a lawn mower

Electronic ignition for vaz 2106

Each owner of the legendary classic model VAZ 2106 is well aware of all the problems associated with the operation of this car, since in most cases he eliminates them on his own. Such problems include malfunctions of the contact (cam) ignition system of the VAZ 2106. Constantly burning contacts required cleaning and adjustment, because of the backlash of the bearing and the distributor bushing, the engine’s operation resembled a “shake”, especially at idle. The electronic ignition system is designed to solve all these emerging problems.

Scheme

Diagram of a contactless ignition system VAZ 2106:

1. ignition distributor sensor; 2. spark plugs; 3. screen; 4. contactless sensor; 5. ignition coil; 6. generator; 7. ignition switch; 8. storage battery; 9. switch

Ignition system malfunctions by reference.

How to expose

For work you will need a 12-volt control light, a 13 key and a crankshaft key:

You need to set the ignition on the idle engine, with the “negative” battery terminal disconnected.

Set the piston of the first cylinder of the internal combustion engine to the ignition position. To do this, you need to unscrew the spark plug from it. We plug the spark plug hole with a finger and at the same time turn the crankshaft clockwise with a wrench.

When there is a compression stroke, the air under pressure will begin to push the finger strongly. this is what you need.

Now it is important to clearly align the mark on the pulley with the second one, which you are looking for on the timing cover. The mark in the middle means that the ignition advance is set by 5 degrees.

It happens that some people cannot find their tags. But in fact, there are always labels. Just wipe the surfaces well with a metal brush, add light.

After setting the marks, you can remove the key. Wrap the removed spark plug back and connect the armor wire.

The next stage of work will be to determine the ignition moment:

Before starting, connect the negative terminal of the battery.

Using a 13 key, slightly loosen the mounting nut of the ignition distributor.

Here you will need a prepared control light with two wires. We connect one terminal to ground, the second to the low-voltage ignition coil.

Turn on the ignition by turning the key to position “I”.

It is necessary to carefully turn the ignition distributor housing clockwise until the control lamp goes out.

After that, it is necessary to smoothly turn the distributor rotor counterclockwise. until the contact is open and the light comes on again.

Now you need to tighten the mount and check the behavior of the machine on the go.

Adjustment

Closed contact angle correction

The ignition adjustment of the VAZ 2106 begins with the simplest operation of removing the distributor cover, then the crankshaft turns until the maximum distance between it and the distributor is reached. Following this, they begin to unscrew the screws that fix the contact group on the bearing plate and between the contacts, a probe is introduced to determine and select the optimal position for the group. Ideally, everything is determined by the applied force to move the stylus, which should be minimal, having found a section that meets this requirement, the position of the group is fixed by tightening the screws. The size of the gap also matters for its determination, the thickness of the probe should be 0.44 mm. It is the adjustment of the gap that provides the required value of the angle of closed contacts, its optimal value is 55 ± 3 °.

If the parameters correspond to the norm, then you can proceed to the second stage, which consists in adjusting the advancing ignition angle. To begin with, we will determine that the distributor breaker in the type of engine under consideration needs to implement the opening moment simultaneously with the spark in the first cylinder. This provides for the advance of the top dead center of the piston stroke for the first cylinder by 0 ± 1 °.

Correction of the lead angle using a stroboscope

There are several ways to adjust this indicator, on which the correct ignition adjustment of the VAZ 2106 as a whole largely depends. The most efficient way to cope with this task is a method involving the use of a stroboscope. The device must be connected to the automotive electrical network, while it is necessary to dismantle and plug the vacuum correction hose from the distributor. Following this, the engine is warmed up, until it holds idle speed, followed by loosening the bolt responsible for fixing the distributor housing.

The light emitted by the stroboscope is directed to the crankshaft pulley, the rotation of the distributor housing will allow to achieve a position that ensures that the visible position of the mark on the pulley is opposite the corresponding marks applied to the timing cover. In this position, the distributor body is fixed by tightening it with bolts. The presence of idle speed of the power unit during the adjustment process is of decisive importance. If the revolutions are higher, a centrifugal regulator will take part in the work, which will distort the adjustment results.

Choosing and buying a kit

Experts advise to purchase domestic kits made in Stary Oskol. These sets have proved their high quality more than once. They are more reliable than all other analogues. As for the Hall sensor, it is not recommended to purchase Kaluga-made Autoelectronica products in the future.

Setting up UOZ

Electronic ignition is installed and now let’s see how the ignition timing is adjusted. This operation can be performed in three different ways. with a stroboscope, with a light bulb, and also with a spark.

Using a stroboscope

When everything is ready, remove the tube from the vacuum regulator, start and warm up the engine. The motor should idle normally. Then loosen the bolt or nut that secures the ignition distributor housing. The stroboscope is directed to the crankshaft, or rather to its pulley. The setting itself is so that the mark on the pulley is in a special way to the marks on the timing cover. By rotating the distributor, you can make the mark move. When the position is found, the distributor can be tightened.

In general, this is practically the only accurate way to install the UOZ on engines with a contactless ignition system. It is described in detail in books, where it is also written how to properly install the ignition on the VAZ-2106. The ignition is adjusted in the same way.

How to install the ignition on a VAZ-2106: instructions, operating procedure and photos

A properly functioning ignition system is the key to reliable engine operation and easy starting. In addition, fuel consumption and dynamic characteristics also depend on the ignition moment. Incorrect torque can cause engine detonation, which can lead to very disastrous consequences. Let’s see how to install ignition on a VAZ-2106, and also talk about electronic ignition and installing an ignition lock on this model from AvtoVAZ.

UOZ by ear

How to install the ignition on a VAZ-2106 with your own hands? Sometimes it may happen that the advance angle recommended by the factory is not enough for normal engine operation. Then the stroboscope should be thrown into the trash. there will be no sense from it. The engine has a certain mileage, wear and factory parameters are no longer suitable for it. Then it’s worth tuning using your ear. Let’s see how to install the ignition on a VAZ-2106 using only ears.

The engine runs at idle speed, and by rotating the distributor, an increase in speed is achieved. If you increase the angle, the rpm will increase and the engine will stabilize. From this position, you need to slightly turn the distributor in the direction of decreasing the angle. just a little. Then the distributor is tightened.

Contactless ignition on the VAZ-2106

Normally, a contact-type ignition system was installed on this model. Many had a lot of problems with her. For this reason, most car enthusiasts change contact ignition to a contactless or electronic system. This was installed on the VAZ-08 model and beyond. The contactless system includes the following elements. This is an ignition coil, distributor or distributor with a hall sensor, switch and wiring.

You can purchase accessories either separately or as a set. There are usually no problems with the purchase of kits. But if the components are purchased separately, then you should pay attention to the length of the shaft in the distributor. The thing is that the engine in this model can be of different modifications. It is better to look at the markings on the engine in advance. If the marking is 2103 or 2106, then the distributor must be with a longer shaft. Before installing contactless ignition on a VAZ-2106, you need to make sure that the distributor will fit, since it is not cheap.

Unlike engines marked 2101 and 21011, 2106 has a different piston stroke. Sometimes, in special cases, instead of a standard crankshaft, a crankshaft from Niva models is installed. This will increase the stroke of the piston. This tuning will not in any way affect the length of the distributor shaft, which is selected by the marking on the engine block.

About installing the ignition switch

The ignition switch is also part of the engine ignition system design. Sometimes the contact group or the mechanical part wears out in it. It will not be superfluous to consider how to install an ignition lock on a VAZ-2106.

Before installing the element, it must be removed. To do this, disconnect the negative terminal from the battery, then remove the decorative trims on the steering column. It is then important to sketch or write down where the wires are connected. After that, using a Phillips screwdriver, unscrew the lower fasteners of the ignition lock. Next, insert the key into the lock and turn it to the zero position in order to disable the steering wheel lock mechanism. A thin awl is pressed on the latch, due to which the lock can be held in place. By pulling the key, the lock can be removed.

After the lock mechanism is removed, a new lock is installed in the same way in the reverse order.

Initial installation of a hazel grouse ignition engine D-240

1 Initial installation of grouse ignition

2 Elimination of floating revolutions

3 We set the ignition ZIL-130

In order to initially install the ignition hazel grouse on the D-240 engine. It is necessary to bring the piston of the 1st cylinder to TDC for the compression stroke. It can be done this way.

MTZ-82

Take an electrode or a piece of wire and lower it into the hole for the nozzle to the piston. On the valves on the head, it is necessary to catch the compression stroke and bring the piston to the top dead center. When the electrode moves up, turning the shaft with a knee key, we catch the TDC. When we insert the TDC we do the following.

With a key, turn the injection pump by the shaft on the pump, which secures the grouse gear. We bring up the injection stroke, observing the fuel inlet from the first plunger.

Grouse ignition MTZ-82

When we have brought the piston in the compression stroke and the pump in the injection stroke, we put the ignition hazel grouse in place and fasten it with 2 bolts. This will be an approximate insertion of the ignition, and then, as the engine is running, at your discretion, set the ignition earlier or later by moving the 2 ignition adjustment bolts.

WATCH THE VIDEO

Elimination of floating revolutions.

The barking of the engine occurs when the hazel grouse begins to walk in the splines of the injection pump shaft. Due to the slightest backlash of hazel grouse and the injection pump shaft, backlash is generated during engine operation. The pump, under the action of the plunger springs, begins to change the fuel injection angle and the engine barks.

All this can be eliminated in a simple way. Remove the ignition cover, unscrew the hazel grouse, pull it out of the landing site. With a welding machine, we weld small dots in the slots of the hazel grouse. Next, with a diamond file we adjust it to the size of the pump shaft so that the hazel grouse fits tightly into the landing and there is no backlash.

High pressure pump

So let’s remove the floating speed. If this does not help, then you will have to contact the repairmen of the injection pump, which means another problem, the pump cracks in the injection pump crankcase were demolished. The masters will replace them for you. Here are 2 reasons for the floating speed of the D-240 engine that I know.

WATCH THE VIDEO

Ignition adjustment for mtz 80-82 instructions

remove the force from the internal combustion engine.

you insert an electrode into the socket without coating.

you rotate the K.V. until the electrode rises up.

remove the valve. cover and make sure that the valves have a clearance on the first cylinder.

you take the K.V. back. by about 15-20g, imitating the lead.

6.remove the front hatch cover to set the lead.

release all fastening bolts or nuts. if the euro drive.

you remove the tube from the first pump union. 9. you fix the “gazulka” of the pump in the position of max. feed-start.

10 start a smooth rotation of the pump before the fuel level starts to move.

11 tightening the fixing bolts or nuts of the pump euro drive.

you start the internal combustion engine. At the beginning of the detonation of a short and responsiveness in a set of revolutions, either you add a little lead, or you a little late.

How to set the ignition on the MTZ-82 tractor with your own hands: we disassemble it carefully

We insert the ignition on the ZIL-130 diesel

On ZIL-130 cars of the 80-90s with an old cabin, it is difficult to insert the ignition. To set it up, you need to unscrew and remove everything that will interfere with us so that we can see the ignition hazel grouse. On my car, as shown in the video, you need to remove the compressor, remove the compressor plate and only then you can get to it.

To get there, remove the ignition cover, it is on 3 bolts. We unscrew the hazel hen with 2 bolts. We take out the bolts and look at the hazel grouse on it there should be 2 marks and. In the direction where, if we move it to 1 hole, we will make an early ignition, if. then later. There is just a mark on some hazel grouses without and-.

Installation of ignition MTZ-82

Here we look from the front of the car at the engine, move clockwise if we move it earlier, if counterclockwise then later. You will immediately understand by the operation of the engine. The only negative and very big is that it is inconvenient to do everything and you have to climb up to the grouse of ignition in the bottom with your head in three deaths to somehow dodge.

WATCH THE VIDEO

Auto experts articles

We install the ignition on MTZ 80 and 82

Ignition on modern Belarusian-made technology is almost impossible to adjust.

But sometimes the machine operators have to replace the magneto.

After repair, it is necessary to install the ignition on MTZ 80 or 82.

The specialists of LLC “” will tell you how to do it correctly.

how to correctly set the ignition on the MTZ 80 fuel pump | Topic author: Lilia

Alexander very simply pump diesel fuel into the injection pump pump and scroll it by the advance clutch until diesel fuel appears from the first fitting under the tube, then put the engine on the TDC of the first cylinder and fix the injection pump by making the injection three divisions earlier

Page from category → Power of technology It will be interesting for you

Photo gallery “Self-adjustment of the distributor”

Tuning and repair of the ignition system

How to properly adjust the system operation? If you do not know how to set the ignition on Tavria, then we are ready to teach you this. The principle of setting SZ is to change the position of the distributor in relation to the installation volute. Before you start tuning, you need to open the hood and look at this snail and distributor. Put labels on each element. this will allow you to put everything back in place if you make mistakes during the repair process.

The setup procedure looks like this:

- Get behind the wheel, put the key in the ignition of your Tavria and start the engine.

- Then, on a running power unit, you need to turn the switchgear slightly. first in one direction and then in the other direction. At this moment, you need to listen to how the engine works, whether the dynamics of revolutions has changed. You need to catch the moment when the engine speed will be at its maximum. Usually this is not a specific point, but a place in half a division on the site. The most optimal ignition is in this range. If the power unit of your car works with detonation, then try to set a later ignition.

- Then the distribution unit must be fixed in this position, and then diagnose the operability of the internal combustion engine in different operating modes.

- When the distributor is fixed, you need to ride a little. Accelerate the vehicle to approximately 60 km / h, shift into fourth gear, and then slow down to approximately 40 km / h and press the accelerator pedal sharply again. At this moment, detonation should appear, but literally for 1-2 seconds, no more. If so, then we can assume that half of the work is done.

- In addition, you also need to check the power of the internal combustion engine. In the event that the engine power is not particularly high, then you can try again to adjust the distributor drive. In this case, you will need tweezers, as it will make this task much easier with it. If you look at the distributor, you will notice that the cut under it on the drive is slightly offset to the side, so you should not make mistakes and install the drive incorrectly (video author. Tavriy Repair channel).

You can also adjust the distributor directly, the essence of this task is to change the level of tension of the weights, as well as setting the vacuum regulator. But keep in mind that to implement this procedure, you will need a special stand, which can not always be found even at a service station.

Device malfunctions and how to fix them

For what reasons the distributor may refuse to work and how can the situation be corrected:

- The distribution unit is loose, which led to incorrect motor operation. Due to the loosened fastening, the lead angle could be lost, which in turn would lead to a difficult start, a decrease in power, as well as unstable idle speed. Fuel consumption will also increase. In this case, you just need to tighten the screw that secures the device using a wrench.

- The high voltage wires are connected to the switchgear in the wrong sequence. This can lead to the fact that the internal combustion engine will not start at all or will start, but at the same time pops will be heard from under the hood, the car will go jerky. Open the service book and specify how the high-voltage wires should be connected, reconnect them.

- Another malfunction is the broken mechanism cover. As practice shows, the breakdown site is usually clearly visible even with the naked eye. Due to breakdown, current leakage is possible, which contributes to malfunctions in the operation of the internal combustion engine. In this case, the only option would be to replace the cover.

- Oxidation or destruction of contacts has occurred in the distributor cover. If we are talking about oxidation, then you can clean the contacts with a solvent, if the problem is destruction, then the elements must be replaced.

- The contact ember on the cover is worn out, while the motor will be difficult to start. Either the coal or the cover as a whole is replaced.

- Hall sensor breakage. Such a malfunction will lead to the impossibility of starting the motor, the controller should be replaced. It is possible that there was a break in the wiring from this controller to the connector, then the device needs to be checked more carefully.

- The upper bearing is worn out. Unstable idle speed will be a sign of malfunction. The problem is solved by replacing the roller with a centrifugal regulator, as well as a bearing device. Or the distribution mechanism will have to be changed completely.

- The vacuum advance regulator is out of order. With such a malfunction, the transport power unit will not be able to pull the car uphill, the engine power will significantly decrease, as well as its throttle response. This happens as a result of the fact that the regulator itself is used in order to set the lead angle a little earlier in the mode of high load on the motor. The reason may lie in the lack of tightness of the body of this device or in the jamming of the nozzle from the carburetor connected to it. Also, the problem may be a defective pivot plate. The solution to the problem may be to eliminate leakage problems or replace failed components. As a last resort, you can completely replace the regulator.

- Problems in the operation of the centrifugal regulator. The symptoms will be similar. As for the reasons, it is necessary to check the springs of the weights, they could weaken or fail as a result of wear, the damper rings of the weights could also be lost, the weights themselves can jam. It is necessary to dismantle the distributor and replace the regulator itself, since its repair in most cases is impractical.

How to install a distributor and set the ignition on ZAZ 1102 Tavria with your own hands?

The ignition system (SZ) of the vehicle includes many nodes and devices interconnected. One of the main components of such a system in ZAZ cars is a distributor. How to correctly install the Tavria distributor, what malfunctions are characteristic of this device and how to repair it, we will tell below.

In what cases is ignition installation necessary?

Adjustment of the ignition system in ZAZ 1102 cars can be carried out if there are such signs of malfunction:

- Detonation appears. When the engine is running, in particular when the driver presses the gas pedal, an unpleasant sound of metal begins to be heard from under the hood. Experts in such cases say that “fingers knock”.

- The power unit did not work at full capacity. The thrust of the engine has significantly decreased, and the number of revolutions of the internal combustion engine has also decreased, and the revolutions can float, that is, it either rise or fall.

- The car engine as a whole began to function unstably at low speeds.

- Fuel consumption increased.

- In the event that the switchgear is configured for a later ignition, this can lead to overheating of the power unit.

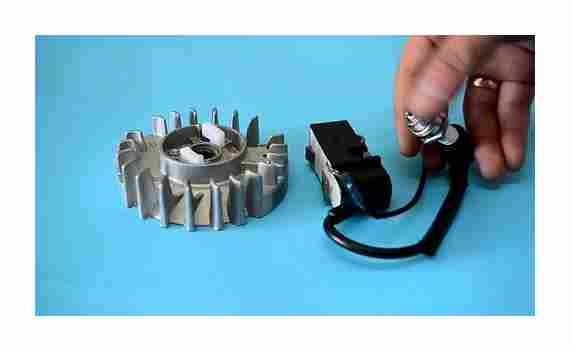

Briggs and Stratton Engine Coil test and replace

Naturally, the described faults may indicate other problems as well. When such problems appear, you need to check the candles, coil, high-voltage wires to make sure that the reason is not them.

Installation of ignition on a VAZ-2106

- Installation of ignition on a VAZ-2106

- How to set the ignition timing

- How to set contactless ignition on a VAZ

VAZ 2106 is a car that has become a legend. Cheap, easy to maintain and repair, extremely unpretentious, comfortable and roomy. This is the car that many people choose today. Despite the fact that its technical data is very similar to the famous seven, its suspension is much softer, more pleasant on the go. The only drawback is the outdated engine with a chain drive of the gas distribution mechanism. Of course, the chain is much stronger than the rubber used in belts. But it makes a lot of noise, it has a lot of weight, and this affects the engine power. The ignition system in the six is of two types. contact and non-contact.

For a more accurate ignition adjustment, you will need to first place the timing chain on the marks. To do this, you need to remove the radiator and the cover that covers the mechanism. Drain all fluids in advance to avoid leakage. Remove the chain and install the camshafts and crankshafts according to the marks. This will balance the operation of the cylinders. Now put on the chain, the damper, pull all the threaded connections and assemble the assembly. Install the radiator last. Now you need to act on the basis of which ignition system is used on your car.

Contact system

To carry out the work, you need a 0.4 mm dipstick and a screwdriver. Remove the distributor cover, under it you will see a slider and a contact group. So, you need to use a 38 key to set the crankshaft according to the marks. Looking from the front, you can see one notch on the pulley and three on the cover housing that covers the timing mechanism. The far right mark is 0 degrees of ignition advance, the middle one is 5 degrees, the left is 10 degrees.

You can adjust in several ways:

stroboscope;

control lamp;

for a spark;

aurally.

The latter method is the most inaccurate, but it is quite suitable for repairs in the field. You need to set the distributor shaft so that the contacts are in the maximum open state. This position should correspond to the first cylinder. And we adjust the gap, which should be no more than 0.4 mm. Otherwise, we carry out the adjustment.

Contactless ignition system

Everything is a little simpler here, since there is no need to adjust the breaker gap. But the rest of the actions are reduced to the same as in the contact system. That is, you need to set the crankshaft so that the piston in the first cylinder is at TDC. Also, the distributor is set to the position corresponding to the first cylinder. Check the ignition installation with a stroboscope and proceed to testing.

Bring the engine to operating temperature and take a short trip. How does the car behave on the road? Does the engine revs easily? Evaluate acceleration, throttle response, in case of unsatisfactory results, correct the ignition setting. When the tests have already been carried out on the road, then the adjustment can be considered complete.